September 2019 Publication

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

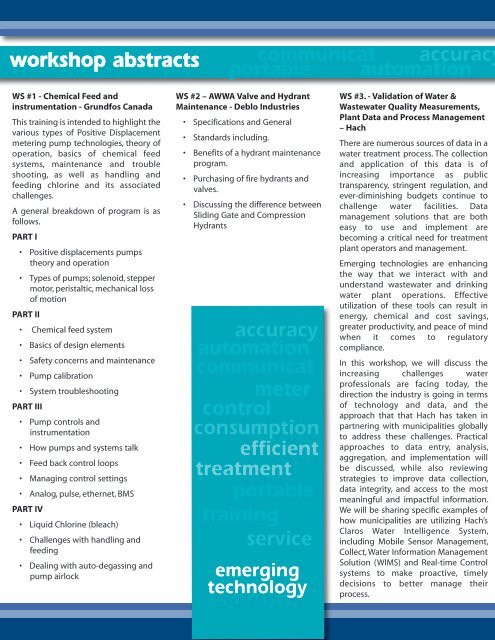

workshop abstracts<br />

communicat accuracy<br />

portable automation<br />

processes<br />

meter<br />

consumption treatment<br />

efficient meter<br />

control<br />

training<br />

service<br />

WS #1 - Chemical Feed and<br />

instrumentation - Grundfos Canada<br />

This training is intended to highlight the<br />

various types of Positive Displacement<br />

metering pump technologies, theory of<br />

operation, basics of chemical feed<br />

systems, maintenance and trouble<br />

shooting, as well as handling and<br />

feeding chlorine and its associated<br />

challenges.<br />

A general breakdown of program is as<br />

follows.<br />

PART I<br />

• Positive displacements pumps<br />

theory and operation<br />

• Types of pumps; solenoid, stepper<br />

motor, peristaltic, mechanical loss<br />

of motion<br />

PART II<br />

• Chemical feed system<br />

• Basics of design elements<br />

• Safety concerns and maintenance<br />

• Pump calibration<br />

• System troubleshooting<br />

PART III<br />

• Pump controls and<br />

instrumentation<br />

• How pumps and systems talk<br />

• Feed back control loops<br />

• Managing control settings<br />

• Analog, pulse, ethernet, BMS<br />

PART IV<br />

• Liquid Chlorine (bleach)<br />

• Challenges with handling and<br />

feeding<br />

• Dealing with auto-degassing and<br />

pump airlock<br />

WS #2 – AWWA Valve and Hydrant<br />

Maintenance - Deblo Industries<br />

• Specifications and General<br />

• Standards including.<br />

• Benefits of a hydrant maintenance<br />

program.<br />

• Purchasing of fire hydrants and<br />

valves.<br />

• Discussing the difference between<br />

Sliding Gate and Compression<br />

Hydrants<br />

accuracy<br />

automation<br />

communicat<br />

control<br />

meter<br />

consumption<br />

efficient<br />

treatment<br />

portable<br />

training<br />

service<br />

emerging<br />

technology<br />

WS #3. - Validation of Water &<br />

Wastewater Quality Measurements,<br />

Plant Data and Process Management<br />

– Hach<br />

There are numerous sources of data in a<br />

water treatment process. The collection<br />

and application of this data is of<br />

increasing importance as public<br />

transparency, stringent regulation, and<br />

ever-diminishing budgets continue to<br />

challenge water facilities. Data<br />

management solutions that are both<br />

easy to use and implement are<br />

becoming a critical need for treatment<br />

plant operators and management.<br />

Emerging technologies are enhancing<br />

the way that we interact with and<br />

understand wastewater and drinking<br />

water plant operations. Effective<br />

utilization of these tools can result in<br />

energy, chemical and cost savings,<br />

greater productivity, and peace of mind<br />

when it comes to regulatory<br />

compliance.<br />

In this workshop, we will discuss the<br />

increasing challenges water<br />

professionals are facing today, the<br />

direction the industry is going in terms<br />

of technology and data, and the<br />

approach that that Hach has taken in<br />

partnering with municipalities globally<br />

to address these challenges. Practical<br />

approaches to data entry, analysis,<br />

aggregation, and implementation will<br />

be discussed, while also reviewing<br />

strategies to improve data collection,<br />

data integrity, and access to the most<br />

meaningful and impactful information.<br />

We will be sharing specific examples of<br />

how municipalities are utilizing Hach’s<br />

Claros Water Intelligence System,<br />

including Mobile Sensor Management,<br />

Collect, Water Information Management<br />

Solution (WIMS) and Real-time Control<br />

systems to make proactive, timely<br />

decisions to better manage their<br />

process.<br />

WS #4 - FUNDAMENTALS OF<br />

PUMPING – John Brooks Company<br />

The presentation begins with the basic<br />

description of both Centrifugal and<br />

Positive Displacement pumps and their<br />

application. Specifically focused on<br />

Centrifugal Pumping – the concepts of<br />

impeller design (Open, Semi-Open and<br />

Enclosed) are discussed along with<br />

Volute design (Single, Double and<br />

Diffuser). A pump application is<br />

presented to illustrate a basic pump<br />

selection along with motor sizing and<br />

installation “good practices”.<br />

The concept of Pump Trouble-Shooting<br />

is discussed in reference to Low-Flow,<br />

No-Flow and Noisy Operation. The latter<br />

allows for an in-depth presentation of<br />

Cavitation in which the 3-types (Suction,<br />

Recirculation and Discharge) are<br />

discussed and demonstrated (Glass-<br />

Face Pump). Actual pump components,<br />

that indicate the different types of<br />

cavitation, will be available for the<br />

attendees to inspect. The possible<br />

approaches to solving cavitation are<br />

also reviewed and applied to the Glass-<br />

Face pump demo.<br />

Most of the pump hydraulic concepts<br />

discussed will be illustrated using the<br />

Glass-Face pump demo. Several “real<br />

world” examples will be applied to the<br />

Demo-Pump that will require the<br />

attendees to use gauge readings and<br />

pump curves to achieve a solution. We<br />

will also demonstrate the pump priming<br />

process and air-binding.<br />

Finally, there will be several Pump cutaways<br />

available for the attendees to<br />

inspect and ask questions. These cutaways<br />

allow for in depth and specific<br />

maintenance techniques to be reviewed<br />

(impeller clearance adjustment, removal<br />

of blockages, mechanical seal<br />

replacement etc).<br />

WS #5 - A Survey of Meter & Meter<br />

Reading Technologies – Badger<br />

Meter<br />

In the last five years, we have seen an<br />

significant increase in new technology<br />

developments in our industry. With the<br />

improvement in battery technology and<br />

the decrease of component costs,<br />

ultrasonic and electromagnetic meter<br />

technologies have been implemented<br />

in smaller residential meters as well as<br />

improvements made in larger electronic<br />

meters for the commercial and<br />

industrial market. New meter features<br />

such as remote control shut-off valves<br />

activated from the curb or from the<br />

office as well as integrated<br />

pressure/temperature sensors are now<br />

available. Meter reading technology has<br />

improved with carrier grade networks<br />

including twenty-year life cellular radios<br />

and Low-Power Wide-Area Network<br />

(LPWAN) products supporting Smart<br />

Cities and the Internet of Things (IoT).<br />

Software has gotten a lot smarter with<br />

proactive alerting via analytics. This<br />

workshop will explain the new<br />

technologies, their importance to the<br />

industry and survey products<br />

introduced to the market.<br />

WS #6 - Iron and Manganese<br />

Removal - Delco Water<br />

1. Iron and Manganese<br />

a. Soluble vs<br />

b. Insoluble<br />

2. Canadian Drinking Water<br />

Regulations<br />

3. Chemistry of Iron and Manganese<br />

Removal<br />

4. Problems associated with<br />

5. Methods of Removal/treatment<br />

a. Aeration<br />

b. Chemical Oxidation<br />

c. Bio-catalytic oxidation<br />

d. Sedimentation<br />

e. Sequestering<br />

f. Filtration<br />

g. Membrane technologies<br />

6. Comparison of Biological Filtration<br />

and Manganese Greensand Filtration<br />

7. Filtration<br />

a. Common filter types<br />

b. Underdrains<br />

c. Filter media<br />

8. Optimal Filter Operation<br />

9. Trouble shooting Iron and<br />

Manganese removal<br />

WS #7 – To be announced<br />

learning never<br />

exhausts the mind.<br />

- Leonardo da Vinci