2018WinterPipeline2

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

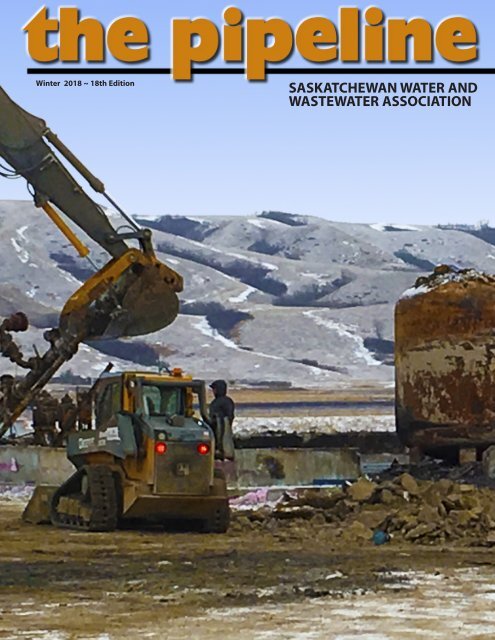

Winter 2018 ~ 18th Edition<br />

SASKATCHEWAN WATER AND<br />

WASTEWATER ASSOCIATION

Winter<br />

The pipeline is produced quarterly by the<br />

Saskatchewan Water and Wastewater Association.<br />

Produced by Campbell Printing Ltd., Prince Albert, SK<br />

For article /photograph submissions or for further<br />

information or content ideas please contact<br />

SWWA Office Manager Calle Behnke<br />

Work: 306-668-1278<br />

Toll Free: 888-668-1278<br />

Email: office@swwa.ca<br />

Box 7831 Saskatoon, SK S7K 4R5<br />

3<br />

20<br />

18<br />

4| Kelly’s Corner<br />

5| Presidents Message<br />

7| Whats in Your Toolbox?<br />

9| Changing the Culture in the Workplace<br />

10| Piapot Water Treatment Plant<br />

14| Member Profiles<br />

15| Operator Certification Board<br />

17| Leadership is Like<br />

Looking Down a Manhole<br />

25| Up-Coming Workshops<br />

26| The Awards<br />

28| The Banquet<br />

17<br />

30| The Conference<br />

32| The Tradeshow<br />

36| WaterAid - Mali<br />

38| Overview of Drinking<br />

Water and<br />

Waste Management<br />

39| Need Help?<br />

41| Training or Tragedy<br />

43| Looking for a<br />

Supplier?<br />

45| Conference<br />

Sponsors<br />

9

KELLY’S CORNER<br />

Finding the<br />

I recently had a friend buy a house for the first<br />

time, she was very excited at hitting this<br />

milestone as it was a goal she has worked<br />

towards for a while now. When she purchased<br />

the house, she never thought about the fact<br />

that her garage is detached with a small<br />

driveway away from the house. With the first<br />

snow, she had gotten home after a long day at<br />

work and realized as she made the turn to<br />

drive in, that the unsheltered space between<br />

the house and garage was completely drifted<br />

in full of snow. Three hours later and with a lot<br />

of shovelling she was in the garage. The next<br />

day, the first thing she did after work was get<br />

a snow blower. Now four snows later, that<br />

which had been a huge problem after the first<br />

snow, was no longer a problem because she<br />

had the right tools to make the situation less<br />

stressful and less work.<br />

Do you have the proper tools that you need to<br />

do your job? What are some key things that<br />

you need to put in place to make doing your<br />

job less stressful or in some cases less timeconsuming?<br />

How can you do your job<br />

working smarter rather than harder?<br />

For those of you who just attended this last<br />

conference you have been given a lot of tools<br />

to take back and use in your jobs. Tools that<br />

help in the technical aspect and tools that<br />

help in the day to day way you do things as a<br />

worker and as a leader.<br />

Attending the conference and tradeshow is a<br />

huge part of having the tools you need as an<br />

operator to do your job. You get the CEU’s<br />

needed to maintain certification,<br />

opportunities to see technology that can help<br />

you, and a vast network of professional<br />

individuals who either have the answer or can<br />

Right Tools<br />

point you in the right direction for the answer.<br />

Tools help make our job or personal life easier<br />

as long as we have the ones needed for the<br />

different aspects of the job we are looking to<br />

do. As an operator you can check out the<br />

SASKOCB website for certification<br />

information on the tools needed to renew or<br />

qualify. The SaskH20 website has even more<br />

tools available for you to use and the SWWA<br />

website has all the training information<br />

needed to help you maintain your operator<br />

status as well as supplier information to help<br />

you find the part or parts you may need.<br />

One of the tools we gave out this year to all<br />

attendees was a supplier directory; this<br />

directory has information on all the suppliers<br />

who participated in the SWWA 2018<br />

tradeshow. The directory is also available for<br />

download on the supplier portion of the<br />

website. Speaking of the supplier part of the<br />

site, did you know that one of the tools we<br />

have set up is that you can enter what it is you<br />

need in the search bar and it will pull up all<br />

the suppliers who were at the show that can<br />

help you with what you are looking for?<br />

With the proper tools our jobs seem less<br />

daunting and stressful and more manageable.<br />

Have a very merry Christmas and a fantastic<br />

end to 2018 see you in 2019!<br />

Kelly Kish<br />

SWWA Pipeline Editor<br />

SWWA<br />

SWWA EXECUTIVE___________________<br />

TIM COX ~ PRESIDENT<br />

City of Swift Current<br />

Work: 306-778-2725 Fax: 306-778-1634<br />

Email: t.cox@swiftcurrent.ca<br />

KELLY KISH ~ PAST-PRESIDENT<br />

Town of Kipling<br />

Work: 306-736-8805 Fax: 306-736-2396<br />

Email: glokel@sasktel.net<br />

RYNETTE MOORE-GUILLAUME ~ VICE PRESIDENT<br />

SaskWater<br />

Work: 306-694-3941 Fax: 306-694-3207<br />

Email: rynette.moore@saskwater.com<br />

KARLIS VAN CAESEELE~ TREASURER<br />

Town of Langenburg<br />

Work: 306-743-2219 Fax: 306-743-2453<br />

Email: karlisvc@sasktel.net<br />

CORY MCMAHON ~ SECRETARY<br />

Town of Biggar<br />

Work: 306-948-5136 Fax: 306-948-5136<br />

Email: corden@sasktel.net<br />

DIRECTORS_________________________<br />

SUSAN DOBROWNEY<br />

City of Saskatoon<br />

Work: 306-975-2534 Fax: 306-975-7906<br />

Email: susan.dobrowney@saskatoon.ca<br />

OWEN GREEN<br />

Town of Rosthern<br />

Email:publicworks@rosthern.com<br />

LUKE LOCKHART<br />

Town of Outlook<br />

Phone: 306-860-7575<br />

email: townofoutlookwater@hotmail.ca<br />

REPRESENTATIVES________________<br />

GOVERNMENT<br />

KELLY NEUERT<br />

Water Security Agency<br />

Work: 306-787-7911<br />

Email: kelly.neuert@wsask.ca<br />

SUPPLIERS<br />

WADE SHUTKO<br />

ClearTech<br />

Email: wshutko@cleartech.ca<br />

Jordan Webb<br />

Mueller<br />

Email: JWebb@muellerwp.com<br />

SWWA PRESIDENT’S MESSAGE<br />

Conference<br />

Wrap-UpSWWA 2018<br />

That seemed to come and go in the<br />

blink of an eye, didn’t it?<br />

It seems like just yesterday we started getting things in order and before you know it,<br />

it’s Friday afternoon and we were closing up the conference for another year. As we<br />

put another conference to bed, the SWWA board would like to thank all the sponsors<br />

who contributed to make this years’ event a success. We were also fortunate to have<br />

a ton of great presenters this year, and we received very positive feedback from many<br />

of our attendees. It certainly gives us a nice pat on the back and lets us know we’re<br />

keeping the ship pointed in the right direction.<br />

The keynote address was delivered by the ‘Water Brothers’, renowned television<br />

celebrities and water activists! The message of global water awareness was a hit with<br />

delegates, and hopefully struck enough of a cord to initiate the action required for our<br />

part in the crisis! In addition, the address reiterated the importance of our Operators,<br />

and that the jobs they do every day are more significant than most people realize or<br />

give credit … well done guys and girls!<br />

This year, more than 460 members were on hand, and the majority left with the<br />

available 1.2 CEU’s for certification. Also, it pays to mention that most of the attendees<br />

signed up online, and despite a few glitches, it seems as though our delegation has<br />

grasped the new method of registration. This certainly eases the stress on the office<br />

during the last two months!!<br />

Make sure to keep your 2019 calendars handy (included in your conference bag), and<br />

use them to update future workshop dates as they become available online at<br />

www.swwa.ca . You’ll also notice an extra booklet in your bag. This contains all of your<br />

suppliers’ information! Use it as a quick reference to contact your reps when parts and<br />

service are required!<br />

I hope everyone took as much out of the conference as I did, it’s always a great<br />

learning experience, and I hope you all had a fun time as well.<br />

Take care, enjoy the winter, and we’ll see you all again next year.<br />

Tim Cox, SWWA President<br />

we want<br />

YOU<br />

Get involved<br />

We are looking for SWWA members who<br />

would like to be involved with various SWWA<br />

events from networking events to the annual<br />

conference.<br />

CONTACT CALLE AT THE SWWA OFFICE,<br />

OFFICE@SWWA.CA FOR MORE INFORMATION.

PROVEN<br />

THROUGH<br />

PERFORMANCE<br />

CONTACT KAYDEN INDUSTRIES TODAY!<br />

Toby Bird<br />

Business Development Consultant<br />

tbird@kaydenindustries.com<br />

T 403.571.6688<br />

C 403.993.9269<br />

Kayden Industries has experience in Dredging, Desludging and<br />

Mechanical Dewatering of municipal lagoons. Kayden prepares prior to<br />

the job commencing by properly surveying the lagoon, laboratory testing<br />

the material, then proposing the most e cient equipment and chemical<br />

package. At the end of the project we deliver a post dredge scan to prove<br />

our performance.<br />

403.571.6688<br />

24/7 SUPPORT: 1.855.571.6688<br />

Manfacturing Plant:<br />

Sales & Executive O ce<br />

3348 58 TH Avenue S.E.<br />

1630 801 6 TH Avenue S.W.<br />

Calgary, AB, T2C 0B3<br />

Calgary, AB, T2P 3W2<br />

KAYDEN’S PROMISE TO YOU<br />

Kayden’s success over the past 20 years has been built on<br />

manufacturing one of the largest, most reliable and most<br />

e cient horizontal decanting centrifuges available in the<br />

dewatering industry.<br />

These high capacity centrifuges are specically designed<br />

for dewatering, and when combined with the most e cient<br />

dredges built in North America they create a mechanical<br />

desludging and dewatering package unsurpassed in the<br />

industry.<br />

Kayden can assure all clients that our technology will deliver<br />

industry leading results in the hands of trained operators<br />

who follow best practices in operation and technology<br />

deployment.<br />

Traditionally when we think about a toolbox we think of<br />

tangible items, those things that we can hold in our hands<br />

like hammers, pliers, etc. This month when I heard that the<br />

theme of the Pipeline was, “What’s in Your Toolbox?” I started<br />

to think about what does that mean to an operator in a<br />

water or wastewater facility?<br />

Of course, it means the tangible items that we need to do<br />

our everyday jobs. We need the correct tools to do our work<br />

including everything from hand tools, sampling equipment,<br />

machinery and the instruments that we use for sample<br />

analysis. But, what about the intangible tools that we need?<br />

The intangible tools that we need are the skills that<br />

operators possess to perform their daily work. An operator<br />

in a water or wastewater facility is required to have a broad<br />

spectrum of understanding of many trades and fields.<br />

Operators need to understand fluid dynamics, electricity,<br />

and pumping theory, as well as have a vast knowledge of<br />

water quality and chemistry. An operator may be called on<br />

to troubleshoot all kinds of equipment in their facilities and<br />

must have the network of specialists to call on when the<br />

issue is beyond their ability.<br />

Operators of water and wastewater facilities must rely on<br />

the training that they have received during their<br />

preparation for certification exams and the experience that<br />

they have in their facilities to troubleshoot and optimize<br />

What’s<br />

Toolbox?<br />

IN YOUR<br />

their processes. By participating in continuing education<br />

each year, operators can expand their knowledge base and<br />

gain a deeper understanding of specific topics. This is one of<br />

the advantages of requiring education to maintain<br />

certification.<br />

Other resources that are available to the operator include<br />

the breadth of knowledge and guidance available from the<br />

Water Security Agency (WSA). The WSA employs experts in<br />

many fields that can assist operators in analyzing problems<br />

ranging in nature from the steps required to resample after<br />

a positive bacteriological sample to highly complex issues<br />

like controlling organic substances in the process to reduce<br />

disinfection by-products.<br />

There are private consultants that can assist with jobs that<br />

are only performed periodically that may require<br />

experienced personnel, specialized equipment or additional<br />

skilled workers. Tasks like uni-directional flushing, leak<br />

detection, reservoir maintenance, remote monitoring and<br />

cleaning or plant optimizations can be facilitated through<br />

private companies.<br />

So, I guess the question is not just “What’s in Your Toolbox –<br />

But Who’s in Your Toolbox?” as well.<br />

Dawn Dierker<br />

ATAP

Mission is Simply More Intelligent<br />

Advanced Monitoring • Low Cost • Managed SCADA<br />

Changing THE<br />

Proactive<br />

Notifications<br />

Notifications<br />

• Alarms dispatched to all<br />

your devices—phone,<br />

tablet, computer, fax,<br />

pager<br />

•Customize notifications<br />

to be simple or<br />

sophisticated<br />

•Convenient alerts<br />

Secure Data<br />

• Defense-in-depth security<br />

policies<br />

•Multiple security measures<br />

layered to protect your<br />

system<br />

•Securely access your data<br />

in the office or field<br />

• State-of-the-art web portal<br />

features live data, multiple<br />

windows, and more<br />

Purpose-Built<br />

Hardware<br />

Hardware<br />

•Standardized RTUs are<br />

economical to buy, install,<br />

and operate<br />

•Advanced remote-control<br />

business logic<br />

•New MyDro RTU—smart<br />

and expanded I/O, LCD<br />

screen, enhanced<br />

electronics<br />

MyDr<br />

Convenient<br />

Support<br />

Support<br />

•All resources for no<br />

charge<br />

• U.S.-based technical<br />

support 24-7-365<br />

•Live weekly webinars,<br />

newsletters, instructional<br />

videos<br />

•Audit trail for<br />

accountability<br />

Mission-Managed<br />

• Comprehensive reports<br />

that display your data at<br />

a glance<br />

•No software or cellular<br />

carrier relationships to<br />

maintain<br />

•Continual system<br />

enhancements<br />

• Everything necessary is<br />

included—no hidden fees<br />

culture<br />

IN<br />

THE<br />

WORKPLACE<br />

There are many factors that determine safety<br />

culture in the workplace, and how people view<br />

safety. Safety culture can change the way a<br />

company does business and how their<br />

employees do day to day items. There are many<br />

factors when looking at changing the culture in<br />

your workplace, things like how the workers<br />

look at safety in general. It starts at the top and<br />

goes right down to the bottom, from the<br />

owner of the company to the lowest worker<br />

on the totem pole.<br />

Some of the things that can change the<br />

culture in your workplace are things like<br />

communication. Weekly safety<br />

meetings and toolbox talks are a great way<br />

to communicate and have the employees<br />

take the lead. Inform your workers about all<br />

safety news and any new safety items that may<br />

come out in the workplace. Training is always a<br />

good way to show workers that you have<br />

commitment to safety. Trained employees are<br />

more aware of hazards around them, they also<br />

are more willing to take safety more seriously.<br />

Lead by example, if the workers see that even<br />

the highest person in the company follows the<br />

rules it makes them want to do the same. It’s<br />

from wearing PPE to following the proper<br />

policies and procedures. Employees will not<br />

follow if they don’t see it from their supervisors.<br />

It’s more than talking the talk you have to walk<br />

the walk.<br />

Implement a positive reporting process makes a<br />

worker want to report potential hazards and<br />

help keep their fellow workers safe. When an<br />

employee feels safe to come and report hazards<br />

the culture will change for the better and the<br />

workplace will be that much safer. Involve<br />

workers in developing the policies and<br />

procedures, let them have a part in the process<br />

so they can feel needed. Ask them how they<br />

would like the policies to look like, what types of<br />

things they think work better.<br />

Lastly, having a Joint Health and Safety<br />

Committee, demonstrates the commitment to<br />

safety. It shows a good safety culture between<br />

the workers and the employer.<br />

Sheldon Matton<br />

Loraas Disposal<br />

lead by example, if the workers see that even the<br />

highest person in the company follows the rules it<br />

makes them want to do the same.<br />

(877) 993-1911 | 123mc.com | sales@123mc.com

Piapot Water Treatment Plant<br />

Up In Flames<br />

On October 29 at 11:30 pm an alarm sounded at the Piapot<br />

Water Treatment Plant located on the Piapot First Nation. When the operator<br />

went to check it out the inside of the building was filled with smoke and fire<br />

which had sparked a grass fire outside the facility.<br />

In years past, a municipal agreement had been made with a surrounding<br />

municipality but due to “lack of funds there was no agreement in place on<br />

the night of the fire” as stated by Ira Lavalle in an interview with news talk<br />

CJME on Oct. 30. A call was put in to a local community however no truck<br />

came, the RCMP did respond and made sure the fire was kept under control.<br />

The Piapot community helped get the fire under control and the situation<br />

has the community banding together and the mood remains helpful and<br />

optimistic. This has brought up the need for access to a fire truck and is<br />

something that is being reviewed by Indigenous Services Canada the<br />

provincial officials with emergency management and fire safety to develop<br />

a plan moving forward. At this time the cause of the fire has not yet been<br />

determined.<br />

In a phone Interview with Don Poon of SAL Engineering Ltd. who is the<br />

Project Manager he spoke of the three phases needed to get things moving.<br />

The Water Treatment Plant that was in place prior to the<br />

fire had Green Sands filters that removed the iron and<br />

manganese before the RO process.<br />

Indian National Affairs Canada was also approached for<br />

their take on the situation. The following is their response.<br />

At this point has it been determined what type of plant<br />

will replace the one that was destroyed by the fire (i.e. what<br />

type of technology will be used, where will it be located,<br />

capacity, estimated cost, size, etc.)?<br />

At this early stage, the look and design of the new Piapot<br />

Water Treatment Plant has not been determined. The focus<br />

of the Project Management Team (PMT), which consists of<br />

representation from a number of partners including<br />

Indigenous Services Canada (ISC), is focusing on three<br />

areas:<br />

1To ensure water is available to community<br />

members. This includes purchasing and delivering<br />

bottled water to residents who had water piped<br />

to their homes from the previous plant, and<br />

trucking in water from neighbouring<br />

communities to homes that are on truck delivery.<br />

2Securing a temporary water treatment plant to<br />

produce water for the core area and facilities (e.g.<br />

school, band office, healthcare centre) within the<br />

community and to provide water for truck<br />

hauling.<br />

3Starting the feasibility and pre-design stage of<br />

developing a new treatment plant. This is always<br />

the first step when a new plant is to be<br />

constructed. At this stage, decisions on which<br />

technologies will be included, location, water<br />

source, etc. are determined by the PMT.<br />

PHASE<br />

PHASE<br />

PHASE<br />

1<br />

2<br />

3<br />

To have water provided to the school and distribution system<br />

immediately. This was done the day following the fire and only<br />

one day of school was lost.<br />

To create a temporary solution to the lack of water for the<br />

community. The solution for the time is hauling water but a more<br />

cost-efficient solution (temporary Water Treatment Plant) is<br />

needed.<br />

A proposal has been submitted to the federal government<br />

looking at a total cost of $13 million to replace the plant and<br />

temporary and emergency measures.

Members of the team discuss, collect, share and<br />

expedite all details associated with the project. This<br />

includes determining the physical structure, funding<br />

sources (insurance, First Nation, federal government),<br />

jurisdiction, provincial and federal regulations, and<br />

community interests – all with the objective of<br />

completing the project in the most efficient and<br />

effective manner.<br />

Describe the federal government’s response to the<br />

disaster.<br />

First Nations are responsible for immediate action in<br />

an emergency situation with support from Tribal<br />

Councils, the Circuit Rider Training Program, ISC, and<br />

provincial agencies.<br />

Immediately following the fire, ISC officials traveled<br />

to the community to attend the initial emergency<br />

response meeting. During this meeting, which had<br />

representation from the Piapot First Nation, the File<br />

Hills Qu’Appelle Tribal Council, the Province and ISC,<br />

we committed to working with the community to<br />

address their immediate short-term water needs. In<br />

addition, our officials participated in a discussion<br />

concerning funding to replace the treatment facility<br />

that had been destroyed.<br />

ISC also confirmed we would have representation on<br />

the PMT, which was established to address the short,<br />

medium and long-term water supply needs of the<br />

community.<br />

What supports does ISC provide to communities to<br />

help ensure plants are being operated by certified<br />

operators?<br />

ISC provides funding to First Nations communities to<br />

train water treatment plant operators.<br />

Trained and certified plant operators are key to<br />

reducing risk and to help ensure safe drinking water<br />

in First Nation communities. To support First Nations<br />

in developing and retaining the capacity to operate,<br />

service and maintain public on-reserve water and<br />

wastewater systems, ISC funds the Circuit Rider<br />

Training Program and operator certification training.<br />

The Circuit Rider Training Program is a mentoring and<br />

long-term capacity-building program that uses<br />

traveling trainers, called Circuit Rider Trainers. The<br />

Circuit Rider Trainers visit First Nation communities<br />

such as Piapot, to assist operators in obtaining and<br />

maintaining their certification to manage and<br />

operate their respective facilities.<br />

Circuit Rider Trainers also provide system operators with on-site,<br />

hands-on training on how to operate, maintain, and monitor their<br />

communities’ drinking water and wastewater systems. Water quality<br />

monitoring on reserve is overseen by First Nations Inuit Health and<br />

they also provide support and training for this.<br />

The goals of the Circuit Rider Training Program include:<br />

n<br />

n<br />

n<br />

n<br />

Supporting on-reserve water and wastewater system operators<br />

in developing and maintaining the capacity to manage their<br />

systems;<br />

Improving the maintenance, management and effectiveness of<br />

on-reserve drinking water and wastewater systems;<br />

Reducing the number and duration of drinking water advisories<br />

(DWAs); and,<br />

Helping First Nations communities to realize the full-service life<br />

of their water and wastewater infrastructure.<br />

Has it been determined when the new plant will be completed,<br />

operational and commissioned to the First Nation?<br />

No. As the PMT is only in the feasibility and pre-design stage, we cannot<br />

confirm a date as to when the new plant will be completed and ready for<br />

operation. From start to finish, the process to plan, tender, build and<br />

commission a water treatment plant usually takes approx. 2 years.<br />

As noted by INAC and stated by Don Poon in the phone interview the<br />

process for building a new plant takes time as does approval. We will be<br />

watching and following up in the New year with the steps being taken to<br />

get a good working solution in place while the new plant is being<br />

approved and built.<br />

It is not always easy to work through and handle an incident like this one<br />

but a few huge things to note happened during this crisis:<br />

1<br />

A community pulled together, remained optimistic and was<br />

helpful ensuring the fire did not spread and that the grass fire<br />

was controlled<br />

2<br />

3<br />

The Piapot<br />

Water was restored to the school within 24 hours of the fire<br />

ensuring class time of only one day was missed<br />

The operators of the Piapot First Nation worked hard with the<br />

project managers brought in (Don Poon and Lawrence Lukey)<br />

to find a solution that would work for the time being.<br />

community<br />

has banded<br />

together and<br />

remains<br />

positive

MEMBER PROFILE<br />

ROWENA<br />

FOURHORNS<br />

Level 2 Water Treatment Plant<br />

Operator for Piapot First Nation<br />

& Carry The Kettle First Nation<br />

What led you into your current<br />

field? Was it planned or a<br />

detour?<br />

In 1989, opportunities rose for<br />

First Nations women to<br />

participate in training for water<br />

plant operators. I took the<br />

training and have been with the<br />

industry ever since.<br />

How long have you been in the<br />

industry?<br />

I have been in the water plant<br />

industry for 30 years; since 1989.<br />

Is there someone who has been<br />

a mentor to you in your<br />

professional life and personal<br />

life and why?<br />

My mentors are those people<br />

who had taken the time to help<br />

me and stand by me-family,<br />

friends, coworkers and other<br />

water professionals. I also credit<br />

Garry Tenaschuk with ATAP. He<br />

helped me to feel at ease in an<br />

overwhelming environment. Also<br />

at time when women were not<br />

seen as water plant operators.<br />

If you could give advice to<br />

someone looking to get into<br />

the industry or to a student<br />

looking into a future career<br />

what would you say?<br />

“Go for it”, I encourage a lot of<br />

younger people to look into this<br />

field of work. It may not be a lot<br />

of pay at first, but after gaining<br />

experience and acquiring the<br />

certifications-you’re not limited<br />

to one place, it opens the doors<br />

across Canada.<br />

What type of education do you<br />

currently hold?<br />

I have my Grade 12 GED. I also<br />

acquired the Level 2<br />

requirements for the Operator<br />

Certification Board to be certified<br />

in 2006.<br />

What are ways you give back to<br />

the industry?<br />

I help other First Nations water<br />

plants when I can; I also do<br />

school tours of the water<br />

treatment plants. We also set up<br />

information booths at health &<br />

career fairs in our communities.<br />

What is the most rewarding<br />

part of your job?<br />

Providing safe and potable water<br />

to the communities I work in.<br />

What are your future plans for<br />

your career?<br />

Retire.<br />

What are ways you currently<br />

incorporate to help combat<br />

stress and overwork?<br />

I am still learning different ways<br />

to combat stress and overwork.<br />

Over the years of being in this<br />

field, being an operator had<br />

become a part of my everyday<br />

life. I spend a lot of time travelling<br />

when I can; spending time with<br />

family and friends-they are the<br />

most important to me.<br />

What led you into your current<br />

field? Was it planned or a<br />

detour?<br />

My lead into the Water Plant was<br />

a detour and looking for a<br />

change from my previous<br />

employment. In September<br />

2017, I had just happened to<br />

stop at our community water<br />

plant to visit the operator,<br />

Rowena Fourhorns. She<br />

informed of an immediate<br />

opening available at the plant. I<br />

applied with our band<br />

administration, interviewed and<br />

started October 2017.<br />

How long have you been in the<br />

industry?<br />

Up to this point-November 28,<br />

2018, I have been in the water<br />

industry for one year and one<br />

month.<br />

Is there someone who has<br />

been a mentor to you in your<br />

professional life and personal<br />

life and why?<br />

In my professional life, I look up<br />

to those who are more<br />

experienced and willing to help<br />

me; people who take the time to<br />

explain things to me and allow<br />

me to do job duties on my ownfind<br />

my own way that works for<br />

me.<br />

In my personal life, I turn towards<br />

my family and a few close<br />

friends. Family and friends who<br />

support, listen and encourage<br />

me through many different<br />

paths.<br />

What is the most rewarding<br />

part of your job?<br />

The most rewarding for me,<br />

would be the self-discovery in<br />

my own abilities. I came from a<br />

previous work experience that<br />

MEMBER PROFILE<br />

MARNIE FRANCIS-WATER<br />

Plant Operator-Piapot First Nation Water Treatment Plant<br />

had nothing to do with the<br />

Water Industry and that was a<br />

HUGE change in my life. Doing<br />

the day to day job duties in and<br />

around the water plant and<br />

community helped me discover<br />

some abilities that I forgot I had<br />

or didn’t know I had!<br />

If you could give advice to<br />

someone looking to get into<br />

the industry or to a student<br />

looking into a future career<br />

what would you say?<br />

Try it…..There is nothing wrong<br />

with trying out different fields of<br />

work to help a person decide<br />

what is best for them or what<br />

works for themselves and family.<br />

The worst a person can do to<br />

themselves, is not TRY. You never<br />

know until you TRY. Give the<br />

experience some time, work at it<br />

and then come to a conclusion.<br />

What type of education do you<br />

currently hold?<br />

I have my Grade 12 diploma,<br />

some community college &<br />

university classes in Agricultural<br />

Business & Social Work, Youth<br />

Care Work and I have just<br />

received my Level 1 Water<br />

Treatment & Water Distribution<br />

certification with OCB.<br />

What are ways you give back<br />

to the industry?<br />

I look forward to the future and<br />

planning for our community.<br />

With our recent loss, I would like<br />

to share our experience with<br />

other First Nation Water Plant<br />

Operators and planning for a<br />

community crisis.<br />

What are your future plans for<br />

your career?<br />

I plan on remaining on with<br />

Piapot First Nation Water<br />

Treatment Plant and continuing<br />

to work on obtaining my Level 2<br />

certifications within the next<br />

year or two.<br />

What are ways you currently<br />

incorporate to help combat<br />

stress and overwork?<br />

I have incorporated doing things<br />

that I enjoy: riding horses,<br />

quadding, entering barrel racing<br />

events, taking horses to bucking<br />

horse events, reading and<br />

puttering around my yard. I<br />

found that being in this field of<br />

work has its days of stress and<br />

overwork, if I let it. We have an<br />

excellent crew of back up<br />

operators here in our<br />

communtiy and my coworker:<br />

Rowena Fourhorns and I work<br />

out a lot of scheduling of<br />

weekends, holidays, etc. So that<br />

we can enjoy the things we like<br />

doing and places we like to visit.<br />

Family is very important to us<br />

and we ensure that everyone<br />

working with us has the time<br />

they need to be with family.<br />

The Saskatchewan<br />

Operator<br />

Certification Board<br />

The Saskatchewan Operator Certification Board (SaskOCB) is responsible for<br />

certifying Water and Wastewater Operators within the province of<br />

Saskatchewan. We work at arm’s length with the Water Security Agency (WSA)<br />

and make our decisions based on the regulations and standards put in place<br />

by the WSA.<br />

We accept applications for new applicants, upgrades and renewals by mail,<br />

email or fax. We review applications at the next scheduled Board meeting.<br />

Your certification is valid for two (2) years and you will receive a renewal notice<br />

in the mail a few weeks before your renewal date. You can always download<br />

an application from our website if you decide to renew early -<br />

http://saskocb.ca/uploads/docs/Renewal%20Application%20October%205%<br />

202017%20(1).pdf<br />

Our website has all the information you need for your current certification,<br />

upgrades and renewals.<br />

To check your certification you can log in to your account anytime<br />

http://saskocb.ca/operator-login. Once you’re logged in you can verify and<br />

update your personal information, certification classes, renewal date, CEU<br />

submitted.<br />

You will need to contact the office via email – info@saskocb.ca to obtain your<br />

temporary password to access your information.<br />

The Operator Certification Board does not facilitate courses or exams for water<br />

classifications, take registration for upcoming SWWA conferences or New<br />

North Workshops.<br />

You cannot access your Saskatchewan Water and Wastewater Association<br />

(SWWA) membership information through our office or website. You need to<br />

contact them or log in to their website.<br />

You can always call or email us with your questions or concerns<br />

Saskatchewan Operator Certification Board<br />

c/o Mail Room<br />

3211 Albert Street<br />

Regina, SK S4S 5W6<br />

Email – info@saskocb.ca<br />

Phone – 306-789-3430<br />

Fax – 306-789-3429<br />

Website – www.saskocb.ca

ClearTech Introduces the Lovibond PVT<br />

Series of Process Turbidimeters in Canada<br />

ClearTech is the Canadian factory authorized<br />

service centre and stocking distributor for<br />

the new Lovibond PVT Series of Process<br />

Turbidimeters in Canada. Lovibond, a leading<br />

manufacturer of water analysis products<br />

designed these turbidimeters to monitor<br />

Introducing the<br />

PTV Process Turbidimeters<br />

by Lovibond<br />

Accurate<br />

Easy to Use<br />

Low Maintenance<br />

Wherever there’s water<br />

See Turbidity<br />

in a New Light<br />

▼<br />

the low levels of turbidity found in drinking<br />

water. The PVT Series received US EPA<br />

approval as listed the USA Federal Register /<br />

Vol 82 / No. 143, in section 40 CFR 141.74(a)<br />

(1), published on Thursday, July 27, 2017.<br />

“This is a big milestone,” says Michael Sadar,<br />

Lovibond’s Research and Develop Manager.<br />

“We worked hard to develop a system that<br />

was not only user friendly, but that is able<br />

to achieve the level of accuracy that the<br />

operators as well as the regulators expect<br />

from a system like this. We’re really proud of<br />

what we were able to accomplish, and we<br />

think that operators are really going to like<br />

the simplicity of the overall design of the<br />

instrument as well as the data management<br />

tools that the mobile interface provides.”<br />

See the New PTV Process Series by<br />

ADVERTORIAL<br />

With an emphasis on simplifying processes,<br />

data management, and reducing water<br />

usage, the design of the PTV Series<br />

considered every aspect of process turbidity<br />

workflow. The system is configurable to offer<br />

operators a variety of options including<br />

integrated flow indication and bi-directional<br />

Bluetooth® communication between the<br />

sensor and a mobile device. Additional<br />

accessories to assist with installation, sample<br />

management and routine procedures such as<br />

calibrations and cleanings are also available.<br />

As a stocking distributor and factory<br />

authorized service centre, ClearTech<br />

offers complete installation and ongoing<br />

maintenance service on the PVT Series<br />

Turbidimeters.<br />

To order and for more information about<br />

the PVT Series, contact ClearTech at<br />

1.800.387.7503 or orders@cleartech.ca.<br />

For more about ClearTech’s commitment to<br />

water treatment visit www.cleartech.ca.<br />

<br />

1-800-387-7503<br />

Leadership<br />

is Like Looking<br />

Down a<br />

MANHOLE!<br />

The day I found myself looking down into the inside of a<br />

manhole, knowing that within 2 months I was going to be<br />

determining what needed to be done to repair worn out<br />

manholes and pipes, I realized how little I knew. I had a lot to<br />

learn! A lot. I needed to add to my “manhole toolbox”. I found<br />

that there is an entire world underground that most people know<br />

absolutely nothing about, and don’t care about until their<br />

basement is flooded with sewage.<br />

This is a great illustration of what<br />

it takes to be a leader. Most<br />

people like to think they<br />

understand what a leader does,<br />

what they can do better, what<br />

they’ve done wrong, and how<br />

they can fix things. The problem<br />

is, until we’ve stood looking down<br />

into the “manhole” of leadership,<br />

we have little idea about what<br />

kind of crap we’ll have to deal<br />

with, in order to keep things flowing as smooth as possible for<br />

everyone else. Until we’ve felt the weight of leadership, our ideas<br />

are usually just theories, we really don’t know what tools we’ll<br />

need to lead well.<br />

Leadership is often messy. We don’t always see what’s coming<br />

down the pipe at us until it pops out right in front of us and then<br />

we’re wading through it, trying to clean up the mess that results!<br />

Manholes and leadership have something else in common – we<br />

need the right tools to deal with the situation. We need to add to<br />

our leadership toolbox, just like I needed to add to my manhole<br />

toolbox. We need the right tools at the right time.<br />

Leadership is never constant. Things continually change.<br />

Technology, materials, weather, materials, government codes,<br />

safety regulations, town/RM/ City councils, and employees are<br />

always changing. We need to have the tools, and the knowledge<br />

to deal successfully with all these changes.<br />

Some of the older manholes are still made of brick. We use<br />

I knew all about sewers.<br />

At least I thought I did.<br />

How much could there<br />

be to know?<br />

I turned on the tap – fresh water came in.<br />

I pulled the plug, or flushed<br />

and all the problems went away.<br />

Or did they?<br />

different methods for repairing those older ones than the newer<br />

cast concrete manholes. We need to alter our approach and use<br />

some different tools to make them efficient again and to keep<br />

things “flowing”. Leadership today necessitates using different<br />

tools, putting a different set of skills to use if we’re going to keep<br />

everything “flowing” in our departments.<br />

If you’ve been a leader for any amount of time, you know that it’s<br />

not a 40 hour a week job, it takes extra time and effort to lead<br />

well. We need to invest some of that time in ourselves, adding to<br />

our toolbox, adding to what we know. How do we do that!!!!????<br />

READING – we can learn from people who have done<br />

what we need to do<br />

LISTENING – podcasts and audiobooks are a great<br />

way to learn<br />

WATCHING – instead of “surfing” –<br />

watch videos with a purpose<br />

TALKING – time with people who are doing<br />

what we want to learn to do<br />

There’s no way you would settle for only knowing how to turn on<br />

a tap and flush a toilet – you need more than that to do your job!<br />

So, then don’t settle for only knowing a couple of “tricks” when it<br />

comes to leading your department! Get the tools and the<br />

knowledge you need. After all, your people are worth it!<br />

PS – Those “surprises” that pop out at us, won’t be so challenging<br />

when we have the right tools to deal with them!<br />

If you click on the link below, you’ll find a ton of resources, that<br />

we’re adding to almost daily, to help you fill your “leadership<br />

toolbox”!<br />

Thanks for what you do for our communities!!<br />

Todd Reimer<br />

www.bootsonthegroundcoaching.com<br />

todd@bootsonthegroundcoaching.com

Tyler Klath<br />

Cell: (306) 203-3800<br />

TF: 1-888-554-0638<br />

tyler@ahmcelroy.com<br />

A.H. McElroy Sales & Service (Canada) Ltd.<br />

Saskatchewan, Manitoba and Nunavut<br />

Website: www.ahmcelroy.com<br />

Since 1958<br />

Trevor Eden<br />

Western Canada Territory Manager<br />

trevor.eden@robar.ca<br />

ROBAR INDUSTRIES LTD.<br />

12945 - 78th Ave, Surrey, BC Canada V3W 2X8<br />

Tel 604.591.8811 Cell 778.836.7490<br />

1.800.663.6553 Fax 604.591.5288<br />

1.800.665.6553<br />

www.robarindustries.com<br />

LISA VAN ELSAKKER<br />

Sales Representative<br />

Flocor Inc.<br />

503 47th Street East<br />

Saskatoon, Saskatchewan<br />

Canada, S7K 5B5<br />

Tel: (306) 242-6788<br />

Fax: (306) 242-5089<br />

Cell: (306) 229-5208<br />

TF: (800) 667-3002<br />

Email: lvanelsakker@ocor.ca<br />

www.ocor.ca<br />

!"#$%&'()$%*+,()-,%*.)/0'10,(,%<br />

9,/(*++(2,0/(4*)"/'(4*#)"4*)"/(*&-(4*)"/()/"*)."&)(&""-#:(<br />

Providing Complete Solutions for<br />

Water & Wastewater Challenges<br />

Dillon Petrucha, Technical Sales Manager<br />

Phone: 306-231-3688<br />

Toll-Free: 1-855-682-6125<br />

E: dpetrucha@sapphire-water.ca<br />

Box 3615 Highway #20 North<br />

Humboldt, SK S0K 2A0<br />

www.sapphire-water.ca<br />

;&(50#$&"##($&(7"4*&(#$&>"(?@AB(<br />

!"#$%&'($&#)*++*)$,&(*&-(.*)"/$*+(#011+2(3,/(4*#)"(4*)"/(*&-(-$#)/$50)$,&((#2#)".#!<br />

6,/)7(8*))+"3,/-(<br />

"#$%&'(#!)*+,!-(*'%!./$0!<br />

1234!567/86%&!"9%0!<br />

)6(#%:!;3=>>?@!<br />

5(AA!B&%%:@=233=4>?@!<br />

B7C:!;3=;>

TC<br />

<br />

3807 Arthur Rose Ave.<br />

Saskatoon, SK S7P 0C7<br />

PH. (306) 242-4155<br />

Direct Line (306) 651-4782<br />

Cel. (306) 222-2114<br />

Fax. (306) 242-6020<br />

• Manhole Restoration<br />

Toll Free 1-866-242-4155<br />

• Concrete Repair and<br />

E-mail: jerry@topshotconcrete.com<br />

Restoration<br />

Website: www.topshotconcrete.com<br />

• Shotcreting<br />

• Concrete Pump Sales & Service<br />

Adam Speed<br />

Mid Continental Pump Supply Ltd.<br />

Pumps & Valves Fire Protection Municipal Industrial<br />

!"#$%&'%()*+!"#$%$&$<br />

!"#$%&"'()"'*+(,"&"-*.<br />

F5G((((((H304I('(()*+'+<br />

J"KG(((((H304I(,-*)*./'<br />

7*''G(((((H/0LI(+/-),0'0<br />

MA"$'G(N%5&@5".#OA$BC%&DEAD@C%A<br />

/0012/344(!%.#5(16*(7<br />

)"+8"#%%&9():9(();=<br />

???@A$BC%&#$&*&#"'DEAD@C%A<br />

Microfiltration/<br />

Reverse Osmosis<br />

Bulk Handling<br />

Solutions for<br />

Water Treatment<br />

Don Burgess<br />

Bay 110, 44 Riel Drive<br />

St. Albert, AB T8N 5C4<br />

Ph: (780)460-8433 Fax (780)418-2227<br />

don.burgess@dwg-process-supply.com<br />

Low Fouling, High<br />

Productivity, RO<br />

Membrane<br />

Allan Miskolczi - Technical Sales Rep<br />

Cell: 306-381-9244 • Toll Free: 1-877-624-5757<br />

Email: amiskolczi@johnbrooks.ca<br />

www.johnbrooks.ca<br />

Alex McGregor<br />

Territory Manager - Northern Alberta and Saskatchewan<br />

amcgregor@neptunetg.com<br />

Edmonton, Alberta<br />

780-999-1825<br />

Water Softeners and<br />

Specialty Metals Removal<br />

On-Site Chlorine<br />

Generation<br />

Manufacturer Representatives For Quality Water Treatment Equipment<br />

www.neptunetg.com<br />

ADVERTISING •<br />

David Tidy<br />

Senior Regional Sales Manager<br />

Metcon Sales & Engineering Ltd.<br />

15 Connie Crescent, Unit 3<br />

Concord, Ontario L4K 1L3<br />

P 905.738.2355 x 230<br />

M 416.346.1764<br />

F 905.738.5520<br />

E davidt@metconeng.com<br />

W www.metconeng.com<br />

Water and Wastewater Products<br />

CORIX Water Products provides quality service and solutions<br />

from waterworks and HDPE supplies to water meters,<br />

engineered products, and packaged systems.<br />

Visit us in booth 96 at the SWWA Tradeshow.<br />

www.corixwaterproducts.com<br />

Established in 1939<br />

GENE WALTERSON<br />

Director/Advisor<br />

Industrial Composite<br />

Sales<br />

Commercial & Industrial Services Ltd.<br />

1035 Mission Street<br />

Winnipeg, Manitoba R2J 0A4<br />

P: (204) 233-0671<br />

C: (204) 981-2200<br />

F: (204) 233-6938<br />

gene@carlsonindustrial.ca<br />

www.carlsonindustrial.ca<br />

Kyle Monette<br />

Director of Sales, Manitoba/Saskatchewan<br />

kylem@atstraffic.ca<br />

C 306.536.4456 T 306.525.0548<br />

F 306.565.8808<br />

410 A Henderson Drive<br />

Regina, SK S4N 5W9<br />

atstraffic.ca | Since 1966<br />

ADVERTISING •

ISO REGISTERED<br />

1500 QUEBEC AVENUE<br />

SASKATOON, SK S7K 1V7<br />

P 800.387.7503<br />

F 888.281.8109<br />

24 HR EMERGENCY 306.664.2522<br />

orders@cleartech.ca<br />

Keith MacCharles<br />

Email: keith@airmastersales.com<br />

P: (204) 944-7446 C: (204) 781-5199 F: (204) 632-9747<br />

Toll Free: 1-800-788-6805<br />

400 Keewatin St. Winnipeg, Manitoba R2X 2R9<br />

www.airmastersigns.com<br />

P.O. Box 92173<br />

RPO Meadowbrook<br />

Edmonton, AB<br />

T6T 1N1<br />

GLEN GRUNDBERG<br />

Regional Manager - Western Canada<br />

Cell: 780-910-1717<br />

Fax: 780-449-5300<br />

Glen@densona-ca.com<br />

www.densona.com<br />

NEVER WORRY<br />

ABOUT YOUR<br />

AMMONIA / cBOD 5 / TSS / PHOSPHORUS / NITROGEN<br />

LIMITS AGAIN.<br />

Go to nexom.com/saskatchewan to<br />

meet FRANCIS BORDELEAU, P.Eng,<br />

Nexom’s Sales Manager<br />

for Saskatchewan.<br />

AL STANLEY<br />

SALES REPRESENTATIVE<br />

GALAXY PLASTICS LTD & BREN TECHNOLOGIES<br />

9-30321 Fraser Highway<br />

ABBOTSFORD, BC V4X 1T3<br />

WWW.GALAXYPLASTICS.COM<br />

WWW.BREN-TECH.COM<br />

OFFICE: 604-857-9660<br />

FAX: 604-857-9674<br />

TOLL FREE: 1-877-808-1088<br />

CELL: 403-615-7655<br />

EMAIL: astanley@galaxyplastics.com<br />

Measurement and Control Equipment<br />

advertising works. . .<br />

CORIX Control Solutions provides measurement and control<br />

equipment to the oil, gas, industrial, and municipal market<br />

sectors in Western Canada.<br />

Visit us in booth 95 at the SWWA Tradeshow.<br />

www.corixcontrolsolutions.com<br />

ADVERTISING •<br />

Matthew Martin<br />

Branch Manager<br />

FABCO PLASTICS SASKATOON LIMITED<br />

Plastics For Today’s Industry<br />

mmartin@fabcoplastics.com<br />

3926 Arthur Rose Avenue<br />

Saskatoon, SK<br />

Canada S7P 0C9<br />

Tel: 306.955.6005<br />

Cell: 306.280.7170<br />

Fax: 204.694.7876 Fax: 204.694.7876 Fax: 204.694.7876 Fax: 204.694.7876<br />

ADVERTISING •

Why advertise in the<br />

Pipeline?<br />

Because it can<br />

EFFECTIVELY<br />

BOOST your SALES!<br />

UPCOMING WORKSHOPS<br />

April 9 & 11 - TAPPING – Jordan Webb, Mueller<br />

April 17 & May 1 - Water Quality, Sampling & Projects<br />

- WSA staff<br />

May 7 & 9 - Hydrant Operation & Maintenance<br />

Jordan Webb, Mueller<br />

Other workshops in the works:<br />

Pumps<br />

Filter Maintenance<br />

Emergency<br />

Preparedness<br />

Due Diligence<br />

Reverse Osmosis<br />

DATES<br />

April 9 & 11<br />

April 17 & May 1<br />

May 7 & 9<br />

Check the website for the most up to date<br />

information on all upcoming 2019 workshops.<br />

The website is updated as the information is available.<br />

www.swwa.ca<br />

ADVERTISING •<br />

SWWA<br />

Golf Tournament 2019<br />

May 31 Nipawin<br />

don’t miss<br />

the fun<br />

- book today!

the<br />

Awards<br />

OPERATOR OF THE YEAR<br />

Small Systems<br />

Tyler Hilderman<br />

Tyler has been with the Town of<br />

Strasbourg since 2015, he started as<br />

assistant foreman and in 2017 was<br />

promoted to foreman. He is known<br />

for his tireless work and ability to get<br />

the job done in the best way<br />

possible. His professionalism,<br />

intelligence, humility and<br />

determination are well respected by<br />

those he works with and his<br />

community.<br />

OPERATOR OF THE YEAR<br />

Large Systems<br />

Tracey Wolfe<br />

Tracey is the Waterworks Manager for<br />

the City of Meadow Lake. Tracey has<br />

been instrumental in new initiatives<br />

with water programs. She has been<br />

pro-active in all communication with<br />

council and regulators at the water<br />

Security Agency strengthening<br />

relationships during her time there.<br />

Tracey has worked tirelessly and<br />

often without time off during one of<br />

the City’s worst raw water quality<br />

challenges as new processes for<br />

water treatment and facilities have<br />

been brought on. Tracey is well<br />

regarded by colleagues and her<br />

community for her hard work ethic,<br />

intelligence and determination to<br />

ensure the best results for her City.<br />

taking time to<br />

recognize<br />

our Industry<br />

Career Leaders<br />

LIFETIME MEMBER<br />

Don Webb<br />

Don began his career with Mueller Canada straight out of<br />

University. For 43 years he was known as the Mueller Man by<br />

everyone. Don was at the very first SWWA conference and he<br />

has not missed one since. Don has been a great friend of the<br />

SWWA since the beginning with his company sponsoring<br />

events, teaching courses, participating in golf tournaments<br />

and always having a smile and a laugh ready. While we won’t<br />

be seeing him at many conferences moving forward Arizona<br />

tends to be nicer than Saskatoon in November, he has<br />

promised to be around for the golf tournaments and any<br />

prankster exploding golf balls that may come his way. Thanks,<br />

Don, for all you have done for the industry and SWWA it is<br />

appreciated.<br />

LIFETIME MEMBER<br />

Kevin Dyck<br />

Kevin started in the warehouse at Flocor in 1979 in Regina. In<br />

1988 he moved to inside sales and 2007 was promoted to Branch<br />

Manager. In his 38 years he was well known and well respected<br />

by those in the industry. He was always willing to help out and<br />

was a permanent fixture at the SWWA conferences and in<br />

training with the SWWA through the years. Kevin will be greatly<br />

missed by his customers and SWWA. Thanks, Kevin, for all you<br />

have done for both the industry and SWWA.<br />

SUPPLIER OF THE YEAR<br />

As voted on by those in attendance at the<br />

SWWA conference, Flocor is the recipient<br />

of the 2018 SWWA Supplier of the Year<br />

Award. The supplier of the year is for the<br />

supplier company who goes above and<br />

beyond to ensure that their customers are<br />

taken care of. Congratulations on being<br />

the recipient for 2018.

Mali: Healthy Communities Program<br />

n WaterAid Canada embarked on an ambitious project to transform lives through water,<br />

sanitation and hygiene in the ati and la districts of central Mali. Together, thanks to<br />

generous supporters like SWW change is now happening. Toilets are being built, hygiene<br />

practices are changing and soon, even more communities will have access to safe water.<br />

n Mali and around the world midwives have a challenging role in helping to ensure the safe<br />

delivery of babies. Without access to clean water and soap in healthcare clinics, this critical job<br />

becomes much more challenging. Ami works as a midwife at the health centre in Dougouolo,<br />

Mali. She is in charge of prenatal consultations, delivery, postnatal consultations and family<br />

planning. She has seen first hand the impact that the Mali: Healthy Communities program<br />

has had on the health centre staff and patients. New water taps, washbasins and latrines were<br />

installed inside the delivery room and new taps were provided in the yard of the healthcare<br />

centre.<br />

WaterAid/B.Ouedraogo<br />

Abdou Sogoba, 50, head of<br />

household, posing with two of his<br />

children in his compound, in the<br />

Circle of Bla, Mali.<br />

“Now there is a change thanks to the project support. We have tap stands in the yard of the<br />

health centre and we have taps inside the clinic rooms for our various needs. With these taps<br />

everywhere, we can easily have clean water to drink, wash our hands and clean the materials.<br />

The maternity ward has a tap, a washbasin and clean water available inside. So there is no need<br />

for me to leave the room to seek water while a woman in is labour needs my assistance. This is<br />

a valuable improvement to our working conditions and it contributes to preventing some<br />

infections and it helps us save time and energy to take care of patients. mi<br />

Ami, 45, midwife in the health<br />

centre of Dougouolo has<br />

running water and soap now to<br />

wash her hands inside the clinic.<br />

“I decided to invest and get a good latrine”<br />

Abdou Sogoba and his family live in the village of Toukoro, Mali. They had a traditional latrine<br />

in their compound that was simply a hole enclosed by some pieces of wood. hen the wood<br />

rotted and crumbled, the family was left without a toilet. nfortunately, this scenario is not<br />

uncommon in rural ali.<br />

Abdou decided to participate in some community meetings that were happening in his village.<br />

hese meetings, part of the ommunity ed otal anitation approach, bring<br />

communities together to discuss their hygiene and sanitation situation and the effects poor<br />

hygiene has on their health. hese meetings are the first step in encouraging community-led<br />

action to build toilets and eliminate open defecation. Abdou learned about different types of<br />

latrines and realized he needed a more solid and safe option for him and his family. e<br />

decided to invest and build a new latrine with a an lat or anitation latform slab, an<br />

improvement from the traditional latrine he had before.<br />

WaterAid/B.Ouedraogo<br />

ur research has shown in several countries around the world, that the decision needs to first<br />

come from the individual that they want and see value in a toilet for their family.<br />

Abdou himself was not convinced that he wanted to invest his money in a latrine until he<br />

participated in the community meetings and in a WaterAid hygiene education session. Abdou<br />

recogni ed that he had the funds needed, he ust had been lacking the knowledge and<br />

knowhow. he crumbling of his former traditional latrine followed by the awareness he gained<br />

through the meetings motivated Abdou to invest in an improved latrine for his family.<br />

ince I got the new improved latrine built, I feel at ease using it. I m glad to use it. All the<br />

family members are proud of it. Everyone uses it. I appreciate the fact that the hole for<br />

defecation is always closed. I think that with this improved latrine, we can avoid contracting<br />

some diseases.” - Abdou

Overview<br />

OF DRINKING WATER<br />

AND WASTEWATER<br />

MANAGEMENT<br />

Staff involved in the management of drinking<br />

water and wastewater are part of the<br />

Environmental and Municipal Management<br />

Services Division of the Water Security Agency.<br />

These staff develop and deliver the Agency’s<br />

drinking water, wastewater and liquid domestic<br />

waste management regulatory programs and<br />

associated services.<br />

They develop legislation, regulation,<br />

environmental code chapters, standards, guidance<br />

and monitoring programs related to drinking<br />

water, wastewater and surface water quality<br />

management as a means to help protect human<br />

health and environmental quality.<br />

Annual reports to the public on the state of<br />

provincial water and wastewater facilities is a<br />

requirement of legislation.<br />

The drinking water and wastewater management<br />

program consists of the following work units:<br />

Environmental Protection Services Section,<br />

Engineering and Approvals Unit, Environmental<br />

Services Section- North and South, and the<br />

Environmental Information Section.<br />

ensuring safe<br />

drinking water<br />

and protection of<br />

human health<br />

and the<br />

environment<br />

Environmental Protection<br />

Services Section<br />

n Develops standards, guidelines, protocols,<br />

policy and legislation to ensure safe<br />

drinking water, minimize environmental<br />

effects of wastewater discharges and<br />

maintain/improve uses of surface water<br />

resources in Saskatchewan. This section<br />

also participates on a number of<br />

federal/provincial committees which<br />

develop and coordinate water standards<br />

across Canada, including the federalprovincial-territorial<br />

Committee on<br />

Drinking Water and the Canada-wide<br />

Strategy on Municipal Waste Water<br />

Effluents.<br />

n Establishes operator certification standards<br />

and liaises with the Operator Certification<br />

Board and education providers as a means<br />

to advance Government’s strategic<br />

drinking water objectives and safe drinking<br />

water<br />

n Participates in development of raw water<br />

protection initiatives, provides water<br />

resource monitoring and guidance to<br />

groups undertaking monitoring of<br />

intensive livestock operations<br />

n Permit issuance and review of pesticide<br />

applications to water.<br />

n Permit issuance and oversees the liquid<br />

domestic sewage-hauling program.<br />

Engineering Approvals Unit<br />

n Reviews and approves waterworks/sewage<br />

works construction projects to ensure<br />

works meet sound engineering principles,<br />

safe treatment technologies, production<br />

and delivery of safe water and minimal<br />

impact of wastewater discharges.<br />

n Develops waterworks and sewage works<br />

design standards and guidance as a means<br />

to ensure effective and capable<br />

infrastructure.<br />

Environmental Services Section<br />

n Operational permitting, inspection and<br />

compliance of regulated waterworks and<br />

sewage works in Saskatchewan to ensure<br />

safe drinking water and protection of<br />

human health and the environment.<br />

n Delivery of effective preventative<br />

compliance assurance functions by<br />

Environmental Project Officers with<br />

compliance related assistance from<br />

Conservation Officers with the Ministry of<br />

Environment<br />

n Provision of technical advice in the event of<br />

waterworks/sewage works system<br />

emergencies, system failures or upsets to<br />

protect human and environmental health<br />

that these problems may represent. Issues<br />

Precautionary Drinking Water Advisory<br />

when situations or reports indicate a<br />

potential problem with regulated drinking<br />

water supply. Provides water and<br />

wastewater treatment and system<br />

management advice and response in the<br />

event of a waterborne disease outbreak.<br />

n Provides guidance to waterworks owners<br />

to manage and resolve concerns in the<br />

event of adverse water quality monitoring<br />

results. Tracks and monitors compliance<br />

with drinking water quality standards (e.g.:<br />

bacteriological water quality, etc) that can<br />

have direct, short or long term health<br />

effects;<br />

Environmental Information Section<br />

n This section is responsible for the<br />

management of the Agency’s drinking<br />

water and wastewater information. The<br />

Environmental Information Section<br />

provides drinking water and wastewater<br />

information for every municipal and<br />

industrial waterworks and sewage works<br />

regulated by the Water Security Agency via<br />

the SaskH20.ca website<br />

Need<br />

Help?<br />

The SWWA Office can help you with the following and all information can be found on<br />

the SWWA website.<br />

n Replacement certificates for SWWA courses taken<br />

n Information on upcoming courses<br />

n Annual Golf tournament information<br />

n Conference and tradeshow information<br />

n Job Postings<br />

n Supplier information on products and services<br />

n Membership<br />

The SWWA office can help you with information on any of the above and you can contact<br />

Calle Mondays to Thursdays from 8am till 4pm. The office is closed on all statutory<br />

holidays.<br />

Important things to know:<br />

February 4 marks the date that conference registration for 2019 will be available online.<br />

All credit card payments must be done online. A lot of time has been spent perfecting<br />

the small bugs that come from making the website as user friendly as possible and we<br />

appreciate the patience as we have worked through flaws in the system and are now<br />

confident that we have seen the last of the bugs. Online payment is 100% secure on the<br />

website. If you are unsure what your login information is please contact the SWWA office.<br />

Conference Registrations being paid for by cheque must be done by printing the form<br />

out and filling it out and sending along with the payment to the address on the form. The<br />

SWWA is not responsible for payments not received or sent to a wrong address.<br />

The SWWA office does not invoice, payment for events is due at the time of purchase.<br />

Membership for the SWWA is in the name of the individual not the employer. If a person<br />

attends the annual conference the membership for the following year is included in the<br />

conference fee. Membership runs from January 1 to December 31 yearly.<br />

Supplier memberships are in the name of the company. You can register up to 6 persons<br />

with your company under the supplier membership. Supplier membership with SWWA<br />

are ONLY with SWWA, if you wish to be part of the WCW membership you will need to<br />

have an MSSA membership.<br />

When signing up for an event online, the system cannot have the same email used for<br />

more than one person, if there is not a separate email for a person or they do not have<br />

an email simply choose the option does not have email and a system generated fake<br />

email will be created to add the individual to the database.<br />

got questions?<br />

Simply go to the contact us portion of the website and enter your information and<br />

you will receive a response during the noted office hours. Our office number is also<br />

available if you prefer to call rather than email.

TRAINING OR TRAGEDY:<br />

The importance of<br />

Operator Training<br />

A WCW SPC Event<br />

SEMINAR<br />

Feb. 13, 2019<br />

Saskatoon at the<br />

Western<br />

Development<br />

Museum<br />

The Walkerton tragedy was one that changed the look of the industry.<br />

Operator Certification became a mandatory requirement due to the<br />

tragedy. This one day workshop wil cover the circumstances that lead to<br />

the tragedy, the result of the situation that is still being seen today In the<br />

community, through the health and wellness of those affected by the<br />

contaminated water. Health problems were seen almost immediately by<br />

those who were elderly and had low immune systems and others felt the<br />

affects but were not sure why they were getting sick.<br />

DESCRIPTION<br />

• Overview of case studies related to disease breakouts &<br />

Chemical Contamination from authentic events<br />

• How training is an operators best insurance<br />

• A profile on how the multi year decline of a municipal water<br />

system could have been prevented<br />

• Explore how cultural complacency and decades of false<br />

assumptions lead to a blueprint for disaster<br />

• Health problems & affects to the general population and how<br />

to deal with a health situation of this proportion and be<br />

prepared to handle such a crisis if it should occur<br />

And much more….<br />

TOPICS<br />

INCLUDE<br />

WHO SHOULD ATTEND?<br />

• Administrators<br />

• Operations Staff<br />

• Supervisors<br />

• Consulting Engineers<br />

• Regulators<br />

• Municipal Utility<br />

Providers<br />

Time<br />

Event<br />

8:30 – 9:00 Registration<br />

9:00 – 12:00 Bruce Davidson<br />

10:00 – 10:15 Coffee<br />

12:00 – 1:00 Lunch<br />

1:00 – 3:00 Dr. Steve Hrudey<br />

3:00 – 3:15 Coffee<br />

3:15 – 4:30 Dr. Steve Hrudey<br />

4:30 – 5:00 Final Remarks & Questions<br />

SCHEDULE<br />

OF EVENTS<br />

register online at<br />

www.swwa.ca

BRINGING IT ALL<br />

TOGETHER<br />

Looking for a<br />

SWWA<br />

Supplier?<br />

It goes<br />

where<br />

you go!<br />

The Supplier Directory is<br />

NOW AVAILABLE ON-LINE<br />

and under the Pipeline App<br />

so it goes where you go!<br />

Pumps, controls and people - for every application<br />

Innovative technologies mean we can offer you the<br />

highest total efficiency in wastewater pumping<br />

solutions. Whatever your unique pumping or<br />

treatment challenges may be, Grundfos can<br />

help you succeed.<br />

www.grundfos.ca<br />

SWWA MISSION: The objective of the<br />

Association is to provide an opportunity for education,<br />

training and skill enhancement to the staff involved in<br />

the day to day operation and maintenance of water and<br />

wastewater systems.<br />

The SWWA fulfills this mission by offering CEU<br />

courses for all workshops, and by continuing to offer<br />

1.2 CEU’s for those who meet requirements at the<br />

SWWA Annual Conference. The SWWA is a advocate of<br />

networking and offers networking events at the annual<br />

conference and through the Annual golf tournament.<br />

E. office@swwa.ca | P. 306.668.1278 | www.swwa.ca

Thank you. . .<br />

for your continued support of the<br />

Saskatchewan Water and<br />

Wastewater Association!<br />

~~~ GOLD SPONSORS ~~~<br />

~~~ SILVER SPONSORS ~~~<br />

~~ CONFERENCE SPONSORS ~~

Winnovators<br />

We solve<br />

problems at<br />

work every<br />

day. But<br />

what if our<br />

problemsolving<br />

could<br />

change lives?<br />

WaterAid/ Ben Roberts<br />

Solve<br />

Fund<br />

WaterAid/ Fermín López<br />

WaterAid/ Yiannis Katsaris<br />

Learn<br />

WaterAid’s employee<br />

development programme<br />

solves real issues, funds<br />

life-changing work and<br />

teaches new skills.<br />

See what it takes<br />

to be a Winnovator !<br />

www.wateraid.org/uk/waterinnovators<br />

or contact Nefertiti Saleh at<br />

nsaleh@wateraidcanada.com for more<br />

information.