May 2021

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

MAY <strong>2021</strong><br />

The self-adhering externa al<br />

airtight & vapour permeab ble<br />

membrane<br />

>>> • ROOFCERT UPDATE • EAVES DETAIL ISSUES • SOLAR SURGE • SHINGLES • >>>

B Y<br />

YOUR<br />

SIDE<br />

With decades of experience working<br />

globally with hundreds of Contractors on<br />

thousands of buildings, at Siderise we have<br />

the understanding and insight of what it<br />

takes to correctly and safely install passive<br />

fire safety to the external envelope.<br />

With our Site Services team delivering<br />

on-site training to installers and our<br />

Inspection App to enable remote review<br />

of installations, we have the ingenuity<br />

to help you deliver a world class install.<br />

Our Integrity. Your Workmanship.<br />

Safe Buildings.<br />

Discover more at<br />

siderisebyyourside.com<br />

siderisebyyourside.com

Editor’s Comment<br />

MATT DOWNS<br />

EDITORIAL DIRECTOR<br />

MATTDOWNS@MEDIA-NOW.CO.UK<br />

07963 330774<br />

The self-adhering externa al<br />

airtight & vapour permeab ble<br />

membrane<br />

Whilst the events of the past year or so have had an impact on all areas<br />

of life, training and teaching have been hit particularly hard.<br />

As expected, this has had an impact on the roofing sector’s flagship<br />

accreditation scheme RoofCERT, which was building up a head of steam prior<br />

to the first lockdown. But as NFRC CEO James Talman points out in his column<br />

on page 18, progress has still been made over the last year despite “three<br />

lockdowns, CITB spending cuts and roofing contractors being exceptionally<br />

busy.” As James explains, “through adaptation and innovation” over 100<br />

roofing operatives have still been accredited with “700 more in the pipeline.”<br />

Looking forward it’s going to be a busy time for RoofCERT as training and<br />

assessment restrictions lift, and as James says the important work of creating<br />

relationships with housebuilders – which will increase the exposure of utilising<br />

RoofCERT accredited roofers to the wider industry – will take centre stage,<br />

alongside opening up the Experienced Worker Route to accreditation which will<br />

help push towards the target of 2,000 accredited roofers.<br />

Elsewhere in this issue, in his regular column John Mercer tackles eaves<br />

details (page 20); Marley’s Stuart Nicholson says don’t get left behind on the<br />

solar surge (page 22); the team at Quantum Insulation talk BBA Information<br />

Bulletin No. 4 (page 59); and Rob Firmin discusses water flow reducing layers<br />

on page 60. So read on for all this and much more!<br />

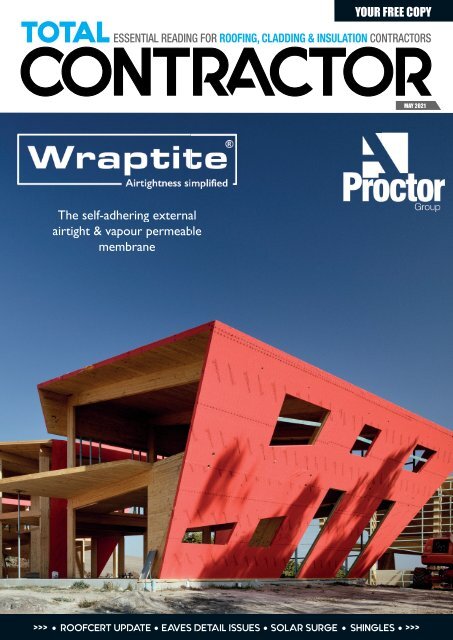

Front cover courtesy of A. Proctor Group. The team discuss issues<br />

around moisture management when utilising CLT construction on page 48.<br />

FOLLOW US @TOTCONTRACTORUK<br />

SIGN UP FOR YOUR E-NEWSLETTER AT<br />

WWW.TOTAL-CONTRACTOR.CO.UK<br />

Advertising:<br />

Publishing Director: Andy Dunn<br />

DD: 01892 732 047<br />

Mob: 07963 330777<br />

Email: andydunn@media-now.co.uk<br />

Commercial Manager: Jake Roxborough<br />

DD: 01892 732 047<br />

Mob: 07956 133314<br />

Email: jakeroxborough@media-now.co.uk<br />

The content of Total Contractor magazine (and website) does not necessarily reflect the views of the editor or publishers and are<br />

the views of its contributors and advertisers. The digital edition may include hyperlinks to third-party content, advertising, or<br />

websites, provided for the sake of convenience and interest. The publishers accept no legal responsibility for loss arising from<br />

information in this publication and do not endorse any advertising or products available from external sources. No part of this<br />

publication may be reproduced or stored in a retrieval system without the written consent of the publishers. All rights reserved.<br />

I’d also like to make you aware of our new title Greenscape magazine which<br />

we have launched for the green roof and solar PV sectors in association with<br />

GRO. The first print issue is now out and you can view the digital version over<br />

at www.greenscapemag.co.uk!<br />

find us on facebook<br />

Matt<br />

£345<br />

LY<br />

Including<br />

delivery<br />

Registered office: 1 Forstal Road, Aylesford, Kent, ME20 7AU<br />

Supported by:<br />

Aluminium Bi-F<br />

Doors<br />

old<br />

mak<br />

e the smart<br />

er choice<br />

FROM<br />

Quote turnaround<br />

ONL within hours<br />

NEW<br />

* Up to 1200mm sash<br />

widths<br />

CUST<br />

per leaf<br />

Stock colours:<br />

White, Black, Grey,<br />

Grey on White<br />

10OMER<br />

* Per leaf price is unglazed and may<br />

vary depending on size and specification of<br />

the door. Lead time is based on a standard colour. Postcode restrictions apply<br />

Call: 01642 610799<br />

ww<br />

ww.madefw<br />

.madefortrade.co<br />

* Discount applies to new trade customers and first,<br />

single item pur chase only of the Korniche Roof Lantern.<br />

DISCOUNT<br />

QUOTE REF:<br />

TC-B01<br />

%<br />

MAY <strong>2021</strong> TC 3

Contents<br />

3 KEY FEATURES<br />

22<br />

22 FUTURE ROOFS: PV<br />

Marley’s Stuart Nicholson says with the changes<br />

to Part L next year, many new build roofs will<br />

include solar PV as standard, so roofers need to<br />

make sure they don’t miss out...<br />

30 HIT SHINGLES!<br />

SR Timber’s Shaun Revill believes that the<br />

combination of lockdown and the focus on<br />

sustainability means there’s never been a<br />

better time to add shingles to your offering<br />

34 MATERIAL CHOICES<br />

SIG Design & Technology’s Paul Jacobs says<br />

designing and installing roofing using multiple<br />

materials is a great business opportunity, but it<br />

can be a risky challenge for the roofer<br />

30<br />

FURTHER READING<br />

Pic credit: Featherstone Homes<br />

24 TRAINING DAYS<br />

We talk to Roof Slate Lecturer Steve Dowell of South<br />

Devon College in our CUPA PIZARRAS college focus<br />

32 ROOFLIGHTING REVOLUTIONS<br />

Total Contractor takes a look behind the scenes at NARM to<br />

hear about the challenges its tackling in rooflighting<br />

40 EPDM & MODULAR BUILDING<br />

Adrian Buttress explains why he believes EPDM can<br />

play its part in ‘circular construction’<br />

50 CLADMASTER PART 2<br />

Vivalda’s Andy Thomas address the common mistakes<br />

made when ordering fixings for cladding projects<br />

34<br />

56 PIR / FLAT ROOF FOCUS<br />

Nigel Blacklock of Bauder and the IMA explains why PIR<br />

is a great fit for flat roofing applications<br />

60 ALL YOU NEED TO KNOW ABOUT:<br />

Rob Firman talks water flow reducing layers in the first<br />

of a new series of articles from Polyfoam XPS<br />

4 TC MAY <strong>2021</strong>

REGULARS<br />

18 NFRC ROOFING FOCUS<br />

James Talman provides an update on RoofCERT<br />

which, despite the challenges of last year, is<br />

still making progress and is set push on<br />

further with new initiatives<br />

20 PERFECTLY PITCHED<br />

In his latest consultant case study, John<br />

Mercer discusses a clay plain tile roof project<br />

he was called to which was suffering water<br />

ingress through the fascia and bargeboards<br />

59 QI BY QI COLUMN<br />

In the latest instalment of their regular<br />

column, the experts at Quantum Insulation<br />

focus on what’s changed in BBA Information<br />

Bulletin No. 4<br />

SECTIONS:<br />

TOTAL<br />

ROOFING<br />

20<br />

TOTAL<br />

CLADDING<br />

48<br />

INDUSTRY NEWS<br />

06 PUSH THE BUTTON...<br />

The NFRC has launched a new app which puts all the<br />

latest Health & Safety updates in roofers’ hands<br />

08 MAKE AN INFORMED DECISION<br />

The LRWA says its new Product Register will help users<br />

make an informed choice when it comes to liquid systems<br />

TOTAL<br />

INSULATION<br />

56<br />

VEHICLES, TOOLS<br />

& WORKWEAR<br />

10<br />

68<br />

MAY <strong>2021</strong> TC 5

Industry News<br />

More news, updates and interviews at www.total-contractor.co.uk<br />

IOR URGES ACTION<br />

FOR SITE VISITORS<br />

The Institute of Roofing (IOR) is urging site<br />

visitors to apply for a Professionally<br />

Qualified Person (PQP) CSCS card to<br />

address concerns raised by manufacturers<br />

about access to construction sites.<br />

The problems follow the withdrawal of the<br />

CSCS visitor card which stopped being issued<br />

at the end of February 2020. Existing visitor<br />

cards remain valid until their listed expiry date.<br />

Recent reports from manufacturers have<br />

highlighted that without this card, members of<br />

their inspection teams are struggling to get<br />

onto site to carry out their role for projects.<br />

The IOR has investigated the issue and found<br />

that the PQP card is the most appropriate<br />

alternative. Valid for five years, a PQP card<br />

certifies that the holder is a qualified member<br />

of an approved professional body, and has the<br />

skills and knowledge required to work on a<br />

construction site without special supervision,<br />

even if they are not typically based on site.<br />

The IOR is an approved body, so all its<br />

members can apply for a PQP card, which can<br />

be done via the CSCS website. Applicants will<br />

need to supply proof of membership. Stuart<br />

Hicks, CEO of the IOR, said: “Our membership<br />

can be used as proof of qualification, or<br />

working towards a qualification, which is the<br />

criteria needed to apply for a PQP card. Gaining<br />

this card will overcome the issues that visiting<br />

staff from manufacturers and other disciplines<br />

have experienced in gaining access to<br />

construction sites to carry out their work. If any<br />

of our members have colleagues that would<br />

benefit from this route to a PQP card, they will<br />

need to apply for an IOR membership via our<br />

website and achieve a grade of Associate,<br />

Member or Fellow. This will depend on meeting<br />

certain qualification criteria which can be<br />

viewed on our website.”<br />

www.instituteof roofing.org<br />

HEALTH & SAFETY AT THE TOUCH OF A BUTTON<br />

NFRC has launched a brand-new app focused Commenting on the launch of the app, Bob<br />

on health and safety for NFRC members and Richardson, NFRC Head of Technical and Training,<br />

their operatives. The app fully digitalises the said: “This app provides an important day-to-day<br />

popular ‘Health & Safety Passport’, which reminder for operatives – even when there is no<br />

previously had been a printed booklet that phone signal – on the safe working practices that<br />

operatives could carry with them on site. This must be considered an essential part of all site<br />

will mean operatives will now have access to working. It contains a wealth of information, from<br />

all the health and safety information they need working at height to fire safety to Covid-safe<br />

from their smartphone.<br />

guidelines, complementing site-specific health<br />

and safety documentation.<br />

As part of the launch, the Passport’s content has<br />

been fully updated to include recent changes in He added: “The Covid-19 pandemic has<br />

legislation and guidance, and new sections giving demonstrated the importance of being agile and<br />

advice and information on mental health and getting critical information and updates out to the<br />

Covid-19. NFRC says the app is future-proofed to industry quickly. Through this innovative new app,<br />

allow the team to remotely update information as we will be able to update the Health & Safety<br />

and when it is required, so operatives always Passport in real-time, rather than reprinting and<br />

have the latest information<br />

distributing thousands of booklets every time<br />

when they open the app.<br />

health and safety legislation changes.<br />

Contractors can therefore be assured that<br />

As a Member Benefit, the<br />

the information their operatives have is<br />

app will only be<br />

the most up-to-date.”<br />

available for NFRC<br />

Members and their<br />

He concluded: “We hope that this is<br />

operatives, and any<br />

just the beginning and if the app<br />

roofing operatives who<br />

proves popular, we will be able to<br />

have not received their<br />

expand the content to include other<br />

log-in details are<br />

NFRC technical guidance and in<br />

encouraged to contact the<br />

time other areas of NFRC<br />

NFRC Helpdesk.<br />

activity.”<br />

ONDULINE IS NOW PART OF ONDURA GROUP<br />

Onduline, the lightweight roofing<br />

and professional customers.<br />

specialist, has announced it is now<br />

The Group brings together three<br />

part of the newly-created Ondura<br />

leading companies under one roof:<br />

Group, an international business<br />

Onduline, for lightweight roofing<br />

dedicated to waterproofing<br />

solutions and pitched roofs, alwitra,<br />

solutions for buildings.<br />

high quality waterproofing systems for flat<br />

The Group has been formed by Naxicap Partners roofs, and CB, façade and roof membranes for<br />

following the acquisition of the Polish company CB pitched roofs.<br />

in 2019, and of Germany-based alwitra.<br />

Paul Duffy (pic), MD for Onduline in the UK, said:<br />

Ondura says it provides a unique solution for “As part of Ondura Group we can offer an even<br />

waterproofing roofs and buildings for both private wider portfolio of solutions to our customers.”<br />

6 TC MAY <strong>2021</strong>

DAKEA<br />

ROOF WINDOWS<br />

ARE BUILT<br />

FOR THE TRADE.<br />

At Dakea, we pride ourselves on<br />

delivering high-quality, affordable roof<br />

windows that are easy to install and<br />

backed with a 20-year guarantee.<br />

AS COMMITTED TO YOU,<br />

AS YOU ARE TO THE TRADE.<br />

Find out more at<br />

dakea.co.uk<br />

Or give us a call<br />

+44 20 3970 5080<br />

DakeaChannel<br />

@HiDakea<br />

@dakea_UK

Industry News<br />

More news, updates and interviews at www.total-contractor.co.uk<br />

NEW AJW CATALOGUE<br />

DELIVERS SO MUCH<br />

AJW Distribution has launched a<br />

comprehensive new catalogue which not<br />

only showcases its range of roofing and<br />

cladding solutions, but also provides its<br />

customers with an extensive range of<br />

product information.<br />

The company wanted to make the buying<br />

process easier for its customers when<br />

deciding which product to use for each<br />

project; for example, ensuring they purchase<br />

the right tile for the low-pitched extension they<br />

are working on.<br />

AJW says the new catalogue also gives<br />

customers a guide which they can showcase<br />

to their client so they are aware of what tiles<br />

they can choose for their project.<br />

A spokesperson for AJW explained: “The<br />

Marketing team have done an outstanding job<br />

working on this catalogue through the Covid<br />

Pandemic. We are extremely proud of what we<br />

have achieved and what we will be presenting<br />

to our customers. We have received great<br />

support from our suppliers and showcase a<br />

number via adverts and case studies throughout<br />

the catalogue.”<br />

Marketing Assistant, Cintia Woods,<br />

commented: “For me, it has been a pleasure<br />

to be able to create these exceptional 400<br />

pages filled with key information on the<br />

products and eye-catching adverts, all<br />

delivered with a fresh and clean design. I hope<br />

you will like it as much as we do at AJW.”<br />

For more information, please visit<br />

www.ajwdistribution.com<br />

LIQUIDS: MAKE AN INFORMED DECISION<br />

The Liquid Roofing and<br />

The LRWA says every product in<br />

Waterproofing Association<br />

the Register is listed with key<br />

(LRWA) has launched a free,<br />

features and a link to further<br />

online tool that enables users to<br />

information such as approved<br />

quickly assess the suitability of<br />

applications, evidence of<br />

liquid roofing systems.<br />

durability, and properties in<br />

relation to fire. There is also a function that allows<br />

Aimed at contractors, specifiers, and distributors,<br />

different liquid systems to be compared.<br />

the LRWA says the Product Register compiles<br />

information from third-party certifications, Sarah Spink, CEO of the LRWA, said: “Selecting an<br />

including agrément and European Technical inappropriate product can result in a project failing,<br />

Approval (ETA) certificates, into an easy-to-read so verifying the performance of a liquid is essential.<br />

format, and it allows the user to search for a The data in agrément and ETA certificates will<br />

preferred manufacturer via a drop-down list or a confirm whether the system will meet specified<br />

product name if known.<br />

requirements, but this information can be difficult to<br />

understand and one of our biggest concerns is that<br />

Alternatively, if the user is unsure about which liquid<br />

people don’t read it properly. This can lead to<br />

roofing system to use, they can carry out a search<br />

inaccurate assumptions or a reliance on<br />

using six filters, which will create a random list of<br />

manufacturers’ product claims, some of which can<br />

potential products.<br />

be misleading. The Product Register has been<br />

The filters include the material, for example, designed to overcome these issues. It brings verified<br />

polyurethane; the type of roof that needs<br />

product data into one place, which is easy to search<br />

waterproofing such as inverted, pitched or a terrace; and navigate, enabling anyone seeking to install or<br />

the level of foot traffic; the required lifespan of the specify a liquid waterproofing solution to make an<br />

roof area; what type of substrate will be coated; and informed decision.”<br />

whether it is a new build or refurbishment project. https://product-register.lrwa.org.uk<br />

GRO’S MEMBERSHIP CONTINUES TO GROW<br />

GRO, the Green Roof<br />

with Queen’s University in<br />

Organisation, has seen a big<br />

Belfast with regards to their<br />

influx of new members this<br />

plans to improve biodiversity on<br />

year, including the likes of<br />

the campus.<br />

Proteus Waterproofing,<br />

In the Republic of Ireland, Noel<br />

Mobilane UK, the Green<br />

also explained he has his first private biodiverse<br />

Infrastructure Consultancy, HUBBUB and Greater<br />

green roof installation approved, is working with<br />

Manchester Combined Authority, and the most<br />

Trinity College in Dublin and has recently been in<br />

recent addition is Sweeney Landscape Design.<br />

discussions with Guinness regarding greening<br />

As a leading Green Infrastructure contractor their Enterprise Centre. Noel says his long-term<br />

based in Belfast and operating in both Northern ambition is to establish an Irish Green<br />

Ireland and the Republic of Ireland, Sweeney Infrastructure Association modelled on GRO to<br />

Landscape Design Managing Director Noel represent both the North and South of Ireland.<br />

Sweeney explained in his application that he<br />

currently has his first private biodiverse green Find more green roof and associated news and<br />

roof installation approved and is in discussion content over at www.greenscapemag.co.uk<br />

8 TC MAY <strong>2021</strong>

ROOF<br />

LANTERN<br />

FITTED<br />

IN<br />

MINUTES<br />

SUPPLY & INSTALL<br />

THE MULTI-AWARD<br />

WINNING ALUMINIUM<br />

LANTERN<br />

STRONGER<br />

3m x 2.5m possible with no mid rafters<br />

Premium seals, class leading thermals<br />

SLIMMER<br />

Uninterrupted SLIMMER Sight Lines<br />

Seamless joints and cappings<br />

SUPPORT<br />

The best trade lantern<br />

www.madefortrade.co<br />

Tel: 01642 610799<br />

10%<br />

NEW CUSTOMER<br />

DISCOUNT<br />

QUOTE CODE<br />

IP-K01<br />

FASTER<br />

Average installation under 30 mins<br />

WARMER<br />

Easy installation<br />

Competitive pricing, reliable, fast<br />

lead times & delivery<br />

find us on facebook<br />

* Discount applies to new trade customers and first, single item purchase only of the Korniche Roof Lantern.

Industry News<br />

More news, updates and interviews at www.total-contractor.co.uk<br />

NORTH EAST ‘GET READY FOR ROOFING’ PROGRAMME LAUNCHED<br />

Two North East roofing contractors have joined<br />

forces with Redcar and Cleveland College to help<br />

tackle the industry skills gaps and kick-start<br />

high quality, long-term career opportunities.<br />

Working in conjunction with the college, Stocktonbased<br />

Barclay Roofing and Redcar’s AAA Roofing<br />

have developed an intensive six-week course that<br />

aims to give people who are currently unemployed<br />

the opportunity to test their suitability for a career<br />

in the trade.<br />

Funded by the Tees Valley <strong>May</strong>or and Combined<br />

Authority, those that complete the ‘Get Ready for<br />

Roofing’ programme will receive a guaranteed<br />

interview for a six-month kickstart paid work<br />

placement, and the chance of future employment.<br />

Esme Flounders, Business Development Director at<br />

Barclay Roofing, said: “Here at Barclay Roofing we<br />

are finding it more and more difficult to attract<br />

skilled workers into our business. We know this is an<br />

industry-wide issue, but it is particularly pertinent<br />

across the Tees Valley because of a historic lack of<br />

dedicated training resources in this area. Although<br />

we are fortunate to have very low staff turnover,<br />

with many of our skilled tradespeople being of<br />

long service, as one of the larger roofing<br />

contractors in the region, we feel a responsibility<br />

to our industry to change this and secure the longterm<br />

future of our trade.”<br />

By working directly with employers, the new course<br />

has been created to test aptitude for a career in<br />

the technically demanding roofing industry and<br />

includes everything a candidate will need to safely<br />

work on site and begin longer term accredited<br />

training. Offering an introduction to construction<br />

skills, working at heights, health and safety,<br />

asbestos and abrasive wheels awareness, the<br />

course also covers personal development,<br />

interview skills and the CSCS Test and Green Card.<br />

With the potential to move into employment<br />

following the work placement, Esme added that<br />

Esme Flounders, Business Development Director at Barclay<br />

Roofing and Ben Blackburn, Managing Director of AAA Roofing.<br />

the course is a huge step forward for construction<br />

skills in the Tees Valley, as those who wish to<br />

follow an apprenticeship in a roofing discipline<br />

must currently travel to Newcastle or Leeds.<br />

There are 16 work placements available between<br />

the two employers. Whilst needing a good head for<br />

heights, potential recruits must be aged 18 to 24,<br />

claiming Universal credit and be referred to the<br />

programme by their JCP Work Coach. Candidates<br />

and employers who are interested in learning<br />

more can contact the team on 01642 865561 or<br />

email employability@stockton.ac.uk<br />

RUSSELL SUPPLIES MOD PROJECT IN SOUTH<br />

Russell Roof Tiles has been selected for its to bring all units back from Germany. This<br />

first Ministry of Defence (MOD) re-roofing programme includes funding for accommodation<br />

project in Oxfordshire – the latest in a long improvements and will provide about 1,500 new<br />

line of MOD contracts.<br />

homes for Service families, 4,500 new single living<br />

accommodation bed spaces and working, technical<br />

The manufacturer says it created a specific delivery<br />

and training infrastructure.<br />

schedule to hit extremely tight deadlines supplied<br />

by the main contractor, leading infrastructure firm Russell Roof Tiles says it was able to provide the<br />

Amey. With an estimated completion date of necessary advice to ensure that the tiles and<br />

Autumn <strong>2021</strong>, the development is part of the Army accessories ensured consistency and longevity for<br />

Basing Programme (ABP) in Shrivenham,<br />

MOD while minimising future lifetime costs of the<br />

Oxfordshire.<br />

roof once installed.<br />

The Army Basing Programme (ABP) is a £1.8 billion For the Oxfordshire project Russell Roof Tiles is<br />

capital infrastructure programme, delivering Service supplying tiles from its Commercial Range –<br />

Family Accommodation homes for Service personnel Highland in Cottage Red. The Highland tile is a<br />

and their families, as well as refurbishing key traditional flat roof tile with a mock joint which is<br />

infrastructure. It is providing the facilities to enable laid broken bonded. The manufacturer says the<br />

nearly 100 Army units to relocate, reconfigure, Russell Commercial Range tiles are traditional sized<br />

disband or re-role and deliver the Government’s interlocking tiles in a variety of profiles which<br />

Strategic Defence and Security Review commitment provide a cost-effective roofing solution.<br />

SOLAR SHOWS UP!<br />

175 MW of photovoltaic (PV) solar capacity<br />

was installed across the UK from January –<br />

March <strong>2021</strong>, new figures released by Solar<br />

Energy UK and Solar Media show.<br />

This significant growth over the winter period<br />

brings the UK’s total installed PV capacity to<br />

more than 14 GW, generating enough<br />

electricity to power over 3 million homes.<br />

Ground-mounted solar parks form 70% of<br />

the new capacity, while post-subsidy rooftop<br />

markets also continue to thrive. Rooftop solar<br />

capacity has seen 14% year-on-year growth.<br />

Subsidy-free solar PV in the UK now exceeds<br />

1 GW, or 7.3% of total installed capacity. On<br />

a rolling basis, 660 MW of new capacity was<br />

installed in the 12-month period to 31 March<br />

<strong>2021</strong>, and the UK could be on track to deliver<br />

a gigawatt of new solar capacity this year.<br />

10 TC MAY <strong>2021</strong>

Handrails:- EasyGuard<br />

free-standing Guardrails<br />

*CurveyGuard – an aesthetically pleasing curved rail.<br />

*EasyGuard – raked or straight legs dependant on<br />

application. *FoldGuard – folding handrail.<br />

Trip hazard reduction – long thin base-plates with<br />

Counterweights used on un-secured ends only. Placed at 2m<br />

centres maximum to enable use for leading edge protection.<br />

Galvanised or powder coated finish. Protective mats 5mm<br />

bonded to the base plates.<br />

Standards – Exceeds Class A EN13374- Class A; For<br />

leading edge protection HSE/SR 15, September 1988.<br />

Nationwide delivery or contract installation. – Free material<br />

quantifying service – info@safetyworksandsolutions.co.uk<br />

Ladders:- Easy Fit<br />

Compliant to both BS/EN 5395 and 14122 –<br />

To comply with the standards for<br />

permanent ladders all mild steel then hot<br />

dipped galvanised to BS/EN 1461.<br />

All typical ladders bespoke – email<br />

info@safetyworksandsolutions.co.uk for a<br />

survey check sheet.<br />

Easy Fit, all ladder components are Easy<br />

to assembly; in manageable parts Easy to<br />

handle and install.<br />

Rest Platforms and ladders with special<br />

fixing requirements; solutions provided by<br />

Safetyworks in house.<br />

(All components for British Standard<br />

compliant ladders require steel components<br />

with timber and aluminium recommended<br />

for temporary use only)<br />

HANDRAILS<br />

-<br />

LIFELINES<br />

-<br />

WALKWAYS<br />

-<br />

FALL GUARDS<br />

-<br />

FLEXIDECK<br />

-<br />

DEMARKATION<br />

-<br />

LADDERS<br />

-<br />

STEELWORK<br />

-<br />

Tel: 01487 841400<br />

www.safetyworksandsolutions.co.uk

Industry News<br />

More news, updates and interviews at www.total-contractor.co.uk<br />

BOND IT EXPANDS AND RESTRUCTURES<br />

Bond It, one of the UK’s fastest growing<br />

manufacturers of sealants, adhesives and<br />

building chemicals, has announced it is about<br />

to undergo a huge change as we enter quarter<br />

2 of <strong>2021</strong>.<br />

On the back of its recent acquisition of the Rescue<br />

Tape brand of self-fusing Silicone Tape,<br />

manufactured in North Carolina and distributed<br />

through warehouses in North Carolina and Los<br />

Angeles, the company has now successfully<br />

launched the Bond It brand into the North<br />

American market.<br />

As a result, David Moore, one of the company’s<br />

founding partners, will take on the role of CEO of<br />

Bond It Group and will split his time equally<br />

between the UK and the USA to oversee the<br />

smooth integration and distribution of Bond It<br />

products into the States.<br />

To help him in this role, Bond It has announced<br />

the appointment of Dean Morgan as Managing<br />

Director of the UK operation. Dean will bring with<br />

him a wealth of experience of manufacturing, as<br />

well as already having a long established<br />

relationship with Bond It.<br />

David Moore explained: “Dean was instrumental<br />

in guiding Bond It through the implementation of<br />

ISO 9001, 140001 and the recent 450001<br />

FOUR IOR HONORARY FELLOWS ANNOUNCED<br />

The Institute of Roofing (IOR) has named four<br />

honorary fellows in recognition of their longstanding<br />

service and outstanding contribution<br />

to the roofing industry.<br />

The honorary fellowships have been awarded<br />

worldwide to Detlef Stauch, Peter Plum, Reid<br />

Ribble and Dr Bill Chan.<br />

Graeme Millar, board director at the IOR, said: “All<br />

four honorary fellows have made massive<br />

contributions to the roofing industry and are still<br />

Global expansion and restructuring of Bond It: Dean Morgan,<br />

left, has been appointed Managing Director, Bond It UK, with<br />

David Moore, right, becoming CEO of Bond It Group.<br />

systems and has worked with us for 12 years as a<br />

consultant.<br />

“I believe Dean is the right person to guide Bond It<br />

to its next level of evolution.”<br />

Dean has gained over 40 years of experience in<br />

various manufacturing companies and has indepth<br />

knowledge of trouble shooting, product<br />

development, management systems and driving<br />

improved financial performance.<br />

The company says he will be a major asset in his<br />

new role and will direct the company looking to<br />

streamline the processes already existing as part<br />

of its ISO Management System, looking to improve<br />

efficiency, productivity and quality of the<br />

reputable Bond It brands.<br />

www.bonditgroup.com<br />

doing so. Their dedication is truly exceptional, and<br />

this has had a positive impact both in the UK and<br />

right across the world.”<br />

Stuart Hicks, CEO of the IOR, added: “It is<br />

fantastic to see honorary fellowships being<br />

awarded across four different continents and to<br />

people who have demonstrated some of the<br />

strongest and most impressive skills across our<br />

industry. Their valued contributions have helped<br />

to shape standards and enhance professionalism<br />

in the UK and internationally.”<br />

CUPA COMMITS TO<br />

COLLEGE STUDENTS<br />

Spanish slate manufacturer CUPA PIZARRAS<br />

has announced it is continuing its college<br />

sponsorship scheme for a third year and<br />

extending it to include an additional college.<br />

The annual program includes CPD<br />

presentations, free of charge slate pallets and a<br />

trip to CUPA PIZARRAS’ quarries in Spain, when<br />

COVID-19 allows.<br />

Recommended to CUPA PIZARRAS by the<br />

National Federation of Roofing Contractors<br />

(NFRC), the colleges were chosen for the<br />

outstanding achievements of their students.<br />

Currently on the sponsorship scheme are South<br />

Devon College, Leeds College of Building,<br />

Newcastle College, Edinburgh College, Dundee<br />

and Angus College and finally Bolton College,<br />

which was a new addition this academic year.<br />

CUPA PIZARRAS says a core part of the<br />

sponsorship includes the presentation of its<br />

RIBA-approved CPD, The Definitive Natural<br />

Slate, to the colleges. This CPD covers<br />

everything a construction professional needs to<br />

know about natural slate, from production<br />

process to installation.<br />

“Despite many of the colleges having to switch<br />

to online learning over the past year, restricting<br />

the students’ hands-on learning, all the<br />

students have been able to benefit from the<br />

online CPD seminars, YouTube training videos<br />

and technical guides that we were still able to<br />

provide,” commented Julian Gomez, Director of<br />

Marketing at CUPA PIZARRAS.<br />

12 TC MAY <strong>2021</strong>

Innovation<br />

unlocked<br />

Get ready..<br />

Another game<br />

changing product from<br />

Made for Trade is on<br />

the horizon<br />

ALUMINIUM SYSTEMS

Industry News<br />

ROOFING MOVES &<br />

APPOINTMENTS<br />

• NARM, the National<br />

Association of Rooflight<br />

Manufacturers, has<br />

appointed Tom Ogilvie as<br />

Chairman. He takes over the<br />

role from Jim Lowther, who has<br />

announced his retirement following many<br />

years of service to NARM and the broader<br />

rooflight industry.<br />

• SPRA has announced that<br />

Anthony Hogan has joined its<br />

team as a Technical Expert.<br />

Anthony commented: “I am<br />

delighted to be joining SPRA as<br />

it is such a highly respected organisation,<br />

and I look forward to working with Ronan<br />

and the rest of the SPRA team.”<br />

• Kemper System has<br />

appointed Peter Barber as<br />

Technical Sales Manager.<br />

With more than 30 years’<br />

experience of the building<br />

materials and flat roofing industry, Peter<br />

will be responsible for building client<br />

relationships across the south of England.<br />

Working with specifiers and contractors,<br />

he will focus on developing opportunities<br />

for specification both in the new build and<br />

refurbishment sectors.<br />

• Nicola Trainor has joined<br />

Russell Roof Tiles as<br />

Logistics Manager at its<br />

Burton HQ. She joins the<br />

manufacturer with over a<br />

decade’s worth of experience in the<br />

transport sector. As Logistics Manager,<br />

Nicola’s primary focus is to plan and<br />

manage the dedicated transport team and<br />

hauliers, despatching goods from its three<br />

plants to construction sites across the UK.<br />

MARLEY TAKES BIGGER STEP INTO SOLAR<br />

Marley has acquired Viridian Solar.<br />

The acquisition builds upon a commercial<br />

partnership between the two companies<br />

announced in 2020, that saw Viridian Solar’s<br />

BIPV added to Marley’s extensive range of roofing<br />

products to complete a comprehensive roof<br />

system offer for the UK building industry.<br />

Established in 2003, Viridian Solar has gone on to<br />

build a strong reputation as an innovative<br />

“Our ambitious growth plans will now be<br />

manufacturer of high-quality, roof-integrated<br />

supported by the resources and reputation of<br />

solar PV systems, supplying all the major UK<br />

being part of one of the biggest and most<br />

housebuilders.<br />

respected names in the roofing sector, with the<br />

The deal will see Viridian continue to operate as a backing of Inflexion Private Equity Partners, who<br />

standalone entity, retaining its existing<br />

manage assets of £5.4bn globally.”<br />

management team and continuing to support its<br />

David Speakman, CEO of Marley, added: “The<br />

customers directly.<br />

acquisition brings together two complementary<br />

Stuart Elmes, CEO of Viridian Solar, commented: companies, both of which are influential players,<br />

“The last eighteen years have just flown by and, with highly regarded reputations in the<br />

whilst we are proud of what we have achieved as construction market. Viridian’s strong relationship<br />

a team, our eyes remain firmly on the future. We with housing developers and solar distributors is<br />

are looking forward to working with our new complemented by Marley’s commercial reach into<br />

colleagues at Marley to open an exciting new social housing and among roofing installers.”<br />

chapter in the development of Viridian Solar. More from Marley on page 22<br />

SIG UK ACQUIRES F30 BUILDING PRODUCTS<br />

SIG UK has announced that Bristol-based The SIG UK Leadership Team will work closely<br />

construction product supplier F30 Building with staff at F30, investing in its people and<br />

Products has joined the SIG group.<br />

systems to create a strong framework for the<br />

future and to further strengthen the business’s<br />

F30 Building Products is a national supplier with<br />

first-rate service to customers by growing its<br />

a broad range of specialist products. Established<br />

already extensive product range.<br />

in 2012, the company says it prides itself on its<br />

staff’s technical expertise, the non-biased advice Rob Pearce, Managing Director at F30 and<br />

and high levels of customer service they provide, Divisional Director of SIG Construction<br />

along with its comprehensive stock range and Accessories South, said: “This move is in line<br />

commitment to next-day delivery.<br />

with continuing efforts by SIG to strengthen its<br />

local service and increase its offering to<br />

SIG UK says F30 Building Products, which<br />

customers nationwide. I look forward to working<br />

operates from branches in Bristol and Plymouth,<br />

with my new colleagues and expanding our<br />

will continue to trade under its current name and<br />

capabilities for the benefit of customers in the<br />

branding but with the full support of SIG<br />

South West and throughout the UK.”<br />

Distribution’s local network.<br />

14 TC MAY <strong>2021</strong>

Install the fastener.<br />

Adjust the tube-washer.<br />

How clever is that?<br />

• ONE embedment depth<br />

• EASY reliable installation<br />

• FEWER product combinations required<br />

• SAVES TIME time = money<br />

Take the remarkable high performance of the JBS-R fastener for<br />

concrete substrates, add the engineered strength of EJOT’s EcoTek<br />

telescopic tube-washer and the result is mechanical installation for<br />

tapered systems, that saves time, reduces combination headaches<br />

and delivers year-round practicality.<br />

Innovative tooling options make insulation depths from<br />

70 mm to 500 mm a pleasure to install, whatever the weather.<br />

BRIGHT IDEAS<br />

NEW Flat Roofing Fastening<br />

Systems brochure available now.<br />

Ask your EJOT Sales Engineer<br />

EJOT® the quality connection<br />

Email latest@ejot.co.uk<br />

Call 01977 687040

Roof Tube: Video Content<br />

PRESS PLAY ON QUALITY CONTENT<br />

FOR YOUR SECTOR...<br />

Roof Tube is the new platform for digital content from the leading players in your sector.<br />

Easily accessible on any device, Roof Tube is packed full and constantly updated with<br />

practical, informative and entertaining video content, including how-to’s; project and<br />

product focuses; installation advice; training and webinars; plus interviews and opinions<br />

from those operating throughout the roofing, cladding and associated sectors.<br />

In the second instalment<br />

of Vivalda Group’s CladMaster<br />

series, Vivalda London Branch<br />

Manager Andy Thomas outlines<br />

three things you need to get<br />

right when ordering fixings.<br />

With this year’s LRWA Virtual<br />

Dragon Team Challenge under way,<br />

follow the progress on social media<br />

and take a look back at last year’s<br />

event over on Roof Tube<br />

E<br />

TUBE<br />

PRACTICAL VIDEOS<br />

INSTALLATION ADVICE<br />

STEP BY STEP GUIDANCE<br />

THE ONLINE<br />

COMMUNITY FOR<br />

ROOFING AND<br />

CLADDING<br />

INDUSTRY<br />

16 T C MAY <strong>2021</strong> ESSENTIAL READING FOR ROOFING, CLADDING & INSULATION CONTRACTORS

Technical Roofing<br />

Consultant John Mercer<br />

provides practical advice<br />

and guidance on how<br />

to reduce the risk of<br />

efflorescence forming on<br />

concrete roof tiles<br />

The experts at<br />

Made for Trade have<br />

produced a short video<br />

to show just how easy<br />

the Korniche Lantern is<br />

to install! You really could<br />

be ‘fitting in minutes –<br />

glazing in seconds… and<br />

having a brew before you<br />

know it!’<br />

So head over to www.roof-tube.co.uk to view all these videos and so much more, or<br />

if you’d like to make the most of your digital content, contact Andy or Jake on<br />

01892 732 047 to put your company and products in front of your potential customers!<br />

FIND US AT WWW.ROOF-TUBE.CO.UK<br />

ESSENTIAL READING FOR ROOFING, CLADDING & INSULATION CONTRACTORS<br />

MAY <strong>2021</strong> T C 17

NFRC Roofing Focus<br />

FUTURE PLANS FOR ROOFCERT AS<br />

MOMENTUM CONTINUES TO BUILD...<br />

In his latest column, James Talman, NFRC CEO, gives an update on RoofCERT which,<br />

despite lockdowns and other challenges, is making good progress but still needs further<br />

sector support reach its goals.<br />

Despite three lockdowns, CITB spending<br />

cuts, and roofing contractors being<br />

exceptionally busy, RoofCERT, through<br />

adaptation and innovation, has still been able to<br />

accredit over 100 roofing operatives over the last<br />

year, with 700 more in the pipeline.<br />

As training and assessment restrictions start to<br />

lift, the programme can now support those in the<br />

pipeline to achieve their full accreditation. We are<br />

also able to proceed with a several exciting<br />

initiatives which have been delayed due to<br />

lockdown.<br />

Partnership with housebuilders<br />

One of the key focus areas for RoofCERT this year<br />

will be the home building industry. We are<br />

pleased to have the support of the Home Building<br />

Federation (HBF)’s Home Building Skills<br />

Partnership and are currently working<br />

collaboratively with several large housebuilders,<br />

one example being Redrow Homes.<br />

The quality of new build homes is in the spotlight<br />

currently and this is reflected in the strategic<br />

aims of virtually all of the top ten housebuilders<br />

as set out in their<br />

Annual Reports.<br />

RoofCERT is designed to<br />

help housebuilders<br />

improve quality and<br />

productivity, as well as<br />

help them to identify<br />

any skills and<br />

knowledge gaps. This in<br />

turn will lead to the<br />

development of learning<br />

and training content as<br />

part of the Continuous<br />

Professional Development of<br />

operatives.<br />

“We are one of<br />

the few sectors in<br />

construction that have<br />

created an initiative<br />

like this, and we should<br />

be proud of that”<br />

Experienced Worker Route (EWR) moves<br />

one step closer<br />

There are two main routes to RoofCERT<br />

accreditation for operatives, qualified roofers –<br />

those who hold a vocational qualification – and<br />

experienced roofers with more than five years of<br />

experience through the Experienced Worker Route<br />

(EWR).<br />

Due to the impact of Covid-19, we have not yet<br />

been able to launch EWR so have had to rely<br />

solely on roofers with a vocational qualification.<br />

However, as lockdown has started to ease, we are<br />

now scheduling 100<br />

EWR assessments as<br />

part of a pilot<br />

programme with the<br />

CITB. This will provide<br />

essential feedback for<br />

the roll out of EWR for<br />

those thousands of<br />

experienced roofers who<br />

don’t have a vocational<br />

qualification and whose<br />

CSCS card will need<br />

renewing by 2024. All<br />

Left: James Talman, NFRC.<br />

“One of the key<br />

focus areas for<br />

RoofCERT this<br />

year will be the<br />

home building<br />

industry”<br />

CSCS cards renewed through the Experienced<br />

Worker Route will clearly recognise the RoofCERT<br />

on the card with full details of the individuals<br />

skills on the card’s microchip. We will be<br />

publicising more details on this shortly.<br />

We need your support<br />

So whilst we are progressing in several areas, we<br />

cannot do this alone.<br />

We are one of the few sectors in construction that<br />

have created an initiative like this, and we should<br />

be proud of that. Our initial ambition is to achieve<br />

2,000 accredited roofers which will provide a<br />

platform to develop a sustainable model for<br />

industry to run itself. To achieve this we really<br />

need your support.<br />

If you are a contractor, sign your operatives up; if<br />

you are an operative, start the RoofCERT journey<br />

by booking a knowledge test; if you are a training<br />

provider or part of a training group, could you help<br />

us facilitate health and safety training and<br />

knowledge tests? If you are able to help in any<br />

other way, let us know.<br />

Find out more about RoofCERT / NFRC<br />

https://roofcert.co.uk/<br />

www.nfrc.co.uk<br />

18 TC MAY <strong>2021</strong>

Perfectly Pitched<br />

CONSULTANT CASE STUDY:<br />

EAVES DETAILING IN FOCUS<br />

Technical Roofing Consultant John Mercer teamed up with roofing expert Chris Thomas<br />

for a survey of a traditional handmade clay plain tile roof, which had suffered from water<br />

ingress through the fascia and bargeboards. As John explains, as is often the case, the<br />

issue was with the detailing at the eaves and subsequent troughing in the underlay…<br />

Irecently inspected a traditional handmade<br />

clay plain tile roof where water has been<br />

running through the fascia and bargeboards,<br />

causing damage to the timberwork.<br />

I was accompanied during the inspection by Chris<br />

Thomas, whom I persuaded to come out of<br />

retirement temporarily to assist me. Chris has a<br />

vast wealth of knowledge on roofing, and he wrote<br />

an article many years ago on eaves detailing, so it<br />

was great to have him along.<br />

One of the most common problems I<br />

come across when carrying out<br />

roof surveys is the detailing at<br />

eaves, and in particular the<br />

lack of support for the<br />

underlay behind the fascia<br />

board or eaves tilt fillet. This<br />

causes a trough in the underlay<br />

directly behind the fascia, which can<br />

trap and collect water.<br />

“It is important that the underlay be laid to<br />

ensure that any water in the batten cavity can be<br />

drained safely into the gutters”<br />

Left: John Mercer, Technical Roofing Consultant.<br />

The water invariably leaks<br />

through the underlay as it<br />

finds its way through any cuts<br />

and nail holes.<br />

The importance of the<br />

underlay’s function as a watertight<br />

layer is often overlooked. The underlay<br />

is the last line of defence if water is driven<br />

through the tiling in extreme weather conditions,<br />

and with the use of vapour and air permeable<br />

membranes there is the likelihood of<br />

condensation forming within the batten cavity.<br />

Therefore, it is important that the underlay be laid<br />

to ensure that any water in the batten cavity can<br />

be drained safely into the gutters.<br />

Manufacturer’s details always show the underlay<br />

fully supported at eaves, whether it be by a<br />

plywood board or proprietary plastic underlay<br />

support tray, though it is surprising how often<br />

these are omitted.<br />

Above: Roofing expert Chris Thomas, who accompanied John on this survey, checks the roof pitch at the eaves.<br />

It is not good practice to continue the general<br />

underlay into the gutter as it will degrade through<br />

exposure to sunlight, therefore the common<br />

solution is to install proprietary plastic eaves<br />

support trays which not only support the underlay<br />

behind the fascia at the correct fall, but they also<br />

extend into the gutter and are UV-stable. The<br />

alternative solution is to fit a timber support and<br />

lay a minimum 300mm wide strip of 5U<br />

bituminous underlay at eaves, which being<br />

resistant to UV degradation can extend into the<br />

gutter.<br />

20 TC MAY <strong>2021</strong>

Above left: Diagram shows air path through eaves ventilator. Right: Wrongly installed underlay with sag behind fascia.<br />

The rafter pitch on the roof surveyed is 45<br />

degrees, therefore it should be quite simple to<br />

provide a support for the underlay at the eaves.<br />

Unfortunately, the fascias are set too high,<br />

resulting in a ‘bellcast’ eaves detail. This does<br />

not contravene BS 5534 recommendations for<br />

double lapped plain tiles, provided that the tiles in<br />

the bellcast section of the roof are still set above<br />

their minimum recommended roof pitch, which in<br />

this case they are. But it does make correctly<br />

detailing the eaves support and underlay more<br />

difficult. A fall in the underlay must be<br />

maintained behind the fascia; if this is not<br />

possible, it would be necessary to lower the<br />

fascias. The eaves detail was further complicated<br />

because there are over fascia ventilators<br />

installed, therefore an air path from the<br />

ventilators to the roof space must be maintained.<br />

The distance between the top of the fascia and<br />

fascia ventilator to the first course under-eaves<br />

tiling batten was too short to fit standard plastic<br />

underlay support trays without having to cut each<br />

tray. Therefore, the solution found was to install<br />

specially cut softwood timbers to support the<br />

underlay to the correct fall towards the gutter,<br />

shaped to maintain the air path from the eaves.<br />

The diagram above left shows the detail.<br />

When constructing a roof, the fascias or tilt fillets<br />

should ideally be set to support the tiles at the<br />

same relative pitch as the tiles above. This<br />

becomes even more important where the roof<br />

pitch is at, or close to, the minimum<br />

recommended roof pitch of the tiles. If the tiles in<br />

the eaves courses are set below their minimum<br />

recommended pitch, there is a risk of water<br />

ingress through the tiling at the point in the roof<br />

where there is most water as it runs down from<br />

the roof slope above.<br />

For double lapped plain tiles, a change in pitch –<br />

which is what a bellcast eaves is – affects tiles<br />

in several courses up from the eaves, not just at<br />

the point of the change in pitch. For single lapped<br />

tiles, a bellcast eaves is not recommended<br />

because it directly affects the way the tiles<br />

overlap and can interfere with the headlaps’<br />

normal water-shedding function.<br />

Have you got a pitched roofing query or topic you’d like<br />

John to discuss? Email mattdowns@media-now.co.uk or<br />

contact John on the details below:<br />

Contact John Mercer<br />

www.johnmercerconsultant.co.uk<br />

@Johnmercer3<br />

In summary:<br />

• Set the fascias or tilt fillets to support<br />

the eaves course tiles at the same relative<br />

pitch as the tiles above.<br />

• Ensure there is full support behind the<br />

fascia for the underlay to lay at an<br />

adequate fall towards the gutter.<br />

• Do not extend the roof underlay into the<br />

gutter. Install proprietary underlay support<br />

trays or use strips of 5U bituminous<br />

underlay which is more resistant to UV<br />

attack.<br />

• Ensure a clear air path is maintained for<br />

ventilation at eaves into the roof space.<br />

MAY <strong>2021</strong> TC 21

Solar PV Opportunities<br />

FUTURE ROOFS WILL BE SOLAR<br />

ROOFS – SO DON’T MISS OUT!<br />

When changes to Part L are introduced next year, it is anticipated that many new build<br />

roofs will include solar PV as standard. Stuart Nicholson, Roof Systems Director at Marley,<br />

says all contractors should consider adding solar services to avoid losing revenue.<br />

In January, the Government set out the draft<br />

regulations for the 2025 Future Homes<br />

Standard, which will require all new homes to<br />

be highly energy efficient, with low carbon<br />

heating, and be zero carbon ready by 2025. To<br />

ensure the industry is prepared for this, new<br />

homes will be expected to produce 31% lower<br />

carbon emissions from 2022 as part of changes<br />

to Part L of the Building Regulations.<br />

This improvement in energy efficiency cannot be<br />

made by simple enhancements to the building<br />

fabric and at this stage, solar PV on the roof with<br />

an efficient gas boiler appears to be the easiest<br />

and most cost-effective way for housebuilders to<br />

meet the new Part L targets.<br />

Indeed, if the changes to Part L have the impact<br />

and effect that we expect, around 33% of the roof<br />

covering in new builds could be in solar PV,<br />

alongside continued growth in the retrofit market.<br />

In a highly competitive market, the ability for<br />

contractors to offer these increased solar services<br />

could be the difference between winning or losing<br />

jobs, or risk losing revenue to subcontracted solar<br />

installers.<br />

The future roofing market & solar PV<br />

Solar PV represents such an important part of the<br />

future roofing market that we have recently<br />

acquired Viridian Solar, the manufacturers of the<br />

PV panels in our Marley SolarTile.<br />

The acquisition of Viridian Solar allows us to offer<br />

a fully integrated, easy to install, solar PV roof<br />

system solution from a single source.<br />

Integrated PV systems, like our Marley SolarTile,<br />

are designed so they can be installed by roofing<br />

contractors because they simply replace a section<br />

of roof tiles or slates, acting<br />

as a seamless part of the<br />

roof design. They are easy to<br />

install with a simple push<br />

together design and<br />

electrical connection can be<br />

done once the roofer has<br />

finished fitting the panels, so it<br />

doesn’t hold up the job. It is fully<br />

compatible with our full roof system<br />

and is covered by the 15-year system<br />

warranty.<br />

So what can contractors do now to<br />

prepare for the changes to Part L?<br />

1. Become MCS certified or form a solar<br />

partnership The Microgeneration Certification<br />

Scheme (MCS) covers installations of products<br />

used to produce electricity and heat from<br />

renewable sources, including solar. So, while you<br />

don’t have to be certified to install Marley<br />

SolarTile, it is required that the whole project is<br />

overseen and signed off by an MCS certified<br />

installer.<br />

Therefore, you can either form a partnership with<br />

a certified electrical contractor or become MCS<br />

certified to help differentiate your business. To<br />

apply, you will need to get the appropriate training<br />

for solar PV connection and apply to a<br />

certification body to arrange assessment. More<br />

information can be found at Becoming certified -<br />

MCS (mcscertified.com).<br />

2. Take advantage of free training and<br />

resources To help you make the most of solar PV<br />

opportunities and gain confidence in installation,<br />

we will be running free training courses<br />

throughout <strong>2021</strong>, with face-to-face training<br />

programs taking place when<br />

national lockdown<br />

restrictions and social distancing<br />

guidelines are eased. There are also<br />

easy to follow demonstration videos<br />

and estimating tools on our website.<br />

3. Familiarise yourself with the solar PV<br />

systems available Look for a reliable and highquality<br />

roof-integrated solar PV system, as almost<br />

all new builds favour these over ‘on-roof’<br />

traditional panels because of their superior<br />

aesthetics. With an integrated system, both tiles<br />

and PV are installed together, so there is no<br />

modification to the roof tiles, securing the<br />

warranty.<br />

Our integrated SolarTile is compatible with all our<br />

clay and concrete tiles and slates, so solar PV<br />

can easily be incorporated into any roof design.<br />

The advantage of our system is that it has an<br />

integrated tray so no counter battens are<br />

required, making it easier to install with higher<br />

wind and fire resistance than separate tray<br />

systems.<br />

4. Seek advice For advice on getting started with<br />

solar you can speak to your local Marley roofing<br />

specialist or visit www.marley.co.uk/solarinstall<br />

Contact Marley<br />

01283 722588<br />

www.marley.co.uk<br />

@MarleyLtd<br />

Left: Marley recently acquired<br />

Viridian Solar, who manufactures<br />

the PV panels in its Marley<br />

SolarTile. Inset Stuart Nicholson,<br />

Marley Roof Systems Director.<br />

22 TC MAY <strong>2021</strong>

MEET OUR<br />

REFRESHING<br />

NEW BRAND.<br />

NOW WE HAVE YOUR ATTENTION...<br />

DISCOVER WHAT WE<br />

REALLY DO IN GLASS.<br />

We’re delighted to be celebrating our ‘refreshing’ new<br />

look. Want more in your glass? Discover why we’re in<br />

a glass of our own. Okay, you get the idea ... cheers!<br />

NEW LOOK, SAME TRUSTED EXPERIENCE..<br />

whitesales.co.uk | sales@whitesales.co.uk | 01483 917580

Training Focus<br />

A HANDS-ON APPROACH TO<br />

COLLEGE SPONSORSHIP<br />

Throughout the academic year, CUPA PIZARRAS has been proudly sponsoring six<br />

different colleges across the UK to help students expand their skillset and succeed in<br />

their studies. In the second instalment of this series, Total Contractor met with Steve<br />

Dowell, Lecturer of Roof Slate at South Devon College, to discuss the impact of the<br />

sponsorship on his students and to hear how he has changed his teaching methods to<br />

adapt to the COVID-19 pandemic.<br />

Could you tell us about the sponsorship<br />

and how your students have benefitted?<br />

CUPA PIZARRAS’ college sponsorship provides<br />

pallets of free slate to the colleges for use during<br />

training as well as training videos and merchandise.<br />

It is an incredible opportunity that ensures we have<br />

enough slate to teach all the required practices.<br />

Roofing materials can be expensive to purchase<br />

and of course we do experience a high level of<br />

material wastage with the students who are just<br />

starting out; with breakages, not cutting, dressing<br />

or holing the slates correctly. The donation of<br />

these slates means students are able to keep<br />

practicing until they are competent with their<br />

tools and know how to set roofs out properly.<br />

Under normal circumstances, there is also the<br />

opportunity for four apprentices from each college<br />

to visit Spain and see CUPA PIZARRAS’ quarries.<br />

We’ll obviously have to see how things are given<br />

the pandemic, but in previous years this really<br />

helped to stimulate some healthy competition<br />

within the class for a spot on this trip, which has<br />

led to improved attendance, attention to detail,<br />

and all written course work completed to a high<br />

standard.<br />

The sponsorship makes a big difference to the<br />

students. Being an apprentice can be challenging<br />

as it is necessary to juggle both learning new<br />

skills and working. I think being backed by a highquality<br />

product manufacturer, providing us with<br />

slate and training really gives the students the<br />

confidence to succeed.<br />

Despite many of the challenges we faced when<br />

we had to switch to online teaching over the past<br />

year, restricting the students’ hands-on learning,<br />

all the students have been able to benefit from<br />

the online training videos and technical guides.<br />

Due to COVID-19, how have your<br />

students been impacted?<br />

It has been difficult for them<br />

because their practical skills have<br />

been impacted and this will have to<br />

be taught at some point. However,<br />

they have had the advantage of working<br />

with roofing material non-stop for the past 12<br />

months. They are also all fortunate because none<br />

of them were furloughed during the pandemic and<br />

were able to gain some real hands-on experience<br />

at their apprenticeships, which is one of the most<br />

important parts of their education.<br />

How have you changed your teaching<br />

techniques to adapt to the current<br />

situation?<br />

Although we are not in a classroom setting, we<br />

have ensured that all our students still receive<br />

quality training and learning. Naturally, we moved<br />

everything online and we have continued with<br />

face-to-face video meetings. While the students<br />

were working at their apprenticeships, I would<br />

visit them on site to make sure everything was<br />

running smoothly for them.<br />

As we are all working and teaching remotely, it is<br />

important to me that the students are still able to<br />

Above: Apprentices from South Devon<br />

College, one of the colleges CUPA supports.<br />

connect with one another. The<br />

pandemic can be isolating and I did<br />

not want them to feel as if they were<br />

having to learn alone. When we had online<br />

classes, it was great to see them catch up amongst<br />

themselves and to still develop that friendship<br />

despite us all being in separate locations.<br />

How has CUPA PIZARRAS provided support<br />

to your students during the pandemic?<br />

The students have not only had hands-on<br />

experience with CUPA PIZARRAS slate, but have<br />

also been greatly supported with online CPDs,<br />

YouTube videos and technical guides. CUPA<br />

PIZARRAS has given the students a diverse<br />

approach to understanding and learning the<br />

products and the benefits of using them. Although<br />

the pandemic has changed the way we learn,<br />

CUPA PIZARRAS has remained dedicated to the<br />

students’ learning.<br />

Contact CUPA PIZARRAS<br />

www.cupapizarras.com/uk/<br />

@CUPAPIZARRAS_en<br />

24 TC MAY <strong>2021</strong>

HUGE STOCK FOR NEXT DAY DELIVERY<br />

PAVING & DECKING SUPPORTS<br />

Fixed and adjustable supports for exterior elevated floors<br />

The Pedestal line offers a range of fixed and adjustable supports to<br />

ensure a simple and versatile installation of outdoor raised flooring<br />

by<br />

Proucts by<br />

Elevate supply a comprehensive, high quality range of roof drainage products from<br />

renowned manufacturer Eterno Ivica including pedestal and decking supports, roof<br />

drainage & ventilation, soft surface tiles and composite decking systems.<br />

Contact Darren – 07593 447693<br />

T: 0845 862 0240 • E: info@elevateproducts.co.uk

Underlays<br />

ROOFSHIELD EXPOSURE TESTS<br />

The A. Proctor Group’s technical team carried out in-house exposure tests on<br />

Roofshield in 2019 – purely for their own knowledge – which proved very timely and<br />

provided some interesting findings for projects that were left exposed during<br />

lockdown…<br />

In early 2019, the A. Proctor Group’s (APG)<br />

technical team began in-house testing to<br />

measure the effects of extended outdoor<br />

exposure on the performance properties of their<br />

popular air and vapour permeable roofing<br />

underlay, Roofshield.<br />

Their timing was impeccable. Soon after the 12-<br />

month test was complete, Covid-19 forced the<br />

closure of some building sites across the UK while<br />

at the same time the full effects of Brexit began to<br />

be felt on supply chains, particularly that of roofing<br />

battens and tiles. With this combination of<br />

scenarios beyond anyone’s control, contractors had<br />

no choice but to leave roofing membranes exposed<br />

for longer than manufacturers’ recommendations.<br />

The results of APG’s extended exposure testing<br />

could not have arrived at a better time.<br />

The maximum recommended exposure time for<br />

any construction membrane is determined by<br />

extensive testing by the manufacturer which looks<br />

at the membrane’s basic components, any<br />

additives, and the structure of the final product<br />

itself. For some of the higher regarded<br />

membranes, these recommendations are backed<br />

up by independent third-party testing like LABC<br />

and BBA. But, APG says, sometimes testing by<br />

well-known industry figures in laboratory<br />

conditions, however rigorous, isn’t the type of<br />

reassurance people are looking for.<br />

Never mind the chaos of a global pandemic or the<br />

radical shakeup of a country’s well-worn economic<br />

model. Everyday scenarios like delivery delays,<br />

scheduling mix-ups, and even inclement weather<br />

are what make ‘how long can a membrane be left<br />

exposed for?’ one of the most common questions<br />

that comes to APG’s technical department.<br />

The original purpose of APG’s in-house tests then<br />

Above: A. Proctor Group’s Roofshield underlay.<br />

was not to re-write Roofshield’s 20+ years tried<br />

and tested performance specification, rather, by<br />

simulating a normal delay to a roofing project,<br />

APG wanted to give contractors that extra bit of<br />

reassurance.<br />

It is important to understand here that, given the<br />

purpose of the experiment, the ad hoc nature of<br />

the test, and the small sample size, that the<br />

findings of the 12-month trial described here are<br />

anecdotal only. The results will not inform any<br />

future changes to Roofshield’s current installation<br />

guidance, performance specification, or<br />

accreditations by third parties.<br />

The test was carried out at the APG’s head office in<br />

Blairgowrie, Scotland, between Jan 2019 and Jan<br />

2020. The test consisted of sheets of Roofshield<br />

being mechanically fixed to an angled wooden rig to<br />

mimic a typical pitched roof installation. The<br />

angled plane of the ‘roof’ was then oriented to be<br />

south-facing to receive maximum UV exposure, and<br />

care was taken to position the rig so that any risk<br />

of shading was minimised.<br />

Over the next 13 months, samples of the exposed<br />

membrane were tested on a quarterly basis by<br />

the independent testing organisation BTTG. A<br />

sample of the membrane was tested at the<br />

beginning of the trial to set a baseline against<br />

which subsequent performance measurements<br />

could be compared. The samples were tested<br />

using the standard metrics for air and vapour<br />

permeable roofing underlays: water penetration,<br />

air permeability, and vapour permeability.<br />

The results for air and vapour permeability were<br />

excellent, with very little loss in performance.<br />

While the samples’ performance with these<br />

metrics did decrease gradually over time, the<br />

results remained within Roofshield’s published<br />

BBA-certified performance specification for the<br />

entire 12-month experiment.<br />

The 3, 6 and 9-month Roofshield samples all<br />

achieved Class W1 for water penetration.<br />

Considering the BBA Site Practice Bulletin Number<br />

2 guidance is to protect any membrane that needs<br />

to be left exposed for more than a few days with a<br />

tarpaulin, APG regards this as outstanding.<br />

This ensured that once the building sites were<br />

open and the primary water shedding layer<br />

installed, the roof underlay would perform its<br />

main function of secondary water shedding,<br />

vapour and air permeable. There was no need to<br />

strip roofs and install new underlay.<br />

The APG technical team wish to stress the results<br />

of this or any other in-house test are not a licence<br />

to ignore published guidance – and point out that<br />

in the case of Roofshield, current recommendations<br />

for handling, installation, storage, and maximum<br />

exposure times should be followed. If a delay in<br />

installing the primary covering – the slates, tiles –<br />

on your roofing project is inevitable, APG says it is<br />

always best practice to protect Roofshield with a<br />

tarpaulin as soon as possible to keep UV exposure<br />

to an absolute minimum.<br />

Contact A Proctor Group<br />

01250 872 261<br />

www.proctorgroup.com<br />

26 TC MAY <strong>2021</strong>

Fixfast launches state of the art<br />

UK manufacturing facility.<br />

MADE IN THE UK<br />

Fixfast has invested in its Maximum Reliability, Minimum Fuss promise with the addition<br />

of a cutting-edge manufacturing facility in Kent. Our increased local production capacity<br />

means you can be sure you’ll get the fasteners you need when you need them.<br />

T: +44 1732 882387 | E: sales@fixfast.com | W:fixfast.com/manufacturing

Pitched Roofing<br />

EFFICIENCY UP BUT NOT AT EXPENSE<br />

OF QUALITY OR SUSTAINABILITY<br />

Chris Piper, Sales Director for Housing Developers at Ibstock PLC, which includes the<br />

Forticrete brand, provides his insight into the latest trends and developments in roofing<br />

technology that are supporting roofing professionals in achieving a more efficient and<br />

sustainable method of building.<br />

Whilst 2020 saw unprecedented<br />

disruptions to the sector, the<br />

environmental credentials of both new<br />

and existing residential properties continued to be<br />

a key focus, as sustainability targets outlined by<br />

the government’s Future Homes Standard placed<br />

further pressure on professionals, not only with<br />

regard to their methods of construction, but the<br />

environmental credentials of the materials used.<br />

Last year, contractors also worked extremely hard<br />

to sustain an increased rate of building in a bid to<br />

overcome the backlog in new developments due<br />

to lockdown, whilst simultaneously meeting the<br />

significant increase in demand caused by the<br />

extension of the Stamp Duty holiday and the<br />

confirmation of the Affordable Homes<br />

Programme.<br />