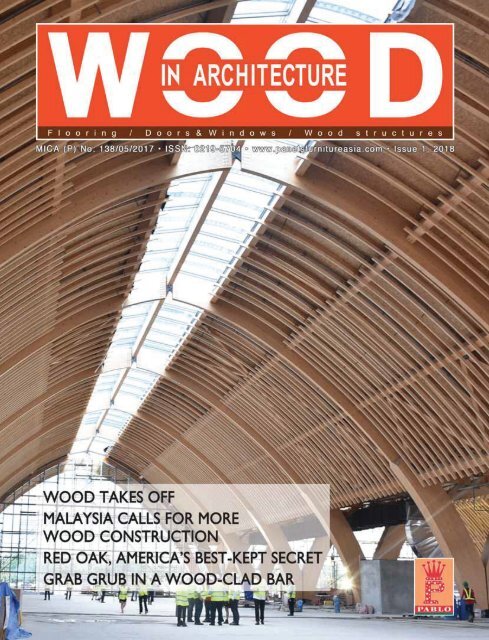

Wood In Architecture Issue 1, 2018

First published in 2017, Wood in Architecture (WIA) is a bi-annual trade magazine devoted to the international timber construction sector. The newest addition to the Panels & Furniture Group of wood magazines, WIA features in-depth insights to the latest industry news, incredible projects and leading trade events. WIA is an advocate for timber as a material of choice for today’s built environment, and is the perfect source of inspiration for architects, builders, engineers and interior designers across the globe.

First published in 2017, Wood in Architecture (WIA) is a bi-annual trade magazine devoted to the international timber construction sector. The newest addition to the Panels & Furniture Group of wood magazines, WIA features in-depth insights to the latest industry news, incredible projects and leading trade events. WIA is an advocate for timber as a material of choice for today’s built environment, and is the perfect source of inspiration for architects, builders, engineers and interior designers across the globe.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

04 Editor’s Note: A meless classic<br />

<br />

12 American white oak glulam for Lord’s Cricket Ground<br />

<br />

16 <strong>Wood</strong> takes o<br />

<br />

26 Nature’s advocate<br />

<br />

31 Liquid kitchen<br />

<br />

40 New tool to assist due diligence<br />

42 Red oak, America’s best-kept secret uncovered<br />

<br />

48 Prey Fit<br />

50 European laminate ooring sees renewed demand from Asia<br />

52 mura: Versale, durable and sustainable<br />

54 Masters of innovaon<br />

56 <br />

61 <br />

63 <br />

64

Singapore MICA (P) No. 138/05/2017<br />

panelsfurnitureasia.com<br />

Editor | Lee Zhuomin<br />

zhuominlee@pabloasia.com<br />

Assistant Editor | Pang Yanrong<br />

yanrong@pabloasia.com<br />

Assistant Editor | Sarah Si<br />

sarahsi@pabloasia.com<br />

Lee Zhuomin | Editor<br />

Deputy Executive Editor (Chinese Edition)<br />

Wendy Wei | pabloshanghai@163.net<br />

Graphic Designer | Edwin De Souza<br />

edwin@pabloasia.com<br />

Admin & Circulation Manager | Shu Ai Ling<br />

circulation@pabloasia.com<br />

General Manager,<br />

Pablo Beijing & Shanghai | Ellen Gao<br />

pablobeijing@163.com<br />

Associate Publisher | Pamela Buckley<br />

pamela@pabloasia.com<br />

A<br />

university recruitment advertisement in the subway reads: Her grandmother lived<br />

in a wooden house; her mother lived in a concrete building; what would her children live in?<br />

<strong>Wood</strong> was always the go-to material when people needed to erect shelters. <strong>In</strong><br />

Southeast Asia’s tropics, generations lived under the same wooden roof and in close-knit<br />

kampongs for security and community. As industrialisation kicked in, these kampongs—and<br />

the community spirit—slowly disappeared to make way for modern cities.<br />

Malaysian architect Azman Md Nor once lived in such a kampong where most<br />

household items were made of wood. It was how he started adopting this material for<br />

his projects and eventually became a keen evangelist for it. He bagged the second prize<br />

for his project, Anjung Kelana, at the inaugural Malaysian <strong>Wood</strong> Awards in 2017 (p. 26).<br />

While the Philippines is probably the last place in the world you’d expect to find a wooden<br />

airport, one is currently being built in Cebu. It will be completed by June <strong>2018</strong> (p. 16).<br />

Although times have changed, wood is still as popular today as it was yesterday. The<br />

same unassuming material is a constant in structural and interior applications. It is strong,<br />

versatile and durable, easy to machine, seismic and fire resistant, and quick to put up. It<br />

stores carbon as the building stands, making it a favourite of eco-conscious architects<br />

and urban planners. It is a classic in a “you can’t go wrong with it” way in modern interior<br />

design. It is well-loved for its earthy feel in flooring (p. 48), it adds a dash of elegance to<br />

posh places (p. 31).<br />

With so many uses for wood, you may be forgiven for wondering how the earth<br />

will ever satiate the appetite for more. The truth is, wood use encourages responsible<br />

forest ownership so the lumber shop will always be in business. The plant-as-you-harvest<br />

algorithm is complex but we have tried to simplify an example on p. 40.<br />

Coming back to “what would her children live in,” we think it is going to be a wooden<br />

skyscraper. | WIA MENA<br />

CONNECT WITH US:<br />

Publisher | William Pang<br />

williampang@pabloasia.com<br />

<strong>Wood</strong> in <strong>Architecture</strong> is a member of<br />

PABLO PUBLISHING PTE LTD<br />

Pablo Publishing Pte Ltd<br />

3 Ang Mo Kio ■ Street 62 ■ #01-23 ■ Link@AMK<br />

Singapore 569139 ■ Tel: (65) 6266 5512<br />

E-mail : info@pabloasia.com<br />

Website : www.panelsfurnitureasia.com<br />

Company Registration No: 200001473N<br />

All rights reserved. Views of writers do not necessarily reflect the views of the<br />

Publisher. No part of this publication may be reproduced in any form or by any<br />

means, without prior permission in writing from the Publisher and copyright<br />

owner. Whilst every care is taken to ensure accuracy of the information in<br />

this publication, the Publisher accepts no liability for damages caused by<br />

misinterpretation of information, expressed or implied, within the pages of<br />

the magazine. All advertisements are accepted on the understanding that the<br />

Advertiser is authorised to publish the contents of the advertisements, and in<br />

this respect, the Advertiser shall indemnify the Publisher against all claims<br />

or suits for libel, violation of right of privacy and copyright infringements.<br />

<strong>Wood</strong> in <strong>Architecture</strong> MENA is a controlled-circulation magazine with two<br />

issues a year. It is mailed free-of-charge to readers who meet a set of criteria.<br />

Paid subscription is available to those who do not fit our terms of control.<br />

Please refer to subscription form provided in the publication for more details.<br />

Printed by Times Printers Pte Ltd<br />

@panelsfurnitureasia<br />

4 ISSUE 1 • <strong>2018</strong> • WOOD IN ARCHITECTURE

<strong>2018</strong><br />

by Panels & Furniture Group<br />

4 th Edition<br />

25 – 27 June <strong>2018</strong><br />

Shanghai, China<br />

ASIA’S SPECIALISED WOOD MATERIALS<br />

WOOD PRODUCTS TRADE SHOW<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

www.sylvawoodexpo.com

NEWS<br />

SOUTH KOREA RAISES GDP FORECAST TO<br />

3%, BUT WOOD DEMAND TO REMAIN LOW AS<br />

FEWER HOUSING STARTS EXPECTED<br />

By Tai Jeong, Canada <strong>Wood</strong> Korea<br />

- Domestic consumption forecast to rise 0.1 percentage point<br />

- Fewer housing starts and building permits issued in first 11 months of 2017<br />

- Lower lumber demand expected as cooling measures on housing to continue into <strong>2018</strong><br />

Bank of Korea has raised South<br />

Korea’s GDP growth forecast for <strong>2018</strong> to<br />

three per cent on the back of domesc<br />

consumpon recovery and robust export<br />

growth.<br />

With minimum wages raised by 16<br />

per cent to 7,530 Won (US$6.60)—the<br />

biggest jump in about two decades—<br />

starng this year, consumer prices are<br />

expected to rise by 1.7 per cent.<br />

February’s Winter Olympics will<br />

also boost private consumpon by 0.1<br />

percentage point in the rst quarter of<br />

this year.<br />

The Korean Won fell to a three-year<br />

low of 1,061.2 Won against the U.S. Dollar<br />

on January 2. Analysts say this will further<br />

fall below 1,000 Won if the geopolical<br />

risk on the Korean Peninsula eases.<br />

2017 TRADE<br />

Exports soared to an all-time high of<br />

US$573.9 billion in 2017, a 16 per cent<br />

increase thanks to recovery in the global<br />

economy.<br />

Trade volume exceeded US$1 trillion,<br />

as imports expanded 17.7 per cent to<br />

US$478.1 billion.<br />

Consumer prices grew 1.9 per cent<br />

in 2017 from a year earlier, marking the<br />

steepest gain in ve years since 2012, on<br />

the back of a strong industrial goods and<br />

nancial services sector.<br />

Unemployment stood at 3.3 per cent<br />

in December, up 0.1 percentage point<br />

from a year earlier.<br />

HOUSING CONSTRUCTION<br />

Cooling measures on South Korea’s<br />

housing market have seen fewer starts<br />

and building permits, especially in the new<br />

apartment market in Seoul.<br />

Housing starts fell 14.6 per cent<br />

to 90,497 while the number of units<br />

signicantly decreased 23.2 per cent to<br />

440,382 units in Nov last year.<br />

Housing permits during this period<br />

also dropped 10.2 per cent and 13.2 per<br />

cent respecvely to 107,308 and 552,558<br />

from a year earlier.<br />

While the overall residential<br />

construction sector is struggling, the<br />

number of wood building permits issued<br />

in the rst 11 months of 2017 increased<br />

1.7 per cent to 15,841 buildings from<br />

a year earlier. <strong>Wood</strong> building starts,<br />

however, fell 6.5 per cent to 12,954<br />

buildings during this period.<br />

The total oor area of wood building<br />

permits for the same period in 2017<br />

increased 5.8 per cent to 1,451,320m 2<br />

but that of wood building starts decreased<br />

slightly 3.8 per cent to 1,198,515m 2 from<br />

a year earlier.<br />

LUMBER SHIPMENTS<br />

B.C. sowood lumber exports to South<br />

Korea for the rst 11 months of 2017 fell<br />

5.7 per cent to 238,184cbm compared<br />

to 252,651cbm during the same period<br />

in 2016.<br />

This is mainly due to the government’s<br />

efforts in limiting the supply of new<br />

homes (from August 2016), especially<br />

apartments in Seoul to keep household<br />

debt and rising home prices in check.<br />

However, the export value for the<br />

same period rose a slight 2.8 per cent to<br />

US$54.6 million (CAD$68.678 million) for<br />

the same period in 2016.<br />

Lumber prices in Canada have trended<br />

upward for almost two years and reached<br />

13-year highs in July, 2016. On the other<br />

hand, Nordic lumber prices have been<br />

depressed in U.S. Dollar terms, resulng<br />

their current price levels to be the lowest<br />

they have been in eight years. | WIA<br />

<strong>Wood</strong> construction in South Korea: The Forest<br />

Genetic Resources Department at the Korea<br />

Forest Research <strong>In</strong>stitute features the largest<br />

wood-framed building in the country.<br />

6 ISSUE 1 • <strong>2018</strong> • WOOD IN ARCHITECTURE

NEWS<br />

JAPANESE CONSTRUCTION COMPANY<br />

DEBUTS FIREPROOF WOODEN PILLAR,<br />

DRIVES ADVENT OF WOODEN HIGH-RISES<br />

Japanese construcon company has<br />

developed a wooden pillar capable of<br />

withstanding re for three hours without<br />

burning down.<br />

Shelter Co.’s invention will allow<br />

future wooden buildings to be largerscaled,<br />

scoring one for high-rise wood<br />

construcon.<br />

“Japan has a tradition of wooden<br />

buildings, such as Shinto shrines and<br />

Buddhist temples, that are unparalleled<br />

in the world,” Shelter President<br />

Kazuyoshi Kimura said in an interview<br />

with Asahi Shimbun. “We would also<br />

be able to pursue urban planning<br />

with wooden buildings even when<br />

it comes to modern architecture,<br />

where fire resistance and safety are<br />

required.”<br />

The pillar is a three-ply structure<br />

made of plasterboards covered with<br />

a rectangular wooden pillar. The<br />

plasterboards, in turn, are wrapped with<br />

yet another layer of wood.<br />

When tested in a furnace, the<br />

wooden cover as well as wet plaster<br />

kept the interior rectangular pillar safe.<br />

There were no burn marks on it even<br />

aer being exposed to temperatures up<br />

to 1,000 degrees Celsius for 12 hours.<br />

Shelter originally patented their<br />

invenon in 2009, and produced wooden<br />

products that could be used as pillars,<br />

walls or other building components<br />

capable of resisng re for an hour in<br />

2013, followed by more products that<br />

could withstand ames for two hours<br />

in 2015.<br />

The company has aained approval<br />

from the Ministry of Land, <strong>In</strong>frastructure,<br />

Transport and Tourism to apply the<br />

technology in structures reaching over<br />

15 storeys. | WIA<br />

A rendering of<br />

the pillar, where a<br />

rectangular wooden<br />

pillar is covered by<br />

plasterboards, which<br />

are, in turn, wrapped<br />

in yet another layer<br />

of wood.<br />

Image credit:<br />

Shelter Co.<br />

WOOD IN ARCHITECTURE • ISSUE 1 • <strong>2018</strong><br />

7

NEWS<br />

HEAVY INDUSTRIES MUST NOW PAY FOR<br />

WASTE EMISSIONS UNDER CHINA’S NEW<br />

ENVIRONMENT LAW<br />

By Lydia Chen, Canada <strong>Wood</strong><br />

rst environment protecon<br />

tax law kicked in on January 1 this year,<br />

replacing a pollutant discharge fee<br />

system which, for decades, had been in<br />

place but lacked teeth.<br />

Under the new law, companies will<br />

have to pay levies for waste discharged<br />

into the environment—such as sulphur<br />

dioxide and sewage. They will also be<br />

taxed for noise polluon.<br />

The tax rates range from 1.2 – 12<br />

yuan per unit of atmospheric polluon;<br />

1.4 – 14 yuan per unit of water polluon;<br />

ve yuan per tonne of coal waste; and<br />

1,000 yuan per tonne of hazardous<br />

waste. They are determined based<br />

on each company’s operations. For<br />

example, a furniture manufacturer that<br />

earns 50 million yuan per year may<br />

report an overall tax rate of 300,000<br />

– 700,000 yuan, or up to a two per<br />

cent increase on the factory price of its<br />

products, according to industry analysts.<br />

The new law is intended to<br />

discourage heavy-pollung industries,<br />

many which have ocked to the country<br />

to take advantage of its low costs and<br />

weak environmental regulaons.<br />

China has imposed a “pollutant<br />

discharge fee” since 1979. However,<br />

loopholes in the system have seen<br />

companies evading taxes, especially<br />

the bigger ones that contribute to the<br />

local economy. Now any tax reducon<br />

or exemption request must undergo<br />

strict approval procedures and be<br />

documented.<br />

Tackling pollution was listed as<br />

one of the "three tough bales” China<br />

aims to win in the next three years,<br />

according to the Central Economic Work<br />

Conference that concluded in December.<br />

“The launch of the environmental<br />

tax is more serious than the pollutant<br />

discharge fee system and marks<br />

China’s rst real eort to use nancial<br />

mechanisms to curb polluon,” Liang<br />

Yinlei, partner of Tax Department at<br />

Ernst & Young Greater China, said<br />

in an interview with Jiefang Daily.<br />

“Some manufacturers may buy more<br />

environmentally-friendly equipment to<br />

reduce its sewage waste in order to pay<br />

less tax.”<br />

Between January and November<br />

last year, China invesgated over 35,600<br />

cases of environmental violaon, a 102<br />

per cent year-on-year increase from<br />

2016. | WIA<br />

Stock image by veeterzy on Unsplash<br />

EXPECT SIGNIFICANT CHANGES IN DUBAI’S<br />

PROPERTY MARKET: DELOITTE<br />

will be a year of change for Dubai’s<br />

real estate market. Across the hospitality,<br />

residenal, retail, oce and industrial<br />

segments, events such as the introducon<br />

of Value Added Tax (VAT) and 3D prinng<br />

will transform the property sector,<br />

according to a new report from Deloie.<br />

“Developers, operators and investors<br />

will need to navigate their way through<br />

increasing geopolical uncertainty, the<br />

adopon of disrupve technologies and<br />

the introducon of VAT. How well they do<br />

so will determine their performance in<br />

<strong>2018</strong> and beyond,” Marn Cooper, head<br />

of Development Strategy & <strong>In</strong>vestment<br />

in Deloie’s Real Estate and Construcon<br />

team, said.<br />

The introducon of VAT in the UAE will<br />

represent one of the biggest challenges<br />

for Dubai’s real estate market.<br />

“It not only forces the real estate<br />

sector to relook at their own pracces and<br />

procedures, but those of businesses in the<br />

value chain with whom they interact,”<br />

Bruce Hamilton, a partner in Deloie’s<br />

<strong>In</strong>direct Tax team, said.<br />

“How well the real estate market, of<br />

whom developers are a crucial sector,<br />

comes to grips with these changes could<br />

impact the sector in <strong>2018</strong> and for years<br />

to come.”<br />

<strong>In</strong> addition, the introduction of<br />

VAT on construction materials and<br />

professional services may cause cash<br />

ow and working capital pressures for<br />

some developers.<br />

Disruptive technologies such as<br />

3D printing will also become more<br />

mainstream. The city is targeng for 25<br />

per cent of new buildings to be 3D printed<br />

by 2025.<br />

Other changes to expect are a more<br />

diverse development nance market and<br />

increased connecvity with the global<br />

economy. | WIA<br />

8 ISSUE 1 • <strong>2018</strong> • WOOD IN ARCHITECTURE

NEWS<br />

MENA TO MORE THAN TRIPLE<br />

RENEWABLE ENERGY USE BY 2035<br />

Middle East is expected to more<br />

than triple its share of renewables<br />

in the power mix from 5.6 per cent<br />

(16.7 gigawas) in 2016 to 20.6 per cent<br />

(100GW) in 2035, according to a new<br />

report by Siemens.<br />

Natural gas will remain the<br />

number one power source in the<br />

region, represenng 60 per cent of<br />

installed capacity through 2035.<br />

“We expect the majority of new<br />

power generation capacity to be<br />

via highly efficient combined-cycle<br />

power plants, but renewables will<br />

also gain a substantially increased<br />

share of the energy mix,” said Dietmar<br />

Siersdorfer, CEO, Siemens Middle East<br />

and UAE.<br />

With economic diversification<br />

and populaon growth accelerang,<br />

the growth in power demand in the<br />

region—approximately 3.3 per cent<br />

per year—will be realised through<br />

efficient natural gas-fired power<br />

plants.<br />

Aside from new capacity<br />

addions, an addional 45GW could<br />

also be realised through eciencies<br />

brought about by upgrading facilies<br />

above 30 years old.<br />

By 2035, the region will require a<br />

total of 483GW of power generaon<br />

capacity, an addional 277 GW from<br />

2016.<br />

Solar power will account for<br />

addions of around 61GW. There is<br />

signicant potenal for wind power<br />

generaon in Saudi Arabia and Egypt,<br />

but this potential is not entirely<br />

reflected in the moderate capacity<br />

addions expected.<br />

The report also highlights<br />

digitalisation as a tool to increase<br />

the eciency and exibility of energy<br />

supply, while decreasing producon<br />

costs.<br />

“Digitalisaon is an essenal part of<br />

the future energy landscape, and turning<br />

big data into smart data will enable us<br />

to be more reliable, energy efficient<br />

and cost effective,” said Siersdorfer.<br />

“However, we must remember that with<br />

greater interconnecvity, the use of data<br />

analycs and cloud technologies comes<br />

with greater exposure to cyber security<br />

threats so organisaons need to be well<br />

prepared.” | WIA<br />

WOOD IN ARCHITECTURE • ISSUE 1 • <strong>2018</strong><br />

9

NEWS<br />

FIRST WOODEN SKYSCRAPER PROPOSED IN<br />

AFRICA WINS INAUGURAL WAFX PRIZE<br />

first proposed wooden<br />

high-rise is a mixed-use condominium<br />

consisng residenal spaces, sporng<br />

facilies, sky gardens and a carpark.<br />

The 87-metre tall Lagos <strong>Wood</strong>en<br />

Tower is designed by Hermann Kamte,<br />

an architect from Cameroon. It aims<br />

to improve the urban conditions of<br />

the residents living in the Nigerian<br />

city. It also addresses the problem of<br />

poorly-planned construcon in many<br />

African cies by pushing the boundaries<br />

of contemporary<br />

architecture.<br />

The brief was<br />

initially submitted<br />

for Metsä <strong>Wood</strong>'s<br />

City Above the<br />

City, a global<br />

competition that<br />

invited architects<br />

to rethink new<br />

housing on top<br />

of existing urban<br />

buildings.<br />

Recognised<br />

as one of the<br />

world’s most<br />

forward-looking<br />

architectural<br />

concepts, the<br />

Lagos Tower won<br />

the Best Cultural<br />

Identity project at<br />

the inaugural WAFX<br />

Prize in 2017, along<br />

with the Rethinking<br />

the Future Awards<br />

2017. The project<br />

was also a finalist<br />

at the World<br />

<strong>Architecture</strong><br />

Fesval 2017.<br />

"<strong>Architecture</strong> is simple and<br />

incredibly complex at the same me,"<br />

Kamte said. "The challenges are many,<br />

but the potenal rewards are high. <strong>In</strong> my<br />

opinion, architects are like philosophers<br />

- the more they learn the beer they<br />

are.”<br />

The 25-year-old Cameroonian<br />

graduated from the presgious EAMAU<br />

in 2016 and went on to found his own<br />

pracce, Hermann Kamte & Associates<br />

(HKA) in Yaounde, the capital of his<br />

home country. His projects are mainly<br />

based in central African countries such<br />

as Nigeria, Niger and Chad.<br />

"HKA is just embarking on its journey,<br />

but we want to bring a new dynamic to<br />

African architecture," he said. "Our goal<br />

is to contribute to shaping the world, to<br />

ensuring human well-being in harmony<br />

with nature through our designs."<br />

Although African designers and<br />

builders sll use concrete and bricks as<br />

they are far easier and a lot cheaper to<br />

procure, wood, a sustainable resource<br />

could benet African society at large,<br />

Metsä <strong>Wood</strong> wrote in a statement.<br />

“There is sll potenal for this to<br />

change. As we raise the prole of mberbased<br />

architecture, the demand will<br />

grow and wooden building soluons will<br />

become cheaper and more accessible,"<br />

it noted.<br />

"The Lagos design project has<br />

really caught people's attention and<br />

highlighted the potential of wood<br />

construcon in Africa.” | WIA<br />

The 87-metre tall Lagos <strong>Wood</strong>en Tower<br />

could be a trendsetter in Africa.<br />

RECLAIMED WOOD AMONG MATERIAL<br />

TRENDS TO KEEP AN EYE ON IN <strong>2018</strong><br />

and repurposed wood is<br />

one of the trends to look out for in <strong>2018</strong><br />

according to Architect Magazine.<br />

Warm and visually pleasing to the<br />

eye, repurposed wood has become a<br />

choice for architects and designers for<br />

reasons that range from aesthetic to<br />

environmental.<br />

It claims an even smaller ecological<br />

footprint than virgin wood, which<br />

already boasts a smaller carbon footprint<br />

compared to other materials.<br />

A number of companies is already<br />

exploring the opon, with Houtmerk,<br />

based in the Netherlands, making panels<br />

of solid wood called Replex produced<br />

from pieces of recycled wood.<br />

<strong>In</strong> the UK, designer Tristan Titeux<br />

uses not only discarded wood furniture,<br />

but reused MDF, parcleboard, plywood<br />

and engineered lumber as well.<br />

Other material trends include<br />

bioplastic from algae, biomimetic<br />

insulaon, and photovoltaic glass. | WIA<br />

10 ISSUE 1 • <strong>2018</strong> • WOOD IN ARCHITECTURE

NEWS<br />

2017 WOOD DESIGN AND BUILDING<br />

AWARD WINNERS ANNOUNCED<br />

of the presgious 2017<br />

<strong>Wood</strong> Design & Building Awards<br />

programme by the <strong>Wood</strong> Design<br />

& Building magazine have been<br />

announced.<br />

The winning projects were selected<br />

by an esteemed architectural jury<br />

consisting Alan Organschi, principal<br />

at Gray Organschi <strong>Architecture</strong>; Betsy<br />

Williamson, principal at Williamson<br />

Williamson; and Richard Bonnin,<br />

design principal, HGA Architects and<br />

Engineers.<br />

The Canadian <strong>Wood</strong> Council, as<br />

well as the sponsors, Sustainable<br />

Forestry <strong>In</strong>iave, Sansin and Western<br />

Red Cedar, also granted special awards<br />

unique to the programme in 2017. Two<br />

special jury awards were selected, one<br />

for technical innovaon, and another<br />

for public art educaon.<br />

An opportunity to showcase<br />

exceponal wood buildings that inspire<br />

designers to push the boundaries of<br />

wood in construction, submissions<br />

for the awards programme were<br />

thoughtfully designed and perfectly<br />

highlighted wood’s aesthec, funconal<br />

and structural qualies.<br />

“The <strong>Wood</strong> Design & Building Awards<br />

programme has been in existence for<br />

over 30 years,” Eenne Lalonde, vice<br />

president of Market Development for<br />

the Canadian <strong>Wood</strong>, explained. “We’ve<br />

been continually impressed with the<br />

quality of submissions each year, and<br />

it’s a testament to the sophiscaon of<br />

wood products, due to improvements<br />

in technology and advancements in<br />

applicaons.” | WIA<br />

Rundquist Architects<br />

got a Merit for the<br />

<strong>Wood</strong>en Ventilation<br />

Towers, located in<br />

Stockholm, Sweden.<br />

Image courtesy of the<br />

2017 <strong>Wood</strong> Design<br />

& Building Awards<br />

Programme.<br />

WOOD IN ARCHITECTURE • ISSUE 1 • <strong>2018</strong><br />

11

ENGINEERED WOOD<br />

12 ISSUE 1 • <strong>2018</strong> • WOOD IN ARCHITECTURE

ENGINEERED WOOD<br />

“This large-scale commercial application of white oak glulam<br />

should really open architects’ eyes to this alternative option<br />

for their structural materials portfolio…”<br />

WOOD IN ARCHITECTURE • ISSUE 1 • <strong>2018</strong><br />

13

ENGINEERED WOOD<br />

An engineering marvel made of<br />

American white oak features<br />

in the redevelopment of the<br />

Warner Stand at Lord’s Cricket Ground<br />

in London. The primary structure of the<br />

roof is formed from 11 canlever gluelaminated<br />

(glulam) beams, up to 23<br />

metres long, the rst me the species<br />

has been employed in this format on<br />

this scale.<br />

Architects Populous wanted to<br />

create a building that had the impression<br />

of lightness—hence the canopy<br />

comprising fabric rather than glass, and<br />

the 13-metre canlevered secon that<br />

makes it seem to oat over the crowd.<br />

“We wanted to capture cricket’s<br />

summer character and the ambience<br />

of a local club marquee,” said Philip<br />

Johnson, senior principal and project<br />

lead at Populous.<br />

The new four-storey stand has 2,656<br />

seats with improved sightlines, a new<br />

match control suite and beer facilies.<br />

Sustainability is also at the forefront of<br />

the design thinking, with solar thermal<br />

and photovoltaic roof panels to generate<br />

power. It replaces a 1950s structure<br />

and is part of an ongoing masterplan to<br />

improve visitor experience and boost<br />

the internaonal reputaon of Lord’s.<br />

14 ISSUE 1 • <strong>2018</strong> • WOOD IN ARCHITECTURE

ENGINEERED WOOD<br />

Part of the brief was also to have its own visual identy,<br />

while sing sympathecally alongside Lord’s other buildings.<br />

“Lord’s comprises individual stand styles rather than one<br />

stadium design; it’s an architectural campus, described as<br />

‘pavilions around a village green’, so we made design nods to<br />

the other stands, notably the tent-like fabric roof of the Mound<br />

Stand,” Johnson added.<br />

WOOD TECHNICALITIES<br />

American white oak came on the scene through discussions<br />

between Arup and the American Hardwood Export Council,<br />

which also provided technical advice and helped source the<br />

mber.<br />

“The imaginaon of the architects, the inspiraon of the<br />

engineers and the skill and tenacity of the fabricators have<br />

produced a landmark structure, which is a pivotal moment in<br />

the evoluon of mber construcon. This is also an excing<br />

moment for us (AHEC), turning our vision of what might be<br />

possible structurally with our hardwoods, into a reality,” said<br />

David Venables, AHEC European Director.<br />

The American white oak beams were manufactured<br />

by German timber specialist Hess Timber. Each beam<br />

measures 900mm x 350mm at the deepest point. The longest<br />

glulam beam weighs approximately four tonnes and<br />

measures 23.4 metres in length. The AHEC Grown in Seconds<br />

sustainability calculator showed that the 100m 3 of American<br />

white oak lumber used to fabricate the beams would take only<br />

160 seconds to be replaced in the American forest.<br />

“An advantage of American white oak’s stiffness and<br />

uniformity was that we could predict deecon levels and<br />

camber very precisely,” said Markus Golinski, head of Sales,<br />

Hess Timber.<br />

The beams also extend back using the same roof fabric,<br />

but double-skinned with a mid-layer of Aerogel insulaon. “So<br />

we have the same translucency, but, combined with double<br />

glazing and renewables, including ground source heang, it<br />

enables the building to be used for hospitality all year round.<br />

Then on summer match days the wide windows can be thrown<br />

open, creang one space that engages spectators with the<br />

game,” said Johnson.<br />

Lord’s new stand marks another milestone in American<br />

hardwoods’ dicult journey to get to this point in structural<br />

uses, but this project, Venables said, “should really open<br />

architects’ eyes to this alternave opon for their structural<br />

materials porolio at a me when they’re looking to build<br />

more with wood worldwide.” | WIA<br />

Project Details<br />

Client<br />

Location<br />

Completion : June 2017<br />

Architects<br />

Engineers<br />

Engineered wood manufacturer<br />

White oak supplier<br />

Photography<br />

: Marylebone Cricket Club (MCC)<br />

: London, United Kingdom<br />

: Populous<br />

: Arup<br />

: Hess Timber<br />

: Robinson Lumber<br />

: Jon Cardwell<br />

WOOD IN ARCHITECTURE • ISSUE 1 • <strong>2018</strong><br />

15

BIG PICTURE<br />

Airports: Kids seem to love rolling on their floors,<br />

the frequent flier wants to get out as soon as<br />

possible, others just want to go home. We all<br />

feel differently about being in transit and yet<br />

there is one absolute: waiting. Some airport<br />

authorities have decided on wood for their new<br />

terminals to enhance enjoyment, transforming<br />

waiting into something more pleasant. Here, we<br />

wouldn’t mind lingering on, just a little longer.<br />

16 ISSUE 1 • <strong>2018</strong> • WOOD IN ARCHITECTURE

BIG PICTURE<br />

WOOD IN ARCHITECTURE Jackson • ISSUE Hole Airport 1 • <strong>2018</strong><br />

17

BIG PICTURE<br />

<br />

<br />

<br />

<br />

<br />

Images By: Ivan Brodey, Knut Ranstad, Dag Spant<br />

<strong>Wood</strong> serves a practical and<br />

aesthetic purpose in Oslo’s new<br />

terminal expansion.<br />

The Oslo Airport Extension is one of<br />

those places we wished we could,<br />

like Tom Hanks in The Terminal,<br />

stay forever. It is not only dubbed the<br />

world’s greenest airport, it was also<br />

deliberately designed “to create a<br />

particular atmosphere… [especially]<br />

in areas where passengers spend<br />

a lot of time or where they want a<br />

certain amount of calm,” said Chrisan<br />

Henriksen, partner and design manager<br />

at Nordic Oce of <strong>Architecture</strong>.<br />

Architects Nordic were part of<br />

Aviaplan, the group behind the exisng<br />

airport building, which was completed<br />

in 1998 to handle 17 million passengers<br />

a year. 20 years later, the same firm<br />

added a 140,000sqm extension and<br />

modernised the train staon, doubling<br />

capacity to 32 million. Here, wood fulls<br />

its purpose as a structural element and<br />

design feature. “<strong>Wood</strong> denes us here<br />

in Scandinavia and it would therefore<br />

also define Oslo Airport,” Henriksen<br />

commented.<br />

Exposed glue-laminated (glulam)<br />

beams soar high above the busy ground<br />

while large panoramic windows enable<br />

passengers to enjoy the landscape<br />

around the airport.<br />

But the biggest change is a new<br />

300-metre-long pier that extends out<br />

18 ISSUE 1 • <strong>2018</strong> • WOOD IN ARCHITECTURE

onto the tarmac airside. The rounded<br />

pier is held up by glulam arches sourced<br />

from Scandinavian forests. The façade is<br />

mostly glass to let in as much daylight as<br />

possible, while the roof is nished with<br />

oak cladding, protected by a UV-resistant<br />

paint treatment. The wooden façade<br />

gives the pier an aracve aesthec,<br />

but its most important funcon relates<br />

to airport safety.<br />

“A pier that extends out towards<br />

the runways can cause problems<br />

for the air traffic control tower. The<br />

[communication] signals are highly<br />

sensive to distoron and can easily be<br />

reected, for example by metal, making<br />

the tracking on the ground suer. But<br />

with a wooden façade, the signals die<br />

when they hit the pier,” Henriksen said.<br />

<br />

<br />

The massive use of wood also met the<br />

strict environmental requirements set by<br />

the clients. Other low carbon footprint<br />

materials include concrete mixed with<br />

volcanic ash and recycled steel. The<br />

pier is rounded to minimise the external<br />

surface and so save energy. <strong>In</strong> winter,<br />

snow cleared from the runways is stored<br />

in an open pit covered with grained<br />

timber, which cools the terminal in<br />

summer. This reduces the terminal’s<br />

annual energy consumpon by 2 GWh.<br />

The design enables the airport to<br />

cut carbon emissions by 35 per cent<br />

and halve energy consumpon while<br />

at the same me increasing capacity.<br />

It achieved BREEAM “Excellent” rang,<br />

a global benchmark for sustainable<br />

design. WIA<br />

WOOD IN ARCHITECTURE • ISSUE 1 • <strong>2018</strong><br />

19

BIG PICTURE<br />

Construction of Terminal 2 is now underway and expected<br />

to complete in June <strong>2018</strong>. The most impressive feature<br />

of the building is the dramatic roof structure made of<br />

glulam beams.<br />

Image credit: GMR- MEGAWIDE Cebu Airport Corporation.<br />

20 ISSUE 1 • <strong>2018</strong> • WOOD IN ARCHITECTURE

BIG PICTURE<br />

The Philippines’ second largest airport is possibly<br />

the first in Southeast Asia to use engineered wood<br />

for its new terminal building.<br />

Blessed with warm sunshine and peanut buery beaches, it<br />

is no wonder Cebu receives so many visitors a year. Airport<br />

authories expect passenger arrivals to hit 10 million by the<br />

end of 2017, a 12 per cent jump from 2016.<br />

To cope with increasing air trac, the Filipino city is upgrading<br />

the exisng terminal and building a second one, making it the<br />

second largest airport in the country.<br />

The most impressive feature of the new terminal is the dramac<br />

roof structure made of glue-laminated mber beams. The arches<br />

span every 30 metres, which enables Terminal 2 to be as columnfree<br />

as possible. The internal spaces are enclosed by a light and<br />

transparent glazed façade. The arch façade is 15 metres tall and<br />

is accentuated by vercal U channels. With sleek, elegant curves,<br />

the undulang roof is reminiscent of the waves of the seas around<br />

Mactan Cebu Island.<br />

Construcon is already in full swing and expected to complete<br />

in June <strong>2018</strong>. The new terminal, spanning 65,500sqm, will increase<br />

passenger capacity to 12.5 million.<br />

Hong Kong-based <strong>In</strong>tegrated Design Associates (IDA) forms part<br />

of MCIA Terminal 2’s design team. It is also working in tandem with<br />

Budji Layug, Royal Pineda and Kenneth Cobunpue on the design<br />

and look-and-feel of the new terminal.<br />

Envisioned with a unique design that demonstrates the warmth<br />

and friendliness of the local culture, the project is set to transform<br />

the local airport into a world-class facility with a welcoming<br />

ambience that is disnctly Filipino. WIA<br />

WOOD IN ARCHITECTURE • ISSUE 1 • <strong>2018</strong><br />

21

BIG PICTURE<br />

Fort McMurray’s remote location,<br />

fluctuating temperatures and limited<br />

labour force meant that building its new<br />

airport had to be innovative and efficient,<br />

which can only mean one thing—wood<br />

construction.<br />

Major public areas are defined by a mass timber structure comprising cross-laminated timber (CLT) panels in<br />

North America — in this case salvaged from British Columbia’s pine beetle infestation. CLT offers a light and<br />

and reduce the carbon footprint and cost of construction.<br />

Image Credit: Ema Peter.<br />

Home to the boreal forest, the<br />

prairies and the northern lights,<br />

Fort McMurray is unbelievably<br />

beauful.<br />

The Regional Municipality of <strong>Wood</strong><br />

Buffalo in Northern Alberta expects<br />

populaon to double by 2030, thanks<br />

to a burgeoning oil sands industry that<br />

has thrusted the small community onto<br />

the global stage. This unprecedented<br />

growth has also created the impetus for<br />

a large transient populaon—temporary<br />

residents drawn to resource-based jobs<br />

who frequently y back home between<br />

work cycles.<br />

While Canada’s busiest airports have<br />

seen an average annual passenger trac<br />

growth rate of about three per cent a<br />

year, Fort McMurray grew 25 per cent<br />

in 2012 and 2013, and connues to be<br />

Canada’s fastest growing airport. This,<br />

along with more forecasted growth,<br />

inspired the Fort McMurray Airport<br />

Authority (FMAA) to build a new green-<br />

eld airport.<br />

The three-storey, 15,000sqm<br />

building was constructed with signicant<br />

o-site fabricaon, durable materials<br />

and simple technologies in order to<br />

ensure quality and minimise both<br />

the construcon schedule and future<br />

maintenance.<br />

Completed in 2014, the $258-million<br />

project is iconic and memorable, set in<br />

a landscape that is in harmony with the<br />

spirit of its locale. WIA<br />

22 ISSUE 1 • <strong>2018</strong> • WOOD IN ARCHITECTURE

BIG PICTURE<br />

combination with glue-laminated wood beams. The airport is presently the largest application of CLT in<br />

rigid structure with a beautiful warm interior finish. This enabled the team to increase construction time,<br />

WOOD IN ARCHITECTURE • ISSUE 1 • <strong>2018</strong><br />

23

BIG PICTURE<br />

Jackson Hole Airport, a wooden structure, is at home with the mountains.<br />

People y into Jackson Hole, Wyoming, all year round to<br />

visit the Grand Teton and Yellowstone Naonal Parks. <strong>In</strong><br />

summer they hike down the heritage slopes, in winter<br />

they ski. It is the only airport in the United States situated in<br />

a Naonal Park.<br />

<strong>In</strong> conceptualising its design, the airport had to reect its<br />

mountain environment and western heritage. It also had to<br />

be environmentally responsible. Grand Teton Naonal Park<br />

also has strict boundary limitaons and an 18’ height limit—a<br />

challenging framework for design. <strong>In</strong>corporang wood was an<br />

important part to achieving these goals.<br />

<strong>In</strong> the Tickeng Hall 24” diameter FSC-cered Douglas<br />

fir columns anchor the space. The columns are turned<br />

smooth in a rened modern manner in lieu of a convenonal<br />

rustic appearance. Expansive glulam beams dramatically<br />

span across the hall and interface with the columns<br />

via intricately detailed steel connections. Due to height<br />

restricons, a queen post truss system was integrated with<br />

the glulam beams to reduce their depth and bulk, thus<br />

maximising the terminal’s spaciousness. The rhythm and<br />

clarity of the structural system is on display as it marches<br />

over 250’ within the terminal, culminang with the dramac<br />

17’ exterior overhang.<br />

The ceiling and the underside of the exterior overhangs<br />

use 1 x 4 hemlock. The species was selected for its subtle<br />

grain and light, yet rich coloraon that complements the<br />

golden glulam beams. The hemlock ceiling boards are spaced<br />

intermiently to add acouscal value to the terminal that is<br />

primarily hard surfaces of glass, concrete, wood and steel.<br />

Reclaimed weathered snow fence was used extensively in the<br />

millwork and as a wainscot. The weathered grey appearance<br />

oers a nod to the past and is a nice contrast to the new warm<br />

wood structure and ceiling. Glulam beams from the original<br />

demolished building were repurposed into large-scale exterior<br />

and interior benches.<br />

The terminal expansion was completed in 2010 and<br />

achieved USGBC LEED Silver cercaon. WIA<br />

Close-up of the underside of the exterior roof<br />

Steel connections secure the wooden elements in place<br />

FSC-certified Douglas fir columns and hemlock ceiling define the ticketing hall<br />

24 ISSUE 1 • <strong>2018</strong> • WOOD IN ARCHITECTURE

BIG PICTURE<br />

The smallness of mankind is immediately evident against the mountains’ overwhelming magnificence. Image credit: Matthew Millman.<br />

WOOD IN ARCHITECTURE • ISSUE 1 • <strong>2018</strong><br />

25

IN PERSON<br />

Anjung Kelana by Mr Azman.<br />

The project bagged second prize at the<br />

inaugural Malaysian <strong>Wood</strong> Awards in 2017.

IN PERSON<br />

Malaysian architect Azman Md Nor is a huge fan of<br />

wood. He is quietly championing this material in his<br />

country, but the lack of skilled craftsmen and quality<br />

timber, he says, is hindering progress.<br />

Timber is experiencing a renaissance in Southeast Asia as<br />

local architects return to their roots, drawing inspiraon<br />

from the tradional kampong houses of their youth. Or<br />

at least, this is what Azman Md Nor feels is driving the mber<br />

revoluon in the region.<br />

The 55-year-old architect and part-me lecturer grew up<br />

in such an environment—a kampong (or village in Malay) in<br />

Port Dickson where most household items such as toys and<br />

furniture were made from wood.<br />

“We used wood to make whatever we needed, even the<br />

chicken coop. It’s convenient and easy to work with,” Azman<br />

says. At Deakin University where he read architecture, he was<br />

inspired by the late Professor Kevin Borland who took the class<br />

to visit the mber houses he designed, further fanning the<br />

ames for wood appreciaon. However, it was only in 2006 that<br />

the father of four began acvely pursuing projects in mber at<br />

his own pracce, Arkitek Azman Zainal.<br />

Azman’s style can be described as avant-garde, bold and<br />

unique, a “like it or hate it” kind of vibe. He personally feels it is<br />

humanisc, raw and natural, drawing richly from local culture.<br />

“Using wood for the interior is like bringing in all the<br />

aributes of the forest into the hearth. <strong>Wood</strong> has many health<br />

benets,” he says, conrming several studies that a wood-clad<br />

interior calms the nerves and reduces stress levels.<br />

This philosophy is evident in Anjung Kelana, the home and<br />

oce he built for himself. The building brings out the honesty<br />

and raw beauty of mber, and for that, bagged second prize at<br />

the inaugural Malaysian <strong>Wood</strong> Awards last year. According to<br />

the jury, the curved wall structure is “one of the most interesng<br />

design elements of the house, providing structural stability that<br />

speaks volumes of what could be done with mber.”<br />

“Let wood be wood,” he says.<br />

Like many of his peers, Azman agrees that wood is easy<br />

to work with: It can be carved or craed using light handheld<br />

tools; it generates minimal waste as the o-cuts, wood chips and<br />

sawdust can be fashioned into other products; damage can be<br />

easily repaired; old mber works can be reclaimed and recycled<br />

for other purposes.<br />

However, external applications of wood pose a great<br />

challenge in Asia’s tropical climate. The material must bale<br />

WOOD IN ARCHITECTURE • ISSUE 1 • <strong>2018</strong><br />

27

IN PERSON<br />

Azman Md Nor<br />

designs with wood and has his<br />

own practice, Arkitek Azman Zainal.<br />

<strong>Wood</strong> for window frames and grilles are common in<br />

tropical homes<br />

oxidaon due to prolonged exposure to<br />

the sun’s ultraviolet rays. <strong>In</strong> a couple of<br />

years, it will weather into a silvery grey<br />

colour which is not a structural problem<br />

but can be an aesthec concern for some.<br />

The wooden building in the tropics<br />

must be well-venlated to preserve the<br />

mber. “Those who appreciate mber<br />

and want to use it are mainly worried<br />

about decay, termites, aordability and<br />

maintenance. But these can be easily<br />

addressed. For example, decay occurs<br />

because of dampness which can be due<br />

to poor detailing, poor venlaon and<br />

maintenance,” Azman advises.<br />

Having a well-lit and airy indoor space<br />

also improves occupants’ well-being,<br />

he adds.<br />

OBSTACLES IN THE WAY<br />

However, there is sll a long way to go<br />

before wood becomes a choice material<br />

in design and architecture.<br />

<strong>In</strong> Malaysia the industry struggles<br />

with labour shortage. Dependence on a<br />

transient populaon of foreign workers<br />

means few can be trained or retained as<br />

skilled crasmen. It is also increasingly<br />

dicult to have designs built well due to<br />

the lack of quality mber supply—one of<br />

the biggest barriers to building a mber<br />

construcon culture.<br />

Azman stresses that mber delivered<br />

to the construcon site should be ready,<br />

meaning that it should not be deformed,<br />

green or juvenile. Yet over the years,<br />

people have lost condence in mber<br />

because “we don’t know what kind of<br />

quality we are geng at the construcon<br />

site. Subjecng it to tesng at the last<br />

minute is disrupve to the construcon<br />

schedule.”<br />

Other obstacles include low<br />

awareness and poor perception of<br />

timber’s structural strength—a myth<br />

perpetuated by poor mber quality at<br />

the work site.<br />

28 ISSUE 1 • <strong>2018</strong> • WOOD IN ARCHITECTURE

IN PERSON<br />

Over time, wood will weather into a silvery grey, which<br />

can be an aesthetic concern for some.<br />

The curved wall structure is “one of the most interesting design elements of the<br />

house, providing structural stability that speaks volumes of what could be done<br />

with timber,” according to the jury of the Malaysian <strong>Wood</strong> Awards.<br />

CREATIVE PROBLEM<br />

SOLVING<br />

Most architects want to see their designs<br />

come to fruion but in reality, Azman<br />

remarks, this is oen hindered by changes<br />

and volale temperaments “pulling you<br />

in all sorts of direcons."<br />

He says, "You have approvals that<br />

come in so late that by then, the project<br />

has lost its feasibility.<br />

“Then you also have impaent clients<br />

who want to get the design to the ground<br />

even though it is incomplete. This puts a<br />

lot of pressure on us.”<br />

<strong>In</strong> the past 20 years, government<br />

authories have also been fond of the<br />

design-and-build approach, estranging<br />

the architect and his design team away<br />

from the end user, Azman adds. Clients<br />

sometimes employ project managers,<br />

adding an unnecessary layer to the<br />

building procurement system which<br />

makes it increasingly challenging<br />

for the architect to communicate values<br />

that the end-user actually wants or needs.<br />

But at the root of the practice,<br />

architecture is about creave problem<br />

solving, Azman says. “We can organise<br />

ourselves so that we have more control<br />

of our intellectual property. I am now<br />

looking at a designer-maker approach and<br />

seeing where this path leads to.”<br />

Also, if the mber supply chain can<br />

provide quality mber and be backed<br />

up by a systemac delivery system, the<br />

design and building sector can be more<br />

condent in coming up with bold, quality<br />

and innovave designs.<br />

Finally, the industry must stop<br />

perceiving mber as a commodity: Drop<br />

the consumerist behaviour, stop and<br />

enjoy the material, and experience the<br />

design.<br />

This will perhaps give Malaysian<br />

timber research and design its long<br />

overdue recognion in the internaonal<br />

arena of wood architecture. | WIA<br />

WOOD IN ARCHITECTURE • ISSUE 1 • <strong>2018</strong><br />

29

27 - 29 MARCH <strong>2018</strong> | 3 DAYS EXHIBITION<br />

<strong>2018</strong><br />

26 - 30 MARCH <strong>2018</strong><br />

5 DAYS CONSTRUCTION CONFERENCES<br />

KUALA LUMPUR<br />

CONVENTION CENTRE<br />

& CIDB IBS CENTRE<br />

ACHIEVING<br />

PEAK<br />

PRODUCTIVITY<br />

HOSTED BY ORGANISED BY CO-LOCATED EVENTS<br />

www.icw.my | www.ecobuildsea.com

FIT-OUTS<br />

Modern day diners expect more than just new palate<br />

sensations and to impress the discerning, restaurateurs<br />

have taken interior design as seriously as their<br />

kitchen kungfu. Three restaurants show how ‘molten’<br />

wood can create ambience for the evening meal.<br />

WOOD IN ARCHITECTURE • ISSUE 1 • <strong>2018</strong><br />

31

FIT-OUTS<br />

Walk into RAW and it will tell you the story of Chef André<br />

Chiang’s food.<br />

RAW is somemes lauded the best<br />

restaurant in Taipei. It is hard to<br />

get a reservaon, but if you do,<br />

note how Andre Chiang’s arsc vision<br />

for food is translated into a design that<br />

reflects his artistic and minimalistic<br />

creaons.<br />

The architects from WEIJENBERG<br />

used wood in its pure state. The organic<br />

wooden forms are made up of locallysourced<br />

spruce blocks joined together<br />

by local carpenters with techniques used<br />

in shipbuilding. The design was prepared<br />

using 3D modeling soware; the 3D data<br />

was used to determine the tool paths for<br />

the CNC machine.<br />

The central wooden sculpture, a<br />

65-metre long wine bar is held up with<br />

double anchor points on each node.<br />

Since Taipei lies in an earthquake-prone<br />

region, the structure was reinforced<br />

with steel and lateral bracing in order<br />

to tackle the lateral swing in the event<br />

of a tremor.<br />

The design reflects the essence<br />

of RAW’s cuisine which is organic and<br />

natural. It incorporates ne, subtle details<br />

of meculous cra complemented by a<br />

subdued and minimal material palee.<br />

Concrete walls and copper light xtures<br />

minimise distracon, allowing the chef’s<br />

creaon to take centre stage.<br />

The two wooden islands are not<br />

only visually appealing, they also serve<br />

a praccal purpose: They guide the ow<br />

of spaces in between, eliminang the<br />

‘boxy’ feeling usually associated with<br />

paroned areas. | WIA<br />

32 ISSUE 1 • <strong>2018</strong> • WOOD IN ARCHITECTURE

FIT-OUTS<br />

<strong>In</strong> keeping with the artistic side of the chef, the space was designed to fl ow from one region to another guided by the undulating geometry of the<br />

wooden forms. Zones are demarcated through transitions in fl oor materials and the positioning of wooden elements. Image credit: MWPHOTOINC<br />

WOOD IN ARCHITECTURE • ISSUE 1 • <strong>2018</strong><br />

33

FIT-OUTS<br />

Two Cups Bar shies away from the<br />

uninspiring and gaudy that so typifies<br />

China’s urban landscape.<br />

Image credit: Daipu Architects<br />

The bar owner wanted his customers<br />

to enjoy a tipple outdoors over<br />

the unique skyline of the Yuzhong<br />

peninsula. At the same time, Daipu<br />

Architects was experimenng with more<br />

prototype-driven soluons to generate<br />

new building and structural systems.<br />

The project team put this intenon<br />

into Two Cups Bar by introducing a<br />

“mountainous terrain” into the restricted<br />

concrete space. The whole model is<br />

made of pure solid wood and carved by<br />

computerised digital control machines.<br />

The model is designed on computer,<br />

prefabricated, and then assembled on<br />

site, saving considerable me.<br />

This installation can be seen as<br />

topography, landscape or furniture<br />

design. It includes the guide of sight<br />

line at the entrance, spaal parons,<br />

footrests of bar counter, small arcles<br />

for ddling with while drinking, and a<br />

large wooden sofa.<br />

The wood is meant to wear out aer<br />

a few years, giving the pub a rugged,<br />

weathered feel.| WIA<br />

34 ISSUE 1 • <strong>2018</strong> • WOOD IN ARCHITECTURE

FIT-OUTS<br />

Project Details<br />

Client : Two Cups Bar<br />

Location : Chongqing, China<br />

Site area : 120sqm<br />

Outdoor area : 200sqm<br />

Architects : Daipu Architects<br />

Completion : Jan 2017<br />

WOOD IN ARCHITECTURE • ISSUE 1 • <strong>2018</strong><br />

35

FIT-OUTS<br />

Bar Raval pays homage to<br />

the social and gastronomic<br />

culture of northern spain.<br />

36 ISSUE 1 • <strong>2018</strong> • WOOD IN ARCHITECTURE

FIT-OUTS<br />

Bar Raval’s molten curves encourage customers to cradle in and become part of the woodwork. All images courtesy of Jonathan Friedman.<br />

WOOD IN ARCHITECTURE • ISSUE 1 • <strong>2018</strong><br />

37

FIT-OUTS<br />

The fluid flows within the space have an ethereal quality<br />

Celebrated gastronomists Grant van Gameren, Mike<br />

Webster and Robin Goodfellow wanted to take the<br />

culinary experience to a new level of art. Apart from<br />

mouth-watering tantalisers, their new tapas-style bar had to<br />

be reimagined as a stage for performance, interacon and awe.<br />

Toronto-based designers PARTISANS furnished the<br />

space with a molten quality, fostering fluid circulation,<br />

close encounters, honouring the spirit of its Spanish pintxo<br />

counterparts. The rippled surfaces around the standing space<br />

encourage patrons to get comfortable, lean into their so<br />

edges, and become a part of the woodwork.<br />

“It is a 21 st -century response to Spanish Art Nouveau<br />

design,” the architects said. “van Gameren [got us] to execute<br />

an ambious vision… to create an ‘art piece’, a space that would<br />

become an enduring Toronto instuon.”<br />

The team also used advanced digital methods to develop<br />

prefabricated components that could be inserted directly<br />

into the building’s exisng fabric with minimal disrupon.<br />

The team worked directly with fabricators MCM <strong>In</strong>c, which<br />

enlisted Mastercam to adjust the soware code they would<br />

eventually use to mill over 9km of engravings on 75 panels of<br />

wood. The team also worked closely with engineers to develop<br />

customised acouscs and a tailor-made sound system. The<br />

result is a marvel. | WIA<br />

38 ISSUE 1 • <strong>2018</strong> • WOOD IN ARCHITECTURE

24-27 October <strong>2018</strong><br />

<br />

THE WOODWORKING<br />

SHOW IN THE HEART<br />

OF VIETNAM'S<br />

FURNITURE CLUSTER<br />

BINH DUONG<br />

BINH DUONG — THE RIGHT LOCATION<br />

Jointly organised by<br />

HAWA CORPORATION<br />

PANELS & FURNITURE Group<br />

Enquiries For <strong>In</strong>ternational Exhibitors<br />

Pablo Publishing Pte Ltd<br />

3 Ang Mo Kio Street 62 #01-23 Link@AMK<br />

Singapore 569139<br />

Tel: (65) 6266 5512<br />

Email: williampang@pabloasia.com<br />

Venue: Expo Binh Duong<br />

Binh Duong Province, Vietnam.<br />

www.vifawoodmacvietnam.com

MATERIALS & TECHNOLOGY<br />

By <br />

Easy-to-use online maps to track the sustainability of American hardwood trees,<br />

species by species and county by county, are being launched by AHEC.<br />

These interactive maps will provide transparent and<br />

veried data on the sustainable hardwood resources of<br />

the USA, state by state and county by county for traders,<br />

speciers and consumers. A series of online maps forming a<br />

key component of the new americanhardwood.org website<br />

and using data from the U.S. Forest <strong>In</strong>ventory Analysis (FIA)<br />

programme gives new insights into the sustainability of<br />

American hardwood forest resources.<br />

The FIA programme is one of the longest running, most<br />

comprehensive and sciencally rigorous forest inventory<br />

programmes in the world. It dates back to 1928 when the<br />

McSweeney-McNary Forest Research Act iniated the rst<br />

forest inventories in the United States.<br />

<strong>In</strong> 1974 the Federal Forest and Rangeland Renewable<br />

Resources Planning Act (RPA) required the U.S. Department<br />

of Agriculture to prepare Renewable Resources Assessment<br />

every 10 years.<br />

<strong>In</strong> 1998 the U.S. Farm Bill enhanced the FIA programme<br />

with annual updates at state level based on measurement<br />

of a proporon of plots, to produce a naonal report every<br />

ve years.<br />

FIA data derives from a combinaon of sources. Satellite<br />

remote sensing is used to measure area, locaon and main<br />

forest aributes at increasingly high levels of resoluon. More<br />

than 125,000 forest sample plots across the USA provide<br />

detailed informaon on forest type, site aributes, tree<br />

species, tree size, and tree health. Quesonnaire surveys<br />

of landowner plans, values, and intenons are made as well<br />

as a survey of wood processing facilies to track commercial<br />

mber producon.<br />

40 ISSUE 1 • <strong>2018</strong> • WOOD IN ARCHITECTURE

MATERIALS & TECHNOLOGY<br />

The interactive forest maps offer statistical information about America s forest resources such as species, growth and distribution.<br />

Ulisaon studies of logging sites to record how much<br />

wood is actually removed during harvest are also carried out.<br />

FIA data shows that between 1951 and 2011 the volume<br />

of U.S. hardwood growing stock increased from 5.2 billion<br />

m 3 to 12.0 billion m 3 , a gain of over 130 per cent. This trend<br />

occurred because hardwood growth was well in excess of<br />

harvest volume throughout the sixty-year period. FIA data<br />

also shows that U.S hardwood forest area increased at a rate<br />

of 400,000 hectares per year between 2007 and 2012, adding<br />

an area the size of a football pitch every minute during this<br />

period.<br />

The graph shows the long term net growth of hardwoods,<br />

with an The area interactive increasing forest from maps 99 million offer statistical ha in 1953 to 111<br />

million information ha 2012, about adding America an area s forest the size resources of a football pitch<br />

every minute, such as rising species, at a rate growth of 40,000 and distribution. ha per year or in total<br />

an area equal to France, Belgium, Netherlands and Germany<br />

combined. Removals have been reducing since 1996.<br />

The online interacve maps allow users to visualise U.S.<br />

hardwood forest resource information from a bird’s-eye<br />

perspecve to reveal underlying spaal paerns. The most<br />

recent FIA data on the volume of live trees, growth and<br />

harvest is provided for 22 hardwood species which together<br />

account for over 96 per cent of all hardwood standing volume<br />

in the United States. Through a simple and intuive interface,<br />

users can analyse the distribuon of hardwood volume,<br />

growth and removals at naonal level, or drill down to state<br />

and county level.<br />

The online map system was developed by AHEC in<br />

collaboration with BWA Design, a UK-based company<br />

specialising in creave web design. | WIA<br />

WOOD IN ARCHITECTURE • ISSUE 1 • <strong>2018</strong><br />

41

Bloomberg's new European headquarters in London:<br />

The lobby, or ‘Vortex’, features a red oak cladded arch.<br />

Image credit: Foster + Partners and Nigel Young<br />

42 ISSUE 1 • <strong>2018</strong> • WOOD IN ARCHITECTURE

By Michael Buckley,<br />

World Hardwoods, Singapore<br />

About 40 per cent of the U.S. national hardwood<br />

resource is oak, of which red oak accounts for<br />

about three quarters, but it is still under-utilised.<br />

WOOD IN ARCHITECTURE • ISSUE 1 • <strong>2018</strong><br />

43

44 ISSUE 1 • <strong>2018</strong> • WOOD IN ARCHITECTURE

MATERIALS & TECHNOLOGY<br />

There is much discussion as to why red<br />

oak is named as it is. Some say because<br />

the leaves turn red in the fall, rather than<br />

brown as in white oak. Others suggest that<br />

the wood has a reddish nge, although that is<br />

oen not the case. Lincoln* describes red oak<br />

as ranging from biscuit coloured to pink. What<br />

is absolutely sure is that its name has nothing to<br />

do with red wine, for only white oak is suitable<br />

for barrel-making! American red oak is highly<br />

suitable for a whole range of other applicaons<br />

from ooring to furniture, cabinets to coee<br />

tables and every type of joinery from doors to<br />

decorave panels. But many of today’s furniture<br />

makers and interior joinery manufacturers,<br />

especially in Asia, remain unfamiliar with this<br />

oak, one of the most sustainable and available<br />

of all temperate hardwoods.<br />

TECHNICAL CHARACTERISTICS<br />

American red oak is a true Quercus, mainly<br />

Quercus rubra Northern red oak and Quercus<br />

falcata Southern red oak, but there are many<br />

other sub species of red oak in North America<br />

such as Spanish oak, cherrybark oak and<br />

shummard oak. They all exhibit much the same<br />

technical and working properes but, as with<br />

most U.S. hardwoods, they can vary in colour<br />

and grain from region to region.<br />

The percentage of heartwood in red oak<br />

is relatively large particularly in northern<br />

grown material. Northern and southern is not<br />

dierenated by merchants. So as usual when<br />

specifying American hardwoods it is best to<br />

research your source, if physical properes are<br />

more important than visual aesthecs. Most<br />

hardwood importers and distributors are wellversed<br />

in their dierent characteriscs.<br />

<br />

a) 707 kg/m 3 b) 707 kg/m 3<br />

<br />

<br />

10.8% (Green to 6% M.C.)<br />

a) 12,549 MPa b) 15,721 MPa<br />

a) 5,738 N b) 6,583 N<br />

a) Quercus rubra b) Quercus falcate<br />

Northern<br />

Southern<br />

<strong>In</strong>terior staircase in Bloomberg London's new office<br />

Photo credit: Foster + Partners and James Newton<br />

WOOD IN ARCHITECTURE • ISSUE 1 • <strong>2018</strong><br />

45

MATERIALS & TECHNOLOGY<br />

Red oak interior flooring<br />

Image credit: Foster + Partners and Nigel Young<br />

RED OAK is everywhere in Bloomberg’s new<br />

European headquarters. Designed by Foster +<br />

Partners, the dramatic lobby features a dizzying<br />

1,858sqm of cladding while 37,160sqm of the<br />

material spreads out beneath your feet. The multipurpose<br />

room takes up another 1,350m 3 of red oak,<br />

here used in the form of glulam.<br />

So how did so much wood end up in the media<br />

colossus’ office?<br />

Project Architect Michael Jones recalled<br />

[Bloomberg] wanted something “bespoke and<br />

tailored to the way they operate.”<br />

On his part, sustainability considerations let him<br />

to timber. (The office scored a record BREEAM<br />

rating of 98.5 per cent.)<br />

<strong>In</strong> the end, red oak was chosen because it was “a<br />

species with warmth that would mellow and mature<br />

with age,” Jones said.<br />

With so much wood, so much could go wrong,<br />

but the technical challenges have been overcome—<br />

such as micro-perforating the lobby’s vertical<br />

cladding to absorb sound. <strong>In</strong>dividual flooring boards<br />

can also be lifted and refitted at will, a solution that<br />

prevents creaking. Footsteps are also deadened by<br />

an additional acoustic layer between board and<br />

access floor.<br />

“Businesses now want their buildings to<br />

have a different sense of personality and be more<br />

responsive to people who work in them,” Jones said<br />

in hindsight. “Bloomberg loves the result, so do we.”<br />

Red oak represents about 30 per<br />

cent of the total American hardwood<br />

standing timber although the sawn<br />

lumber imported into Southeast Asia<br />

does not reect this, and hence the new<br />

promoon of red oak by the American<br />

Hardwood Export Council (AHEC).<br />

Currently in all Southeast Asian<br />

countries the import of red oak falls well<br />

below the volumes of other American<br />

species. Nevertheless the USA exports<br />

around one million cubic metres of red<br />

oak annually because it is so suitable for<br />

interior uses.<br />

EASY TO WORK WITH<br />

Red oak makes excellent lumber but is<br />

also parcularly easy to slice and peel for<br />

veneer and plywood and is very readily<br />

available from U.S. exporters. The trees<br />

grow large and tall, giving much beer<br />

specicaons of lengths than most other<br />

types of oak. As a result it is widely<br />

used for doors and panelling where its<br />

individual character oers decorave<br />

opons for interiors to designers and<br />

architects for ooring, panelling, interior<br />

cladding and joinery.<br />

The seed of the American red oak is<br />

resistant to re and is a pioneer species<br />

after others have been destroyed by<br />

fires, often started by lightning. <strong>In</strong><br />

Pennsylvania, aer devastang natural<br />

res in the early 1900s, it was red oak<br />

that came back to regenerate the forest<br />

naturally. It has been cut connuously<br />

for widespread use since the European<br />

selers rst arrived 400 years ago and<br />

yet it increases its growing volume<br />

by sound management and natural<br />

regeneraon – always a true measure<br />

of sustainability. <strong>In</strong>teractive maps of<br />

all American commercial hardwoods<br />

newly launched show that annual<br />

growth exceeds annual harvest and<br />

mortality.<br />

Lincoln* describes American red<br />

oak as “weighing around 770 kg/m 3<br />

with medium bending properes and<br />

very good bending with steam.” It has<br />

“high crushing strength” and is mostly<br />

straight grained. Such properes led to<br />

the American Hardwood Export Council<br />

in Europe to select red oak, along<br />

with ash, white oak and tulipwood for<br />

structural tesng by Building Research<br />

Establishment in the UK years ago. The<br />

results are contained in the publicaon,<br />

Structural Design in American<br />

Hardwoods, which provides architects<br />

and engineers with structural data under<br />

codes not previously available.<br />

46 ISSUE 1 • <strong>2018</strong> • WOOD IN ARCHITECTURE

MATERIALS & TECHNOLOGY<br />

HARDY, STRONG AND FIRE<br />

RESISTANT<br />

American red oak is classied as nondurable<br />

although the sapwood is<br />

permeable and easily treated with<br />

preservave, whereas the heartwood<br />

is moderately easy to treat. This fact<br />

also enables American red oak to be<br />

more easily treated with re retardants<br />

than some other hardwood species.<br />

This beer permeability of American<br />

red oak leads to a greater uptake and<br />

retenon necessary to achieve the Class<br />

0 re rang for internal linings used in<br />

escape routes and circulaon areas in<br />

public buildings.<br />

More recently test projects have<br />

revealed red oak as most suitable for<br />

thermal modicaon – so TMT red oak<br />

is now available for exterior applicaons.<br />

Other properes lead to the harder<br />

wood needing pre-boring for nails, but it<br />

machines well and also glues and stains<br />

well to a fine finish. The decorative<br />

properes of red oak are derived from<br />

its strong grain paerns and generally<br />

warm colour.<br />

<strong>In</strong> performance the hardness of red<br />

oak makes it ideal for ooring, and with<br />

its disnct grain paern it shows wear<br />

and tear less than many other species<br />

used today. Given the sustainability of<br />

red oak, speciers can rest assured that<br />

its use threatens no forests but provides<br />

a material with characteriscs that can<br />

spell both ‘contemporary’ and ‘heritage’.<br />

Bloomberg’s new oce in London<br />

is one such marvel, with red oak ed<br />

throughout the 1.1 million sq oce.<br />

| WIA<br />

*“World woods in colour”<br />

William A. Lincoln ISBN 0 85442 028 2<br />

Michael Buckley at World Hardwoods<br />

holds an MPhil for hardwood research<br />

and is a fellow of the <strong>In</strong>stute of <strong>Wood</strong><br />

Science in the UK. He writes widely on<br />

hardwood subjects.<br />

WOOD IN ARCHITECTURE • ISSUE 1 • <strong>2018</strong><br />

47