Download PDF (1.5 MB) - Becker Marine Systems

Download PDF (1.5 MB) - Becker Marine Systems

Download PDF (1.5 MB) - Becker Marine Systems

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

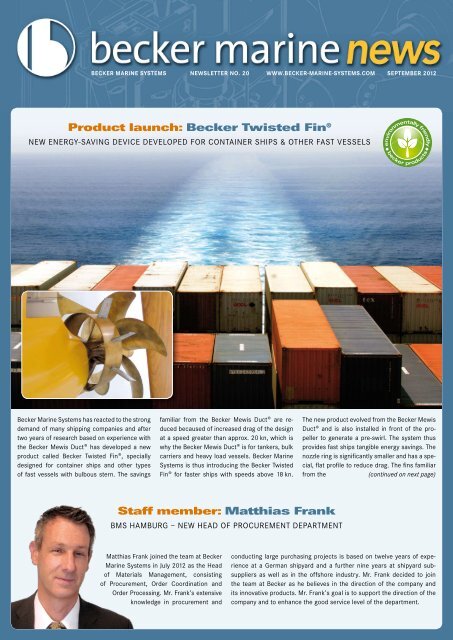

Product launch: <strong>Becker</strong> Twisted Fin ®<br />

new energy-saving device developed for container ships & other fast vessels<br />

<strong>Becker</strong> <strong>Marine</strong> systems has reacted to the strong<br />

demand of many shipping companies and after<br />

two years of research based on experience with<br />

the <strong>Becker</strong> Mewis duct® has developed a new<br />

product called <strong>Becker</strong> twisted fin®, specially<br />

designed for container ships and other types<br />

of fast vessels with bulbous stern. the savings<br />

<strong>Becker</strong> <strong>Marine</strong> SySteMS newSletter no. 20 www.<strong>Becker</strong>-<strong>Marine</strong>-SySteMS.coM Septe<strong>MB</strong>er 2012<br />

familiar from the <strong>Becker</strong> Mewis duct® are reduced<br />

becaused of increased drag of the design<br />

at a speed greater than approx. 20 kn, which is<br />

why the <strong>Becker</strong> Mewis duct® is for tankers, bulk<br />

carriers and heavy load vessels. <strong>Becker</strong> <strong>Marine</strong><br />

systems is thus introducing the <strong>Becker</strong> twisted<br />

fin® for faster ships with speeds above 18 kn.<br />

Staff member: Matthias Frank<br />

BMs ha<strong>MB</strong>urg – new head of procureMent departMent<br />

Matthias frank joined the team at <strong>Becker</strong><br />

<strong>Marine</strong> systems in July 2012 as the head<br />

of Materials Management, consisting<br />

of procurement, order coordination and<br />

order processing. Mr. frank’s exten sive<br />

knowledge in procurement and<br />

the new product evolved from the <strong>Becker</strong> Mewis<br />

duct® and is also installed in front of the propeller<br />

to generate a pre-swirl. the system thus<br />

provides fast ships tangible energy savings. the<br />

nozzle ring is significantly smaller and has a special,<br />

flat profile to reduce drag. the fins famil iar<br />

from the (continued on next page)<br />

conducting large purchasing projects is based on twelve years of experience<br />

at a german shipyard and a further nine years at shipyard subsuppliers<br />

as well as in the offshore industry. Mr. frank decided to join<br />

the team at <strong>Becker</strong> as he believes in the direction of the company and<br />

its innovative products. Mr. frank’s goal is to support the direction of the<br />

company and to enhance the good service level of the department.

Product launch: <strong>Becker</strong> Twisted Fin ®<br />

new energy-saving device developed for container ships & other fast vessels<br />

<strong>Becker</strong> Mewis duct® on the inside of the nozzle<br />

ring extend outwards beyond the nozzle. to prevent<br />

the formation of a swirl with cavitation at the<br />

ends of the fins <strong>Becker</strong> has developed special end<br />

caps for the fins similar to the winglets familiar<br />

from modern aircraft wings and helicopter blades.<br />

the small nozzle ring generates thrust, provides<br />

stability to the fins and reduces vibrations.<br />

computational fluid dynamics (cfd) tests show<br />

an average of 3% energy savings for container<br />

ships. Model tests being carried out in March<br />

this year confirmed these cfd results.<br />

LNG Hybrid: <strong>Becker</strong> initiates emission-free ferry<br />

at <strong>Becker</strong> <strong>Marine</strong> systems the environment means<br />

more than just manoeuvring and propulsion. the<br />

company is meeting its responsibilities towards<br />

reducing shipping emissions worldwide. the idea<br />

to develop an emission-free ferry with very low<br />

draught for shallow european coastal waters<br />

came about after taking a closer look at the<br />

precious and fragile wadden sea national park<br />

near hamburg. the working title of this draft was<br />

“wadden sea ferry“ and is now being finalised by<br />

the name project “fering”.<br />

the newly developed project “fering“ ferry was<br />

designed by ingenieurbüro für schiffstechnik<br />

ingo schlüter gmbh & co. Kg and is exclusively<br />

powered by environmentally-friendly liquefied<br />

natural gas (lng) with no particle emissions.<br />

the additional purchase of emission certificates<br />

makes it possible to offer a completely carbon<br />

neutral, “green” ferry service. pollution of the<br />

sensitive coastal waters with sulfur oxides and<br />

exhaust gas particles will be reduced to zero.<br />

co 2 emissions are reduced by 40% and the out-<br />

put of nitrogen oxides even by as much as 90%.<br />

each passenger will not only benefit from a flexible<br />

booking system with guaranteed transport<br />

for regular customers, but will also be making<br />

a contribution to environmental protection by<br />

purchasing a ticket.<br />

project “fering” is far beyond the first planning<br />

phase. in cooperation with shipping company<br />

schramm group, energy partners eon hanse<br />

wärme and gasnor, classification society Bureau<br />

veritas and the ship designers at ingo schlüter<br />

<strong>Marine</strong> consultants and sdc ship & design consult<br />

a new ferry design is being created that will<br />

already be going into service on the dagebüllföhr-amrum<br />

route in summer 2014. the new<br />

ferry meets the latest environmental protection<br />

standards and at a length of 70 m, a width of14 m<br />

and very low draught will provide space for 250<br />

passengers and 50 cars.<br />

a model of the new “fering” ferry will be on<br />

display at this year’s sMM. the operation of<br />

the best energy-saving results are obtained with<br />

the combination of a <strong>Becker</strong> twisted fin® and<br />

the <strong>Becker</strong> tlKsr® twisted rudder.<br />

Benefits of the new <strong>Becker</strong> twisted Fin®:<br />

• Fuel savings of up to 3%<br />

• reduction of no x and co 2 emissions<br />

• Suitable for newbuildings and retrofits<br />

• no moving parts,<br />

no maintenance required<br />

• Fast installation<br />

• Structural guarantee of many years<br />

two ferries of this design is being planned for<br />

the line to föhr and amrum. Both ships will be<br />

built at european shipyards and equipped with<br />

the latest lng hyBrid technology to ensure<br />

that opera tion in the fragile environment of the<br />

wadden sea will be as low as possible in emis-<br />

sions – without passengers having to accept ticket<br />

prices higher than those of the competition.<br />

in addition to project “fering”, <strong>Becker</strong>’s lng hyBrid<br />

department (www.lng-hybrid.com) is working on<br />

other applications of this environmentally-friendly<br />

propulsion technology. thus, in cooperation with<br />

aida the idea recently arose of employing an lng<br />

hyBrid-powered barge for supplying electricity<br />

to cruise ships during port sojourns.<br />

electricity supplied via the lng hyBrid Barge<br />

from the water will avoid pollution of the port arising<br />

from shipboard, diesel-powered power units.<br />

local residents of the port can also look forward<br />

to air free from soot particles, which has been a<br />

big problem in the hamburg’s new hafencity.

Order highlights: <strong>Becker</strong> <strong>Marine</strong> <strong>Systems</strong> products<br />

stX offshore & shipBuilding<br />

<strong>Becker</strong> <strong>Marine</strong> systems has been selected by<br />

stX offshore & shipbuilding to design and<br />

supply the largest full spade rudders ever built<br />

for Zodiac’s container vessels. each of the<br />

rudders will have an area of 93m 2 . the rudder<br />

type will be <strong>Becker</strong> <strong>Marine</strong> systems’ well proven<br />

tlKsr® (twisted leading edge King support<br />

rudder) for the 400.0 m long and 54.0 m<br />

wide 16,000 teu container vessels. this very<br />

remarkable order for six of the largest container<br />

ships continues the long, very professional<br />

and reliable business relationship between<br />

stX offshore & shipbuilding and <strong>Becker</strong> <strong>Marine</strong><br />

systems. stX and <strong>Becker</strong> have already cooperated<br />

successfully in previous large container<br />

ship projects. the rudders will be produced in<br />

europe and asia at <strong>Becker</strong> <strong>Marine</strong> systems’<br />

subcontracting fabricators.<br />

together with the above order for the tlKsr®<br />

rudders, stX placed another order with <strong>Becker</strong><br />

<strong>Marine</strong> systems for the delivery of six <strong>Becker</strong><br />

Mewis duct® with an option of three more for<br />

stX Mr product tankers for various ship owners.<br />

in total, <strong>Becker</strong> <strong>Marine</strong> systems has received<br />

orders for 16 <strong>Becker</strong> Mewis duct® for<br />

the same type and ship size from stX. the<br />

<strong>Becker</strong> Mewis duct® are designed to gain up<br />

to 6% propulsion efficiency in loaded condition<br />

for stX Mr product tankers.<br />

china navigation gerMan governMent<br />

<strong>Becker</strong> <strong>Marine</strong> systems has been awarded the<br />

order from china navigation in singapore for<br />

the delivery of eight <strong>Becker</strong> Mewis duct®.<br />

china navigation has signed Zhejiang ouhua<br />

shipyard to build a series of 31,000 dwt Multi<br />

purpose vessels, with the design originating<br />

from neptun ship design. the vessels will carry<br />

2,082 teu, but are also designed to carry general<br />

cargo and various other cargoes. despite<br />

the already optimised hull lines the tailor-made<br />

<strong>Becker</strong> Mews duct® added another 4% of energy<br />

saving during the model tank test at hsva. the<br />

first <strong>Becker</strong> Mewis duct® of this order will be delivered<br />

at the end of 2012.<br />

<strong>Becker</strong> <strong>Marine</strong> systems signed a contract for<br />

the delivery of eight twisted full spade rudders<br />

(tlKsr®) with dalian shipbuilding group and<br />

hudong Zhonghua shipbuilding. the high-efficiency<br />

rudders of 75 m 2 will equip 10,000 teu container<br />

vessels for china shipping container lines<br />

(cscl). Broad experience with high-efficiency full<br />

spade rudders and the convincing results of tank<br />

and cavitation testing were the main reasons for<br />

cscl choosing the rudders from <strong>Becker</strong> <strong>Marine</strong><br />

systems for their container vessels of 335.0 m<br />

length and a service speed of around 24 kn. all<br />

vessels will be delivered in 2013.<br />

the german government has ordered a new<br />

deep-sea research vessel as a replacement for<br />

the existing Sonne vessel. the order was given<br />

to Meyer neptun group. <strong>Becker</strong> <strong>Marine</strong> systems<br />

has offered the shipyard the delivery of a special<br />

heracles flap rudder. the <strong>Becker</strong> spade highlift<br />

performance flap rudder gives the vessel<br />

the necessary manoeuvrability for its working<br />

profile in high speed and low speed conditions.<br />

the two <strong>Becker</strong> rudders have a rudder area of<br />

7.26 m 2 per rudder with a max. rudder angle of<br />

2 x 45°. according to the shipyard the german<br />

government will take delivery of the research<br />

vessel in 2014.<br />

dalian & hudong Zhonghua coBelfret<br />

cobelfret ordered two <strong>Becker</strong> Mewis duct® for<br />

their bulker newbuildings at yangfang ship yard in<br />

china. the energy-saving <strong>Becker</strong> Mewis duct® is<br />

an essential part of the environmentally-friendly<br />

35,000/37,000 dwt “seahorse 35/37” handysize<br />

bulk carrier concept. the design fulfills the<br />

2025 energy efficiency index, eedi. the vessel<br />

type has an overall length of 180.0 m, a breadth<br />

of 30.0 m and a service speed of approx. 14 kn.<br />

of the existing orders of the “sea horse 35/37”<br />

design, 16 vessels will be equipped with the<br />

<strong>Becker</strong> Mewis duct®.

tp://farm5.static.flickr.com/4152/4839805687_bb08cd7727.jpg<br />

Historic picture: <strong>Becker</strong> SMM presentation in 1976<br />

Under construction: New Hamburg headquarters building<br />

with the purchase of property situated between Blohmstraße<br />

and Ziegelwiesenkanal at the inland port of hamburg-harburg<br />

<strong>Becker</strong> <strong>Marine</strong> systems has finally found the ideal location for<br />

the construction of its new company headquarters. construction<br />

of the new hamburg headquarters has already commenced and<br />

relocation from the neuländer Kamp offices to Blohmstraße is<br />

planned for mid-2013.<br />

due to the continuous growth of the company additional space<br />

is urgently needed for the steadily rising number of employees.<br />

although the current head office was built in 2003, it no longer<br />

meets space requirements. the new company building will have<br />

room for over 150 employees and, with direct access to the water,<br />

will provide the ideal setting for our team.<br />

for the 25 th time the sMM is taking place in<br />

hamburg this year and <strong>Becker</strong> <strong>Marine</strong> systems<br />

is proud of having been an exhibitor for many<br />

decades at what is now the world’s largest<br />

shipbuilding fair. our historic picture shows<br />

the 1976 <strong>Becker</strong> stand along with company<br />

founder willi <strong>Becker</strong>.<br />

as a company attached to its home it gives<br />

<strong>Becker</strong> <strong>Marine</strong> system great pleasure to take<br />

the opportunity that sMM provides to present<br />

itself to indus try professionals from around<br />

the world in its home town of hamburg. and<br />

thus <strong>Becker</strong> <strong>Marine</strong> systems will also be represented<br />

at the anniversary sMM this year.<br />

visitors can experience presentations on the<br />

company’s wide product range such as the<br />

twisted rudder tlKsr® and twisted flap rudder<br />

tlfKsr, the schilling® Ksr rudder, BiMs <strong>Becker</strong><br />

intelligent Monitoring system and the <strong>Becker</strong><br />

Mewis duct®. recently, <strong>Becker</strong> has received<br />

an order for the largest full spade rudder ever<br />

built measuring more than 90 m 2 . new products<br />

developed by <strong>Becker</strong>’s r&d department will<br />

also be introduced. one full-scale energy-saving<br />

innova tion will be presented at the outside area<br />

between hall a1 and hall a2. we are looking forward<br />

to meeting you in hall a1, stand 328 or at<br />

our press conference on thursday, 6 th september<br />

at 11am in the Shanghai room, hall a4.<br />

Retirement, and yet: Tradition will stay on board<br />

Mrs. renate schmidt is second from the left, Mrs. Marin farian second from right.<br />

in 2012 two valued employees are retiring.<br />

Mrs. Marin fabian, who started her work at<br />

<strong>Becker</strong> on 1 st april 1975 in the accounting<br />

department and Mrs. renate schmidt, who<br />

started her work on 16 th May 1983 in the<br />

projects department, are going into welldeserved<br />

retirement.<br />

in total they have been with the company<br />

for 66 years. Both worked under willi <strong>Becker</strong>,<br />

have continued with dirk lehmann and<br />

were respected and much valued by all<br />

colleagues. Mrs. fabian and Mrs. schmidt<br />

have decided to continue working parttime.<br />

we would like to thank both of them<br />

for their good work and loyalty to <strong>Becker</strong><br />

<strong>Marine</strong> systems.<br />

editor:<br />

<strong>Becker</strong> <strong>Marine</strong> systems gmbh & co. Kg<br />

neuländer Kamp 3, 21079 hamburg, germany<br />

tel. +49-40-2 41 99-0, fax +49-40-2 80 18-99<br />

www.becker-marine-systems.com<br />

info@becker-marine-systems.com<br />

Designed and published by:<br />

www.envise.de<br />

schilling® rudders are available in Japan only under the designation<br />

<strong>Becker</strong> sharc fishtail rudder.<br />

eXHiBitionS 2012/2013<br />

workboat show, Morial convention center,<br />

new orleans, usa, stand 521, <strong>Marine</strong> &<br />

offshore supply and <strong>Becker</strong> <strong>Marine</strong><br />

systems, 5 th -7 th december 2012<br />

nor-shipping, shipping trade fair,<br />

oslo, norway, german pavilion,<br />

4 th -7 th June 2013