Spray Nozzles Spray Control Spray Analysis Spray Fabrication

Spray Nozzles Spray Control Spray Analysis Spray Fabrication

Spray Nozzles Spray Control Spray Analysis Spray Fabrication

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

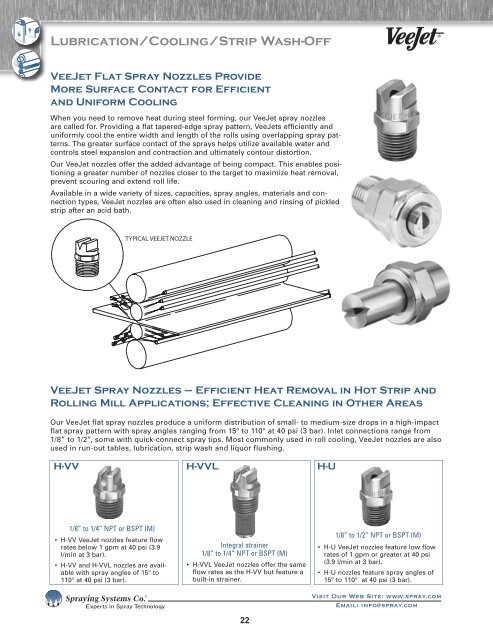

Lubrication/Cooling/Strip Wash-Off<br />

VeeJet Flat <strong>Spray</strong> <strong>Nozzles</strong> Provide<br />

More Surface Contact for Efficient<br />

and Uniform Cooling<br />

When you need to remove heat during steel forming, our VeeJet spray nozzles<br />

are called for. Providing a flat tapered-edge spray pattern, VeeJets efficiently and<br />

uniformly cool the entire width and length of the rolls using overlapping spray patterns.<br />

The greater surface contact of the sprays helps utilize available water and<br />

controls steel expansion and contraction and ultimately contour distortion.<br />

Our VeeJet nozzles offer the added advantage of being compact. This enables positioning<br />

a greater number of nozzles closer to the target to maximize heat removal,<br />

prevent scouring and extend roll life.<br />

Available in a wide variety of sizes, capacities, spray angles, materials and connection<br />

types, VeeJet nozzles are often also used in cleaning and rinsing of pickled<br />

strip after an acid bath.<br />

���������������������<br />

VeeJet <strong>Spray</strong> <strong>Nozzles</strong> – Efficient Heat Removal in Hot Strip and<br />

Rolling Mill Applications; Effective Cleaning in Other Areas<br />

Our VeeJet flat spray nozzles produce a uniform distribution of small- to medium-size drops in a high-impact<br />

flat spray pattern with spray angles ranging from 15° to 110° at 40 psi (3 bar). Inlet connections range from<br />

1/8” to 1/2”, some with quick-connect spray tips. Most commonly used in roll cooling, VeeJet nozzles are also<br />

used in run-out tables, lubrication, strip wash and liquor flushing.<br />

H-VV H-VVL H-U<br />

1/8” to 1/4” NPT or BSPT (M)<br />

• H-VV VeeJet nozzles feature flow<br />

rates below 1 gpm at 40 psi (3.9<br />

l/min at 3 bar).<br />

• H-VV and H-VVL nozzles are available<br />

with spray angles of 15° to<br />

110° at 40 psi (3 bar).<br />

Integral strainer<br />

1/8” to 1/4” NPT or BSPT (M)<br />

• H-VVL VeeJet nozzles offer the same<br />

flow rates as the H-VV but feature a<br />

built-in strainer.<br />

22<br />

1/8” to 1/2” NPT or BSPT (M)<br />

• H-U VeeJet nozzles feature low flow<br />

rates of 1 gpm or greater at 40 psi<br />

(3.9 l/min at 3 bar).<br />

• H-U nozzles feature spray angles of<br />

15° to 110° at 40 psi (3 bar).<br />

���������������������������������<br />

���������������������