Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

56<br />

FLUSH-TYPE GREASE NIPPLES WITH SELF-FORMING THREAD<br />

APPLICATION AREA<br />

By using UMETA grease nip<strong>pl</strong>es with self-forming thread (SFT / SFG)<br />

you effectively save the thread-cutting process in the borehole.<br />

VERSIONS<br />

For safety reasons and in order to avoid abrasion wear, the DIN standard for<br />

grease nip<strong>pl</strong>es with self-forming thread demands a specific surface hardness<br />

of 650 HV minimum as well as a particularly wide flank angle of 105° at<br />

the thread. Therefore, we operate this decisive process in our own curing<br />

oven. For a better visual distinction, UMETA self-forming grease nip<strong>pl</strong>es are<br />

yellow passivated. Upon request, they are also available in another surface<br />

colour, e. g. blue passivated = silver coloured.<br />

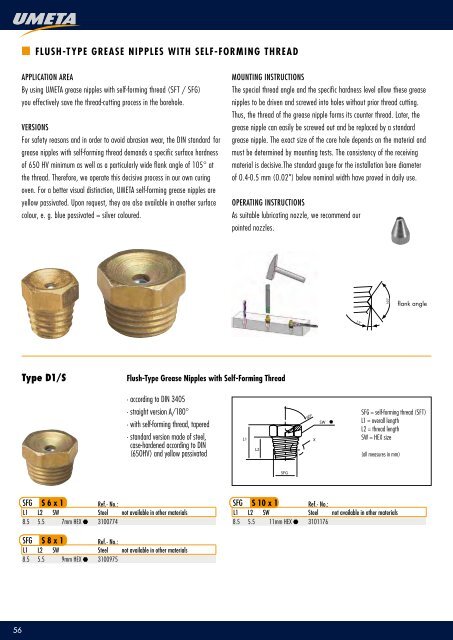

Type D1/S<br />

SFG S 6 x 1<br />

Ref.- No.:<br />

L1 L2 SW Steel not available in other materials<br />

8.5 5.5 7mm HEX 3100774<br />

SFG S 8 x 1<br />

Ref.- No.:<br />

L1 L2 SW Steel not available in other materials<br />

8.5 5.5 9mm HEX 3100975<br />

Flush-Type Grease Nip<strong>pl</strong>es with Self-Forming Thread<br />

· according to DIN 3405<br />

· straight version A/180°<br />

· with self-forming thread, tapered<br />

· standard version made of steel,<br />

case-hardened according to DIN<br />

(650HV) and yellow passivated<br />

MOUNTING INSTRUCTIONS<br />

The special thread angle and the specific hardness level allow these grease<br />

nip<strong>pl</strong>es to be driven and screwed into holes without prior thread cutting.<br />

Thus, the thread of the grease nip<strong>pl</strong>e forms its counter thread. Later, the<br />

grease nip<strong>pl</strong>e can easily be screwed out and be re<strong>pl</strong>aced by a standard<br />

grease nip<strong>pl</strong>e. The exact size of the core hole depends on the material and<br />

must be determined by mounting tests. The consistency of the receiving<br />

material is decisive.The standard gauge for the installation bore diameter<br />

of 0.4-0.5 mm (0.02") below nominal width have proved in daily use.<br />

OPERATING INSTRUCTIONS<br />

As suitable lubricating nozzle, we recommend our<br />

pointed nozzles.<br />

L1<br />

L2<br />

SFG<br />

60º<br />

X<br />

SFG S 10 x 1<br />

Ref.- No.:<br />

L1 L2 SW Steel not available in other materials<br />

8.5 5.5 11mm HEX 3101176<br />

SW<br />

7,5°<br />

105°<br />

SFG = self-forming thread (SFT)<br />

L1 = overall length<br />

L2 = thread length<br />

SW = HEX size<br />

(all measures in mm)<br />

Flankenwinkel flank angle