Parametric die faces in one hour - AutoForm Engineering

Parametric die faces in one hour - AutoForm Engineering

Parametric die faces in one hour - AutoForm Engineering

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

29 30 32 34 36 utoform 21/1/04 3:40 pm Page 4<br />

Cover story: Focus on Cadcam and simulation<br />

CONTACT (EUROPE):<br />

Figure 3-A: A typical addendum profile (red l<strong>in</strong>e) and its def<strong>in</strong><strong>in</strong>g parameters. With<strong>in</strong> a few<br />

seconds, the user can change these “master” global profile parameters, for example to<br />

<strong>in</strong>crease the <strong>die</strong> radius.<br />

In addition, the user can also make local surface modifications to the addendum, by<br />

chang<strong>in</strong>g local profile parameters or directly manipulat<strong>in</strong>g contours such as the punch<br />

open<strong>in</strong>g l<strong>in</strong>e, bar height, etc.<br />

ONE-STEP FORMABILITY<br />

SIMULATION<br />

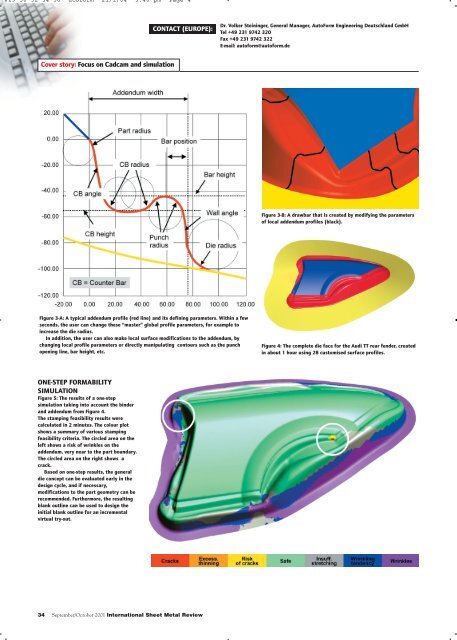

Figure 5: The results of a <strong>one</strong>-step<br />

simulation tak<strong>in</strong>g <strong>in</strong>to account the b<strong>in</strong>der<br />

and addendum from Figure 4.<br />

The stamp<strong>in</strong>g feasibility results were<br />

calculated <strong>in</strong> 2 m<strong>in</strong>utes. The colour plot<br />

shows a summary of various stamp<strong>in</strong>g<br />

feasibility criteria. The circled area on the<br />

left shows a risk of wr<strong>in</strong>kles on the<br />

addendum, very near to the part boundary.<br />

The circled area on the right shows a<br />

crack.<br />

Based on <strong>one</strong>-step results, the general<br />

<strong>die</strong> concept can be evaluated early <strong>in</strong> the<br />

design cycle, and if necessary,<br />

modifications to the part geometry can be<br />

recommended. Furthermore, the result<strong>in</strong>g<br />

blank outl<strong>in</strong>e can be used to design the<br />

<strong>in</strong>itial blank outl<strong>in</strong>e for an <strong>in</strong>cremental<br />

virtual try-out.<br />

34 September/October 2001 International Sheet Metal Review<br />

Dr. Volker Ste<strong>in</strong><strong>in</strong>ger, General Manager, <strong>AutoForm</strong> Eng<strong>in</strong>eer<strong>in</strong>g Deutschland GmbH<br />

Tel +49 231 9742 320<br />

Fax +49 231 9742 322<br />

E-mail: autoform@autoform.de<br />

Figure 3-B: A drawbar that is created by modify<strong>in</strong>g the parameters<br />

of local addendum profiles (black).<br />

Figure 4: The complete <strong>die</strong> face for the Audi TT rear fender, created<br />

<strong>in</strong> about 1 <strong>hour</strong> us<strong>in</strong>g 28 customised surface profiles.