Parts Alliance Garage Essentials Winter 2020

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Excellence in Automotive<br />

Component Distribution<br />

540x420<br />

Bradbury<br />

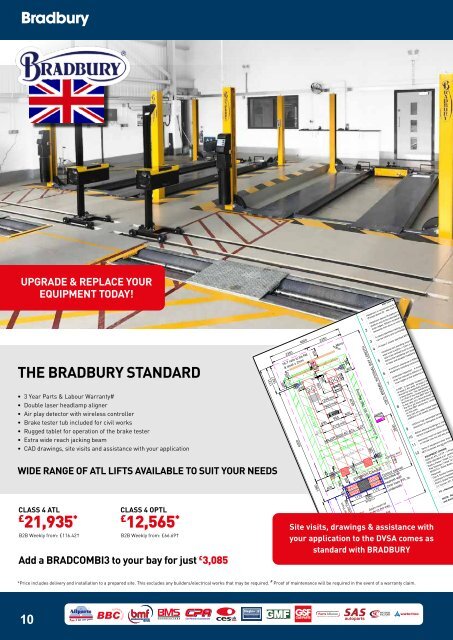

UPGRADE & REPLACE YOUR<br />

EQUIPMENT TODAY!<br />

THE BRADBURY STANDARD<br />

• 3 Year <strong>Parts</strong> & Labour Warranty#<br />

• Double laser headlamp aligner<br />

• Air play detector with wireless controller<br />

• Brake tester tub included for civil works<br />

• Rugged tablet for operation of the brake tester<br />

• Extra wide reach jacking beam<br />

• CAD drawings, site visits and assistance with your application<br />

WIDE RANGE OF ATL LIFTS AVAILABLE TO SUIT YOUR NEEDS<br />

CLASS 4 ATL<br />

£<br />

21,935 *<br />

B2B Weekly from: £116.42†<br />

*Price includes delivery and installation to a prepared site. This excludes any builders/electrical works that may be required. # Proof of maintenance will be required in the event of a warranty claim.<br />

10<br />

CLASS 4 OPTL<br />

£<br />

12,565 *<br />

B2B Weekly from: £66.69†<br />

Add a BRADCOMBI3 to your bay for just £ 3,085<br />

Dingbro Ltd<br />

1731<br />

1627 1627<br />

1731<br />

1627<br />

485 485<br />

485<br />

4600<br />

600<br />

2350<br />

HLT rails to be flat<br />

& level ± 2mm<br />

500<br />

cntrs<br />

2350<br />

500<br />

4600<br />

HLT rails to be flat<br />

& level ± 2mm<br />

500<br />

cntrs<br />

500<br />

6000 6000<br />

410<br />

13611<br />

410<br />

6000<br />

350<br />

600 600<br />

6480 6480 Pit Pit length length<br />

2250<br />

350 350<br />

1130<br />

550<br />

6480 Pit length<br />

1380<br />

1130<br />

13611<br />

2250<br />

550<br />

500<br />

1240 min<br />

500<br />

Mirror<br />

1920 max<br />

630<br />

1380<br />

400<br />

1240 min<br />

140<br />

400<br />

1920 max<br />

630<br />

1860<br />

915<br />

915<br />

1<br />

Mirror<br />

600<br />

2175 min<br />

2175 min<br />

10970 MINIMAL INTERNAL BAY LENGTH<br />

630<br />

In accordance with BS 7980 Marking<br />

500<br />

MAJOR 5230-60 ATL - 5.2T<br />

1761 1761<br />

600<br />

1860<br />

2<br />

600<br />

4870<br />

3522 recess<br />

HEADROOM AREA<br />

780<br />

600<br />

720<br />

GEM 01 ATL 5230-60 Class 4<br />

<br />

<br />

<br />

Headroom in entrance/exit & bay to be 2400mm min<br />

(Except above lift - see note 2) doorway width 2400mm min<br />

3<br />

3522 recess<br />

Headroom above lift platform to be 3800mm from surface of lift<br />

platform and to be extended 500mm either side of lift platform<br />

outer edges, 500mm forward of lift platforms and 1000mm<br />

rearwards from drive on end of lift platforms<br />

4<br />

630<br />

500<br />

HEADROOM AREA<br />

380<br />

1500 Min From<br />

inside Door Face<br />

4500<br />

3350<br />

2641 Can be Outside<br />

A clearly identified viewing area to be allocated where the test<br />

can be clearly and comfortably observed.<br />

At least 2 clearly identified MOT parking bays to be provided, 2500mm x 4500mm<br />

5<br />

In accordance with BS 7980 Marking<br />

MAJOR 5230-60 ATL - 5.2T<br />

1761<br />

1761<br />

600<br />

780<br />

4500 4500<br />

720<br />

2641 2641 Can Can be be Outside Outside<br />

140<br />

600<br />

1500 Min From<br />

3350<br />

4870<br />

380<br />

inside Door Face<br />

10970 10970 MINIMAL MINIMAL INTERNAL INTERNAL BAY BAY LENGTH LENGTH<br />

198 198<br />

6<br />

198<br />

Headlamp test standing area to be 3600mm long by 2100mm<br />

wide level to within +/-6mm in any 3000mm. Headlamp tester<br />

rails to be certified level to within +/-2mm and 600mm clearance<br />

behind the headlamp aim tester optical head.<br />

A clear and durable headlamp datum line to be marked<br />

7<br />

540x420<br />

Console<br />

Ø100mm Conduit<br />

Ø100mm Conduit<br />

1150<br />

1<br />

1170 1170<br />

2340<br />

<br />

<br />

2<br />

BPSATL4<br />

Console<br />

BPSATL4<br />

3500<br />

CONTROL BOX<br />

1000<br />

1170 1170<br />

2340<br />

<br />

1150<br />

A minimum clearance of 600mm between any part of the lift<br />

equipment including control box's & an adjacent wall or other equipment.<br />

1000 1000<br />

<br />

<br />

GEM 01 ATL 5230-60 Class 4<br />

<br />

<br />

<br />

Headroom in entrance/exit & bay to be 2400mm min<br />

(Except above lift - see note 2) doorway width 2400mm min<br />

3<br />

Headroom above lift platform to be 3800mm from surface of lift<br />

platform and to be extended 500mm either side of lift platform<br />

outer edges, 500mm forward of lift platforms and 1000mm<br />

rearwards from drive on end of lift platforms<br />

4<br />

A clearly identified viewing area to be allocated where the test<br />

can be clearly and comfortably observed.<br />

At least 2 clearly identified MOT parking bays to be provided, 2500mm x 4500m<br />

5<br />

Underside Inspection - A minimum of at least 760mm,<br />

(may be reduced to 600mm if testing narrow track vehicles) between the<br />

inner edges of the platforms and at least 1.9m between the outer edges.<br />

A RBT is centrally located in an unobstructed working area at least 9.0m long<br />

8<br />

CONTROL BOX<br />

Control cabinet<br />

<br />

<br />

<br />

3500<br />

RBT area to be flat<br />

and level ± 12mm<br />

2400<br />

1200 1200<br />

Headlamp test standing area to be 3600mm long by 2100mm<br />

wide level to within +/-6mm in any 3000mm. Headlamp tester<br />

rails to be certified level to within +/-2mm and 600mm clearance<br />

6<br />

behind the headlamp aim tester optical head.<br />

A clear and durable headlamp datum line to be marked<br />

7<br />

A minimum clearance of 600mm between any part of the lift<br />

equipment including control box's & an adjacent wall or other equ<br />

9<br />

mounted on<br />

nearest wall<br />

Control cabinet<br />

mounted on<br />

nearest wall<br />

2mtr from FFL to<br />

underside<br />

2mtr from FFL to<br />

underside<br />

RBT area to be flat<br />

and level ± 12mm<br />

2400<br />

1200 1200<br />

Remaining RBT<br />

area must not<br />

exceed 10% slope<br />

(100mm in 1m)<br />

Underside Inspection - A minimum of at least 760mm,<br />

(may be reduced to 600mm if testing narrow track vehicles) betw<br />

inner edges of the platforms and at least 1.9m between the o<br />

8<br />

at least 2.4m wide. At least 3.35m to the front and rear of the RBT centre lin<br />

should be substantially level (which in good building practice is within +/- 1<br />

a level plane). The remainder of the area must not exceed a 10% slope (<br />

1m) Part of the brake testing standing area can be outside the building<br />

the first part of the RBT floor plate is at least 1.5m inside the building<br />

In the case of a 'drive-through' layout where the roller brake tester i<br />

the lift or pit there shall be a clear distance of at least 3.35m betw<br />

and the RBT centre line. Lead-off ramps from floor mounted lifts<br />

on this area<br />

Any part of a roller brake tester is at least 600mm from an in<br />

platform or lift recess (except cross pit rollers)<br />

A RBT is centrally located in an unobstructed working area<br />

10<br />

Remaining RBT<br />

area must not<br />

at least 2.4m wide. At least 3.35m to the front and rear of t<br />

should be substantially level (which in good building prac<br />

a level plane). The remainder of the area must not exce<br />

1m) Part of the brake testing standing area can be outs<br />

the first part of the RBT floor plate is at least 1.5m ins<br />

In the case of a 'drive-through' layout where the rolle<br />

the lift or pit there shall be a clear distance of at lea<br />

and the RBT centre line. Lead-off ramps from floor<br />

on this area<br />

Any part of a roller brake tester is at least 600m<br />

platform or lift recess (except cross pit rollers)<br />

9<br />

10<br />

exceed 10% slope<br />

(100mm in 1m)<br />

1000mm high removable barrier rails may be required<br />

distraction or disruption to test is likely by non MOT<br />

11<br />

Before altering buildings or installing equipment<br />

Vehicle Inspectorate Office to ensure proposa<br />

1000mm high removable barrier rails may be<br />

distraction or disruption to test is likely by<br />

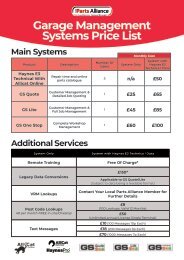

Site visits, drawings & assistance with<br />

your application to the DVSA comes as<br />

standard with BRADBURY<br />

11<br />

12<br />

Doorways must not open directly onto publ<br />

or intrude onto the test bay area<br />

Before altering buildings or installing equ<br />

Vehicle Inspectorate Office to ensure p<br />

12<br />

Items of equipment other than the bra<br />

MOT purposes are not permitted to<br />

Doorways must not open directly onto<br />

or intrude onto the test bay area<br />

Items of equipment other than the<br />

MOT purposes are not permitted<br />

NOTES:<br />

A It is the clients responsibility to obtain Vosa approval by completion of form VT1.<br />

<br />

5230-60 ATL Lift FF - 3 Phase<br />

GEM JB2.8M/A 2.6T Jacking<br />

Radius Plates ( Fitted To L<br />

Play Detector ( Fitted To<br />

BPSATL4 Roller Brak<br />

Required)<br />

Gas & Smoke Ana<br />

Litecheck 6 Hea<br />

PDATL Brake<br />

2 x Convex<br />

<br />

153/165 Bridge Street, Northampto<br />

<br />

<br />

Before altering buildings, purchasing and installation of any test equipment, you shou<br />

Local Vosa Office to ensure that your proposals are acceptable - Possession of pre<br />

which appear to be suitable does not mean that authorisation will be granted. B<br />

Architects responsibility to ensure all details are correct, and all dimensions to b<br />

before commencement of any work. C To be used in conjunction with individ<br />

D Where relevant, all dimensions are to finished floor level.<br />

<br />

5230-60 ATL Lift FF -- 3 Phas<br />

GEM JB2.8M/A 2.6T Jackin<br />

Radius Plates (( Fitted To L<br />

Play Detector (( Fitted To L<br />

BPSATL4 Roller Brake<br />

Required)<br />

Gas & Smoke Analys<br />

Litecheck 6 Headlam<br />

PDATL Brake Peda<br />

2 x Convex ATL M<br />

<br />

153/165 Bridge Street, Northampton NN1 1QG<br />

<br />

<br />

NOTES:<br />

A It is the clients responsibility to obtain Vosa approval by completion of form VT1.<br />

Before altering buildings, purchasing and installation of any test equipment, you should consult the<br />

Local Vosa Office to ensure that your proposals are acceptable - Possession of premises & equipment<br />

which appear to be suitable does not mean that authorisation will be granted. B It is the Clients/<br />

Architects responsibility to ensure all details are correct, and all dimensions to be checked on site<br />

before commencement of any work. C To be used in conjunction with individual site layout drawing.<br />

D Where relevant, all dimensions are to finished floor level.<br />

Desc