Spray Nozzles Spray Control Spray Analysis Spray Fabrication

Spray Nozzles Spray Control Spray Analysis Spray Fabrication

Spray Nozzles Spray Control Spray Analysis Spray Fabrication

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Cooling/Continuous Casting<br />

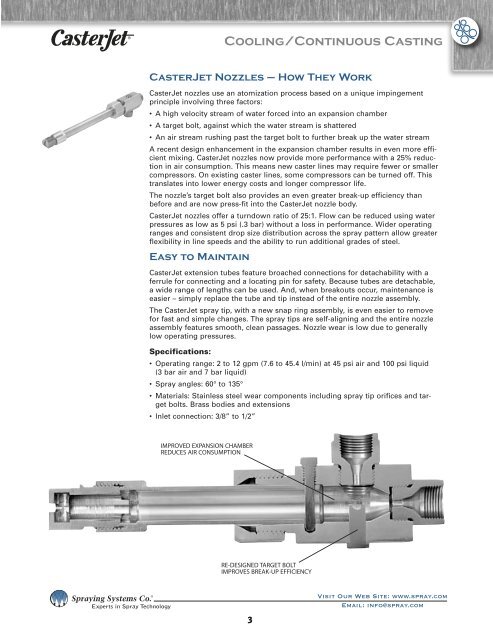

CasterJet <strong>Nozzles</strong> – How They Work<br />

CasterJet nozzles use an atomization process based on a unique impingement<br />

principle involving three factors:<br />

• A high velocity stream of water forced into an expansion chamber<br />

• A target bolt, against which the water stream is shattered<br />

• An air stream rushing past the target bolt to further break up the water stream<br />

A recent design enhancement in the expansion chamber results in even more efficient<br />

mixing. CasterJet nozzles now provide more performance with a 25% reduction<br />

in air consumption. This means new caster lines may require fewer or smaller<br />

compressors. On existing caster lines, some compressors can be turned off. This<br />

translates into lower energy costs and longer compressor life.<br />

The nozzle’s target bolt also provides an even greater break-up efficiency than<br />

before and are now press-fit into the CasterJet nozzle body.<br />

CasterJet nozzles offer a turndown ratio of 25:1. Flow can be reduced using water<br />

pressures as low as 5 psi (.3 bar) without a loss in performance. Wider operating<br />

ranges and consistent drop size distribution across the spray pattern allow greater<br />

flexibility in line speeds and the ability to run additional grades of steel.<br />

Easy to Maintain<br />

CasterJet extension tubes feature broached connections for detachability with a<br />

ferrule for connecting and a locating pin for safety. Because tubes are detachable,<br />

a wide range of lengths can be used. And, when breakouts occur, maintenance is<br />

easier – simply replace the tube and tip instead of the entire nozzle assembly.<br />

The CasterJet spray tip, with a new snap ring assembly, is even easier to remove<br />

for fast and simple changes. The spray tips are self-aligning and the entire nozzle<br />

assembly features smooth, clean passages. Nozzle wear is low due to generally<br />

low operating pressures.<br />

Specifications:<br />

• Operating range: 2 to 12 gpm (7.6 to 45.4 l/min) at 45 psi air and 100 psi liquid<br />

(3 bar air and 7 bar liquid)<br />

• <strong>Spray</strong> angles: 60° to 135°<br />

• Materials: Stainless steel wear components including spray tip orifices and target<br />

bolts. Brass bodies and extensions<br />

• Inlet connection: 3/8” to 1/2”<br />

IMPROVED EXPANSION CHAMBER<br />

REDUCES AIR CONSUMPTION<br />

RE-DESIGNED TARGET BOLT<br />

IMPROVES BREAK-UP EFFICIENCY<br />

3<br />

���������������������������������<br />

���������������������