Helicopter Industry #103

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

EUROPE - MIDDLE EAST - AMERICAS - AFRICA - ASIA - RUSSIA<br />

<strong>#103</strong>

BIGGER. BETTER. BOLDER.<br />

FULL SERVICE<br />

Your source for comprehensive, tip-to-tail aftermarket support<br />

WE DELIVER on what you value most. For over a century, the helicopter<br />

industry has relied on StandardAero to provide best-in-class rotary wing support with<br />

excellent operational efficiency and custom MRO solutions. Through our innovative, safety<br />

driven approach, comprehensive helicopter support capabilities and reliable service provided<br />

by our expert technicians, it’s no wonder why we are the trusted service partner.<br />

Engines<br />

• GE T700/CT7<br />

• Pratt & Whitney Canada PT6T<br />

• Rolls-Royce M250 and RR300<br />

• Safran Arriel 1 & 2<br />

Airframes<br />

• Airbus H125/AS350, H130/EC130, H135 and H225/AS332<br />

• Bell 204/205, 206, 212/412, 222, 230, 407, 427 and 430<br />

• Sikorsky S-76, S-92 and S-61<br />

Dynamic Components<br />

Fuel Systems<br />

Avionics<br />

STCs<br />

www.standardaero.com<br />

helicopters@standardaero.com<br />

+1.204.318.7544<br />

Safety Driven | Innovative | Full Service | Reliable

©A. Pecchi<br />

EUROPE - MIDDLE EAST - AMERICAS - AFRICA - ASIA - RUSSIA<br />

<strong>#103</strong><br />

30<br />

MANUFACTURER<br />

HX50: the new British<br />

industrial project<br />

By François BLANC<br />

02<br />

EDITORIAL<br />

BREAKING<br />

NEWS<br />

By Frédéric VERGNÈRES<br />

MILITARARY<br />

ALAT at the top<br />

By Frédéric LERT<br />

4<br />

38<br />

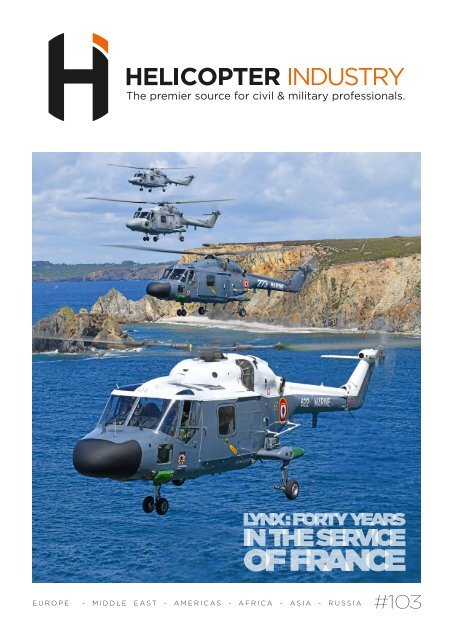

FAREWELL<br />

Lynx: forty years<br />

in the service of<br />

France<br />

By Frédéric Vergnères<br />

PARAPUBLIC<br />

The Dragon’s new approach<br />

By Frédéric VERGNÈRES<br />

16<br />

44<br />

LEGACY<br />

The X3, ten years after<br />

By Frédéric LERT<br />

OPERATOR<br />

Power and precision<br />

By Frédéric LERT<br />

22<br />

50<br />

HI I 1

HELICOPTER INDUSTRY I EDITORIAL I<br />

ARNAUD DEVRIENDT I DIRECTEUR DE LA PUBLICATION<br />

Even from the sky, the world seems to be crawling along: less planes in the airspace, reduced rail traffic and a less<br />

frequented road network. Government arrangements made here and there across the world impart a new rhythm<br />

to the populations. The world health crisis is not yet behind us.<br />

At that moment, the helicopter industry strives to maintain as normal as possible activity. Pending orders must be<br />

fulfilled, what certain provisions guarantee. Nowadays, the consequences of the word health crisis are not really<br />

felt. Based on long lifecycles, military and civil production as well as new aircrafts sells are not subjected to strong<br />

pressure, either promised some decline in the short term.<br />

As in any crisis, especially when it takes on such a scale, operators focus on their missions as soon as the<br />

contractors have maintained them. In the military and parapublic sector, operational maintenance, training<br />

exercises and generally speaking state aircrafts action run their course.<br />

In such a context, the industrial project of a British engineer and Hill <strong>Helicopter</strong>s founder makes us dream of an<br />

enchanting tomorrow. Jason Hill patiently bided his time before he unveiled his vision of the high-end private<br />

helicopter, shaped it and made it alive. Let’s be careful what he’s up to. Although he’s not the only one to work on<br />

the near future of the vertical flight, his approach during such a special period conceals very exciting perspectives.<br />

We invite you to discover our website<br />

Retrouvez l’ensemble de nos informations sur le site<br />

helicopter-industry.com<br />

HI I 2

HELICOPTER ENGINES<br />

RESPONSIVE AND<br />

MISSION-FOCUSED<br />

Responsiveness and focus, these key qualities are shared with our customers<br />

and reflected in their missions every day. With unparalleled helicopter engines<br />

and the steadfast commitment of our support teams, we are a market leader<br />

dedicated to your success.<br />

#ARRIUS #ARRIEL #ARRANO #MTR390 #ARDIDEN #MAKILA #RTM322 #ANETO<br />

safran-helicopter-engines.com<br />

@safran-engines

HELICOPTER INDUSTRY I BREAKING NEWS I<br />

©US Navy<br />

HI I 4

HI I 5

HELICOPTER INDUSTRY I BREAKING NEWS<br />

©Airbus helicopters<br />

PNG LNG ADDS H145 FOR PAPUA NEW GUINEA OPERATIONS<br />

ExxonMobil has signed a contract for two Airbus H145 helicopters to support the PNG LNG Project in Papua New Guinea (PNG).<br />

The new H145 model with a five-blade, bearingless main rotor provides a 150kg increase in useful load.<br />

The aircraft will be based at the Hides Gas Conditioning Plant (HGCP) in Hela Province of the PNG Highlands, and will be used to<br />

transport personnel and equipment in support of PNG LNG Project operations.<br />

In addition to its reliability and superior economics, the new H145’s «hot and high» performance was critical to its selection for use in an<br />

environment requiring routine operations at an altitude of 5,400ft in temperatures up to 35ºC.<br />

The sale is the first by Airbus <strong>Helicopter</strong>s to ExxonMobil and the first order in the oil and gas sector for the new H145 in the Asia Pacific<br />

region.<br />

Ben Bridge, Executive Vice President Global Business, for Airbus <strong>Helicopter</strong>s said «It’s an honour to win the confidence of a safety and<br />

performance focused customer like ExxonMobil for operations in PNG’s highly demanding operational environment. The new H145 has made<br />

a strong start in the market and it’s clear that it has a great future across multiple market segments.»<br />

MORE ABOUT AIRBUS HELICOPTERS<br />

HI I 6

©Russian <strong>Helicopter</strong>s<br />

RUSSIAN HELICOPTERS DELIVERS FIRST ANSAT TO A CLIENT IN EUROPE<br />

Russian <strong>Helicopter</strong>s has delivered a first Ansat helicopter to a client in Europe. The operator of the rotorcraft, which is equipped for<br />

medical operations, is the Ministry of Interior of the Republika Srpska (Bosnia and Herzegovina). This is the first of three helicopters<br />

under the delivery contract.<br />

Ansat for Republika Srpska comes with a medical module equipped with a stretcher and a medical shelf. The helicopter cabin has<br />

place for transporting one patient and two chairs for accompanying doctors. Equipment configuration includes a system for artificial<br />

lung ventilation, tele-ECG allowing to monitor cardiac activity in real time, and various other equipment for the evacuation of patients of<br />

varying severity. The delivery set includes five seats, which can be installed instead of the medical module and carry 7 passengers in the<br />

helicopter cabin. The helicopter also comes with active vibration control system.<br />

«This delivery testifies that Ansat is competitive on the European market, and we see potential for new orders. I am confident that European<br />

operators will appreciate the favorable cost of operating the helicopter, its versatility and reliability. Two more Ansats will be handed over to the<br />

law enforcement agencies of Republika Srpska in 2021 and 2022. They will be additionally equipped with searchlights, fast-rope deployment<br />

system, a winch and an external sling», said the Director General of Russian <strong>Helicopter</strong>s holding company Andrey Boginsky.<br />

The delivery contract of three helicopters to the Republic of Srpska also included the training of three technicians and two pilots of<br />

the customer in the Kazan <strong>Helicopter</strong>s Aviation Training Center. The program included training in the design and maintenance of the<br />

airframe, power plant and systems of Ansat helicopter for aircraft technicians, as well as theoretical training, classes on the new Ansat<br />

simulator and practical flight training for pilots. The cadets successfully passed the exams and received documents that confirm their<br />

qualifications. The Aviation Training Center will provide further multi-stage training of flight and technical personnel as more helicopters<br />

are delivered. During the next 2 years, 4 more pilots and 6 technicians will go through training.<br />

MORE ABOUT ANSAT<br />

HI I 7

HELICOPTER INDUSTRY I BREAKING NEWS<br />

©Helinetwork<br />

HELINETWORK INTERNATIONAL SIGNS AN AGREEMENT<br />

WITH THALES AVIONICS ELECTRICAL<br />

Helinetwork International specialist in the sale of new and overhauled parts for civil and military helicopters announces the signature<br />

of a distribution agreement with THALES AVIONICS ELECTRICAL SYSTEMS (AES).<br />

THALES AES, is a subsidiary of THALES Group specialized in the design, manufacture and support of electrical generation and conversion<br />

equipment for the aeronautics industry.<br />

The starter generators designed by Thales AES will bring maintenance gains thanks to increased reliability and performance.<br />

For Thales AES, the partnership with Helinetwork International will enable the company to extend its market coverage, particularly in<br />

the digital market.<br />

This agreement is an opportunity for Helinetwork International to increase its presence in the aerospace sector by adding a new major<br />

to its list of official manufacturers. Helinetwork International is also an authorized distributor of de SAFRAN, COLLINS AEROSPACE,<br />

LACE, TECH-TOOL PLASTICS, etc.<br />

Rotorplace, the world’s leading helicopter parts e-commerce website, enables operators, manufacturers and workshops to find a wide<br />

range of parts with just a few clicks. All the products on the site come directly from the manufacturers’ stocks with the same guarantees.<br />

MORE ABOUT HELINETWORK<br />

HI I 8

©Russian <strong>Helicopter</strong>s<br />

RUSSIAN HELICOPTERS DELIVERS FIRST BATCH OF HELICOPTER KNOCK-DOWN KITS<br />

TO KAZAKHSTAN<br />

The Ulan-Ude Aviation Plant of the Russian <strong>Helicopter</strong>s holding has delivered two Mi-8AMT helicopter knock-down kits to Kazakhstan to<br />

be assembled on the territory of the customer.<br />

The delivery is based on a trilateral contract signed by Kazakhstan Engineering, Kazakhstan’s Aircraft Repair Plant No. 405 and Russian<br />

<strong>Helicopter</strong>s for semi-knock-down (SKD) assembly of Mi-8AMT / Mi-171E helicopters. The contract, signed in 2019, provides for a total<br />

of 17 helicopter kits during 2020-2022.<br />

The main customers for the Mi-8AMT helicopters in Kazakhstan are the National Guard under the Ministry of Internal Affairs and<br />

the Committee for Emergency Situations. The first batch of Mi-8AMT kits will assembled for the needs of the Committee for Emergency<br />

Situations. «I’m confident that successful implementation of the semi-knock-down assembly project of Mi-8AMT / Mi-171 helicopters in<br />

Kazakhstan will become a significant step forward in the development of the country’s helicopter industry and will allow local enterprises to<br />

increase their scientific and technical potential», said Leonid Belykh, Managing Director of the Ulan-Ude Aviation Plant.<br />

Assembly and adaptation of the helicopters to the customer’s requirements will be carried out by the Aircraft Repair Plant No. 405 in the<br />

city of Almaty. The plant holds the greatest competencies in repairing and maintaining this helicopter type in the Central Asian region.<br />

The plant is certified by both Kazakhstan and international authorities for the repair, modernization and maintenance of Mi-8/17/171<br />

helicopters.The assembled helicopters will be tasked with transportation of passengers and goods, emergency rescue operations,<br />

forest protection, firefighting, ambulance services and law enforcement operations.<br />

The operational experience and extensive service network of the Aircraft Repair Plant No. 405 will provide integrated service support<br />

for customers in the field of deployment.<br />

Kazakhstan has been a long-term partner of the Russian <strong>Helicopter</strong>s and the country operates dozens of Mi-8AMT / Mi-171 helicopters.<br />

The republic became the first foreign operator of the latest Mi-171A2 helicopter.<br />

MORE ABOUT MI-8AMT<br />

HI I 9

HELICOPTER INDUSTRY I BREAKING NEWS<br />

©Bell<br />

THE NEXT STEPS FOR BELL’S ELECTRICALLY DISTRIBUTED ANTI-TORQUE<br />

Bell announced it’s continued pursuit for coveted vertical lift products, evident through our unveiling of Electrically Distributed Anti-<br />

Torque (EDAT), an unconventional tail rotor with innumerable opportunities. In a Vertical Flight Society online webinar on Nov. 16,<br />

Bell’s Program Director for Light Aircraft, Eric Sinusas, shared potential applications for this latest innovation. «I think it has potential<br />

to potentially replace them [traditional tail rotors],” Sinusas said. “There are benefits to the system that the conventional system just does not<br />

have innately.» This unprecedented technology was revealed in February 2020, sparking global interest from rotorcraft community and<br />

technology aficionados for its ingenuity. Since then, Bell continues to test the unique concept, which includes four electrical motors<br />

driving a fixed-pitch, rpm-controlled fan capable of operating speeds around 6,000 to 7,000 rpm. «I think we can say that we have<br />

successfully proven the concept… it works,” Sinusas says. “Now we’re into the phase of optimization and we’re fine-tuning the performance<br />

characteristics, pushing the envelope further.» After participating in the VFS forum, Aviation Week clarified how EDAT’s technology offers<br />

an enhanced experience in terms of extra flight operational support and cost. «The fans are driven by generators run off the tail rotor drive,<br />

with wires to the electrical motors replacing the complex tail rotor shaft and gearboxes running through the tail boom. This eliminates the cost<br />

of maintaining the tail rotor shaft.»<br />

MORE ABOUT EDAT<br />

HI I 10

©Airbus <strong>Helicopter</strong>s<br />

THE CHEETAH WILL REPLACE THE FENNECS<br />

The transition between two felines is being prepared. In service since the 1980s for the oldest and heavily solicited in operations,<br />

the Fennec of the French Air and Space Forces awaits its successor: the Light Joint <strong>Helicopter</strong> (HIL), christened Cheetah. A unique<br />

helicopter, it was chosen by the French Ministry of Armed Forces in March 2017 to meet the needs of all three armies. The single-fleet<br />

concept will make it possible to pool development and operational maintenance costs. In May 2019, French Armed Forces Minister<br />

Florence Parly announced her decision to accelerate the HIL program, led by the French Defense Procurement Agency, to enable delivery<br />

two years ahead of schedule.<br />

The HIL will be delivered to the French Air Force in 2030. This 6-ton aircraft will eventually succeed the fleet’s 40 Fennecs.<br />

MORE ABOUT H160<br />

HI I 11

HELICOPTER INDUSTRY I BREAKING NEWS<br />

©Sikorsky_Lockheed Martin<br />

U.S. NAVY AWARDS SIKORSKY CONTRACT TO BUILD<br />

SIX MORE CH-53K HEAVY LIFT HELICOPTERS<br />

Sikorsky will build six additional production CH-53K King Stallionhelicopters under a new contract for the U.S. Navy. The aircraft<br />

will further support the U.S. Marine Corps in its mission to conduct expeditionary heavy-lift assault transport of armored vehicles,<br />

equipment and personnel to support distributed operations deep inland from a sea-based center of operations.<br />

The six helicopters are part of the 200 aircraft Program of Record for the U.S. Marine Corps, and their addition makes a total of 24 CH-<br />

53K production aircraft now under contract. Under the terms of this most recent contract – known as Low Rate Initial Production (LRIP)<br />

Lot 4 – Sikorsky will begin deliveries of the six aircraft in January 2024.<br />

«This contract award is a testament to the government’s confidence in the CH-53K platform. This award shows that we are working hard to<br />

make the aircraft more affordable,» said Major General Greg Masiello, program executive office, air ASW, assault and special mission<br />

programs. «The capability and affordability of the CH-53K is important to ensure that we provide a valuable addition to the United States Marine<br />

Corps and our friends and allies.»<br />

The CH-53K program has five aircraft on the line at Sikorsky facilities in Connecticut and over two dozen in various stages of production.<br />

The program will deliver the first low rate initial production aircraft in September 2021.<br />

Sikorsky and its suppliers have made significant investments in facilities, machinery, tooling, and workforce training to ramp up<br />

production required for the CH-53K program. For example, for the first time, newly installed 10-ton cranes lifted a 12,000 lb. gearbox<br />

into a CH-53K production aircraft.<br />

HI I 12

«The production of this CH-53K helicopter represents a new era in capabilities, technologies, safety and mission flexibility for the U.S. Marine<br />

Corps. Sikorsky is committed to supporting the Marine Corps to maximize the benefits of this all new helicopter,» said Bill Falk, Sikorsky<br />

CH-53K program director. «Pilots are already training on state-of-the art flight training devices to prepare in a safe, cost-effective manner for<br />

operational deployment,» Falk said.<br />

The CH-53K is also nearing the conclusion of the developmental flight test events in preparation for Initial Operational Test & Evaluation<br />

(IOT&E), having flown more than 2,000 flight hours validating the aircraft’s performance on a ship and in both hot and cold environments.<br />

This year, the aircraft completed:<br />

• Air-to-air refueling with an external load<br />

• Initial sea trials<br />

• Flight tests in extremely hot and dusty conditions at U.S. Army Yuma Proving Ground in Yuma, Arizona<br />

Other accomplishments include:<br />

• Maximum weight single-point cargo hook sling load of 36,000 pounds (16,329 kilograms)<br />

• Forward flight speed of over 150 knots<br />

• 60-degree angle-of-bank turns<br />

• Altitude of 18,500 feet mean sea level (MSL)<br />

• 12-degree slope landings and takeoffs<br />

• External load auto-jettison<br />

• Gunfire testing<br />

MORE ABOUT SIKORSKY<br />

HI I 13

HELICOPTER INDUSTRY I BREAKING NEWS<br />

©Kopter<br />

SH09 THIRD PROTOTYPE ACHIEVED SEVERAL “FIRSTS”<br />

Flight test activities have fully resumed at Mollis, Switzerland, having reassembled the third SH09 prototype (P3) after its return from<br />

Pozzallo.<br />

The flights at Mollis mainly concentrated on testing the new tail rotor and aerodynamic modifications for improved handling in the low<br />

speed envelope. Flights at altitude, in the local area, evaluated the handling characteristics at higher speeds and in autorotation.During<br />

these flights we have been able to achieve several firsts for the SH09. Notably, the first flight at the maximum permissible take-off<br />

weight for P3 and for the first time the aircraft has been to 35 knots in sideways flight.<br />

Next step is to proceed with the upgrade to Garmin avionics and install the final main rotor flight control system.<br />

MORE ABOUT SH09<br />

HI I 14

©Airbus-<strong>Helicopter</strong>s-Patrick-Heinz<br />

31 ADDITIONAL NH90 FOR THE GERMAN NAVY.<br />

On November 20, the Budget Committee of the German Bundestag (Parliament in Germany) validated the additional purchase of 31<br />

NH90 multi-role helicopters for a budget of 2.7 billion euros. A first navalized version called the Sea Lion was to be received in 2019,<br />

to replace the Westland Sea Kings for rescue-SAR and frigate supply missions at the time. This new order for NH90 Mult Role Frigate<br />

<strong>Helicopter</strong>s (MRFH), known as Sea Tiger, will be used primarily for anti-submarine warfare and surface combat. The arrival of these<br />

new machines should enable Deutsche Marine to retire its ageing fleet of Sea Lynx Mk88A Sea Lynx helicopters, with which it currently<br />

operates, by 2025.<br />

MORE ABOUT NH90<br />

HI I 15

HELICOPTER INDUSTRY I FAREWELL I<br />

BY FRÉDÉRIC VERGNÈRES<br />

©MARINE NATIONALE - ©A. PECCHI<br />

HI I 16

HI I 17

HELICOPTER INDUSTRY I FAREWELL I<br />

0<br />

n September 4th, in front of an audience of officers<br />

and three machines with commemorative livery for the<br />

occasion, the French Navy bid farewell to its last Lynx still<br />

in operation. In addition to the helicopter, the entity also put<br />

its prestigious unit, the 34F, to sleep for a few months. For<br />

41 years, the pair will have criss-crossed the globe to ensure<br />

mainly the mission of anti-submarine warfare.<br />

« It’s a feeling shared between emotion and optimism to see the<br />

departure of an aircraft on which I have flown throughout my<br />

career. Nevertheless, this departure opens a new era and a new<br />

chapter in the history of the Navy ». These few words spoken<br />

by Commander François Chaput, the last commander of the<br />

34F, symbolises the attachment of the Navy and its men to<br />

this aircraft.<br />

The Lynx is the result of a Franco-British commercial<br />

cooperation between Aérospatiale and Westland in its<br />

French version. The Lynx is above all an aircraft whose<br />

design is based on Westland’s experience in on-board<br />

helicopters, particularly the WASP model. Above all, it is a<br />

machine designed by the British, for the British, just like the<br />

car on the other side of the Channel. The feline will thus be<br />

developed with innovative technical solutions to make it a<br />

helicopter particularly suited to boarding. A stocky machine<br />

with a very low center of gravity to give it great stability on<br />

marine platforms, the Lynx is also the only machine to have<br />

a main gearbox (MGB) in the shape of a «crushed pyramid».<br />

This technical design makes it possible to lower the height<br />

of the device. Correlated to the blades and a folding beam,<br />

it will facilitate its storage on board frigates and make it a<br />

helicopter fully in line with the requirements of naval forces.<br />

In addition, it remains the only aircraft to have a pitch change<br />

system whose axis runs through the MGB system at its<br />

center. A mechanism that is totally different from the swash<br />

plates usually found on rotating wings, but has undoubtedly<br />

proven itself since the machine was put into service.<br />

HI I 18

A VERSATILE VECTOR<br />

The Lynx was commissioned by France on the 3rd of October<br />

1979, in order to provide the French Navy with a genuine onboard<br />

anti-submarine warfare (ASW) system and thus meet<br />

the requirements of the submarine domain in correlation<br />

with its nuclear deterrent systems. Equipped, among other<br />

things, with a DUAV-4 hardened sonar and, if necessary, two<br />

Mk.46 or MU-90 torpedoes, the forty machines received by<br />

France will be deployed mainly from the F67 (Tourville class)<br />

and F70 (Georges Leygues class) frigates based in Toulon<br />

and Brest. They will be operated by three crew members (two<br />

pilots and a sonar/winch operator or aeronautical helicopter<br />

operator - HELAE). The feline will become an indispensable<br />

tool and a deported vector for these frigates in order to hit<br />

the target as closely as possible in its main ASM mission.<br />

However, history will enrich the operational capabilities<br />

of the twin-turbine and enable it to be deployed in-fine, on<br />

board all helicopter-carrier ships in service with the Navy.<br />

Unlike the English versions, the French Lynx will nevertheless<br />

have evolved marginally. Only a few transformations were<br />

made over the years, such as the introduction of a new,<br />

more powerful engine in 1984 and the integration of carbon<br />

blades, which in practice enabled the helicopter to gain up to<br />

15 knots of top speed.<br />

From its original Mk.2 version to the more advanced Mk.4<br />

version, the Lynx will thus be able to use its operational<br />

capabilities for sea rescue missions (Search and Rescue -<br />

SAR), the fight against illicit trafficking, and the protection<br />

of maritime approaches. Thanks to its ability to intervene<br />

more than 100 nautical miles from the point of departure,<br />

the aircraft has been on the frontline in rescuing the crews<br />

of the Erika in 1999, the Napoli in 2007 and, more recently,<br />

the Modern Express in 2016. In addition to its missions of<br />

state action at sea, this beast of burden will also be used to<br />

transport and support Special Forces. In fact, the aircraft,<br />

operated by three flotillas (31F, 34F and 35F), will be at the<br />

heart of many devices and missions, such as those carried<br />

out in June 1982 during the Lebanese conflict, which saw a<br />

31F aircraft land in the heart of Beirut, then plagued by civil<br />

war. Following state-commissioned operations, the Lynx was<br />

also deployed during Operation Daguet in 1991, then in the<br />

Balkans in 1992, not forgetting the Heracles (Afghanistan),<br />

Harmattan (Libya), and Chammal (Syria-Iraq) missions in<br />

the 2000s, up to the present day. The long list of operations<br />

carried out by the «animal» will lead it to perform more than<br />

210,000 flight hours during its 41 years of service.<br />

HI I 19

HELICOPTER INDUSTRY I FAREWELL I<br />

AN EFFICIENT BUT AGING MACHINE<br />

With four machines still in flight, the 34F flotilla carried out<br />

the Lynx’s latest mission last July, during an operational<br />

mission in support of the strategic oceanic force for SNLE’s<br />

nuclear-powered ballistic missile submarines. Despite<br />

its intrinsic qualities and the possibility of an upgrade,<br />

the withdrawal of the Lynx has become a necessity in<br />

recent years, as François Chaput points out: «The age of<br />

the aircraft no longer allows it to be maintained in sufficient<br />

operational conditions. The maintenance of the Lynx has<br />

proved increasingly difficult, often forcing mechanics to carry<br />

out retro engineering.» The Navy will thus have kept up, until<br />

the end, the maintenance capacities of the aircraft at the the<br />

operational level, within the flotilla in Lanvéoc, and at the<br />

aeronautics industrial workshop (AIA) in Cuers-Pierrefeu. At<br />

the same time, the aircraft will have benefited throughout<br />

its working life from industrial monitoring by Leonardo, a<br />

company created in 2000 from the merger between Italy’s<br />

Agusta and Britain’s Westland. However, its operating costs<br />

will impede on further modernisation. According to a report<br />

submitted to a Member of Parliament last July, the aircraft’s<br />

flight hours have gone from 14,000 to 22,000 euros in four<br />

years for an annual maintenance cost of 17.7 million euros.<br />

And, for an availability rate of less than 16%! This was just<br />

enough to decide on the withdrawal of the beast, not without<br />

regrets according to its crews, who, at the closure of the 34F,<br />

will be reassigned to different units.<br />

A NEW ERA<br />

If the withdrawal of the Lynx marks the end of an era, it is<br />

also synonymous with renewal for the French Navy. The<br />

ASM mission has already been taken over by the NH90<br />

Cayman Marine for several years, notably within the 33F and<br />

31F on board multi-mission frigates (FREMM). The Cayman<br />

Marine, which entered service with the «Royale» in 2011,<br />

thus takes over the entire range of missions carried out by<br />

the Lynx. And, according to some authorities, it is sometimes<br />

not without difficulty, when faced with a last-generation<br />

machine, where it is difficult to maintain operational.<br />

Despite a few uncertainties, the NH90 is in fact becoming<br />

the spearhead of the on-board helicopter component. The<br />

Navy has also opted for another Airbus <strong>Helicopter</strong>, the H160,<br />

and the withdrawal of the Lynx has made it possible to<br />

ratify the project to upgrade the helicopter component by<br />

implementing an interim fleet consisting of H160s and N3<br />

Dolphins. According to François Chaput, « this project has<br />

a promising future and the Lynx’s retirement will also make it<br />

possible to invest in it on a long-term basis. »<br />

If the time of the feline’s retirement has indeed sounded, its<br />

second life within the national museums, in order to preserve<br />

this flying heritage, still remains to be defined. As CF Chaput<br />

underlines, « calls for the delivery of some of the cells to the<br />

historical museum of the helicopter, in Dax, to the museum of<br />

the association of the friends of naval aeronautics in Rochefort<br />

and, why not, to the Museum of the air and space installed on<br />

the airport of Paris - Le Bourget. »<br />

HI I 20

THE REBIRTH OF THE 34F<br />

Last unit to operate on the Lynx, the 34F flotilla will remain one of the specialists in ASM combat. «Due<br />

to the geographical location of the 34F, the main mission of this unit has been the surveillance of the Atlantic<br />

coast in order to protect the SNLE’s based in Brest. The 34F’s mission is totally linked to the frigate’s missions,<br />

which has led it to deployments in the North Atlantic area and the Baltic Sea approaches, in order to ensure<br />

operational maintenance during exercises with our allies. However, even if the latter has become a specialist in<br />

this field, the flotilla will have carried out a wide range of missions, even one-off ones, such as search and rescue<br />

and anti-pollution response», as Commander Chaput points out. With the announcement of the Lynx’s<br />

withdrawal also came the dissolution of the 34F. However, this one, hardly receiving a moment of sleep,<br />

will be reactivated at the beginning of January 2021 by «absorbing» the 22S. The 34F will thus become<br />

the School of Specialisation on Embedded <strong>Helicopter</strong>s (ESHE - Ecole de Spécialisation sur Hélicoptères<br />

Embarqués) and will take over the crew training missions for all helicopter pilots of the French Navy. And<br />

others. For, in addition to the Navy, the unit that hosts the interim fleet of Dauphin N3 helicopters also has<br />

the mission of training pilots from other armies on how to land.<br />

MORE ABOUT LYNX<br />

HI I 21

HELICOPTER INDUSTRY I LEGACY I<br />

BY FRÉDÉRIC LERT<br />

©AIRBUS - ©FREDERIC LERT<br />

HI I 22

HI I 23

HELICOPTER INDUSTRY I LEGACY I<br />

E<br />

On the 6th of September 2010, the X3 took off for the first time from the<br />

Istres air base in the south of France. 50% aeroplane, 50% helicopter,<br />

100% innovative and successful. The actors of the time remember this<br />

extraordinary program...<br />

« CEO Lutz Bertling had decided to launch the study of a fast aircraft,» recalls<br />

Daniel Semioli, who was one of the two test flight engineers in the program,<br />

along with Dominique Fournier. During a meeting in which I took part, he told<br />

us in substance, «The handicap of a conventional helicopter is its speed limited<br />

by its rotor. But as this limit is physically impassable, we have to change the<br />

concept».<br />

HI I 24

THE CONVERTIBLE COMPLEXITY<br />

The fantasy of the fast helicopter is as old as the helicopter<br />

itself. Many avenues have been explored to break the wall<br />

of speed related to the physical constraints of the rotor in<br />

forward flight. So far, only one hybrid helicopter has been<br />

built in the series: the Bell V-22. An aircraft with tilting<br />

propellers carried by the Pentagon’s budgets, and reserved<br />

for the military because of its complexity, alongside its<br />

operating and maintenance costs. But the defects and<br />

dangers of the convertible are well known, especially in the<br />

transition phase with wingtip flaps that make neither good<br />

rotors nor good propellers.<br />

SHADOW PROJECT<br />

Lutz Bertling’s stated objective is to obtain an aircraft<br />

50% faster than a helicopter, but with simple technical<br />

solutions limiting the increase in costs to 20% compared to<br />

a conventional aircraft of equivalent size.<br />

«Our CEO wanted to launch a small development program that<br />

would allow us to respond quickly, and at a lower cost to the<br />

question of the feasibility of such an aircraft» continues Daniel<br />

Semioli. «The idea did not meet unanimous approval in the<br />

company. There was a - moderate - financial risk, of course,<br />

but it was above all Eurocopter’s brand image that could be<br />

strongly impacted by a failure. The history of hybrid aircraft,<br />

with its many accidents, did not argue in our favour ». A very<br />

small team, a dozen engineers at most, worked under the<br />

leadership of Philippe Roesch (program director) and<br />

Thomaz Krysinski to propose a preliminary project to Lutz<br />

Bertling. The responsibility of the final decision lands with<br />

him, as to whether to continue the project. «Actually this was<br />

not about spending a certain amount of money, but about the<br />

team proposing to me a minimum budget needed to achieve a<br />

flying demonstrator aircraft in a very independent skunk works<br />

environment » says Lutz Bertling. «The X3 is certainly one of<br />

the achievements in my career I am most proud off ».<br />

HI I 25

HELICOPTER INDUSTRY I LEGACY I<br />

TECHNOLOGY PUZZLE<br />

In order to move forward quickly and cost-effectively, the<br />

design office team makes the greatest possible use of<br />

already existing sub-assemblies. The cell is that of an old<br />

Dauphin previously transformed to give birth to the EC155<br />

prototype. The rotor is also that of the EC155 prototype.<br />

The main gearbox comes from an EC175. It receives two<br />

additional lateral outputs for power transmission to the<br />

propellers at the wingtips. «The transmission was direct, with<br />

no maintenance bearings in the wing» explains Daniel Semioli.<br />

«We carried out a lot of tests on the development of the drive<br />

shafts, which had to meet the requirements of a super critical<br />

shaft». The manufacturing of the propellers was entrusted<br />

to the company MT Propeller, without of course, revealing<br />

the very special use that would be made of them. In order to<br />

go fast and reduce costs, Eurocopter wanted to use existing<br />

propellers with shorter blades and modified twist. The reverse<br />

motion of a propeller while hovering in flight, should allow<br />

the tail to be balanced. The propeller manufacturer remains<br />

perplexed by the requested specifications and explains to<br />

his customer « We don’t know what kind of aircraft you have<br />

but it will probably not work very well with the propellers you<br />

are asking us for...». As far as the engines are concerned, the<br />

TK team has set its sights on the two RTM322 turbines of<br />

the NH90 prototype, whose speed is adapted to the needs of<br />

the aircraft being prepared. The rear of the EC155’s airframe<br />

is profoundly modified with the addition of a large fixed<br />

double tailplane to stabilise the aircraft on the pitch and<br />

yaw axis. The wing is fitted with flaps set to compensate for<br />

asymmetric rotor wash. A «simplex» type autopilot is slipped<br />

under the skin of the aircraft to ensure that everything<br />

functions in harmony. «The most extraordinary thing is that<br />

the X3 was remarkably stable, and it remained fully controllable<br />

throughout the entire flight envelope without the auto-pilot,»<br />

explains Hervé Jammayrac, pilot of the demonstrator.<br />

HI I 26

HUMAN ADVENTURE<br />

All the assembly work is done in Marignane, in a discreet<br />

but very well guarded shed. As the work progresses, new<br />

skills are added to the existing team. Specialists are coopted<br />

under the seal of secrecy in each of the company’s<br />

sectors. They are chosen on the basis of their technical but<br />

also human qualities to guarantee the complete cohesion of<br />

the team working in commando mode. For Daniel Semioli<br />

as for his colleagues, there is no doubt about it: «We formed<br />

a very close-knit group, with the idea that we were on our way<br />

to succeed (or fail!) all together! The people chosen were very<br />

invested in a project that they knew was unique, and which<br />

would mark their professional career and their passage through<br />

the company». At the same time, the future crew discovered<br />

the functioning of the aircraft with the help of the SPHERE<br />

study simulator, which also enabled Tomasz Krysinski’s team<br />

to better define certain parts of the aircraft. «SPHERE was<br />

very well done and we were not disorientated when we climbed<br />

into the machine for the first flight,» recalls Hervé Jammayrac.<br />

«The aerodynamic effects, the gains... we found on the aircraft<br />

in flight and everything we had encountered on the ground with<br />

the simulator ». On the 31st of July 2010, the prototype left<br />

its hangar at dusk. It was towed through the car parks and<br />

taxiways of Marseille Provence International Airport to the<br />

nearby Etang de Berre. Then it was disassembled into three<br />

sub-assemblies, which were placed on a floating barge. It is<br />

after midnight when the barge left Marignane and headed to<br />

the port of Fos, on the opposite bank. Once there, the subassemblies<br />

were placed on trucks that only had to travel a<br />

few kilometres to reach the Istres air base, in order to cut<br />

the trip as short as possible and stay away from busy roads;<br />

limiting the arousal curiosity a passage is opened for the<br />

sole benefit of the convoy in the fence of the base, in a very<br />

isolated sector. At 1pm on August 1st, the aircraft takes<br />

possession of its new hangar on the air base. Re-assembly<br />

can then begin.<br />

HI I 27

HELICOPTER INDUSTRY I LEGACY I<br />

SIMPLICITY OF PILOTING AND<br />

EXCEPTIONAL PERFORMANCE<br />

« We all shared the same hangar, crew, mechanics, telemetry<br />

team, design office, etc. » says a technician on the program.<br />

« We had lunch together on site, we thought together, the<br />

efficiency was 100%! ». On August 16, 2010 at 6pm, in total<br />

discretion, as the base was emptied of its personnel, the X3<br />

carried out its first fixed point in Istres. Three weeks later,<br />

on September 6, 2010 at 5pm, the X3 took off for the first<br />

time. Two and a half minutes of stationary. « And there’s a<br />

major problem: both wings are flapping! The aircraft is at the<br />

limit of controllability » recalls Daniel Semioli. The origin of the<br />

problem is quickly identified: the flight controls pass through<br />

the canopy and the flapping induces parasitic movements,<br />

which are amplified by the servocontrols. The solutions<br />

were put in place and everything returned to normal within<br />

a few days. The rapid succession of flights shows that<br />

the X3 combines great ease of piloting with exceptional<br />

performance. « Everyday, we were a little more amazed by<br />

the potential of the aircraft. The simplicity of the technical<br />

solutions, which was one of the major characteristics of the<br />

aircraft; our choice to play with the rotor speed and propeller<br />

pitch, without ever losing efficiency; all of these aspects<br />

surprised the aeronautical world, which sometimes thought<br />

that this level of simplicity would not work, » Daniel Semioli<br />

sums up. « A helicopter pilot will master the piloting of this<br />

aircraft in less than five minutes. Contrary to what is known with<br />

convertible aircraft, the vertical and horizontal flight phases<br />

follow one another without transition, without ever endangering<br />

the aircraft’s occupants ».<br />

At the beginning of 2013, with the entire flight envelope<br />

open, the X3 unofficially breaks the speed record for a<br />

gyrodine, at 255 knots. The aircraft then accumulated just<br />

over 140 hours of flight time, well over the 100 hours initially<br />

planned. But the success is such that the aircraft is used<br />

in a large number of communication operations, including<br />

an exceptional «demo tour» in the United States. All the<br />

objectives of the technological demonstrator have been met<br />

and, as a sign of its success, the program is accumulating<br />

honours: Howard Hughes trophy, Hall of Fame for innovation<br />

in the United States, Gold Medal of the French Aeroclub.<br />

Now it’s time for the Racer, which promises to revolutionise<br />

vertical flight.<br />

MORE ABOUT X3<br />

HI I 28

HELICOPTER INDUSTRY I MANUFACTURER I<br />

HI I 30

BY FRANÇOIS BLANC<br />

©HILL<br />

HI I 31

HELICOPTER INDUSTRY I MANUFACTURER I<br />

S<br />

Since the merger of the Westland <strong>Helicopter</strong>s brand into the Italian Leonardo cauldron, the British<br />

helicopter industry has been quite discreet. The launch announcement of a program designed and<br />

to be conducted in Great Britain did not fail to surprise European and other observers. Here is an update<br />

on a project whose genesis dates back to 2007.<br />

Artist’s views intended to show what a particular model of vehicle or aircraft might look like are not<br />

uncommon. In fact, they have never been. However, in the case of Hill <strong>Helicopter</strong>s’ early press releases,<br />

observers could not help but be impressed by some of the most compelling images from around the<br />

world. They will no doubt have lingered, too, on the journey of the concept’s creator and founding<br />

president of Hill <strong>Helicopter</strong>s. Jason Hill is not the first to enter the industrial sphere, nor is he the first to<br />

enter the world of rotary wings. A mechanical engineer from Aston University in Birmingham, England,<br />

he began his career at Agusta Westland while pursuing studies that would lead him to a doctorate in<br />

advanced aerodynamics in the early 2000s. He is currently working on the Lynx program, designing<br />

rotors, composite structures and fuselages.<br />

HI I 32

NOTHING NEW FOR 40 YEARS?<br />

In 2005, Hill left Westland and created his own company,<br />

Dynamiq Engineering. A certified helicopter pilot, he closely<br />

follows the news of the sector. However, he believes no<br />

decisive advances have been made in light helicopters<br />

since the 1980s. This is undoubtedly the starting point of an<br />

initiative that has recently been echoed in the aeronautical<br />

world.<br />

Nevertheless, from 2007 onwards, Jason Hill has been<br />

engaged in in-depth reflection. He launched a study to<br />

design, develop, test and mass-produce a particularly<br />

innovative five-seat, single-engine helicopter. From the<br />

outset, he targeted the private user market, a demand that<br />

he now estimates to be in the range of 500 to 1,000 aircraft<br />

per year. At this stage in the story, several remarks come<br />

to mind. The recent abandonment of the H120 model by<br />

Airbus <strong>Helicopter</strong>s, for example, raises questions about the<br />

existence of a flourishing market for a light single-engine<br />

aircraft for private users. This machine did not (or no longer)<br />

presents the characteristics expected by all or part of the<br />

target clientele. It is also true that the Bell 505, which is also<br />

largely intended for private customers, is not at the cutting<br />

edge of modernity, despite its original cabin and digital<br />

equipment. To be convinced of this, one need only consider,<br />

for example, the origin of its dynamic elements borrowed<br />

from the Bell 206 Jet Ranger family. There was no technical<br />

revolution at Robinson either, with the advent of the R66, the<br />

descendant of a prolific family of lightweight, combustionengine<br />

powered machines. The case of the Kopter SHO9, on<br />

the other hand, would tend to prove Jason Hill right, whereas<br />

the aircraft developed in Switzerland (and now absorbed<br />

by Leonardo) is precisely intended to place a more modern<br />

machine on the market than those of the competitors. The<br />

fact remains that the Hill <strong>Helicopter</strong>s project obviously<br />

pushes the notion of modernity even further.<br />

THE ASSOCIATION OF<br />

SCIENCE AND ART<br />

In 2012, five years after the launch of studies for a new<br />

helicopter concept, Jason Hill called on a core group of<br />

engineers from Dynamiq Engineering. Having reached<br />

a critical stage in the design of his helicopter, he felt that<br />

the program needed to be given a boost. As exciting as the<br />

studies are that he is carrying out, the challenge now is to<br />

complete them within a realistic timeframe. Progress is<br />

coming, and the acceleration is bearing fruit. Not only is the<br />

concept taking shape, the technical solutions selected are<br />

being refined, but a request for a grant from Her Majesty’s<br />

government is also being approved. The amount is not<br />

disclosed, but the recognition of the quality of the work done<br />

and the theoretical viability of the project supports Jason<br />

Hill’s approach at the right time, giving it a certain credibility.<br />

In addition to the innovative technical contributions injected<br />

into the concept, the specifications, from the outset, aim<br />

to give birth to the first helicopter specifically designed<br />

for pilots who own their own machine. The main idea was<br />

to bring the pleasure of piloting and the advantages of<br />

owning a helicopter to the highest level, especially in terms<br />

of freedom of use and flexibility, especially if it is the most<br />

comfortable of all, the most ergonomically designed and the<br />

most flattering to look at. «The combination of science and<br />

art is essential in the design of the HX50,» Hill said in one of<br />

his speeches, conveniently posted on a web-based channel.<br />

Thus, the interior design - cockpit and cabin - is particularly<br />

careful, to make the flight an experience as safe as it is<br />

qualitative, and the simple presence on board an exercise in<br />

pure seduction. Of course, the project promises to be very<br />

ambitious, and totally uncomplicated…<br />

HI I 33

HELICOPTER INDUSTRY I MANUFACTURER I<br />

OPERATION SEDUCTION<br />

Enhance helicopter flight, supply the passengers with an<br />

image consistent with their self-image: the message sent to<br />

the future owners of the HX50 is unequivocal. It’s a message<br />

to a certain global elite, to people who are wealthy and<br />

supposedly ready to afford the most advanced helicopter<br />

ever developed and marketed in its class. A position perfectly<br />

assumed, while Hill <strong>Helicopter</strong>s’ definition of the concept<br />

evokes «the best five-seat turbine-powered helicopter ever<br />

built. However, the notion of «best helicopter» here is not as<br />

peremptory as it might seem. It underscores Jason Hill’s<br />

bias, as he designs a helicopter with a high level of finish,<br />

luxurious equipment, and does not seek any versatility of<br />

use, and especially not the slightest aptitude for utilitarian<br />

missions for his future aircraft. In his remarks, the parallel<br />

with the Aston Martin car brand comes up several times,<br />

as if to enlighten an audience unprepared to witness the<br />

emergence of an aircraft that is both out of the ordinary<br />

and that carries a new interpretation of what the expression<br />

«good English taste» can mean.<br />

However, the demanding consumer of private helicopter<br />

flights may not be quite the only customer for the HX50,<br />

while there is also talk of targeting a fringe of users who are<br />

more accustomed to travelling by airplane.<br />

This is where the performance sought by Hill <strong>Helicopter</strong>s for<br />

its first production contributes to its attractiveness. Cruising<br />

flight at 10,000 feet (about 3,000 meters), fully loaded (800<br />

kg onboard), at an economical speed of 140 knots (260<br />

km/h) and over a distance of 700 nautical miles (about 1,300<br />

km), are on the menu claimed by the HX50. Technically, even<br />

if no engineer will shout utopia, there again, the declared<br />

ambition is to be welcomed. Little said about the technical<br />

characteristics of the HX50, the young British manufacturer,<br />

to date, only mentions a composite material structure, which<br />

guarantees the required rigidity, a significant weight saving<br />

and a good way to erase some of the vibrations induced by<br />

the operation of the machine.<br />

HI I 34

ORIGINAL FLIGHT CONTROLS<br />

AND INSTRUMENTATION<br />

Recently unveiled, the manufacturer of the GT50 engine is<br />

none other than the designer of the HX50. Here again, the<br />

approach may surprise. And once again, Jason Hill has no<br />

shortage of arguments, as he states that current design<br />

resources make it possible to complete a study quickly and<br />

inexpensively. Furthermore, he points out that by planning to<br />

use only proven technical solutions (and the best of them),<br />

while striving to simplify their assembly and implementation,<br />

Hill <strong>Helicopter</strong>s finds itself completely free to set the<br />

performance requirements itself, without ever having to<br />

worry about having to conduct tedious additional studies to<br />

adapt the engine to the aircraft. To date, the data reported<br />

indicates a maximum continuous power of 400 HP (405<br />

hp), 440 HP at takeoff (446 hp), and 500 HP (507 hp) for 30<br />

seconds in an emergency, for an average fuel consumption<br />

of 35 gallons per hour (132.5 l/h).<br />

Translated with www.DeepL.com/Translator (free version)<br />

The name of the manufacturer of the 500hp engine, for the<br />

moment, is not revealed. As for the latest-generation digital<br />

instrumentation, no known supplier has yet been identified.<br />

That said, the simple description of the planned flight<br />

controls might partly explain this cautious statement. Indeed,<br />

the cockpit of the HX50 will not be equipped in a completely<br />

conventional way (apart from the rudder connected to the<br />

anti-torque rotor). The general pitch control, in this case,<br />

will be operated from front to back (and not from bottom to<br />

top). The key point is that this control will be connected to<br />

a central console (inspired by the automotive world), with<br />

an armrest designed to improve piloting comfort, especially<br />

over long distances, and even a support to relieve the forearm<br />

and wrist during certain phases of handling the helicopter’s<br />

systems. The Integrated Pilot Interface (IPI) is located in<br />

the immediate vicinity of the general pitch control (when<br />

the helicopter is in cruise position). This system includes a<br />

central «puck» and numeric keypad, as well as a series of<br />

function selection keys designed to simplify and easily free<br />

the pilot from all the actions he has to perform. This IPI<br />

allows the pilot to set the altimeter setting, select the COM1,<br />

COM2 or NAV frequencies, enter transponder codes, enter<br />

heading, altitude and speed data to be reached and retained<br />

by the autopilot, as well as navigation data. It also offers<br />

immediate access to certain functions, such as setting up<br />

the navigation system, integrating a cell phone, adjusting the<br />

air conditioning and ambient lighting, or accessing the main<br />

menu of the system.<br />

HI I 35

HELICOPTER INDUSTRY I MANUFACTURER I<br />

TARGET 2023<br />

At the top of the general pitch control, a mini-console<br />

includes a FLY/IDLE (idle/flight speed) switch for the<br />

engine, a switch for the landing light, and a third one for<br />

the hydraulic system cut-off test. Beneath the central (and<br />

adjustable) shelf support (it accepts a wide range of shelves<br />

and operating systems) is the main control panel (PCP).<br />

The PCP contains the main battery connection button, the<br />

main avionics connection button, the collision light switch,<br />

the engine start/stop button, the main rotor brake control<br />

and the emergency fuel shut-off valve. The startup sequence<br />

is kept as simple as possible, with the battery, avionics and<br />

collision-avoidance switch in the «on» position. Then simply<br />

press the start button, and the FADEC (1) takes over.<br />

Below the main screen is a secondary set of controls that<br />

manages autopilot modes, air conditioning and defogging,<br />

cabin lighting, map lighting, navigation lights and ambient<br />

lighting intensity.<br />

The cyclic pitch control in turn provides a substantial<br />

improvement, especially because it is not anchored in the<br />

cockpit floor, but «suspended» above the pilot’s legs.<br />

It offers the possibility of individual adjustment «by hand»<br />

for each pilot and, of course, increased ease of getting in<br />

and out of the seat (without having to go around the control<br />

column anchored to the ground). The ergonomics of the<br />

handle are particularly well thought out. When a double<br />

removable control is installed, each pilot can individually<br />

adjust its setting to his or her liking.<br />

To date, the designer of the HX50 claims to be able to take<br />

its first production aircraft off the assembly line (located in<br />

the Midlands region of Great Britain) in the summer of 2023.<br />

This assertion indicates that the project is probably quite<br />

mature 13 years after the initial studies were launched. At<br />

the same time, it confirms that Jason Hill was careful not to<br />

disclose his project too soon. Is he trying to create a certain<br />

element of surprise, while sparing the patience of his future<br />

clients? Three years is relatively short in the life of a program<br />

of this scale... Of course, it remains to be seen whether, like<br />

most industrial helicopter manufacturers, Jason Hill will not<br />

have to deal with unforeseen events that could delay the<br />

entry into service of his firstborn.<br />

MORE ABOUT HX50<br />

HI I 36

<strong>Helicopter</strong> <strong>Industry</strong> TV,<br />

Everywhere ...<br />

Every month, UJ TV & HI TV takes an in-depth look<br />

at two issues making the headlines of the industry<br />

with a distinctive editorial slant and style.

HELICOPTER INDUSTRY I MILITARY I<br />

BY FRÉDÉRIC LERT<br />

©FRÉDÉRIC LERT<br />

HI I 38

HI I 39

HELICOPTER INDUSTRY I MILITARY I<br />

F<br />

or its major annual Baccarat exercise, the Army Light<br />

Aviation (ALAT) has shaken up its habits by training in<br />

the Alps. Beyond the constraints of aerology and weather, it<br />

also had to deal with Covid19...<br />

Every year, ALAT organizes its Baccarat exercise which<br />

brings together on the same ground the three combat<br />

helicopter regiments (RHC) belonging to the 4th Air Combat<br />

Brigade (BAC): the 1st RHC of Phalsbourg, the 3rd RHC of<br />

Etain and the 5th RHC of Pau.<br />

For the fourth edition, about thirty aircraft and 1600 army<br />

soldiers belonging mainly to the 27th mountain infantry<br />

brigade were mobilized. For once it was not customary<br />

for ALAT to play a high intensity combat, facing a heavily<br />

equipped conventional enemy, on a field covering a<br />

quadrilateral of 150 kilometers by 250 km deep. Straddling<br />

four departments, the maneuver area was part of a large<br />

quadrilateral bounded by the cities of Valence, Grenoble,<br />

Gap and Briançon. In addition, there was a live-fire zone<br />

from the Mailly and Sissonne camps. Another special<br />

feature of the 2020 edition of Baccarat was the emphasis<br />

placed on operations in mountainous areas, with all its<br />

peculiarities in terms of aerology, meteorology, and finally<br />

very strong impacts on aircraft performance and operations.<br />

HI I 40

Mountainous and sophisticated adversary, the cocktail was<br />

a strong one, very different in any case from the tactical<br />

situations that French crews have been encountering in the<br />

Sahel for nearly ten years.<br />

« With this edition, I wanted to shake up habits, get out of the<br />

routine, » explained General Frédéric Gout, commander of<br />

the 4th BAC. « We left Afghanistan nearly ten years ago and<br />

the generation of pilots who took part in this OPEX will soon<br />

have completely left the regiments. We will then have lost the<br />

mountain expertise we had acquired there ». Of course, the<br />

current operations in the Sahel mean that the mountains are<br />

not a priority. And the tempo of the operational engagement<br />

is such that opportunities to get to know the summits on a<br />

first-name basis are not common.<br />

An important feature of Baccarat has also been the<br />

participation of foreign nations since its inception. The<br />

2019 edition was marked by a strong Spanish and British<br />

commitment, the former even travelling with a full helicopter<br />

regiment and an infantry company. But this year, COVID-19<br />

put a serious brake on this exchange. Spain threw down the<br />

gauntlet, playing the prudence card. «A reasonable choice that<br />

I fully understand,» General Gout noted. The British chose to<br />

maintain their participation, but with a contingent limited to<br />

only two AH64D Apache AH64s from the 664 Squadron - 4th<br />

Regiment Army Air Corps that made the trip from their base<br />

at Wattisham.<br />

Our detachment is limited to about 30 people, but we had to<br />

come,» insisted squadron leader Tom Brunwin. Our presence<br />

is an excellent opportunity to train in the mountains and<br />

to exchange with our French comrades on their combat<br />

experience in the Sahel.<br />

The Army Air Corps came with 5 aircrew and a convoy of<br />

a dozen vehicles. Two airplanes brought logistics, while the<br />

two helicopters reached the ALAT base in Valence Chabeuil<br />

by their own means and with two stops, the first in Great<br />

Britain and the second in Dijon. With two additional fuel<br />

tanks, our Apache helicopters have a flight time of just over<br />

four hours,» noted the British officer. We could have come<br />

without any problem with only one intermediate stop, but<br />

the bad weather conditions pushed us to take greater safety<br />

margins».<br />

HI I 41

HELICOPTER INDUSTRY I MILITARY I<br />

During the exercise, the British mainly worked with the Tigers<br />

of the 1st French RHC in reconnaissance and destruction<br />

missions, but always under a unified French command. «The<br />

patrols were not mixed with the Tigers, we divided up the<br />

areas of intervention with, for example, the Tigers to the<br />

north of a valley and us to the south. In other cases, the<br />

helicopters could cooperate and even designate each other<br />

laser targets.<br />

The AH64D is of course distinguished at first glance by its<br />

radar placed at the top of the rotor mast, with the different<br />

versions of the AGM-114 Hellfire missile, laser- or radarguided,<br />

as its main armament. The Army Air Corps currently<br />

has 67 Apache Ds in stock, with about fifty in line, divided<br />

into two regiments with two squadrons each, plus two<br />

training squadrons. But early next year, the squadrons will<br />

begin their transformation on AH64E aircraft, of which the<br />

United Kingdom has ordered 50.<br />

The British involvement in Baccarat was all the more<br />

commendable since, because of COVID, the entire<br />

detachment was ipso facto obliged to follow a «fourteen» at<br />

the end of the exercise, on their return to Great Britain.<br />

The shadow of the pandemic loomed over the exercise for its<br />

entire duration and almost led to a last-minute cancellation:<br />

«Three days before the scheduled date, I still didn’t know if<br />

the exercise could be played,» said General Gout. We were<br />

in close contact with the health and prefectural authorities<br />

to know the precise conditions under which we could still<br />

start the exercise. And in the end, we got the green light 72<br />

hours before the start of the exercise, with the constraint<br />

of setting up a draconian monitoring system: all the players<br />

had to wear masks at all times and take their temperature<br />

every morning. In case of symptoms, we had the possibility<br />

to isolate the patient and test him immediately. We received<br />

the results of these tests within 24 hours. Every evening,<br />

we took stock of the health situation with the possibility of<br />

stopping the exercise on the spot in the event of an alert<br />

and therefore of necessity. In the end, we recorded a dozen<br />

suspicious cases, all of which turned out to be negative.<br />

The success of the exercise and the interest shown by the<br />

crews (950 flight hours recorded in ten days) argue in favor<br />

of the creation of innovative scenarios for the years to come.<br />

After the mountains, the 4th BAC will also be working on a<br />

highly amphibious edition next year, with participation in the<br />

study of one or two French Navy Assault <strong>Helicopter</strong> Carriers<br />

(PHA).<br />

MORE ABOUT ALAT<br />

HI I 42

HELICOPTER INDUSTRY I PARAPUBLIC I<br />

BY FRANÇOIS BLANC<br />

©RUSSIAN HELICOPTERS<br />

BY FRÉDÉRIC VERGNÈRES<br />

©DR - ©FRÉDÉRIC VERGNÈRES - ©SÉCURITÉ CIVILE<br />

HI I 44

HI I 45

HELICOPTER INDUSTRY I PARAPUBLIC I<br />

L<br />

ast March, the French civil security authorities and the French civil aviation authority (DGAC)<br />

inaugurated a new IFR approach procedure for the Grenoble - Le Versoud site. This was a small<br />

revolution with big consequences.<br />

Far from being a mass sport, helicopter rescue in the mountains requires precision at all times. Up until<br />

now, the approach on certain sites, starting with the Grenoble - Le Versoud site, remained one of the<br />

most delicate points in France, in terms of weather because of overcast, which affects the descent for<br />

the red and yellow rotating helicopters. After three years of cooperation, the DGAC and the French Civil<br />

Security allowed the Grenoble site to have an IFR «Point In Space-PinS» approach dedicated to rotary<br />

wings.<br />

HI I 46

CONTROLLER MEMORIES<br />

In 2005, deliveries of the first EC145s gave the French civil<br />

security forces IFR capabilities that they had previously<br />

lacked. On this date, few crews had such a license. What’s<br />

more, at a time not so long ago, «GNSS breakthroughs, pure<br />

GPS, were still in their infancy,» says Renaud Guillermet, head<br />

of the Grenoble Civil Security helicopter base. However, the<br />

entity will very quickly turn to the DGAC to develop solutions<br />

for breakthroughs without visibility in mountainous regions.<br />

Starting with the Grenoble site, the first Civil Security<br />

helicopter base was specially created in 1957, in order to<br />

meet mountain rescue needs. Based in a region subject<br />

to the vagaries of the weather, especially in autumn and<br />

winter, «Dragon» crews strive to ensure the safety of their<br />

missions in all areas of flight, especially on approach when<br />

the cloud cover prevents all visibility to the ground. The<br />

first serious studies on the subject came from an air traffic<br />

controller in Versoud, who was at that time, in fully qualified.<br />

In his end-of-study thesis, he addressed a new approach<br />

procedure for a helicopter equipped with GNSS equipment.<br />

«Reading this thesis, we saw that the procedure was feasible<br />

despite a regulatory and technical framework that was difficult<br />

to implement given the available technology, which was not<br />

adapted to our operational needs,» said Renaud Guillermet.<br />

CROSSING THE « CLOUD »<br />

In 2018, on the strength of this initial approach and the<br />

development of onboard technology, Grenoble’s Civil<br />

Security center, which shares its missions at the heart of the<br />

Alpine epicenter between Le Versoud and the Alpe-d’Huez<br />

site during the height of winter tourist season, will re-launch<br />

the project in collaboration with the DGAC and air navigation<br />

services. «We have given our specifications and the services<br />

have built procedures specifically designed for our needs,»<br />

says the manager. The goal is to have a real low altitude<br />

IFR network for helicopters in the Alps, between Annecy,<br />

Chambéry and Grenoble. The specific procedure studied on<br />

Le Versoud includes « an approach by making short branches<br />

of two nautical miles with a 15° turn and three nautical miles<br />

in the other direction, which allows the helicopter to follow<br />

the trajectory of the valley, » the pilot explains. « The main<br />

advantage of this approach is to go and serve a helipad located<br />

in a valley in the Alps and to extend it according to operational<br />

needs. Traditionally, the Isère valley is fairly wide and is covered<br />

by a compact, watertight layer of clouds during the long autumn<br />

and winter period. The RNP (Required Navigation Performance)<br />

approach allows us to cross up to 4,000 feet of stratus. It is<br />

based on points dematerialized by precise GPS coordinates». In<br />

fact, the crew is no longer forced to perform reconnaissance<br />

to find a hypothetical hole to bring their aircraft to the base<br />

or to the Grenoble University Hospital Center (CHU). The<br />

method must be carried out with a GPS that guarantees<br />

a navigational accuracy of 0.3 nautical miles in the final<br />

phase of the approach. The piloting during this stage is<br />

controlled either by the automatic pilot or manually. Despite<br />

a simplification of the sequences and a slight reduction in<br />

the mental workload during this delicate phase for the crew,<br />

« the system must be able to anticipate. The data must be<br />

calculated before the mission starts. When the approach begins,<br />

sequencing is performed at the navigation level to validate the<br />

acquisition of points and control the accuracy of navigation so<br />

that the approach can be maintained. If this one is lost, we carry<br />

out an extraction procedure in order to resume the approach. »<br />

HI I 47

HELICOPTER INDUSTRY I PARAPUBLIC I<br />

WINNING COMBINATION<br />

As you can see, this new procedure should allow the Civil<br />

Security teams to play on the time parameter, especially<br />

for the benefit of injured people repatriated to Grenoble<br />

University Hospital. Beyond that, it will make the delicate<br />

phase of the approach in a complex sector a little safer, and<br />

at the same time, reduce kerosene consumption. This is<br />

an important factor, given that the unit can carry out up to<br />

1,500 missions a year. « This gives us the advantage of leaving<br />

with less fuel, and therefore improve performance, especially<br />

when we need to get as close as possible to the victims to be<br />

assisted, » adds the pilot. Using this procedure allows us, for<br />

example, to save four minutes on a trip from Alpe d’Huez<br />

to Grenoble University Hospital. However, while the use of<br />

technology has made the approach phase easier, it would<br />

not be effective without the knowledge and experience of<br />

the field acquired over the years by the crews. A winning<br />

combination, according to the head of the Grenoble base:<br />

« We still have the advantage of experience in the areas where<br />

we work, because we’ve been based there for many years.<br />

This gives us a very good understanding of our environment,<br />

which is essential for our missions. » It’s therefore easy to<br />

understand the importance and validity of such a man/<br />

machine combination, which nevertheless remains subject<br />

to external hazards, especially from other aircraft in the<br />

vicinity, despite local control, as Guillermet points out: «<br />

There’s a lot of work to be done on the separation of traffic,<br />

between an IFR helicopter and a whole bunch of aircraft that are<br />

VFR below and above the layer. »<br />

A PROCEDURE RESERVED<br />

FOR CIVIL SECURITY<br />

The implementation of this procedure, which may seem<br />

a little long in view of the tools available for more than a<br />

decade, is nevertheless quite logical, as Renaud Guillermet<br />

explains: «When I arrived in Grenoble fifteen years ago, we<br />

were just two IFR pilots. Things have obviously changed a lot.<br />

To carry out this procedure, we started from scratch, without<br />

involving the time parameter. In eliminating this constraint,<br />

we were able to move forward in the right direction, avoiding<br />

unnecessary pressure. »<br />

HI I 48

The tests, which lasted almost three years, were carried out<br />

in direct collaboration between the Dragon 38 teams and the<br />

DGAC. In order to validate the IFR points, the French civil<br />

aviation agency provided a special calibration bench on<br />

board one of the Civil Security machines. « The DGAC teams<br />

really did a remarkable job. They listened to us and helped us<br />

move this program forward, » says the manager. At the same<br />

time, and at the request of the DSNA (Direction des services<br />

de la navigation aérienne de la DGAC), the crews of Dragon<br />

38 and 74 had to develop a theoretical and practical training<br />

program in order to obtain validation from the Direction de<br />

la sécurité de l’aviation civile (DSAC) at the end of March<br />

2020. At the same time, the controllers at Versoud received<br />

specific training to welcome the Dragons in IFR. « We are<br />

pioneers, » says Renaud Guillermet. « Things will undoubtedly<br />

evolve, and that’s what this type of program is all about. Among<br />

other things, we’ll have to further refine the performance of<br />

the systems, always taking into account the specific nature of<br />

our missions in the heart of the Alpine valley, in uncontrolled<br />

airspace. »<br />

After an edition at the AIP (Aeronautical Information<br />

Publication) on March 26th, 2020, this Performance Based<br />

Navigation (PBN) approach remains, for the DSAC, a<br />

procedure exclusively reserved for Civil Security. « A procedure<br />

tailored to our needs, but for the time being exclusively intended<br />

for pilots at the Annecy and Grenoble bases » said Renaud<br />

Guillermet. However, depending on requirements, it could be<br />

opened up to other state operators (Gendarmerie), or even<br />

private operators of the EC145. For these airspace users, it<br />

would then be necessary to go through a private organization<br />

in order to validate the entire procedure.<br />

MORE ABOUT SÉCURITÉ CIVILE<br />

HI I 49

HELICOPTER INDUSTRY I OPERATOR I<br />

BY FRÉDÉRIC LERT<br />

©FRÉDÉRIC LERT<br />

HI I 50

HI I 51

HELICOPTER INDUSTRY I OPERATOR I<br />

H<br />

istorically a specialist in heliborne electrical work, Airtelis, a subsidiary of RTE (Ré-seau de<br />

Transport d’Electricité), is the only user in Europe of two H225s fully equipped for aerial work.<br />

Illustration with a power line reconstruction site in the Ariège valley.<br />

A valley located in the heart of the French Pyrenees. The national road number 20 traces its path<br />

towards Andorra and Spain, sharing the little free space between the railway line and the Ariège River.<br />

A few kilometers before arriving at Savignac les Ormeaux, turn right, then take a small road that climbs<br />

up to the foothills of the mountain, progress a few hundred meters to reach the Airtelis caravan and its<br />

technical assistance trucks that have settled on a flat stretch of land. This is the ideal spot to set up the<br />

base camp for the current construction site: the renovation of a few kilometers of a high-voltage power<br />

line, the dismantling and removal of the old cables and pylons, and the installation of new equipment.<br />

It took two weeks of work, a job site like no other for the Airtelis team and its H225, which accumulates<br />

up to six hours of flight time every day.<br />

HI I 52

SUPERTRAMP TOUR<br />

The H225 is the heavyweight model of the operator<br />