Insulate Magazine Issue 13

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

The only independent insulation industry trade magazine<br />

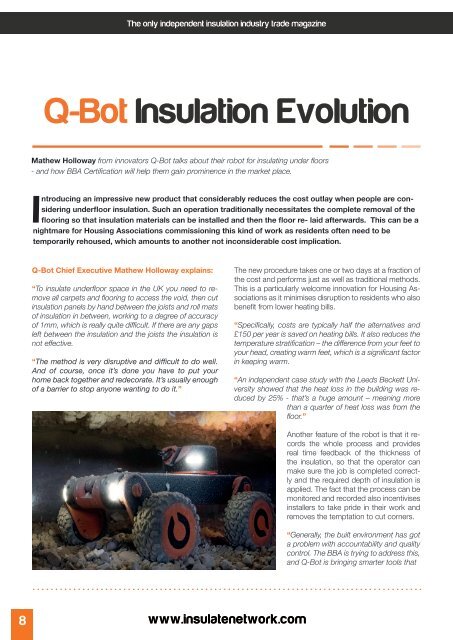

Q-Bot Insulation Evolution<br />

Mathew Holloway from innovators Q-Bot talks about their robot for insulating under floors<br />

- and how BBA Certification will help them gain prominence in the market place.<br />

Introducing an impressive new product that considerably reduces the cost outlay when people are considering<br />

underfloor insulation. Such an operation traditionally necessitates the complete removal of the<br />

flooring so that insulation materials can be installed and then the floor re- laid afterwards. This can be a<br />

nightmare for Housing Associations commissioning this kind of work as residents often need to be<br />

temporarily rehoused, which amounts to another not inconsiderable cost implication.<br />

Q-Bot Chief Executive Mathew Holloway explains:<br />

“To insulate underfloor space in the UK you need to remove<br />

all carpets and flooring to access the void, then cut<br />

insulation panels by hand between the joists and roll mats<br />

of insulation in between, working to a degree of accuracy<br />

of 1mm, which is really quite difficult. If there are any gaps<br />

left between the insulation and the joists the insulation is<br />

not effective.<br />

“The method is very disruptive and difficult to do well.<br />

And of course, once it’s done you have to put your<br />

home back together and redecorate. It’s usually enough<br />

of a barrier to stop anyone wanting to do it.”<br />

The new procedure takes one or two days at a fraction of<br />

the cost and performs just as well as traditional methods.<br />

This is a particularly welcome innovation for Housing Associations<br />

as it minimises disruption to residents who also<br />

benefit from lower heating bills.<br />

“Specifically, costs are typically half the alternatives and<br />

£150 per year is saved on heating bills. It also reduces the<br />

temperature stratification – the difference from your feet to<br />

your head, creating warm feet, which is a significant factor<br />

in keeping warm.<br />

“An independent case study with the Leeds Beckett University<br />

showed that the heat loss in the building was reduced<br />

by 25% - that’s a huge amount – meaning more<br />

than a quarter of heat loss was from the<br />

floor.”<br />

Another feature of the robot is that it records<br />

the whole process and provides<br />

real time feedback of the thickness of<br />

the insulation, so that the operator can<br />

make sure the job is completed correctly<br />

and the required depth of insulation is<br />

applied. The fact that the process can be<br />

monitored and recorded also incentivises<br />

installers to take pride in their work and<br />

removes the temptation to cut corners.<br />

“Generally, the built environment has got<br />

a problem with accountability and quality<br />

control. The BBA is trying to address this,<br />

and Q-Bot is bringing smarter tools that<br />

8<br />

www.insulatenetwork.com