medicine&technology 01.2019

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

■ [ TECHNOLOGY ]<br />

Polymer Plain Bearings in<br />

Knee, Lighter and Quieter<br />

Plain bearings in the prosthesis | Plain bearings made of high-performance polymers<br />

are self-lubricating and are lighter and quieter than bronze bearings. Thus, after extensive<br />

testing, manufacturer of prosthetic knee joints, Otto Bock, decided to go with<br />

the plastic solution.<br />

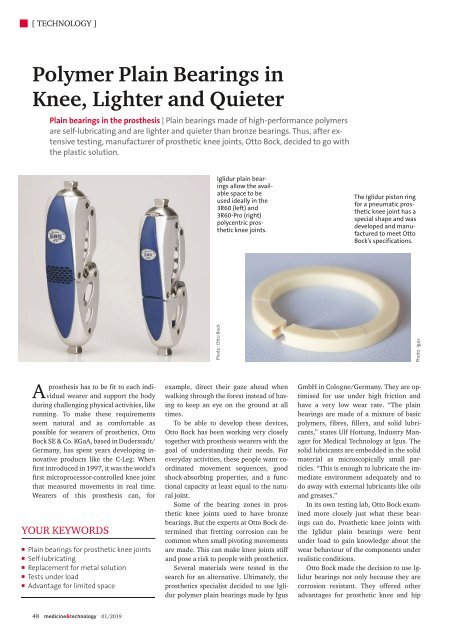

Iglidur plain bearings<br />

allow the available<br />

space to be<br />

used ideally in the<br />

3R60 (left) and<br />

3R60-Pro (right)<br />

polycentric prosthetic<br />

knee joints.<br />

The Iglidur piston ring<br />

for a pneumatic prosthetic<br />

knee joint has a<br />

special shape and was<br />

developed and manufactured<br />

to meet Otto<br />

Bock’s specifications.<br />

Photo: Otto Bock<br />

Photo: Igus<br />

A<br />

prosthesis has to be fit to each individual<br />

wearer and support the body<br />

during challenging physical activities, like<br />

running. To make these requirements<br />

seem natural and as comfortable as<br />

possible for wearers of prosthetics, Otto<br />

Bock SE & Co. KGaA, based in Duderstadt/<br />

Germany, has spent years developing innovative<br />

products like the C-Leg: When<br />

first introduced in 1997, it was the world’s<br />

first microprocessor-controlled knee joint<br />

that measured movements in real time.<br />

Wearers of this prosthesis can, for<br />

YOUR KEYWORDS<br />

■<br />

■<br />

■<br />

■<br />

■<br />

Plain bearings for prosthetic knee joints<br />

Self-lubricating<br />

Replacement for metal solution<br />

Tests under load<br />

Advantage for limited space<br />

example, direct their gaze ahead when<br />

walking through the forest instead of having<br />

to keep an eye on the ground at all<br />

times.<br />

To be able to develop these devices,<br />

Otto Bock has been working very closely<br />

together with prosthesis wearers with the<br />

goal of understanding their needs. For<br />

everyday activities, these people want coordinated<br />

movement sequences, good<br />

shock-absorbing properties, and a functional<br />

capacity at least equal to the natural<br />

joint.<br />

Some of the bearing zones in prosthetic<br />

knee joints used to have bronze<br />

bearings. But the experts at Otto Bock determined<br />

that fretting corrosion can be<br />

common when small pivoting movements<br />

are made. This can make knee joints stiff<br />

and pose a risk to people with prosthetics.<br />

Several materials were tested in the<br />

search for an alternative. Ultimately, the<br />

prosthetics specialist decided to use Iglidur<br />

polymer plain bearings made by Igus<br />

GmbH in Cologne/Germany. They are optimised<br />

for use under high friction and<br />

have a very low wear rate. “The plain<br />

bearings are made of a mixture of basic<br />

polymers, fibres, fillers, and solid lubricants,”<br />

states Ulf Hottung, Industry Manager<br />

for Medical Technology at Igus. The<br />

solid lubricants are embedded in the solid<br />

material as microscopically small particles.<br />

“This is enough to lubricate the immediate<br />

environment adequately and to<br />

do away with external lubricants like oils<br />

and greases.”<br />

In its own testing lab, Otto Bock examined<br />

more closely just what these bearings<br />

can do. Prosthetic knee joints with<br />

the Iglidur plain bearings were bent<br />

under load to gain knowledge about the<br />

wear behaviour of the components under<br />

realistic conditions.<br />

Otto Bock made the decision to use Iglidur<br />

bearings not only because they are<br />

corrosion resistant. They offered other<br />

advantages for prosthetic knee and hip<br />

48 medicine&<strong>technology</strong> 01/2019