January 2024

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

JANUARY <strong>2024</strong><br />

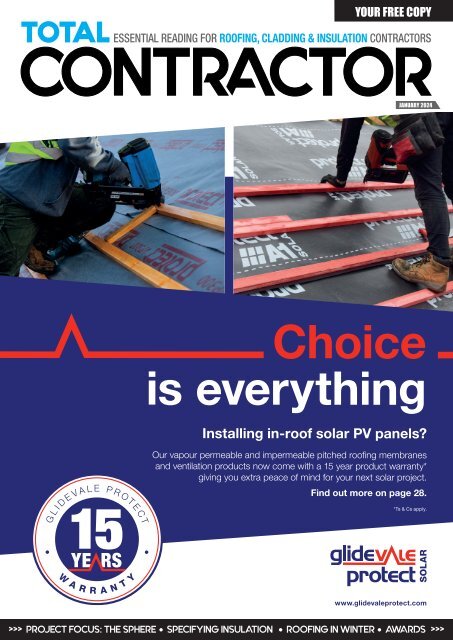

Choice<br />

is everything<br />

Installing in-roof solar PV panels?<br />

Our vapour permeable and impermeable pitched roofing membranes<br />

and ventilation products now come with a 15 year product warranty*<br />

giving you extra peace of mind for your next solar project.<br />

Find out more on page .<br />

*Ts & Cs apply.<br />

www.glidevaleprotect.com<br />

>>> PROJECT FOCUS: THE SPHERE • SPECIFYING INSULATION • ROOFING IN WINTER • AWARDS >>>

FREE<br />

INSTALLER<br />

TRAINING<br />

• Lightweight and easy to handle.<br />

• Universal system compatible with all Sandtoft roof tiles and roof membranes.<br />

• Directly mounted - No trays required (like other competitor panels do).<br />

• Aluminium flashing meaning no adhesive is required.<br />

• Panel to panel connection in less than 1 minute making it easy to install.<br />

Fancy some free in-roof<br />

solar panel training?<br />

Scan the QR code above<br />

to take our free online<br />

training course.

Editor’s Intro<br />

MATT DOWNS<br />

EDITORIAL DIRECTOR<br />

MATTDOWNS@MEDIA-NOW.CO.UK<br />

07963 330774<br />

For a building to really stand out on the Las Vegas strip, you know it’s<br />

going to have to reach new levels in terms of innovation, as well as<br />

collaboration between all involved to ensure it’s a success.<br />

Choice<br />

is everything<br />

Installing in-roof solar PV panels?<br />

Our vapour permeable and impermeable pitched roofing membranes<br />

and ventilation products now come with a 15 year product warranty*<br />

giving you extra peace of mind for your next solar project.<br />

Find out more on page .<br />

*Ts & Cs apply.<br />

And that’s what’s been achieved with The Sphere, which opened its doors<br />

as a concert and events venue in September 2023. Billed as the largest<br />

spherical structure in the world, the numbers are quite staggering; its<br />

exterior facade has approximately 1.2 million LED pucks mounted on it and<br />

each puck consists of 48 individual diodes, with each of the programmable<br />

diodes able display 256 million colours, making its ‘Exosphere’ the largest<br />

screen in the world! Kalzip was commissioned to construct and install the<br />

‘Exosphere’, and we caught up with Dan Vinet, of Kalzip Inc. USA, to discuss<br />

the challenges involved with such a unique facade project on such a grand<br />

scale. As Dan explains on page 32: “The envelope itself consists of<br />

approximately 170 tonnes of profiled aluminium panels, which were<br />

prepared for use in the Koblenz factory. On site in Las Vegas, approximately<br />

4,500 profiled sheets were then further manufactured and prepared for<br />

installation. This was no simple task, as each of the aluminium profiles is<br />

approximately 8m 2 in size and weigh 35kg.”<br />

Elsewhere in this issue, Richard Williams of Aztec Solar Energy provides ten<br />

tips when installing solar PV panels and battery storage systems (page 14);<br />

Kevin Taylor of Marley explains how roofers can boost their businesses in the<br />

winter period (page 16); Bob Richardson points out why roofing contractors<br />

really shouldn’t miss out on submitting projects for the UK Roofing Awards<br />

<strong>2024</strong> (page 20); plus we bring you a number of the latest launches for your<br />

sector, including Proctor Air, the new roofing underlay from A Proctor Group...<br />

Enjoy the issue!<br />

Matt<br />

Advertising:<br />

Publishing Director: Andy Dunn<br />

DD: 01892 732 047<br />

Mob: 07963 330777<br />

Email: andydunn@media-now.co.uk<br />

Registered office: 1 Forstal Road, Aylesford, Kent, ME20 7AU<br />

www.glidevaleprotect.com<br />

Cover courtesy of Glidevale Protect. Head to page 28 to find out more.<br />

www.glidevaleprotect.com<br />

FOLLOW US: TOTAL CONTRACTOR MAGAZINE<br />

SIGN UP FOR YOUR E-NEWSLETTER AT<br />

WWW.TOTAL-CONTRACTOR.CO.UK<br />

Editorial Director Matt Downs<br />

DD: 01892 732 047<br />

Mob: 07963 330774<br />

Email: mattdowns@media-now.co.uk<br />

The content of Total Contractor magazine (and website) does not necessarily reflect the views of the editor or publishers and are<br />

the views of its contributors and advertisers. The digital edition may include hyperlinks to third-party content, advertising, or<br />

websites, provided for the sake of convenience and interest. The publishers accept no legal responsibility for loss arising from<br />

information in this publication and do not endorse any advertising or products available from external sources. No part of this<br />

publication may be reproduced or stored in a retrieval system without the written consent of the publishers. All rights reserved.<br />

Supported by:<br />

34<br />

Coral Morgan of Minster explains how<br />

distributors can support contractors when it comes<br />

to facade specification on page 34.

Contents<br />

3 KEY FEATURES<br />

22<br />

16 OPPORTUNITIES IN<br />

WINTER<br />

Marley’s Kevin Taylor discusses the<br />

opportunities for roofers to add value to their<br />

offering during the winter months<br />

32 THE SHAPE OF THINGS<br />

TO COME...<br />

We take a closer look at Kalzip’s work<br />

constructing and installing the Exosphere on The<br />

Sphere project in Las Vegas, as Dan Vinet<br />

discusses the numbers, processes and<br />

challenges involved in bringing this breathtaking<br />

project to life<br />

34 SAFER FACADE SPEC<br />

Coral Morgan of Minster explains how<br />

distributors can support contractors with all<br />

aspects of facade specification<br />

FURTHER READING<br />

18 COMPONENTS & SYSTEMS<br />

Mark Parsons of Russell Roof Tiles looks at the key<br />

areas those choosing and using roofing products should<br />

focus on<br />

22 IMA AWARDS 2023<br />

Simon Ashworth of BMI UK & Ireland looks back at the<br />

winning projects at the IMA Awards 2023<br />

24 A MORE BALANCED YEAR?<br />

Adrian Buttress of PermaGroup focuses on the<br />

challenges and opportunities for the year ahead<br />

26 SOLAR PV IN <strong>2024</strong><br />

Chris Cowling of Aztec Solar Energy looks ahead to even<br />

brighter times for solar PV in <strong>2024</strong>...<br />

32<br />

40 ALL THE RIGHT INFO<br />

Rob Firman of Polyfoam XPS looks at the challenges<br />

around construction product information<br />

42 SURVEYOR FOCUS<br />

Daniel Smith of Gradient discusses his role as a<br />

surveyor and highlights what he loves about his job<br />

46 SAFETY FOOTWEAR CONCERNS<br />

With tests showing safety footwear that doesn’t perform as<br />

advertised is available in the UK, Alan Murray of BSIF<br />

highlights what you need to be aware of...<br />

4 TC JANUARY <strong>2024</strong>

REGULARS<br />

20 NFRC ROOFING TALK<br />

NFRC’s Bob Richardson, who is also Head Judge<br />

at the UK Roofing Awards, discusses the potential<br />

benefits of submitting your project for an award<br />

this year, and highlights how simple the process<br />

is to be in with a chance of winning a prestigious<br />

trophy!<br />

38 KNAUF INSULATION<br />

TECH TALK<br />

As the Building Safety Act shines a spotlight on<br />

product choice, in his latest column Bradley<br />

Hirst explains what documentation you need to<br />

verify test data for insulation<br />

SECTIONS:<br />

TOTAL<br />

ROOFING<br />

14<br />

TOTAL<br />

CLADDING<br />

32<br />

INDUSTRY NEWS<br />

06 LIGHTING UP IN ROOFING<br />

An OHID survey shows more than 1 in 5 roofing employees<br />

in England are smokers – 3x higher than other sectors!<br />

08 CCPI CONTINUES TO GROW<br />

Leading merchants and distributors have added their<br />

support to the Code for Construction Product Information<br />

TOTAL<br />

INSULATION<br />

38<br />

06<br />

Glidevale Protect<br />

discusses the new NHBC<br />

Standards and the support<br />

available in navigating<br />

ventilation strategies in<br />

conjunction with the use of<br />

pitched roofing underlays.<br />

VEHICLES, TOOLS<br />

& WORKWEAR<br />

46<br />

JANUARY <strong>2024</strong> TC 5

Industry News<br />

BOB 85258 TEXT<br />

SERVICE BOOST<br />

A construction charity has seen a 105.5%<br />

increase in messages to its text helpline<br />

after the launch of an initiative to take the<br />

mental health message to construction<br />

sites and estates teams across the UK.<br />

Hays, the construction recruitment specialist,<br />

joined forces with the charity Band of<br />

Builders (BoB) in October, taking the lead on<br />

visiting sites and reaching out to both bosses<br />

and operatives to discuss tackling the<br />

industry’s mental health crisis and<br />

signposting support that is readily available,<br />

free and easy to access.<br />

The push to raise awareness has prompted a<br />

105.5% jump in messages to the text line<br />

launched by BoB to help tradespeople and<br />

construction workers – which the charity<br />

says is a worrying number but evidence that<br />

more people in the sector are seeking help.<br />

The latest figures from the helpline show that<br />

texts about depression, financial difficulties<br />

or relationship issues accounted for 52.9% of<br />

messages. Thankfully, the charity says the<br />

number of cries for help from construction<br />

workers considering taking their own lives<br />

has decreased from 30.4% to 13.1% in the<br />

last three months.<br />

BoB CEO Gavin Crane said: “Hays is uniquely<br />

placed to take the mental health message to<br />

sites, and the fact that the number of<br />

messages to our text service has more than<br />

doubled in the last three months highlights<br />

the impact they are having in signposting<br />

members of the construction community to<br />

that all-important first step in asking for<br />

help.”<br />

“It’s vital to keep signposting where<br />

construction workers can get help if they are<br />

struggling with their mental health; they can<br />

text BOB to 85258,” he added.<br />

www.bandofbuilders.org<br />

More news, updates and interviews at www.total-contractor.co.uk<br />

NHBC STANDARDS <strong>2024</strong>: CHOICE IS KEY<br />

FOR COMPLIANCE<br />

With the recent NHBC standards, Glidevale<br />

Protect says it is supporting housebuilders,<br />

developers, architects and contractors with<br />

reliable technical information and a wide range<br />

of compliant solutions.<br />

The new NHBC Standards <strong>2024</strong> apply to every new<br />

home registered with the NHBC where the<br />

foundations are started on or after 1st <strong>January</strong><br />

<strong>2024</strong>. They support the recent uplift to Building<br />

Regulation Part L and the proposed Future Homes<br />

Standard by offering new guidance on the use of<br />

integrated in-roof solar PV panels and associated<br />

ventilation strategies. The Standards contain<br />

revisions to clause 7.2.15 ‘Ventilation, vapour<br />

control and insulation’ stipulating that where arrays<br />

of integrated in-roof solar roof panels are used, the<br />

whole roof covering should be treated as air<br />

impermeable unless the panel manufacturer is able<br />

to demonstrate their system is air permeable. The<br />

Standards subsequently reference ventilation<br />

guidance for impermeable roof coverings on both<br />

cold and warm roofs to require adherence to<br />

BS 5250: 2021 – Management of moisture in<br />

Buildings – Code of practice to help prevent the risk<br />

of condensation build up in the roof space.<br />

To assist housebuilders in navigating ventilation<br />

strategies in conjunction with the use of pitched<br />

roofing underlays, Glidevale Protect offers a wide<br />

range of product solutions to ensure compliance<br />

doesn’t impact on choice. The company’s<br />

comprehensive range of type LR vapour permeable,<br />

air and vapour permeable and type HR impermeable<br />

underlay options can be used to effectively support<br />

the installation of integrated, in-roof solar PV panels<br />

when utilised in conjunction with the manufacturer’s<br />

broad range of high and low level ventilation<br />

products on both cold and warm pitched roofs.<br />

Using a tried, tested and trusted underlay and<br />

ventilation solution ensures that the customer has<br />

choice when specifying products to be used on a<br />

development with solar PV. This includes the<br />

company’s new product innovation, Protect A1<br />

Solar, an HR impermeable pitched roofing underlay.<br />

When used alongside the manufacturer’s high and<br />

low level ventilation products, the need for a<br />

ventilated counter batten space above the<br />

membrane is eliminated, saving labour time and<br />

material cost. www.glidevaleprotect.com<br />

SURVEY: 1 IN 5 IN ROOFING IS A SMOKER<br />

More than one in five employees in roofing in England smoke, according to data from the Office for<br />

Health Improvement & Disparities (OHID). That’s three times higher than other industries.<br />

Figures reveal the employee smoking inequality gap has grown by 5% over half a decade and roofing<br />

professionals are falling behind national trends for smoking cessation. Smoking prevalence in roofing<br />

roles means these employees are 65% more likely to smoke, when compared to the average smoking<br />

rate in England. The data insights, collated by Vape Club, highlight the need for equal smoking cessation<br />

support for all in society. The government has set a target of reducing the number of smokers to 5% of<br />

adults in England by 2030. To achieve this, encouraging roofing workers to use smoking cessation<br />

methods will be key. The UK government launched a world-first 'swap to stop' scheme, in which 1 in 5<br />

of all smokers in England will be provided with a free vape starter kit to help them quit. A recent trial by<br />

the University of East Anglia (UEA) and the NHS Stop Smoking Service found a vape starter kit helped<br />

42% of participants to quit within a month. A further 15% had quit after 12 weeks.<br />

www.gov.uk/government/news/smokers-urged-to-swap-cigarettes-for-vapes-in-world-first-scheme<br />

6 TC JANUARY <strong>2024</strong>

MANUFACTURERS OF<br />

PVC SINGLE PLY<br />

MEMBRANES<br />

Agrément Certificate<br />

14/5118<br />

Trevissome Park - Installed by Pellow Flat Roofing<br />

Alongside our extensive range of flat roofing materials, our dedicated<br />

teams offer a collection of services to support your flat roofing projects<br />

from start to finish:<br />

Installation Training Courses<br />

hosted by expert technicians.<br />

Specification, calculation, &<br />

tapered scheme services.<br />

Site visits, roof surveys, core<br />

samples, adhesion tests, etc.<br />

Regular site inspections<br />

throughout your project.<br />

CPD Presentations by our<br />

Specification Team.<br />

10 to 35 year warranties,<br />

with options for IBGs.<br />

uksales@danosa.com<br />

www.danosa.co.uk

Industry News<br />

CHAS PROTECT<br />

INSURANCE LAUNCHED<br />

CHAS has joined forces with Towergate to<br />

introduce CHAS Protect, an innovative<br />

insurance service designed specifically for<br />

contractors and tradespeople, that<br />

rewards careful contractors.<br />

Applying CHAS's experience in supply chain<br />

risk management and Towergate's proficiency<br />

as a specialist business insurance broker, this<br />

collaboration aims to provide CHAS members<br />

with a bespoke insurance offering that<br />

recognises their commitment to operating<br />

responsibly. The lower risk profile associated<br />

with holding CHAS accreditation grants CHAS<br />

members access to contractor-friendly<br />

insurance premiums and customised policy<br />

enhancements under the CHAS Protect policy.<br />

This comprehensive coverage spans business,<br />

tools, equipment, and vehicles and features<br />

exclusive additional perks for CHAS members.<br />

These include extended ‘new for old’<br />

replacement for stolen or damaged<br />

equipment, complimentary tax advice, and<br />

24-hour legal support as well as mental<br />

health support for both business owners and<br />

their employees. At a time when the<br />

economic climate is extremely challenging and<br />

the cost of claims is soaring due to rising<br />

labour and material costs, CHAS Protect is<br />

designed to help CHAS contractors to<br />

safeguard their business, tools, vehicles and<br />

livelihood.<br />

Commenting on the launch of CHAS Protect,<br />

Alex Minett, Head of New Global Markets at<br />

CHAS, says: “This partnership between CHAS<br />

and Towergate marks true innovation in the<br />

industry, offering insurance products tailored<br />

to reward our CHAS members' lower risk<br />

profiles. The contractor-friendly premiums and<br />

personalised policy enhancements showcase<br />

one of the many ways CHAS adds value to its<br />

members as part of their accreditation.”<br />

www.chas.co.uk<br />

More news, updates and interviews at www.total-contractor.co.uk<br />

NEXT STEP FOR CCPI: DISTRIBUTORS &<br />

MERCHANTS SIGN UP TO PLAY THEIR PART<br />

Leading merchants and distributors<br />

have stepped up to support the<br />

Code for Construction Product<br />

Information (CCPI) and committed<br />

to raise standards in the industry.<br />

Belgrade Insulations Ltd, CCF Ltd<br />

Amanda Long<br />

commit to the CCPI. In adopting the<br />

principles of the Code, merchants<br />

and distributors are supporting the<br />

construction industry’s need for<br />

greater accuracy and clarity in terms<br />

of the product information being<br />

(part of the Travis Perkins Group), Quantum<br />

Insulation Ltd, SIG Trading Ltd and VJ<br />

Technology Ltd are the first merchants and<br />

distributors to commit to assessment against<br />

the CCPI and are therefore playing an<br />

essential role in driving much needed change<br />

across the sector.<br />

A 4-clause version of the CCPI has been<br />

specifically designed and targeted for merchants,<br />

distributors and wholesalers. This has been<br />

achieved with the support of the Builders<br />

Merchants Federation (BMF) and its members<br />

through their regional groups, the Construction<br />

supplied upon which installation decisions are<br />

based. This is critical as so often they are<br />

reproducing and managing construction product<br />

information. Watch this space for further CCPI<br />

merchants and distributors announcements to<br />

come!”<br />

The CCPI Merchants and Distributors assessment<br />

means that the organisation will be assessed to<br />

have the necessary product information<br />

processes and systems in place to uphold the<br />

Code, and will adhere to the clauses diligently<br />

whilst proactively promoting and supporting the<br />

adoption of the Code with their suppliers.<br />

Products Association (CPA – which is also the<br />

CCPI, having announced its first product set<br />

organisation credited as the founder of the CCPI),<br />

verifications at the beginning of September<br />

the Electrical Distributors Association (EDA) and<br />

[2023], is gaining momentum. The Scheme now<br />

the NMBS.<br />

has approximately 50 companies either already<br />

Dame Judith Hackitt, author of the Building a<br />

Safer Future Review and Chair of the Industry<br />

Safety Steering Group, said: “I am delighted to<br />

see Merchants and Distributors signing up to this.<br />

This will have a significant impact on the<br />

behaviour of the whole supply chain. Well done to<br />

through or in process for the CCPI Organisational<br />

Assessment, (which is the gateway element of the<br />

CCPI assessment process), and more than 50<br />

product sets (relating to in excess of 700<br />

products) with product information either verified<br />

or in process of verification.<br />

these early adopters.”<br />

The launch of the CCPI Merchants and<br />

From the National Construction Products<br />

Distributors version now provides the opportunity<br />

Regulator, Duncan Johnson, Deputy Director<br />

for this critical element of the supply chain<br />

Construction Products, said: “Effective<br />

ecosystem to play its part in delivering positive<br />

management of product information is an<br />

tangible change in the sector, helping to deliver<br />

essential element of ensuring better, safer<br />

greater confidence to customers and benefiting<br />

buildings. OPSS warmly welcomes this latest CCPI<br />

building safety. Merchants and distributors are<br />

initiative.”<br />

central to the supply ecosystem of construction<br />

Amanda Long (above), Chief Executive of CPI Ltd,<br />

the not-for-profit independently-run organisation<br />

set-up to manage the CCPI, said: “It is great to<br />

see the first merchants and distributors adopt and<br />

products and managing product information. It is<br />

estimated that somewhere between 50-60% of<br />

products go out through merchants and<br />

distributors. www.cpicode.org.uk<br />

8 TC JANUARY <strong>2024</strong>

The Air<br />

To The<br />

Throne<br />

The next generation air and vapour permeable, highly<br />

water resistant roofing underlay. Its characteristics<br />

allow even very complex pitched roofs to breathe.<br />

Available with a 15 year warranty.<br />

For more information on Proctor Air and<br />

vapour permeable system solutions:<br />

contact@proctorgroup.com +44 01250 872 261 www.proctorgroup.com

Industry News<br />

More news, updates and interviews at www.total-contractor.co.uk<br />

NEW CHAIR AND VICE<br />

CHAIR AT IOR<br />

The Institute of Roofing (IoR) has announced<br />

a new Chair, Graeme Millar (FIoR), and Vice<br />

Chair, Mark Dunn (FIoR).<br />

As an IoR Fellowship member since<br />

2014, Graeme’s experience in<br />

construction spans more than 40<br />

years when he began his career as<br />

a trainee slater at William Millar and<br />

Sons in 1978. He is the fifth-generation<br />

roofing contractor in his family. His high-profile<br />

career has seen him serve as Managing<br />

Director of Bain and Irvine Ltd for 33 years, as<br />

well as Managing Partner for Graeme Millar<br />

Roofing Consultants for 20 years. Graeme<br />

(pictured above) is currently President and<br />

Head of Technical at the International<br />

Federation for the Roofing Trade (IFD), and<br />

former President of the National Federation of<br />

Roofing Contractors.<br />

The IoR’s new Vice Chair, Mark Dunn<br />

(FIoR), has worked in the roofing<br />

industry since 1985 and is now<br />

Head of Training at Sika Liquid<br />

Plastics. He has worked his way up to<br />

management roles after coming ‘off the tools’<br />

earlier in his career. Mark (left) is passionate<br />

about roofing, which is seen in his work and<br />

commitment to training through the courses he<br />

delivers at Sika Liquid Plastics and for the IoR.<br />

Mark has been a member of the Institute since<br />

2005, and became one of its regional officers<br />

which, he said, provided him with the<br />

opportunity to “…give something back to the<br />

industry…” and enables him to use his<br />

knowledge and expertise to help future<br />

generations of roofing.<br />

The new Board appointments come as<br />

discussions are taking place between the<br />

Chartered Institute of Building (CIOB) and the<br />

IoR, with a view to integrate the Institute into the<br />

CIOB’s diverse membership and global<br />

operations. www.instituteofroofing.org<br />

PROCTOR AIR ENTERS THE MARKET<br />

Innovation has run through the Proctor<br />

family since its earliest records, and since<br />

taking over in 2012, the company’s<br />

Managing Director, Keira Proctor, has<br />

continued this tradition, building on this<br />

foundation of trust, honesty, and hard work<br />

from the very same desk where her father<br />

and grandfather made the company what it<br />

is today.<br />

The A. Proctor Group Ltd has been at the<br />

forefront of pitched roofing membrane technology<br />

for over a quarter of a century. 25 years working<br />

with its partners across the construction<br />

industry, helping to evolve standards, and<br />

delivering quality results on projects across the<br />

UK and around the world.<br />

The company says Proctor Air is the result of this<br />

quarter century of experience on sites and on<br />

drawing boards, listening to and responding to<br />

the challenges faced by the industry.<br />

The next evolution of<br />

roofing underlay<br />

technology,<br />

Proctor Air<br />

has been developed<br />

and manufactured to the<br />

company’s precise specifications<br />

and requirements. This ensures the onsite<br />

performance of its material mirrors the offsite<br />

performance, while a 15 year warranty<br />

ensures peace of mind for any project, now and in<br />

the future.<br />

Hydrophobic additive in all three layers of this<br />

next generation product amplifies water holdout,<br />

and the company says this, alongside optimized<br />

levels of permeability to both air and moisture<br />

vapour, ensures Proctor Air delivers the most<br />

robust and dependable performance.<br />

This, the A Proctor Group says, means Proctor Air<br />

can be specified on all roof types not just without<br />

low- and high-level ventilation, or a vapour<br />

control layer, but with confidence.<br />

After 25 market-leading years, The A. Proctor<br />

Group says it is once again pushing roofing<br />

forward and embracing the future of membrane<br />

technology.<br />

www.proctorgroup.com<br />

The “Air” to the throne<br />

has arrived... A Proctor Group’s<br />

Proctor Air membrane.<br />

10 TC JANUARY <strong>2024</strong>

TAYLOR ROOFS MAKES CUSTOMER’S XMAS!<br />

Taylor Roofs’ Managing Director Jamie Taylor (Santa) and his staff presenting the cheque to Judy.<br />

DELIVERING<br />

TOGETHER<br />

Over 140 energy efficiency and insulation<br />

professionals, industry figureheads and<br />

government officials came together at an<br />

event celebrating the transformational work<br />

undertaken by the sector.<br />

The event, held as a partnership between the<br />

National Home Decarbonisation Group (NHDG)<br />

and the National Insulation Association (NIA),<br />

also placed a focus on the government’s future<br />

net zero and wider decarbonisation plans.<br />

Christmas came early for West Lothian lady<br />

Judy Irons who was the lucky winner in local<br />

company Taylor Roofs’ biggest ever<br />

competition giveaway.<br />

Anyone who accepted the Bathgate firm’s quotes<br />

between June and August last year, and went<br />

ahead and had a new roof installed, was entered<br />

into a prize draw, with the company pledging to<br />

cover up to £15,000 of the full balance.<br />

The quote for Judy, from Craigshill, Livingston,<br />

came in at £9258.79, and when her name came<br />

out of the hat, Taylor Roofs Managing Director<br />

Jamie Taylor and his team donned their festive<br />

costumes and dropped in on her at work to<br />

present the stunned winner with a cheque for that<br />

amount!<br />

Jamie Taylor explained: “Judy’s roof was over 50<br />

years old and the tiles had become porous, the<br />

membrane and old Cellotex below had started to<br />

fail and allow water ingress. There was also a lot<br />

of condensation forming in her home as a result of<br />

the roof’s condition.<br />

“We installed a new roof with oriented strand<br />

board (OSB), new underlay, timbers, Marley roof<br />

tiles and associated dry fitting systems (no<br />

cement mortar) to ensure a maintenance-free<br />

solution.<br />

“The roof has also had low level and high-level<br />

ventilation to ensure the home can breathe<br />

“One of our core values<br />

at Taylor Roofs is<br />

giving back, and when<br />

better to do that than at<br />

Christmas time? The<br />

smile on her face said<br />

it all” – Jamie Taylor<br />

properly in the modern climate – properly<br />

ventilating roof spaces is now more important<br />

than ever.<br />

“This is all covered by Taylor’s 10-year materials<br />

and workmanship warranty, and we were<br />

delighted that Judy was another satisfied<br />

customer when the job was finished.<br />

“It’s the first time we have run a competition like<br />

this and it was a great feeling telling Judy she had<br />

won and then handing over a cheque for nearly<br />

£10,000.<br />

“One of our core values at Taylor Roofs is giving<br />

back, and when better to do that than at<br />

Christmas time? The smile on her face said it all.”<br />

When receiving the cheque prior to Christmas,<br />

Judy said: “It’s amazing! What a great early<br />

Christmas present. Thanks to the whole team at<br />

Taylor Roofs, they’ve been absolutely amazing.”<br />

www.taylorroofs.co.uk<br />

Senior representatives from the Department for<br />

Energy Security and Net Zero (DESNZ) were also<br />

in attendance, including the Minister for Energy<br />

Efficiency and Green Finance. Lord Callanan<br />

spoke to attendees about the scale of ongoing<br />

decarbonisation commitments and policies.<br />

Derek Horrocks (right) - who is the<br />

chair of both the National Home<br />

Decarbonisation Group and the<br />

National Insulation Association -<br />

placed a focus on the power of<br />

collaboration across the sector and how it will<br />

serve to create a robust supply chain capable of<br />

delivering long-term government commitments<br />

for net zero.<br />

Derek said: “This year (2023) has seen great<br />

steps forward when it comes to the<br />

decarbonisation of homes and journey towards<br />

net zero, and it’s been a great opportunity to<br />

come together and reflect on that, as well as<br />

discuss how to overcome any challenges. The<br />

core fact remains that the work being done<br />

across the sector to decarbonise homes is<br />

working to make a real-life difference to real<br />

people. It makes sure that people’s homes are<br />

safe and healthy, while also lowering energy bills<br />

too. This has a profound and proven impact on<br />

people’s health and wellbeing – and serves to<br />

tackle the biggest crises being faced today with<br />

rising fuel poverty, pressure on the NHS and<br />

climate change. www.nhdg.org/<br />

JANAURY <strong>2024</strong> TC 11

It’s more<br />

than a roof<br />

It’s a Marley Solar Roof System.

LEARN MORE<br />

You may just see a roof. But by installing the complete<br />

Marley Solar Roof System, you’ll see benefits of a solution<br />

designed to work together, whilst making the most of the<br />

growing demand for roof integrated solar panels.<br />

It’s more than a roof, it’s an opportunity for roofers.<br />

marley.co.uk

Solar PV & BESS<br />

BATTERY AFFORDABILITY IS<br />

TRANSFORMING SOLAR POPULARITY<br />

Commercial organisations have been slower to adopt battery storage than the domestic<br />

solar market, primarily due to storage capabilities and affordability. Yet according to<br />

Richard Williams, founder and Managing Director of Aztec Solar Energy Ltd, that’s now<br />

changing as the challenges organisations once faced are easily remedied. Based at the<br />

University of Warwick, Richard has over 30 years in the energy services sector and<br />

below shares his views on how battery storage is transforming a sector’s ability to turn to<br />

greener energy solutions.<br />

The economic attractiveness of solar energy<br />

has accelerated over the last five years<br />

with more businesses adopting it to combat<br />

rising energy costs and deliver long-term energy<br />

security. Until now the expense of installations,<br />

the difficulties of a retrofit, and lack of energy<br />

storage has been a barrier, but that’s no longer<br />

now the case.<br />

Installing rooftop solar power is one of the best<br />

investment opportunities available.<br />

Batteries have become much more competitively<br />

priced and rather than return the energy<br />

harvested to the grid – where you don’t always<br />

get the best price – they allow you to store that<br />

power and draw on it as needed and<br />

accommodate peaks in demand. Batteries can be<br />

force-charged overnight at lower electricity rates<br />

“The economy of<br />

scale with battery<br />

production is<br />

bringing the<br />

prices down and<br />

making them a costeffective<br />

solution”<br />

and the energy used in the day when electricity<br />

rates are higher.<br />

Even if PV panels have been installed, battery<br />

storage can be added afterwards. Many are<br />

taking this option as the economy of scale with<br />

battery production is bringing the prices down<br />

and making them a cost-effective solution.<br />

Batteries have reduced both in cost and in size by<br />

Left: Richard Williams is foremost an engineer,<br />

as well as founder and Managing Director of<br />

Aztec Solar Energy Ltd, the nationwide<br />

engineering-led consultancy and installer of<br />

bespoke solar photovoltaic (PV) and battery<br />

energy storage systems (BESS).<br />

at least 40% over the last five years.<br />

Here are ten top tips for installing solar<br />

photovoltaic (PV) panels and battery systems<br />

(BESS). These of course sit alongside good<br />

roofing practice when installing renewable energy<br />

systems.<br />

1. Initial assessment<br />

i) Check the age, condition and load capacity of<br />

the roof<br />

ii) The roof should be entirely non-combustible. If<br />

not, consider installing a non-combustible layer<br />

The drop in price and reduction in size of<br />

battery storage solutions is making solar PV<br />

more attractive to commercial properties<br />

14 TC JANUARY <strong>2024</strong>

etween the solar panels and roof.<br />

iii) For new roofs understand the risks of flat vs<br />

pitched roofs<br />

iv) Ensure there is a completed H&S risk<br />

assessment, including working at heights.<br />

2. PV location<br />

The amount of sunlight and shading is key.<br />

Consider the surroundings and risk of debris from<br />

leaves etc. Look at on-going accessibility for<br />

maintenance and repair. Be aware that without<br />

safe access this could increase costs further<br />

down the line.<br />

“Evaluate the fixings in<br />

relation to the weatherrelated<br />

conditions in<br />

the area, durability,<br />

maintenance, and<br />

lifecycle”<br />

3. Type of PV panel<br />

PV panels vary from manufacturer to<br />

manufacturer. Ensure they conform to the most<br />

recent and relevant technical standards. Evaluate<br />

the fixings in relation to the weather-related<br />

conditions in the area, durability, maintenance,<br />

and lifecycle.<br />

4. Installations<br />

i) There are 2 main types of PV installation:<br />

(a) Integrated into the roof surface (Building<br />

Integrated Photovoltaic - BIPV)<br />

(b) Above the roof surface (Stand-off systems)<br />

ii) Different types of roof coverings present<br />

different installation challenges. Ensure that<br />

weathertightness, thermal insulation, ventilation<br />

and structural stability are not compromised by<br />

the installation.<br />

5. Inverters<br />

The PV inverter converts the variable direct<br />

current (DC) output from a PV panel into<br />

alternating current (AC). Its size dictates the push<br />

“Batteries have reduced both in cost and in size<br />

by at least 40% over the last five years”<br />

pull capabilities and size of the battery and<br />

should be matched to the usage pattern of your<br />

building/site demand.<br />

6. Battery storage systems<br />

i) Modern lithium ion batteries are slim. They are<br />

sleek and lightweight so can be wall mounted or<br />

standalone.<br />

ii) Batteries should be located in fire rated<br />

compartments away from combustible<br />

surroundings.<br />

7. Constantly ‘live’<br />

The ‘live’ nature of PV panels means careful<br />

consideration of how panels are isolated:<br />

i) dedicated remote switch<br />

ii) integrated isolator switch<br />

iii) via a fire alarm system<br />

8. Handover<br />

Once commissioned a handover should include<br />

training, a quality inspection, and a full test of<br />

the system. Certification of all electrical work in<br />

compliance with the relevant UK standards.<br />

9. Inspections<br />

i) Monitor energy production<br />

ii) Only use competent electrical engineers<br />

(NICEIC, ECA etc)<br />

iii) Periodic panel cleaning and inspection will<br />

help maintain an efficient system<br />

iv) A full visual inspection by a competent person<br />

should be conducted annually<br />

v) Inspections are also advised following extreme<br />

weather<br />

10. Accreditation<br />

All PV contractors should be accredited to a<br />

national trade body and follow mandatory<br />

guidelines, as well as being trained in general<br />

construction site practice and specific training or<br />

competence appropriate to solar PV and BESS<br />

installations.<br />

Contact Aztec Solar Energy<br />

www.aztecsolarenergy.co.uk<br />

0845 467 5058<br />

JANUARY <strong>2024</strong> TC 15

Pitched Roofing<br />

THE ADDED VALUE OF WINTER<br />

READY ROOFS<br />

Kevin Taylor (pictured), Training and Technical Support Manager at Marley, says the winter<br />

months can present additional ‘business building opportunities’ for roofing contractors...<br />

As the dark winter months approach, many<br />

car or van drivers think nothing of taking the<br />

time to get their vehicles ‘winter ready’. A<br />

‘to-do’ list could include a new battery, ensuring<br />

winter screen wash levels are topped up, tyres are<br />

checked, and the ice scraper is at the ready. They<br />

are commonsense and simple actions that ensure<br />

winter driving is stress-free.<br />

Roofs on the radar<br />

But many households would also be giving<br />

themselves peace of mind if they applied the same<br />

thought to undertaking similar checks on their<br />

roofscapes. Ensuring the roof is maintained properly<br />

and is winter ready can mean, for example, that<br />

small and easily solved roof issues do not escalate<br />

and become a highly inconvenient and expense<br />

problem.<br />

So, while roofing contractors may see a reduction in<br />

the number of new roofing projects starting during<br />

the winter months, there are ways they can<br />

proactively position themselves to generate<br />

business opportunities across repair and<br />

maintenance.<br />

Added value service for roofing contractors<br />

There are four key roofing areas that contractors<br />

should concentrate on when it comes to<br />

undertaking a pre-winter roof check.<br />

When complete, the check findings will enable<br />

contractors to have informed conversations with<br />

homeowners and agree on any remedial or ongoing<br />

maintenance actions which could be needed.<br />

Roofers are in the unique position in that they can<br />

access an often-out-of-bounds area of the building<br />

and act as expert eyes that homeowners can rely<br />

on.<br />

1. Roof Tiles: Checking from a safe position,<br />

“Roofers are in the<br />

unique position in<br />

that they can<br />

access an often out<br />

of bounds area of the<br />

building and act as<br />

expert eyes”<br />

contractors can assess whether there are any<br />

missing or cracked roof tiles, ridge tiles, hip tiles, or<br />

other fittings. It is important to get any cracked or<br />

missing roof tiles repaired as soon as possible as<br />

any water or snow getting into the roof at that point<br />

can track down the roof timbers and cause<br />

inconvenient and expensive damage to ceilings and<br />

internal walls.<br />

2. Lofts: Condensation can be a big problem over<br />

the winter months because people stay indoors for<br />

longer periods, they turn up the heating and don’t<br />

open the windows. This creates increased volumes<br />

of warm, moist air which finds its way to the loft<br />

space, hits the cold underside of the roof coverings,<br />

and re-forms back into water droplets.<br />

The droplets can track down the roof timbers and<br />

drip onto ceilings, often creating dampness and<br />

mould if left unchecked. The best way to minimise<br />

the risk of condensation in existing roofs is to<br />

ensure that there is a flow of ventilation from eaves<br />

to eaves, or ideally eaves to ridge.<br />

Contractors should advise homeowners to declutter<br />

their loft before the coldest weather arrives, and<br />

check that insulation is not blocking the airflow at<br />

the eaves. This should ensure that there is<br />

sufficient airflow throughout the roof to minimise<br />

the risk of condensation and the potential damage it<br />

can cause.<br />

3. Gutters: An essential winter ready roof<br />

check should always look at the gutters<br />

and make sure they are clear of vegetation<br />

and debris. If it is safe to do so, contractors<br />

should offer to clear the gutters, and the<br />

outlets/downpipes and, if this is an annual problem,<br />

should suggest that the household fits gutter guards<br />

to prevent the problem from re-occurring.<br />

Homeowners should also be informed that failure to<br />

address this issue over time can result in water<br />

backing up behind the fascia board and into the roof<br />

and staining down the face of the brickwork.<br />

4. Mortar and flashings: As with the roof tiles,<br />

contractors can observe if there is any missing<br />

mortar from the ridge and hip tiles, the valleys, or<br />

the verge tiles. They can also check that all<br />

flashings are still securely fixed into the brickwork,<br />

not turned up at the edges, and there is no missing<br />

pointing.<br />

If applicable, it is also sensible to see that the soil<br />

pipes flashings remain intact, and that the pipe is<br />

correctly sealed with a collar or similar. If any issues<br />

are spotted, roofers can help address them without<br />

delay and prevent driving rain and snow getting into<br />

gaps and, ultimately, the roof.<br />

Carrying out competitively priced winter ready roof<br />

checks can be an added value service offering for<br />

roofing contractors that will strengthen client<br />

relationships and help identify costly roof problems<br />

before they magnify, saving homeowners the timeconsuming<br />

inconvenience and unwanted expense of<br />

major roofing work.<br />

Contact Marley<br />

www.marley.co.uk/roofsystem<br />

01283 722222<br />

Marley<br />

16 TC JANUARY <strong>2024</strong>

Pitched Roofing<br />

SPECIFYING & INSTALLING ROOFING<br />

COMPONENTS AND SYSTEMS<br />

Mark Parsons, Technical Director at Russell Roof Tiles, provides advice on the main<br />

aspects that those specifying roofing solutions should consider.<br />

In the ever-evolving landscape of construction,<br />

specifiers, housebuilders and contractors are<br />

increasingly exploring avenues for efficiency<br />

and cost-effectiveness. Often prompted by<br />

requests for alternatives from within the supply<br />

chain or by installers, these considerations bring<br />

to light the delicate balance between perceived<br />

initial cost savings and future liability, as well as<br />

the risk of a greater cost where substitutions do<br />

not carry the same warranties or even invalidate<br />

guarantees offered by the original manufacturer.<br />

Maintaining high standards amidst<br />

substitution requests<br />

Given the current challenging climate, we<br />

recognise the growing trend of exploring<br />

alternative roofing products. Whether driven by<br />

availability issues or cost-saving measures, it is<br />

important to emphasise the importance of<br />

aligning proposed changes with the high<br />

standards inherent in a<br />

manufacturer’s original<br />

specifications for a roofing system.<br />

The holistic approach to<br />

roofing systems<br />

Manufacturers across the construction<br />

industry consistently underline the rigorous<br />

standards products need to meet to deliver<br />

quality and reliability. However, it is imperative to<br />

view the full roofing system holistically to ensure<br />

optimum performance and longevity.<br />

Manufacturers – such as Russell Roof Tiles –<br />

specify concrete roof tiles and accompanying<br />

accessories, where every component plays a vital<br />

role in the overall system.<br />

Impact on guarantees and warranties<br />

For example, we provide RussSpec – which is a<br />

15-year guarantee when using the whole roof<br />

“Deviating from specified accessories could<br />

introduce compatibility issues, potentially<br />

affecting the whole roofing system's<br />

performance and appearance”<br />

Left: Mark Parsons, Technical Director at Russell<br />

Roof Tiles.<br />

solutions. This is applicable where<br />

the specification has been followed<br />

and detailed in accordance with<br />

advice provided in the fixing<br />

specification and instruction. Having<br />

guarantees of this kind in place, the contractor<br />

knows the manufacturer is committed to<br />

providing a high-quality product.<br />

These roofing systems are meticulously<br />

developed for specific products. So, the inclusion<br />

of third-party fittings or components may<br />

compromise the validity of these assurances.<br />

Deviating from specified accessories could<br />

introduce compatibility issues, potentially<br />

affecting the whole roofing system’s<br />

performance and appearance. Additionally,<br />

customer support and technical service are<br />

intricately linked to the use of recommended<br />

accessories, making it challenging to extend the<br />

same level of support for accessories from other<br />

manufacturers.<br />

It is also important to be aware of a guarantee’s<br />

limitations. For example, products must be<br />

installed as specified and substitution of<br />

components with other products at any stage of<br />

construction will invalidate guarantees.<br />

By working closely with a manufacturer which<br />

has guarantees, the contractor is in a stronger<br />

position to ensure a viable roofing solution as<br />

well as maintaining all future needs. The<br />

technical team at Russell Roof Tiles is also on<br />

hand to answer questions, ensuring issues are<br />

minimised before, during and after installation.<br />

Drone shot of Rochdale Golf Club's new roof<br />

using products from Russell Roof Tiles.<br />

18 TC JANUARY <strong>2024</strong>

Compliance and standards<br />

Using specific roofing accessories such as our<br />

RussFast Dry Ridge, Russell Dry Verge, purpose<br />

designed fixings and other components comply<br />

with relevant British Standards, ensuring<br />

seamless integration and customisation. Whilst<br />

alternative products may offer apparent cost<br />

savings, they may be lacking in some features,<br />

leading to complications during installation and<br />

compromising the overall integrity of the roof.<br />

Navigating regulatory changes<br />

It is also important to ensure the chosen supplier<br />

adheres to all current legislation, such as the<br />

2022 Construction Products Regulation which<br />

covers compliance and testing.<br />

In addition, following the Grenfell Tower fire, the<br />

Hackitt & Regulations Review has set the industry<br />

a challenge of radical transformation. Dame Judith<br />

Hackitt’s Independent Review of the Building<br />

Regulations and Fire Safety: Final Report (Hackitt<br />

“Substitution of<br />

components with other<br />

products at any stage<br />

of construction will<br />

invalidate guarantees”<br />

Report) identified that the construction regulatory<br />

system was unfit for purpose, and outlined<br />

proposals for regulatory reform and how industry<br />

needed to change the principles of how it operates.<br />

Building Safety Act 2022 and duty holders<br />

New regulations introduced duty holders for<br />

compliance, and emphasise the importance of an<br />

integrated approach. Deviating from specified<br />

components may lead to unnecessary complexity<br />

in investigation, warranty and liability. Under the<br />

Building Safety Act 2022, for example, duty<br />

holders such as the principle contractors have<br />

new responsibilities, for example to also include<br />

information within a digital framework. Pre-<br />

Construction Information (PCI) requires digital<br />

record keeping for traceability, which is simpler to<br />

deliver from a single roofing components supplier.<br />

Deviating from specified components may lead to<br />

unnecessary complexity in investigation,<br />

warranty, and liability. Duty holders, including site<br />

teams, are urged to ensure competence,<br />

knowledge, and skills in collaboration with<br />

suppliers to navigate these changes effectively.<br />

Supporting partnerships through<br />

adherence to standards<br />

In a sector facing increasing legislation, it is vital<br />

that those specifying roofing solutions partner<br />

with manufacturers who are aware of the latest<br />

standards, expectations and compliance, and can<br />

deliver quality products to customers and their<br />

clients.<br />

Contact Russell Roof Tiles<br />

www.russellrooftiles.com<br />

Russell Roof Tiles<br />

For further r<br />

inform<br />

ation<br />

or a hire quotation call<br />

01858 412 100<br />

Email: sales@cookerhire.com<br />

www.cookerhire.com

NFRC Roofing Talk<br />

COULD YOUR COMPANY WIN A<br />

UK ROOFING AWARD IN <strong>2024</strong>?<br />

Bob Richardson, NFRC Head of Technical and Training, who is also Head Judge at the UK<br />

Roofing Awards, discusses the entry process and requirements, and explains how<br />

companies can really benefit from submitting their projects to the annual awards event…<br />

The UK Roofing Awards <strong>2024</strong> is on the<br />

horizon, and entries are now open at<br />

nfrc.awardsplatform.com. Projects can be<br />

submitted until 12 <strong>January</strong> for the judges’<br />

consideration.<br />

We encourage firms of all sizes and in all roofing<br />

and cladding disciplines to enter the Awards. It<br />

only takes a short amount of time and there is no<br />

entry fee. The judges reward quality<br />

workmanship, problem solving, health and safety,<br />

and great supply chain management – all of<br />

which can be achieved by any firm with a<br />

commitment to excellence.<br />

Is there an award for projects in my<br />

discipline?<br />

Entries are welcome in 16 project categories:<br />

• Bituminous Hot Applied Liquid<br />

Waterproofing; • Cold Applied Liquid<br />

Waterproofing; • Fully Supported Metal;<br />

• Green Roofing; • Heritage Roofing;<br />

• Leadwork; • Mastic Asphalt Multidiscipline<br />

Project over £250k; • Rainscreen<br />

Facades; • Reinforced Bitumen Membranes;<br />

• Roof Slating; • Roof Tiling; • Sheeting and<br />

Cladding; • Single Ply Roofing; • Small Scale<br />

Project (Under £25k); • Solar PV<br />

One entry will also take the Industry Choice<br />

Award, voted for online by everyone across the<br />

UK roofing and cladding industry. Finally, the<br />

project deemed by the judges as best across all<br />

categories will gain the prestigious title of Roof of<br />

the Year 2023.<br />

Can I nominate a great individual for an<br />

award?<br />

Companies with a standout young roofer,<br />

apprentice or trainee are encouraged to nominate<br />

them for the Young Roofer of the Year Award,<br />

gaining recognition for the individual for their<br />

hard work, commitment and a great start to their<br />

career in roofing.<br />

If you have someone in your team who goes the<br />

extra mile for best practice in health and safety,<br />

you can also nominate them for the Health and<br />

Safety Individual of the Year Award.<br />

Are we eligible to enter?<br />

It’s not only NFRC Member companies who can<br />

enter. Individuals being nominated must be<br />

employed by, or the roofing project must have<br />

been completed by a roofing contractor with<br />

membership of at least one of the following trade<br />

associations/organisations:<br />

FTMRC; GRO; LRWA; MAC; MCRMA; NFRC;<br />

NFRC Competent Person Scheme (formerly<br />

known as CompetentRoofer); SPRA.<br />

We worked on the project but weren’t the<br />

roofing contractor – can we enter?<br />

Manufacturers, architects and specifiers are very<br />

welcome to submit projects but must ensure that<br />

the roofing contractor is a member of one of the<br />

above listed trade associations/bodies. The<br />

award always goes to the roofing contractor – but<br />

where the entry was submitted by a supplier, they<br />

will be mentioned if the project gets shortlisted.<br />

Is our work impressive enough to win a<br />

UK Roofing Award?<br />

Winning, and being shortlisted, is about more<br />

than just a flashy project. Aesthetics are of<br />

course important, but as we all know, ‘the devil is<br />

in the detail’ so attention to detail on a small<br />

project is just as important as on a big build. The<br />

judges will look at your evidence of good project<br />

management and problem solving, the interfaces<br />

with other trades, any apprentices taken on or<br />

training that was required, in conjunction with<br />

exceptional craftsmanship, as well as rewarding<br />

firms who have gone above and beyond on health<br />

and safety.<br />

It is important to paint a picture with the<br />

information provided with your submission<br />

including photos of before, during and after the<br />

project, so the judges can evaluate the whole<br />

process including any innovation so they can<br />

understand the due care and attention paid to<br />

critical elements of the project.<br />

How do we enter?<br />

Entries can submitted at<br />

nfrc.awardsplatform.com, where you will fill in<br />

a form with details about your project, add your<br />

photos, and submit. You don’t have to do it all in<br />

one go: you can make an account to save your<br />

progress and return another time to finish it.<br />

For more information on nominating someone for<br />

the NFRC Health, Safety and Environment in<br />

Roofing Awards – Individual Award 2023, please<br />

email joannelear@nfrc.co.uk.<br />

We encourage you to enter the Awards whether or<br />

not you’ve submitted a project before – you and<br />

your team deserve recognition for the great work<br />

you’ve done in 2023, and this is a fantastic way<br />

to gain that recognition on the UK-wide stage!<br />

Contact NFRC<br />

020 7638 7663<br />

www.nfrc.co.uk<br />

NFRC<br />

20 TC JANUARY <strong>2024</strong>

TAKE YOUR<br />

ROOFING BUSINESS<br />

TO THE NEXT LEVEL WITH NFRC<br />

Technical advice, the industry quality stamp and fantastic<br />

profile-raising opportunities—for all roofing disciplines<br />

NFRC sets the highest<br />

standards for work across<br />

all roofing and cladding<br />

disciplines. But we’re much<br />

more than the industry’s quality<br />

assurance stamp. Membership<br />

of the trade association offers<br />

contractors and suppliers a<br />

range of powerful technical<br />

and commercial advantages.<br />

These include a profile on our website<br />

and directory listing, making your<br />

business easier for clients to find. Plus<br />

exclusive access to technical support and<br />

updates, an exclusive health and safety<br />

app, and advice on training provision.<br />

For suppliers, key benefits include<br />

numerous opportunities to engage with<br />

roofing contractors all over the country.<br />

And as the voice of the roofing sector,<br />

NFRC makes our members’ views<br />

heard where it matters most. We work<br />

with government, standards bodies<br />

and training providers to promote the<br />

interests of the industry, and of the<br />

construction market as a whole.<br />

2023 UK Roofing Awards<br />

Fully-supported Metal winner<br />

Roles Broderick Roofing Limited<br />

3 | Working Towards Zero Avoidable Waste in the Roofing Sector<br />

NFRC trade<br />

membership benefits<br />

WHAT BEING AN NFRC MEMBER MEANS FOR YOU<br />

3 | Working Towards Zero Avoidable Waste in the Roofing Sector<br />

NFRC supplier<br />

membership benefits<br />

EXCLUSIVE ACCESS TO OUR ROOFING<br />

CONTRACTOR MEMBERS<br />

Call 020 7638 7663 or visit<br />

nfrc.co.uk/TCbenefits to request our<br />

benefits brochure—and find out more<br />

about what NFRC membership can do<br />

for your business.<br />

Have you heard about NFRC’s NEW regional NVQ Assessment<br />

Service dedicated to roofing and cladding?<br />

This service offers the opportunity to get qualified,<br />

on-site in a real working environment.<br />

Like to find out more?<br />

Email careers@nfrc.co.uk

Flat Roofing<br />

CELEBRATING THE BEST IN FLAT<br />

ROOFING AT IMA AWARDS<br />

Simon Ashworth, Portfolio Manager for Flat Roofing at BMI UK & Ireland, reflects on the<br />

IMA Awards 2023, which showcased some of the very best projects in flat roofing that<br />

have helped to transform roofscapes in towns and cities across the UK...<br />

Roofs are integral to a building's<br />

overall structure, so the standards<br />

for design, manufacture and<br />

installation need to be high. Since its<br />

formation in the 1990s, the Intelligent<br />

Membrane Association (IMA) has<br />

championed the highest standards in flat<br />

roofing in the UK. At a recent awards<br />

ceremony, the IMA’s flat roofing projects<br />

were celebrated, with categories covering<br />

everything from the specifics of flat roofing<br />

applications to installation successes.<br />

Alongside celebrating individual projects, the<br />

awards also touched on Icopal’s milestone<br />

achievement of 100 years of manufacturing in<br />

Manchester. To mark the occasion, some<br />

additional awards were added to this year’s<br />

roster, including Excellence in Refurbishment,<br />

New Build Roofing and Workmanship.<br />

We’d like to again offer our congratulations to<br />

each of our winners – and to those who were<br />

nominated in their respective categories.<br />

Overcoming challenging roofs with<br />

excellence<br />

Flat roofing projects are rarely without some<br />

challenges, whether that’s water ingress,<br />

skylights, or access. The projects submitted in<br />

the IMA Awards were no exception.<br />

Winning in the Reinforced Bitumen Roofing<br />

category, Tucker & Tunstalls Ltd’s work on<br />

Halliday Court is just one example. The 2,250sqm<br />

roof was prone to leaks, with several skylights<br />

and soil vent pipes needing to be navigated.<br />

Throughout the project, the site remained fully<br />

operational, requiring the team to maintain a safe<br />

Above: RTL Group Ltd won the Eco Active award for the John Lewis &<br />

Partners, Kingston upon Thames, project.<br />

and comfortable environment with minimal<br />

impact on residents.<br />

With the industry increasingly looking to offer<br />

more sustainable solutions, it was no surprise to<br />

see multiple projects showcasing how they had<br />

placed an emphasis on long-term sustainability<br />

through effective roof design. With two projects<br />

recognised in the IMA Awards, Mac Roofing<br />

demonstrated how sustainability impacted each<br />

– be it in achieving a BREEAM Excellent rating for<br />

the new Salvation Army headquarters, or<br />

delivering on strict sustainability requirements for<br />

a leading automotive manufacturer.<br />

In other categories, RTL Group’s work with John<br />

Lewis demonstrated how BMI Icopal’s Noxite<br />

system is actively supporting sustainability<br />

efforts, with projects in Killingworth and Kingston<br />

upon Thames recognised.<br />

IMA Award Winners of 2023<br />

Reinforced Bitumen:<br />

• Highly commended: Salnor Roofing Services<br />

Ltd, Nine Mile Ride Primary School.<br />

• Winner: Tucker & Tunstalls Ltd, Halliday Court.<br />

Eco Active:<br />

• Highly commended: RTL Group Ltd,<br />

John Lewis & Partners, Killingworth.<br />

• Winner: RTL Group Ltd, John Lewis &<br />

Partners, Kingston upon Thames.<br />

Liquid Applied Waterproofing:<br />

• Winner: Mac Roofing & Contracting<br />

Services Ltd, The Salvation Army.<br />

Installation Team of the Year:<br />

• RTL Group Ltd, John Lewis & Partners, Kingston<br />

upon Thames.<br />

Large Scale Project of the Year:<br />

• Winner: Mac Roofing & Contracting Ltd, BMI<br />

Mini Manufacturing Plant.<br />

Excellence in Refurbishment:<br />

• Joint winners: Midland Roofing (Derby) Ltd,<br />

Glenmere Primary School; and NRA Roofing &<br />

Flooring Services Ltd, St Peter and St Paul CE<br />

Academy.<br />

Excellence in New Build Roofing:<br />

• Winner: Mac Roofing & Contracting Services<br />

Ltd, M-Sparc.<br />

Excellence in Workmanship:<br />

• Winner: Itech Roofworks Ltd, Heathrow Airport<br />

Terminal 3.<br />

Contact BMI UK & Ireland<br />

www.bmigroup.com/uk/<br />

BMI UK & Ireland<br />

22 TC JANUARY <strong>2024</strong>

GREAT<br />

WITH<br />

SLATE<br />

TILE<br />

WITH<br />

STYLE<br />

NEW HERITAGE VALLEY<br />

The unique, dry-fix, invisible valley<br />

trough, for a heritage aesthetic<br />

that’s cost-effective and<br />

simple to achieve!<br />

BRE tested<br />

to PD CEN/TR<br />

15601<br />

Test B & D<br />

• Unique S-profile design<br />

• No valley roof tile required<br />

• No special eaves closures required<br />

• Far less tile-and-a-half or slate-and-a-half required<br />

• BRE weather resistance tested<br />

www.filon.co.uk<br />

Telephone 01543 687300 Email: sales@filon.co.uk

Market Overview<br />

‘THERE ARE SIGNS WE’RE MOVING TO<br />

A MORE BALANCED YEAR’<br />

The past 12 months have been turbulent for the construction industry, not least of all in<br />

the supplier market – material shortages have begun to ease, but there have been new<br />

challenges to face within regulation and authenticity. There has been positive growth in<br />

construction output during the latter half of the year, but it is slow, and not all sectors are<br />

experiencing the increase. As we embark on <strong>2024</strong>, Adrian Buttress (pictured), MD of<br />

PermaGroup, reviews 2023 and looks at what may be in store for the year ahead...<br />

There has been a positive shift in<br />

construction projects for certain areas of<br />

the industry, but I think there have been<br />

undoubted challenges that have put many<br />

businesses to the test.<br />

The Office for National Statistics (ONS) reported<br />

that monthly construction output increased 0.4%<br />

in volume terms in September 2023; this came<br />

solely from an increase in repair and<br />

maintenance (2.1%) but was partially offset by a<br />

decrease in new work (0.8% fall) on the month.<br />

At sector level, three out of the nine sectors saw a<br />

rise in September 2023, with the main contributor<br />

to the monthly increase seen in private housing<br />

repair and maintenance, which increased 3.0%.<br />

So, while there are some businesses that will be<br />

experiencing a lift, the struggles continue for others.<br />

Battle on costs<br />

One of the circumstances that we have picked up<br />

on is the competitive push on price cuts to win<br />

more business, as the industry continues to try to<br />

encourage the uptake of new work. This<br />

unfortunately only adds to the problem, as<br />

consumer spending also remains low.<br />

It has therefore been important for supply and<br />

distribution firms to educate their contractors and<br />

consumers about the importance of quality,<br />

reliability and compliance – rather than focusing<br />

on a price tag. More than ever, cowboy products<br />

have entered the market to take advantage of<br />

people looking to make savings, but in the long<br />

run this can turn out to be a costly<br />

mistake.<br />

Despite the availability of materials<br />

returning to post-pandemic levels,<br />

there is now a greater risk of cheaper<br />

and inferior products becoming lost in the mix<br />

if contractors aren’t aware of the quality<br />

assurances to look out for. It can be tempting for<br />

contractors to seek low costs on behalf of their<br />

clients, however, compliance has and always will<br />

ensure long-term savings and reliability. Any good<br />

supplier should know the tell-tale signs of a<br />

substandard product, and price is a big factor, so<br />

we’re urging all our customers and clients to stay<br />

vigilant well into the new year.<br />

Financial stability<br />

Looking ahead, I think for the first part of <strong>2024</strong><br />

the market will be fairly similar in terms of the<br />

economic climate, with interest rates and<br />

inflation still requiring some improvement for both<br />

businesses and consumers. There have been<br />

significant steps to reduce inflation, and this will<br />

hopefully encourage a better flow of spending and<br />

more informed choices, which will greatly benefit<br />

suppliers.<br />

Economists say the main reason for the latest<br />

drop is a reduction in the energy price cap, which<br />

took effect on 1 October. This is also an important<br />

reminder of the whole industry’s role in helping to<br />

bring energy use lower, by offering more efficient<br />

solutions and again, encouraging sound<br />

investments and reliable installers. This applies<br />

for both commercial and domestic<br />

projects, and requires full supply<br />

chain cooperation from specifying<br />

efficient solutions to correct effective<br />

installations.<br />

In the latter part of this year, I hope to see<br />

more normality return to the sector, in terms of<br />

prices levelling out, which will help to overcome<br />

some of these challenges and ensure trustworthy<br />

brand names and businesses are more visible.<br />

Final thoughts<br />

Despite many difficult obstacles in 2023, there are<br />

signs indicating we are moving into a more<br />

balanced year for the sector. While there are some<br />

areas we cannot plan for, we can still maintain<br />

personal development, training, industry awareness<br />

and overall, being a trusted resource for customers<br />

and contractors. If we have learnt anything from the<br />

past few years, it’s about keeping these core<br />

fundamentals even during difficult periods.<br />

PermaGroup is on track for record sales, which<br />

my team and I are proud to have achieved and to<br />

take into <strong>2024</strong>. We have used the past year<br />

(2023) to make some ambitious growth plans<br />

including introducing more members to our team<br />

and appointing a new Managing Director. We also<br />

have some more exciting announcements that<br />

will start to roll out as soon as <strong>January</strong>.<br />

Contact PermaGroup<br />

permagroup.co.uk/<br />

24 TC JANUARY <strong>2024</strong>

DISCOLOUR<br />

Kytun<br />

<br />

Aluminium<br />

Dry<br />

Roofing<br />

Solutions<br />

• Will Not Discolour<br />

• Will Not Crack<br />

• Maintenance Free<br />

• 20 Year Guarantee<br />

• Fully Recyclable<br />

Dry Valle alley Trough<br />

Continuous Slate Dry Verge<br />

ALU<br />

RANGE<br />

WARRANTY<br />

30 YEAR<br />

A<br />

DUR LUMINIUM<br />

ABILITY<br />

WARRANTY<br />

20 YEAR<br />

A L<br />

W<br />

CUMINIUM<br />

ARRANT<br />

OLOUR<br />

Y<br />

WILL NOT<br />

WARP<br />

WILL NOT<br />

BS 8612<br />

BS 5534<br />

www.kytun.com<br />

Continuous Tile Dry Verge

Market Overview<br />

‘A BRIGHTER & GREENER FUTURE’<br />

Chris Cowling (pictured), Aztec Solar Energy’s Commercial Director, reflects on a mixed,<br />

yet fast-moving year for the solar photovoltaic (PV) and battery storage market in 2023,<br />

and looks ahead to even brighter times in <strong>2024</strong>.<br />

When reflecting on the past 12 months<br />

there would be few that would not<br />

struggle to use the word ‘challenging’ to<br />

describe 2023. It feels somewhat overused,<br />

however, coming through a disruptive global<br />

pandemic, with an economy impacted by significant<br />

conflict in Europe and latterly the Middle East, it<br />

has, without question, been just that. Yet 2023 also<br />

saw pockets of real buoyancy, not least in the UK<br />

solar energy market. Underpinned by a strong desire<br />

for business owners to protect livelihoods by<br />

adopting cost-effective and self-managed<br />

approaches to energy and sustainability, while<br />

protecting a planet for future generations.<br />

So, it’s fair to say, 2023 has been a real mixed bag<br />

– often presenting a dichotomy of business<br />

decisions.<br />

PV – an investment opportunity<br />

For Aztec Solar Energy, we have been fortunate –<br />

the UK solar energy market has seen substantial<br />

growth. 2023’s estimate is that it will have reached<br />

over 15GW of installed capacity and the upward<br />

curve continues, expecting to hit 43GW within the<br />

next five years.<br />

Globally, despite lingering supply chain and trade<br />

issues, a similar picture is replicated with continued<br />

significant growth predicted. As a share of global<br />

energy generation, in 2021 global PV was 3.6%, it<br />

had risen in 2022 to 4.5%. It has become the most<br />

rapidly growing regeneration technology and one of<br />

the best energy investment opportunities.<br />

Volatility<br />

Alongside the ups are inevitably some downs. The<br />

complex and ever shifting economic backdrop<br />

continues to create volatility and is taking its toll in<br />

the general construction market. Further impacted<br />

by predictions that commercial new builds are<br />

slowing down, we are seeing debt risk and<br />

borrowing rising; yet our access to a<br />

wide range of funding options means<br />