ECOBuilder_Specifiers Journal 2018_2019

ECOBuilder_Specifiers Journal 2018_2019

ECOBuilder_Specifiers Journal 2018_2019

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

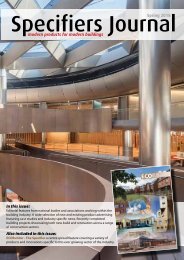

The Macallan New Distillery & Visitor Experience<br />

Rogers Stirk Harbour + Partners<br />

The new Macallan distillery and visitor<br />

experience is set into the landscape<br />

of the estate that has been distilling<br />

the world’s leading single malt since<br />

1824. The Macallan is one of the most<br />

sought after whiskeys in the world<br />

and wanted to create a building that<br />

could reveal the production processes<br />

and welcome visitors while remaining<br />

sensitive to the beautiful surrounding<br />

countryside.<br />

The new distillery will enable<br />

production of The Macallan to increase<br />

by a third if required. Internally, a series<br />

of production cells are arranged in a<br />

linear format with an open-plan layout<br />

revealing all stages of the production<br />

process at once. These cells are<br />

reflected above the building in the<br />

form of a gently undulating timber<br />

roof. Grass-covered peaks rise and fall<br />

from The Macallan estate grounds,<br />

signalling to approaching visitors the<br />

activities housed beneath. Set into the<br />

naturally sloping contours of the site,<br />

the design makes direct references to<br />

ancient Scottish earthworks.<br />

The visitor experience starts with an<br />

introduction to The Macallan in an<br />

exhibition and gallery area, before<br />

progressing through a sequence of<br />

spaces that follow the production<br />

story of the whiskey. Natural materials<br />

– local stone, timber and the living<br />

meadow roof – as well as the<br />

landscaping design not only evoke<br />

the environment and ingredients of<br />

whiskey production but also serve to<br />

provide an atmospheric journey for<br />

the visitor.<br />

The roof structure is in two principle<br />

parts, the primary tubular steel support<br />

frame and the undulating domes and<br />

valleys of the timber grid shell. The<br />

primary steel frame is laced through<br />

the centre of the timber beam structure<br />

and helps to resist the torsional forces.<br />

The timber domes act in compression<br />

and the interconnecting valleys are<br />

hung between the domes. All of the<br />

roof beams are straight and all of<br />

the cassettes are flat double skinned<br />

panels. This provides a facetted<br />

appearance so important for the<br />

engineered landscape. Despite the<br />

highly repetitive and rotational roof<br />

geometry the finished structure<br />

is constructed from over 380,000<br />

components. The beams are a<br />

composite of glulam and laminated<br />

veneered lumbar (LVL) and steel<br />

reinforced in certain key locations. All<br />

of the timber beams are vertical and a<br />

constant expressed depth of 750mm<br />

which allows for considered and neat<br />

interfaces with internal partitions as<br />

well as the solid and glazed façades.<br />

Running the full length of the eastern<br />

and southern elevations of the<br />

building is full height double glazing.<br />

The façade is composed of 3m wide<br />

structurally bonded double glazed<br />

panels which are supported from the<br />

base and restrained at the head with<br />

a flexible movement joint. The façade<br />

is further supported by full height<br />

vertical triple-ply glazed mullions.<br />

These maintain excellent internal<br />

views out to the landscape beyond.<br />

On top of the timber roof structure<br />

is a layered roof build-up of circa<br />

300mm in depth. This is made up<br />

of some 150mm of vapour barrier,<br />

thermal insulation and waterproofing<br />

and then a further 150mm of green<br />

living roof. As a factory, the roof above<br />

the production distillery does not<br />

require thermal insulation for building<br />

regulation compliance however<br />

insulation is maintained to protect the<br />

irrigated green roof from the warming<br />

and drying effects of the distillery<br />

below.<br />

The roof includes roof-lights and<br />

process ventilation apertures which<br />

are arranged in a halo like ring, directly<br />

related in plan to the circular process<br />

vessels beneath. The ventilation<br />

panels are two tiered in section and<br />

allow for the hot escaping ambient air<br />

of the process hall to vent at the lower<br />

level whilst piped process ventilation<br />

is allowed to penetrate through the<br />

roof vent panels and exhaust at a<br />

higher level. A positive pressure is<br />

always maintained by the escaping<br />

ambient hot air to prevent escaping<br />

process gases from re-circulating.<br />

54 ECO BUILDER: THE SPECIFIERS JOURNAL - <strong>2018</strong>-<strong>2019</strong> ECO BUILDER: THE SPECIFIERS JOURNAL - <strong>2018</strong>-<strong>2019</strong> 55