Helicopter Industry #103

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

HELICOPTER INDUSTRY I LEGACY I<br />

TECHNOLOGY PUZZLE<br />

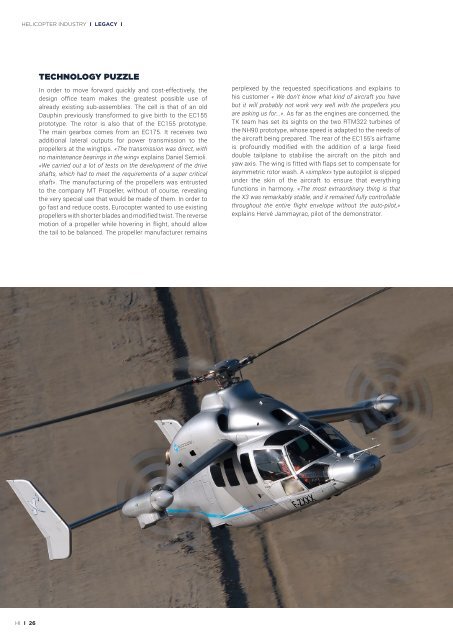

In order to move forward quickly and cost-effectively, the<br />

design office team makes the greatest possible use of<br />

already existing sub-assemblies. The cell is that of an old<br />

Dauphin previously transformed to give birth to the EC155<br />

prototype. The rotor is also that of the EC155 prototype.<br />

The main gearbox comes from an EC175. It receives two<br />

additional lateral outputs for power transmission to the<br />

propellers at the wingtips. «The transmission was direct, with<br />

no maintenance bearings in the wing» explains Daniel Semioli.<br />

«We carried out a lot of tests on the development of the drive<br />

shafts, which had to meet the requirements of a super critical<br />

shaft». The manufacturing of the propellers was entrusted<br />

to the company MT Propeller, without of course, revealing<br />

the very special use that would be made of them. In order to<br />

go fast and reduce costs, Eurocopter wanted to use existing<br />

propellers with shorter blades and modified twist. The reverse<br />

motion of a propeller while hovering in flight, should allow<br />

the tail to be balanced. The propeller manufacturer remains<br />

perplexed by the requested specifications and explains to<br />

his customer « We don’t know what kind of aircraft you have<br />

but it will probably not work very well with the propellers you<br />

are asking us for...». As far as the engines are concerned, the<br />

TK team has set its sights on the two RTM322 turbines of<br />

the NH90 prototype, whose speed is adapted to the needs of<br />

the aircraft being prepared. The rear of the EC155’s airframe<br />

is profoundly modified with the addition of a large fixed<br />

double tailplane to stabilise the aircraft on the pitch and<br />

yaw axis. The wing is fitted with flaps set to compensate for<br />

asymmetric rotor wash. A «simplex» type autopilot is slipped<br />

under the skin of the aircraft to ensure that everything<br />

functions in harmony. «The most extraordinary thing is that<br />

the X3 was remarkably stable, and it remained fully controllable<br />

throughout the entire flight envelope without the auto-pilot,»<br />

explains Hervé Jammayrac, pilot of the demonstrator.<br />

HI I 26