September 2021

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

• BS 5250 UPDATE • INSULATION TIPS • FIXINGS • AUTUMN WORKWEAR • >>><br />

SEPT <strong>2021</strong>

TAKE YOUR<br />

ROOFING BUSINESS<br />

TO THE NEXT LEVEL WITH NFRC<br />

Technical advice, the industry quality stamp and fantastic<br />

profile-raising opportunities—for all roofing disciplines<br />

NFRC sets the highest<br />

standards for work across<br />

all roofing and cladding<br />

disciplines. But we’re much<br />

more than the industry’s quality<br />

assurance stamp. Membership<br />

of the trade association offers<br />

contractors and suppliers a<br />

range of powerful technical<br />

and commercial advantages.<br />

These include a profile on our website<br />

and directory listing, making your<br />

business easier for clients to find. Plus<br />

exclusive access to technical support and<br />

updates, an exclusive health and safety<br />

app, and advice on training provision.<br />

For suppliers, key benefits include<br />

numerous opportunities to engage with<br />

roofing contractors all over the country.<br />

And as the voice of the roofing sector,<br />

NFRC makes our members’ views<br />

heard where it matters most. We work<br />

with government, standards bodies<br />

and training providers to promote the<br />

interests of the industry, and of the<br />

construction market as a whole.<br />

3 | Working Towards Zero Avoidable Waste in the Roofing Sector<br />

NFRC trade<br />

membership benefits<br />

NFRC supplier<br />

membership benefits<br />

Call 020 7638 7663 or visit<br />

nfrc.co.uk/TCbenefits to request our<br />

benefits brochure—and find out more<br />

about what NFRC membership can do<br />

for your business.<br />

NFRC GROUP ALSO INCLUDES<br />

Competent Person Scheme:<br />

self-certify roof refurbishment<br />

to Building Regs<br />

Roofing operatives<br />

competency accreditation<br />

UK’s premier event for<br />

the roofing industry<br />

Supporting hardship, training/<br />

upskilling, volunteering<br />

and environment<br />

Contractors with knowledge,<br />

skills and experience of<br />

heritage roofing systems

Editor’s Comment<br />

MATT DOWNS<br />

EDITORIAL DIRECTOR<br />

MATTDOWNS@MEDIA-NOW.CO.UK<br />

07963 330774<br />

I was pleased to hear that BMI’s Apprentice of the Year competition<br />

will return in November this year (see page 6).<br />

I’ve been fortunate enough to help judge previous BMI Apprentice of the<br />

Year competitions and have seen first-hand how the two-day event, which<br />

tests the apprentices’ business and people skills, alongside their practical<br />

roofing abilities and knowledge, really helps them grow in confidence and<br />

recognise that a long-term career in roofing is possible. But don’t take my<br />

word for it, in this issue we speak to Tom Knight, who was runner-up in<br />

BMI’s 2017 Pitched Roofing competition, about the event and his<br />

subsequent career in roofing, and he told us: “We all got a lot out of the<br />

competition – it really boosted my confidence, and I learnt a lot from the<br />

knowledge sharing. I’d recommend entering to anyone.” Read our interview<br />

with Tom from page 16.<br />

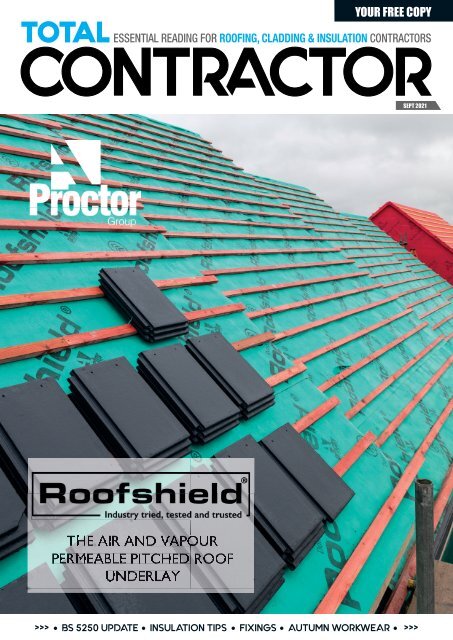

Cover courtesy of A. Proctor Group. Hear how the<br />

Roofshield membrane was crucial for a recent<br />

church refurbishment project on page 30.<br />

FOLLOW US @TOTCONTRACTORUK<br />

SIGN UP FOR YOUR E-NEWSLETTER AT<br />

WWW.TOTAL-CONTRACTOR.CO.UK<br />

No doubt one area the apprentices will have to brush up on is the latest<br />

update to BS 5250. With the recent changes in mind, Technical Roofing<br />

Consultant John Mercer addresses some of the more frequent<br />

condensation-related issues he sees on projects on page 24, whilst<br />

Marley’s Stuart Nicholson provides his eight steps to help contractors<br />

reduce moisture risk in pitched roofs on page 26.<br />

Elsewhere in this issue, Tanya Cooper discusses developments within the<br />

NFRC Competent Person Scheme (page 22); this month’s QI column focuses<br />

on adhesive bonding of insulation boards (page 67); and Rob Firman outlines<br />

all you need to know about inverted roof correction factors on page 68.<br />

So read on for all this and much more...<br />

find us on facebook<br />

Matt<br />

£345<br />

LY<br />

Including<br />

delivery<br />

Advertising:<br />

Publishing Director: Andy Dunn<br />

DD: 01892 732 047<br />

Mob: 07963 330777<br />

Email: andydunn@media-now.co.uk<br />

Registered office: 1 Forstal Road, Aylesford, Kent, ME20 7AU<br />

Commercial Manager: Jake Roxborough<br />

DD: 01892 732 047<br />

Mob: 07956 133314<br />

Email: jakeroxborough@media-now.co.uk<br />

The content of Total Contractor magazine (and website) does not necessarily reflect the views of the editor or publishers and are<br />

the views of its contributors and advertisers. The digital edition may include hyperlinks to third-party content, advertising, or<br />

websites, provided for the sake of convenience and interest. The publishers accept no legal responsibility for loss arising from<br />

information in this publication and do not endorse any advertising or products available from external sources. No part of this<br />

publication may be reproduced or stored in a retrieval system without the written consent of the publishers. All rights reserved.<br />

Supported by:<br />

Aluminium Bi-F<br />

Doors<br />

old<br />

mak<br />

e the smart<br />

er choice<br />

FROM<br />

Quote turnaround<br />

ONL within hours<br />

NEW<br />

* Up to 1200mm sash<br />

widths<br />

CUST<br />

per leaf<br />

Stock colours:<br />

White, Black, Grey,<br />

Grey on White<br />

10OMER<br />

* Per leaf price is unglazed and may<br />

vary depending on size and specification of<br />

the door. Lead time is based on a standard colour. Postcode restrictions apply<br />

Call: 01642 610799<br />

ww<br />

ww.madefw<br />

.madefortrade.co<br />

* Discount applies to new trade customers and first,<br />

single item pur chase only of the Korniche Roof Lantern.<br />

DISCOUNT<br />

QUOTE REF:<br />

TC-B01<br />

%<br />

SEPTEMBER <strong>2021</strong> TC 3

Contents<br />

3 KEY FEATURES<br />

16<br />

16 A KNIGHT ON THE TILES<br />

Following the news that BMI’s Apprentice of the<br />

Year competition will return in November, we<br />

caught up with Tom Knight, runner-up in 2017,<br />

to hear how his roofing career has developed<br />

24 PERFECTLY PITCHED<br />

Technical Roofing Consultant John Mercer<br />

discusses some of the more regular<br />

condensation-related issues he comes across<br />

following the latest update to BS 5250<br />

54 INVESTMENT GAINS<br />

With news of EJOT’s major investment at its UK<br />

HQ, production and logistical facility near<br />

Leeds, Robert Hardstaff outlines the benefits<br />

this will bring to the company and customers<br />

54<br />

FURTHER READING<br />

14 TIMBER FRAME INSULATION<br />

Bradley Hirst of Knauf Insulation provides his top tips for<br />

insulating a timber frame application in our latest column<br />

56<br />

26 REDUCING MOISTURE RISK<br />

Marley’s Stuart Nicholson outlines what contractors<br />

should do to minimise moisture risk in pitched roofs<br />

44 THE RIGHT FLOW<br />

Brian Bell of Marley Alutec addresses the key<br />

considerations to ensure effective flat roof drainage<br />

56 PROJECT FOCUS: FACADE<br />

Schackerley and Keyclad collaborated on the facade<br />

element of a large student accommodation project<br />

62 CONTROLLING COMPLEXITIES<br />

Vivalda Group advises contractors to engage experienced<br />

suppliers when working on cladding remediation projects<br />

76 AUTUMN COLLECTION<br />

Peter Dumigan says when it comes to workwear, fabric<br />

performance and sustainability are key considerations<br />

4 TC SEPTEMBER <strong>2021</strong>

REGULARS<br />

22 NFRC ROOFING FOCUS<br />

Tanya Cooper, Managing Director of NFRC CPS,<br />

discusses her future plans for the roofing<br />

competent person scheme<br />

60 TOTAL TALK: TRUMPF<br />

John Roche discusses the history of TRUMPF,<br />

the machinery and tools specialist’s progress<br />

in the cladding and facade sector, as well as<br />

challenges and opportunities within the market<br />

67 QI BY QI COLUMN<br />

The experts at QI address the key points when<br />

adhesive bonding insulation boards<br />

68 ALL YOU NEED TO KNOW...<br />

about inverted roof correction factors; Rob<br />

Firman of Polyfoam XPS outlines the key points<br />

INDUSTRY NEWS<br />

06 APPRENTICES ASSEMBLE<br />

BMI has announced the return of its renowned<br />

Apprentice of the Year competition – find out more!<br />

12 RUSSELL REACTS TO DEMAND<br />

The manufacturer has invested in two new curing<br />

chambers to increase capacity on concrete hand fittings<br />

SECTIONS:<br />

TOTAL<br />

ROOFING<br />

24<br />

TOTAL<br />

CLADDING<br />

54<br />

TOTAL<br />

INSULATION<br />

66<br />

VEHICLES, TOOLS<br />

& WORKWEAR<br />

06<br />

76<br />

SEPTEMBER <strong>2021</strong> TC 5

Industry News<br />

More news, updates and interviews at www.total-contractor.co.uk<br />

DISTRIBUTION<br />

CHALLENGES<br />

Haulage and distribution are the biggest<br />

concerns referenced in the latest<br />

Construction Availability Statement from<br />

John Newcomb, CEO of the Builders<br />

Merchants Federation and Peter<br />

Caplehorn, CEO of the Construction<br />

Products Association, co-chairs of the<br />

CLC’s Product Availability working group.<br />

Writing on the CLC’s website, they explained:<br />

“Although the overall supply situation has not<br />

changed substantially, there has been a<br />

temporary easing this month, most probably<br />

due to a combination of the holiday period<br />

and some domestic customers delaying or<br />

cancelling projects due to higher costs or<br />

cost uncertainty.<br />

“Timber, cement, roofing products, bricks,<br />

blocks, insulation, steel and cable<br />

management systems remain the products in<br />

shortest supply, while global shortages of<br />

semi-conductors are a cause for concern in<br />

the lighting and appliance sectors. Although<br />

product and material price inflation has<br />

slowed, indications are that it will be 2022<br />

before prices stabilise, with some<br />

manufacturers still to implement double digit<br />

price increases to recover current and future<br />

cost inflation.<br />

“Haulage, however, and the lack of<br />

availability of drivers, are now the major<br />

concerns affecting distribution, with some<br />

suppliers asking builders merchants to<br />

collect their orders as they cannot get<br />

enough drivers to complete deliveries.<br />

Regional distribution is a particular issue,<br />

with some finding challenges arranging<br />

deliveries to Scotland and the South West of<br />

England.”<br />

View the full article at<br />

www.total-contractor.co.uk<br />

BMI’S APPRENTICE COMPETITION RETURNS!<br />

A key highlight in the UK construction calendar<br />

is back with the launch of the BMI Apprentice<br />

of the Year <strong>2021</strong> competition – one of the<br />

leading apprenticeship events in the roofing<br />

sector.<br />

BMI says it actively supports colleges throughout<br />

the UK with their work training roofing apprentices<br />

and the contest seeks to find the UK’s most<br />

promising apprentices, and reward them for their<br />

commitment, ability and potential.<br />

The BMI Apprentice of the Year stands out from<br />

other competitions because of its focus on the<br />

business dimensions of a career in roofing – for<br />

example marketing, finance and presentation,<br />

rather than purely tradecraft, although these<br />

vitally important skills are not overlooked during<br />

the two-day event either.<br />

BMI is proud to say that previous winners and<br />

participants have gone on to start their own<br />

businesses, find more senior roles within the<br />

companies that employ them, represent industry<br />

trade bodies and even become tutors themselves.<br />

Matt Ford won the pitched roof category in 2019,<br />

and has highlighted the way elements of the<br />

competition feed into future success: “For<br />

example, one of the biggest lessons I learnt from<br />

the BMI competition was the importance of<br />

networking, making contacts, and having the<br />

confidence to approach people that I didn’t have<br />

before. That goes for everything from using<br />

LinkedIn, to sourcing materials, to handling social<br />

media. Through the competition I learnt that how<br />

you present yourself is very important and how<br />

that leads to winning work.”<br />

This year’s competition opened on <strong>September</strong> 1st<br />

<strong>2021</strong> and welcomes all those recognised as an<br />

apprentice by their employer, or those working<br />

towards qualified status. Each year, the<br />

competition picks a theme and for <strong>2021</strong> it’s<br />

‘influence’. With this in mind, BMI is looking for<br />

contestants who have what it takes to influence<br />

peers and those in the wider roofing community.<br />

Previous participants have spoken highly about how the BMI<br />

event has taught them new skills and given them confidence.<br />

Closing date for entries is October 1st.<br />

Entrants selected for the final, which takes place<br />

on the 17th and 18th November at the BMI<br />

Academy in Gloucestershire, will receive coaching<br />

on a range of topics including presentation skills,<br />

health and safety, estimating and making<br />

technical assessments.<br />

The event is whole-heartedly backed by BMI’s<br />

college partners and their tutors. As Alan Lander<br />

of the South West Roof Training Group – and tutor<br />

to many finalists – explained: “Everything about<br />

the event is first class and we missed it greatly<br />

during the pandemic. The experience and<br />

takeaways the apprentices get from the<br />

competition are outstanding. The only worry ever<br />

is how BMI will manage to match it year-on-year<br />

– and yet they do!”<br />

Mat Woodyatt, BMI Technical Training Manager,<br />

explained: “BMI Apprentice of the Year is our<br />

chance to recognise and applaud apprentice<br />

success stories across the country. Our<br />

commitment to help train apprentices is<br />

unwavering and the competition allows us to<br />

reward those working hard to achieve their goals.<br />

We are really looking forward to welcoming the<br />

finalists to the BMI Academy in November.”<br />

Enter the pitched roofing and flat roofing events at:<br />

https://redland.co.uk/youngroofers/apprentice-of-the-year-<strong>2021</strong><br />

or:<br />

http://www.icopal.co.uk/Support/Roofers/youn<br />

g-roofers/apprentice-of-the-year-<strong>2021</strong>.aspx<br />

Read our interview with Tom Knight, a<br />

runner-up at the 2017 BMI Apprentice of the<br />

Year event on page 16.<br />

6 TC SEPTEMBER <strong>2021</strong>

ROOF<br />

LANTERN<br />

FITTED<br />

IN<br />

MINUTES<br />

SUPPLY & INSTALL<br />

THE MULTI-AWARD<br />

WINNING ALUMINIUM<br />

LANTERN<br />

10%<br />

NEW CUSTOMER<br />

DISCOUNT<br />

QUOTE CODE<br />

TC-K01<br />

FASTER<br />

Average installation under 30 mins<br />

STRONGER<br />

3m x 2.5m possible with no mid rafters<br />

Premium seals, class leading thermals<br />

SLIMMER<br />

Uninterrupted SLIMMER Sight Lines<br />

Seamless joints and cappings<br />

SUPPORT<br />

The best trade lantern<br />

www.madefortrade.co<br />

Tel: 01642 610799<br />

WARMER<br />

Easy installation<br />

Competitive pricing, reliable, fast<br />

lead times & delivery<br />

find us on facebook<br />

* Discount applies to new trade customers and first, single item purchase only of the Korniche Roof Lantern.

Industry News<br />

More news, updates and interviews at www.total-contractor.co.uk<br />

TIME TO MOVE FROM POLICY TO ACTION ON MODERN SLAVERY<br />

Awareness of the importance of addressing<br />

modern slavery is high among construction<br />

SMEs, but there is a need to move beyond policy<br />

to action according to research carried out by<br />

CHAS, in conjunction with the University of<br />

Nottingham Rights Lab.<br />

CHAS and the Rights Lab surveyed a sample of 229<br />

CHAS member companies, the majority of whom<br />

are SMEs within the construction sector. The survey<br />

sought to assess current knowledge and awareness<br />

of modern slavery along with actions taken to<br />

address this problem and identify opportunities for<br />

improving engagement.<br />

Encouragingly, the results showed high awareness<br />

of the need to tackle modern slavery, with 72% of<br />

respondents confirming they have implemented a<br />

modern slavery policy. However, just 39% of those<br />

surveyed said they were conducting due diligence to<br />

address this issue within their businesses and<br />

supply chains and have done so for more than six<br />

months. Meanwhile, almost one fifth (17%) of<br />

businesses said their organisation has no<br />

intention to carry out due diligence in the<br />

foreseeable future, and 50% of respondents<br />

stated that they currently have no intention to<br />

measure KPIs related to modern slavery. When it<br />

comes to drivers of anti-slavery action, several<br />

factors may come into play, including legislative<br />

and regulatory, operational and commercial, and<br />

reputational drivers to encourage business action. It<br />

is possible the vast majority of respondents have a<br />

modern slavery policy because of requirements by<br />

clients or contracts, particularly by large<br />

organisations captured by the modern slavery<br />

legislation. However, two thirds (66%) of<br />

participants said they do not feel pressure from the<br />

government and large businesses to address<br />

modern slavery, while 67% stated they do not feel<br />

pressure from consumers and other civil society<br />

actors to address the issue.<br />

The Modern Slavery Act 2015 only requires<br />

companies with an annual turnover of £36 million<br />

or more to report on steps taken to address the risk.<br />

However, CHAS believes that with over 90% of all<br />

businesses in the construction sector represented<br />

by SMEs, supporting these organisations to manage<br />

modern slavery effectively is vital to improving the<br />

sector's record on this issue.<br />

To support this goal, CHAS is working with the<br />

Rights Lab to establish a range of tools and<br />

resources to help construction SMEs take positive<br />

action to understand, manage, mitigate and<br />

eliminate the risk of modern slavery and labour<br />

exploitation in the construction supply chain.<br />

www.chas.co.uk<br />

UKCA MARK DELAY WELCOMED BY NFRC<br />

HELPING SMES BUILD<br />

The start date for the new post-Brexit<br />

certification rules for construction products<br />

has been extended by 12 months.<br />

The UKCA (UK Conformity Assessed) mark came<br />

into effect on 1st January <strong>2021</strong>, and was due to<br />

replace the CE mark which had been used to<br />

certify products in Europe, including many<br />

construction products, on 1st January 2022.<br />

This deadline had been seen as unachievable by<br />

many within the sector, especially with regards to<br />

testing capacity and infrastructure, alongside the<br />

time and preparation required by manufacturers<br />

and businesses to prepare to meet the<br />

changeover.<br />

Following pressure to push back the deadline, and<br />

referencing the “impact of the pandemic on<br />

businesses”, and “extensive and ongoing<br />

engagement with business groups”, the<br />

government has announced it has agreed to<br />

extend the transition period for the UKCA mark<br />

until 1st January 2023.<br />

This move has been welcomed by James Talman,<br />

NFRC Chief Executive, who stated: “At a time<br />

when we are facing some of the worst material<br />

availability and inflation in living memory, this<br />

announcement will come as a welcome relief for<br />

manufacturers and merchants.<br />

“We have been telling the government that the<br />

1st January 2022 deadline was not feasible for<br />

some time, with many products simply unable to<br />

receive certification by the deadline. I am glad<br />

that the message has now got through. This extra<br />

time will provide much-needed breathing space<br />

for suppliers to undertake the necessary tests and<br />

acquire the correct paperwork.<br />

“The government should now work with industry<br />

to ensure the supply chain is fully prepared for<br />

the new 2023 deadline, particularly smaller<br />

firms, so we do not face similar problems in the<br />

future.”<br />

The Federation of Master Builders (FMB)<br />

has welcomed the publication of the Bacon<br />

Review.<br />

Brian Berry, Chief Executive of the FMB, said:<br />

“I congratulate Richard Bacon on his review<br />

of Custom and Self Build, and urge the<br />

Government to act on his recommendations if<br />

we are to diversify the housing market and<br />

meet our housing targets, we must reverse<br />

the decline in SME house builders, who<br />

deliver great homes, of high quality, in the<br />

places people want to live. 56% of FMB<br />

house builder members build only as<br />

contractors, and the majority build to the<br />

designs and specifications of a consumer.<br />

The biggest constraint they face is access to<br />

viable small sites on which to build. So I<br />

welcome the review’s focus on the supply of<br />

land, and hope the Government will recognise<br />

the support that local authorities need to help<br />

more SMEs to build.”<br />

8 TC SEPTEMBER <strong>2021</strong>

SEAMLESS LIQUID ROOFING - MARISEAL 250<br />

A 25 year warranty, site survey,<br />

full training and less than<br />

£20m 2 ! *<br />

Top coats Primers Accessories<br />

ALPHATEQ are approved UK distributors for the<br />

Mariseal range of seamless liquid roofing products<br />

Mariseal 250*<br />

A one component, permanent elastic, liquid applied, polyurethane<br />

waterproofing membrane used on roofs, balconies, terraces, pedestrian<br />

and vehicular decks, green roofs, protection over PUR-spray foam.<br />

Colour: Available in both light and dark grey<br />

Size: Available in 25kg drum<br />

Typical coverage: 12.5m 2 per tin<br />

Price: Less than £20m 2<br />

More products available - see our website for details<br />

When you buy from ALPHATEQ you get:<br />

• Comprehensive training with all our products<br />

• Site surveys<br />

• Project specification sheet<br />

• Technical support<br />

• Fully accredited and warranted products<br />

• Excellent customer service<br />

Sales Hotline:<br />

01277 503110<br />

1 Palmers, 101 Crow Green Road, Brentwood Essex CM15 9RP<br />

Email: info@alphateqwaterproofing.com<br />

www.alphateqwaterproofing.com<br />

New Customer? Claim an<br />

EXTRA 10%<br />

DISCOUNT!<br />

Quote TC9 when ordering<br />

Valid until 12.11.21

Industry News<br />

KAY ROSE APPOINTED<br />

TO KEY IOR POSITION<br />

The Institute of Roofing (IOR)<br />

has appointed Kay Rose<br />

(FIoR) as its new Chief<br />

Executive Officer (CEO).<br />

With more than 20 years’ experience<br />

within the construction industry, Kay has<br />

been an IOR board member for five years<br />

and was Vice Chair from 2018 to 2020.<br />

Speaking about her appointment, and plans<br />

for the IOR, Kay said: “As a former board<br />

member, I have a good understanding of<br />

what the IOR wants to achieve and I am<br />

looking forward to dedicating more of my<br />

time to delivering these aims.<br />

“One of my priorities is to make sure the IOR<br />

is seen as approachable and accessible to<br />

everyone in the roofing industry. I feel there<br />

could still be a perception that only certain<br />

people can join trade bodies and that needs<br />

to change. No matter what role someone<br />

has, I want them to know there is a place for<br />

them at the Institute and members at all<br />

levels are supported to build structured<br />

career paths.<br />

“The merchant sector is a key target in this<br />

respect. IOR membership offers many<br />

benefits to those working in distribution who<br />

are regularly providing roofing advice. I want<br />

to clearly promote that message while<br />

enhancing the training opportunities<br />

available to ensure everyone involved in<br />

roofing can improve their knowledge and<br />

career prospects.<br />

“A continued focus on quality will also be<br />

important to ensure the different levels of<br />

membership are adhered to. At the same, I<br />

will be looking at how we could make the<br />

process clearer and more attainable.”<br />

www.instituteofroofing.org<br />

More news, updates and interviews at www.total-contractor.co.uk<br />

EASY MANAGEMENT WITH ‘MY ACCOUNT’<br />

Fixfast has launched ‘My Account’ – a new<br />

self-service online portal which it says allows<br />

customers to make and manage their orders<br />

wherever they are, whenever they want.<br />

The company says the major upgrade to its website<br />

is the latest in a series of investments in its<br />

‘Maximum Reliability, Minimum Fuss’ promise.<br />

“Our 5-star customer service now extends online,”<br />

As well as being able to order from Fixfast’s range of<br />

explained Steve Coppins, Customer Services<br />

more than 5,500 products, logged-in customers<br />

Manager. “We have a ‘Complete Customer Care’<br />

have instant access to all their account information.<br />

philosophy and wanted to build a portal for that<br />

With My Account, Fixfast says customers can:<br />

online – to match the high level of service we’re<br />

• View and track orders, including delivery status already known for by phone and email.<br />

• Create lists of favourite items<br />

“We thought carefully about the most common<br />

requests we get from customers and made sure they<br />

• Download invoices, credit notes and pay online<br />

can access those things easily and intuitively through<br />

• Make quick repeat orders<br />

My Account. By automating many of our processes,<br />

we’re able to give customers the information they<br />

• Access technical information and data sheets<br />

need quickly and at a time that suits them.”<br />

• Set company permissions according to job role. Find out more www.fixfast.com<br />

DRAFT SCOTTISH SOLAR PLANS WELCOMED<br />

Solar Energy Scotland has welcomed<br />

Solar Energy Scotland Chair Thomas<br />

the inclusion of solar into the Scottish<br />

McMillan said: “The solar energy<br />

Government’s and Scottish Green<br />

industry in Scotland welcomes the clear<br />

Party’s draft policy programme<br />

recognition in the cooperation agreement<br />

of the important role solar can play in<br />

The document outlines the joint commitment<br />

Scotland’s drive to meet our 2030 climate<br />

from both parties to confront some of the greatest<br />

obligations. As the cheapest, most readily<br />

challenges faced in Scotland to date, responding to<br />

deployable renewable technology, with substantial<br />

the climate emergency, supporting economic<br />

benefits for the economy and helping to tackle fuel<br />

recovery and strengthening a green and fair<br />

poverty, it is time for the sector to be allowed to<br />

recovery from the global pandemic.<br />

grow and flourish. Scotland’s solar opportunities<br />

Solar Energy UK Chief Executive Chris Hewett (pic) could see deployment increase 15-fold by 2030,<br />

said: “Scotland has a more ambitious target on and this would deliver a solar sector in Scotland<br />

net-zero than the rest of the UK, so we are looking proportional to what is being achieved elsewhere in<br />

forward to working closely with the new government the UK.”<br />

to ensure solar energy can play a full part in the<br />

race to cut carbon emissions. The opportunities are Solar Energy Scotland says it is calling on<br />

huge, from a new generation of solar parks, to colocation<br />

with wind farms, large rooftop schemes target of 4GW by 2030, with an ambitious<br />

Government to set a minimum solar deployment<br />

and using onsite solar to decarbonise heat and Government delivering as much as 6GW over the<br />

transport.”<br />

next decade.<br />

10 TC SEPTEMBER <strong>2021</strong>

Handrails:- EasyGuard<br />

free-standing Guardrails<br />

*CurveyGuard – an aesthetically pleasing curved rail.<br />

*EasyGuard – raked or straight legs dependant on<br />

application. *FoldGuard – folding handrail.<br />

Trip hazard reduction – long thin base-plates with<br />

Counterweights used on un-secured ends only. Placed at 2m<br />

centres maximum to enable use for leading edge protection.<br />

Galvanised or powder coated finish. Protective mats 5mm<br />

bonded to the base plates.<br />

Standards – Exceeds Class A EN13374- Class A; For<br />

leading edge protection HSE/SR 15, <strong>September</strong> 1988.<br />

Nationwide delivery or contract installation. – Free material<br />

quantifying service – info@safetyworksandsolutions.co.uk<br />

Ladders:- Easy Fit<br />

Compliant to both BS/EN 5395 and 14122 –<br />

To comply with the standards for<br />

permanent ladders all mild steel then hot<br />

dipped galvanised to BS/EN 1461.<br />

All typical ladders bespoke – email<br />

info@safetyworksandsolutions.co.uk for a<br />

survey check sheet.<br />

Easy Fit, all ladder components are Easy<br />

to assembly; in manageable parts Easy to<br />

handle and install.<br />

Rest Platforms and ladders with special<br />

fixing requirements; solutions provided by<br />

Safetyworks in house.<br />

(All components for British Standard<br />

compliant ladders require steel components<br />

with timber and aluminium recommended<br />

for temporary use only)<br />

HANDRAILS<br />

-<br />

LIFELINES<br />

-<br />

WALKWAYS<br />

-<br />

FALL GUARDS<br />

-<br />

FLEXIDECK<br />

-<br />

DEMARKATION<br />

-<br />

LADDERS<br />

-<br />

STEELWORK<br />

-<br />

Tel: 01487 841400<br />

www.safetyworksandsolutions.co.uk

Industry News<br />

MARLEY SUPPORTS<br />

MELANOMA FUND<br />

Marley is reminding roofers of the<br />

importance of staying ‘Safe in the Sun’,<br />

whilst supporting the Melanoma Fund.<br />

Daniel Redfern, Marketing Manager at Marley<br />

said: “Contractors working for long periods of<br />

time outdoors, often in direct sunshine and<br />

intense heat, are at risk from sun damage.<br />

So, with our Safe in the Sun campaign, we<br />

aim to provide useful, no-nonsense advice to<br />

make sure all our customers are aware of<br />

the potential risks, and are properly<br />

protected. We encourage roofers to cover up,<br />

use sunscreen and stay hydrated with the<br />

help of our Safe in the Sun kit, featuring a<br />

Marley-branded T shirt, sunscreen and water<br />

bottle – everything you need to stay safe.<br />

What’s more, for every roofer requesting a<br />

Safe in the Sun kit from our website, we will<br />

donate £1 to the Melanoma Fund.”<br />

Michelle Baker, CEO, Melanoma Fund, said:<br />

“Those who work outdoors, such as roofing<br />

contractors, really are on the front line when<br />

it comes to sun damage, including the risk of<br />

melanoma. Many can also underestimate the<br />

importance of sun protection, so we’re<br />

pleased to see Marley taking the issue<br />

seriously, giving advice to the industry to<br />

ensure workers are educated and encouraged<br />

to create better habits. We are very grateful<br />

for its generous support of our work.”<br />

To receive your Safe in the Sun kit and<br />

support the Melanoma Fund, visit the Marley<br />

website www.marley.co.uk/safeinthesun<br />

and register your details – conditions apply.<br />

More news, updates and interviews at www.total-contractor.co.uk<br />

RUSSELL INVESTS TO MEET CONCRETE DEMAND<br />

Due to the high demand for concrete roof tiles<br />

as the construction industry rises above pre-<br />

Covid levels, Russell Roof Tiles says it has<br />

seen a huge increase in the requirement for<br />

concrete hand fittings.<br />

To cope with this increase in demand, the roof tile<br />

manufacturer has invested in two new curing<br />

chambers as part of a wider expansion<br />

consumption and reduce wasted heat. This<br />

programme, which the company says enables it to means we can be more efficient with a lower<br />

increase capacity on certain key concrete hand carbon footprint.”<br />

fittings by 50 per cent.<br />

By investing in high tech temperature and<br />

With the key focus on Hip End and Block End humidity monitoring, Russell Roof Tiles says it is<br />

Ridge concrete products – Russell Roof Tiles says able to maintain the stability required to produce<br />

the investment will also allow it to produce more high quality products whilst adding additional<br />

vent tiles and other handmade items.<br />

volume to its existing product range. Dan<br />

continued: “The investment is to address the<br />

The manufacturer worked closely with specialist<br />

growing demand in the current climate and to<br />

curing contractors to design and build the two<br />

provide greater flexibility in production. The main<br />

new chambers which are now fully operational.<br />

purpose of this project is to support Lockerbie to<br />

Dan Hancox, Business Support Manager at produce more fittings but a large portion of these<br />

Russell Roof Tiles explained: “Following our green are sold in the Midlands – so we have moved<br />

agenda, the new curing chambers have been some production to the local area to avoid extra<br />

designed to be fully insulated and temperaturecontrolled<br />

units to ensure optimisation of energy<br />

transportation costs and save on the<br />

environment.”<br />

MORE TO DO DESPITE IMPROVED PAYMENT TERMS<br />

Construction firm Beard has responded to the mitigate the risk of projects running late due to<br />

latest Build UK figures which show nearly a supply chain issues, is to ensure prompt payment<br />

third of major contractors are paying within as that will inevitably mean better working<br />

the government target of 30 days.<br />

relationships with those suppliers and<br />

subcontractors. We are all aware that construction<br />

Mark Beard, Chairman at Beard Construction said:<br />

sites generate a significant amount of work for<br />

“It has probably never been more important to<br />

smaller suppliers and subcontractors. So, if we<br />

ensure fair treatment of suppliers and<br />

choose to work with them, we have a responsibility<br />

subcontractors including prompt payment of<br />

to support them through prompt payment of<br />

invoices, as the industry continues to bounce back<br />

invoices. The figures from Build UK show that on<br />

from the economic shock of the pandemic. So, it is<br />

average contractors paid subcontractors within 34<br />

encouraging to see that average payment times<br />

days, which is 11 days quicker than in July 2018<br />

improved over the last six months, even by just one<br />

when they first started collecting data. That is<br />

day, particularly as we are faced with the real<br />

commendable progress but we can and should do<br />

challenge of the materials shortage at the moment.<br />

more to adhere to the principles of the Prompt<br />

“In fact, it seems clear to me that one of the ways to Payment Code.”<br />

12 TC SEPTEMBER <strong>2021</strong>

VISOGLIDE PLUS<br />

SLIDING DOORS<br />

NEW<br />

FROM<br />

£1139<br />

*<br />

DELIVERED<br />

15%<br />

FIRST ORDER<br />

INTRODUCTORY<br />

FROM<br />

DISCOUNT<br />

QUOTE CODE<br />

TC-VG01<br />

THERMALLY BROKEN ALUMINIUM<br />

Slim profile, Lipped outer frame, Sobinco locks<br />

INDUSTRY LEADING CUSTOMER SERVICE<br />

Comprehensive install guide & support<br />

LARGE SASH WIDTHS<br />

Up to 6.5m wide in 2 panes. 2-4 panes available<br />

www.madefortrade.co<br />

Tel: 01642 610799<br />

SLIMMER<br />

Uninterrupted Sight Lines<br />

STOCK COLOUR CHOICE<br />

White, Anthacite Grey & Black, Dual Colour<br />

FAST LEAD TIMES<br />

SUPPORT<br />

The best trade lantern<br />

Reliable safe site delivery<br />

find us on facebook<br />

* Price is unglazed and may vary depending on size and specification of the door. Lead time is based on a standard colour. Postcode restrictions apply<br />

* Discount applies to new trade customers and first, single item purchase only of the Smart Visoglide Plus Sliding Doors | Image for representation ony<br />

* Offer price based on a 2 pane, a single sliding door at 2mx2.1m. Unglazed

Industry News<br />

NEW ACCREDITATION FOR IOR ASSOCIATE COURSE<br />

The Institute of Roofing (IOR) has announced<br />

its Associate Course achieved a third-party<br />

accreditation from the Awarding Body of the<br />

Built Environment (ABBE).<br />

The interactive training, which is aimed at anyone<br />

seeking to further their career in roofing, has been<br />

accredited to ABBE Level 3.<br />

First launched in 2015, the Associate Course<br />

enables individuals to broaden their industry<br />

knowledge and gain the skills required to progress<br />

into supervisory and managerial roles.<br />

In recent years, the IOR says the training has<br />

evolved to meet the changing needs of the sector,<br />

and in 2020 the course was updated and moved<br />

to a dedicated online learning platform, enabling<br />

delegates to learn with minimum disruption to<br />

working patterns.<br />

Topics covered include project management, law,<br />

surveying & estimating, tendering & procurement,<br />

roof safety, and sustainability.<br />

Matthew Fry, Chair of the IOR, said: “Achieving an<br />

independent ABBE accreditation is a huge step<br />

forward for the IOR, demonstrating the quality of<br />

the Associate Course and that it meets the<br />

requirements of the sector. Learners that complete<br />

the course can now gain a nationally recognised<br />

ABBE Level 3 award in Roofing Management,<br />

putting them on a more structured career path in<br />

roofing.<br />

“For the IOR, this achievement also brings us one<br />

step closer to securing chartered status. In line<br />

with this aim, we are continually developing and<br />

enhancing the professional qualifications available<br />

through the Institute. This includes working with<br />

the ABBE to develop a course that would enable<br />

delegates to achieve an accredited Level 5 award.”<br />

The Associate Course includes ten modules with<br />

clearly defined learning objectives, which are<br />

individually assessed as the course progresses.<br />

The IOR says it can be delivered in a classroom or<br />

online over 15 weeks or over a timeframe to suit<br />

delegates’ requirements, and all delegates who<br />

complete the Associate Course receive the grade<br />

of Associate Member of the Institute of Roofing<br />

(AIoR). Members of the IOR at Associate Level or<br />

higher can apply for the Professionally Qualified<br />

Person CSCS Card.<br />

www.instituteofroofing.org<br />

KNAUF INSULATION: TECHNICAL COLUMN<br />

THREE TOP TIPS FOR INSULATING A TIMBER FRAME APPLICATION<br />

Timber frame is a widely used construction method, so this month Bradley Hirst (pic), Technical<br />

Services Manager at Knauf Insulation, gives his top tips for installing insulation in this application.<br />

1. Performance first:<br />

Timber frame walls generally<br />

provide better levels of thermal<br />

performance than masonry walls<br />

of comparable thickness.<br />

However, their reduced mass means<br />

the insulation you install must reduce<br />

noise as well as meet the thermal requirements<br />

set out in the building regulations.<br />

We recommend Knauf Insulation FrameTherm Roll<br />

or Slab, which not only has the lowest thermal<br />

conductivity of 0.032W/mK of any Glass Mineral<br />

Wool product on the market, but also offers<br />

exceptional acoustic performance. It also has the<br />

added benefit that it is non-combustible, making it<br />

the safest choice because it will not contribute to<br />

the development or spread of fire should it occur.<br />

Always use a product designed for the application.<br />

We are occasionally asked if Loft Roll can be<br />

installed between studs in timber frame<br />

wall applications. The answer is no<br />

because it won’t deliver the required<br />

thermal performance. It is also not<br />

designed for use vertically, so if it is<br />

used in timber frame walls, the<br />

insulation will slump creating gaps.<br />

2. Create a snug fit:<br />

Another factor is buildability. Choose insulation<br />

that is appropriately sized, because this will<br />

ensure a friction-fit between the insulation, studs,<br />

and substrate.<br />

Rigid boards, for example, are hard to install<br />

correctly. They are supplied in large sheets that<br />

must be cut to size on site, but it is very difficult<br />

to match the insulation board to the profile of the<br />

stud. This means there is likely to be gaps that<br />

reduce thermal, fire and acoustic performance.<br />

Even if you do manage to achieve an exact fit<br />

during<br />

installation, the stud will<br />

bow and shrink, moving away from the insulation<br />

over time, creating more gaps.<br />

By contrast, most Mineral Wool insulation<br />

manufactured for timber framed walls is<br />

appropriately sized to fit 400mm or 600mm stud<br />

centres. Its fibrous nature will create a friction-fit<br />

against the stud and will accommodate the<br />

natural expansion and contraction of the timber,<br />

preventing gaps in the construction over time.<br />

3. Always use a vapour control layer<br />

Installing a Vapour Control Layer (VCL) prevents<br />

the passage of warm, moist air from condensating<br />

on the sheathing board around the stud. If a VCL<br />

is not used, over time the condensation can cause<br />

the timber to rot, damaging the structural integrity<br />

of the building.<br />

www.knaufinsulation.co.uk<br />

14 TC SEPTEMBER <strong>2021</strong>

FOR SALE: CLAUDE N SMITH LTD.<br />

A unique opportunity to own a long-established and respected Collyweston slating and<br />

mining company has presented itself, as the owners of Claude N Smith Ltd. are selling up.<br />

Below, Director Nigel Smith tells us about recent investment and the history of the business.<br />

Established in 1965, Claude Smith moved<br />

the business to a 2.5 acre builder’s yard<br />

with a slate mine in Collyweston. In 2010<br />

my father offered the business to me so he could<br />

enjoy retirement, and my wife and I became<br />

Directors of the company, establishing Claude N<br />

Smith as a Limited business in 2011.<br />

With our focus on quality workmanship and<br />

materials, as Collyweston slate had not been mined<br />

for over 50 years, it was frustrating to see the<br />

quality of reclaimed material continually<br />

diminishing, so we took the opportunity to utilise the<br />

unmined Collyweston slate on our site, and gained<br />

permission to mine slate again with the help of a<br />

mining consultant.<br />

As the only producers of newly mined Collyweston<br />

slate, being able to provide new slate to customers<br />

has opened up an unrivalled market giving us the<br />

ability to undertake any size of roof slating.<br />

We now have a purpose-built slate production<br />

building with offices and welfare facilities, employ<br />

15 full time employees alongside myself and my<br />

wife, and we’ve completed a number of prestigious<br />

roofing projects, and regularly won UK Roofing<br />

Awards for our work. The nature of our business is<br />

95% working on listed buildings which always<br />

require a like-for-like refurbishment and the<br />

removal and installation of both new and reclaimed<br />

slate. This also presents many opportunities to price<br />

for not only the main contract, but also associated<br />

works like chimneys, guttering, lead gutters,<br />

leadwork, insulation, timber repairs and stonework.<br />

We are looking to sell 100% shares of Claude N<br />

Smith Ltd. with its exclusive mining rights, staff,<br />

stock, equipment, plant, vehicles and work. The<br />

premises and slate production building will be on<br />

a leasehold basis, price to be negotiated with<br />

buyer.<br />

The business has great potential to move forward in<br />

many directions, whether it be heritage roofing,<br />

general roofing, Main Contracting, building etc. The<br />

opportunities are there for the business to build and<br />

develop, and most importantly maintain a high<br />

standard of workmanship and keep the art of<br />

Collyweston slating alive for many generations to<br />

come.<br />

Find out more below or at www.claudesmith.co.uk<br />

or email nigel@claude-smith.co.uk<br />

CLAUDE.N.SMITH LTD<br />

Established 1965 • incorp: STAPLETON & SON<br />

FOR<br />

SALE<br />

SPECIALIST COLLYWESTON STONE SLATING AND SLATE MINERS<br />

• Long-established, award winning Collyweston slating and mining business.<br />

• Excellent reputation locally and nationally.<br />

• Highly experienced slaters and mining/slate production staff.<br />

• Exclusive mining rights<br />

• Turnover in excess of £1,000,000<br />

• Pre-tax profit <strong>2021</strong> - £222,978<br />

• Business to operate from leasehold premises (lease terms/price to be agreed on sale)<br />

• Offered for sale to facilitate retirement plans.<br />

• Offers invited<br />

Please contact by email in the first instance for further information: nigel@claude-smith.co.uk<br />

www.claudesmith.co.uk • Tel: 01780 444627 • Email: nigel@claude-smith.co.uk<br />

SEPTEMBER <strong>2021</strong> TC 15

Interview: Tom Knight<br />

A KNIGHT ON THE TILES<br />

Since featuring on our very first front cover, Tom Knight –<br />

Highly Commended in the BMI Apprentice of the Year 2017 –<br />

has continued to have great success in his roofing career.<br />

Total Contractor met up with him on a site near Truro for a chat.<br />

I remember most about the<br />

competition is the Q&A sessions”,<br />

“What<br />

says Tom, recalling his success in<br />

the 2017 Apprentice of the Year. “It was a great<br />

chance to talk to trusted people in roofing – like<br />

Andy King (of A L King Roofing and then President<br />

of the NFRC), Simon Dixon and Gary Walpole<br />

(both also from the NFRC). They have fantastic<br />

experience and expertise to share, which has<br />

really helped guide me in my roofing career.”<br />

It wasn’t the only stand out part of the experience<br />

for Tom. “The section on estimating was brilliant.<br />

It’s been a real help to me when it comes to<br />

quoting. The fault-finding session was also great,<br />

especially when it comes to repair jobs and when<br />

you’re the one that has to identify the issues.”<br />

Prior to entering the roofing industry, Tom was a chef<br />

after leaving college. But the pay and long, antisocial<br />

hours meant it wasn’t for him. Having been<br />

offered a labouring job in roofing, Tom found himself<br />

enjoying the work and with a knack for the trade.<br />

“I’m proud of our<br />

website and promote<br />

our business through<br />

Yell – we get a lot of<br />

work out of it”<br />

Consequently, his employer supported Tom in his<br />

career and provided him with the opportunity for an<br />

apprenticeship and to become a skilled worker. It<br />

was an opportunity he seized with both hands and<br />

– following his training on the job and with Alan<br />

Lander of RoofTrain in Exeter – his talent<br />

blossomed, winning South West SkillBuild as well<br />

as placing highly in the BMI competition.<br />

Having qualified, Tom continued to spend time<br />

honing his skills with his employer and broadening<br />

his roofing experience with his builder uncle. He<br />

then took the opportunity to start his own business,<br />

with a newly financed van and support in the shape<br />

of his father – a very positive time as Tom says he<br />

“We all got a lot out of the<br />

competition – it really boosted my<br />

confidence, and I learnt a lot from<br />

the knowledge sharing. I’d<br />

recommend entering to anyone”<br />

Tom Knight discussing the BMI Apprentice of the<br />

Year competition

Tom Knight was runner-up at the 2017 BMI Apprentice of the Year event and has gone on to enjoy a successful career in roofing.<br />

BMI Apprentice of the Year <strong>2021</strong><br />

This year’s competition – following a break in<br />

2020 owing to Covid – opened for entries on<br />

<strong>September</strong> 1st <strong>2021</strong> and welcomes all those<br />

recognised as an apprentice by their employer,<br />

or those working towards qualified status.<br />

Closing date for entries is October 1st.<br />

Entrants selected for the final, which takes<br />

place on the 17th and 18th November at the<br />

BMI Academy in Gloucestershire, will receive<br />

coaching on a range of topics including<br />

presentation skills, health and safety,<br />

estimating and making technical<br />

assessments. Find out more on how to<br />

enter: https://redland.co.uk/youngroofers/apprentice-of-the-year-<strong>2021</strong><br />

http://www.icopal.co.uk/Support/Roofers/y<br />

oung-roofers/apprentice-of-the-year-<br />

<strong>2021</strong>.aspx<br />

was a “massive help early on”. Following his<br />

father’s final retirement (he’d tried before!), Tom<br />

then teamed up with mate Jack Newton – himself a<br />

national SkillBuild finalist in 2015 – with whom he<br />

works to this day.<br />

Marketing gains<br />

Once again, another key area of focus for<br />

businesses which Tom hadn’t really thought about<br />

prior to the event, came to the fore in the BMI<br />

competition: “I am really conscious of the need for<br />

marketing, and it’s something we work hard at,”<br />

says Tom. “I’m proud of our website and promote<br />

our business through Yell. It’s our main review<br />

platform, and we get a lot of work out of it.”<br />

Tom’s not wrong: his is the most, and best,<br />

reviewed business in his category in the Truro area,<br />

and dozens of former customers aren’t shy in<br />

singing his praises. “It’s also very motivational.<br />

When jobs aren’t going well or there are other<br />

problems, like Covid, it’s a booster to drop onto the<br />

site and read the reviews. We also make sure any<br />

Google reviews feed into it as well, so we’re covered<br />

all ways.”<br />

This superb word-of-mouth and engaged approach<br />

to marketing means that Tom has six months of<br />

work booked ahead of him. Current goals then are<br />

to maintain the business at a consistent level postpandemic<br />

– and get to New Zealand.<br />

Tom was married in 2017, and the big dream was<br />

“I am really conscious<br />

of the need for<br />

marketing, and it’s<br />

something we work<br />

hard at”<br />

to travel to New Zealand in 2020 so his wife Kioni<br />

could meet up with her NZ relatives for the first<br />

time. “We had the tickets and everything – and then<br />

Covid came along. At least we got our money back,<br />

and at least we’ve been able to work outdoors ever<br />

since the lockdowns, which was a result.”<br />

Competition and confidence<br />

In summarising his thoughts about the BMI<br />

Apprentice of the Year competition, Tom says, “We<br />

all got a lot out of the competition, which was more<br />

like a two-day course. It really boosted my<br />

confidence, and I learnt a lot from the knowledge<br />

sharing. I’d recommend entering to anyone.”<br />

Contact BMI UK & Ireland<br />

www.bmigroup.com/uk<br />

@BMIUKandIreland<br />

SEPTEMBER <strong>2021</strong> TC 17

Industry Focus: CCPI<br />

CPA PUBLISHES RESULTS OF<br />

INDUSTRY CONSULTATION ON CCPI<br />

The CPA says the findings, whilst published “slightly later than planned”,<br />

confirm that the industry welcomes and supports the Code, and considers<br />

it a crucial step in the right direction…<br />

The Construction Products Association (CPA)<br />

has released the results of its industrywide<br />

consultation on the new Code for<br />

Construction Product Information (CCPI). The 65<br />

page report – downloadable at<br />

www.buildingsafely.co.uk – details feedback from<br />

35 trade associations representing the views of<br />

many thousands of member firms across the<br />

supply chain, and 180 individual provider and<br />

user organisations of construction product<br />

information, including most of the largest<br />

companies in the industry.<br />

The new Code was developed to prevent some of<br />

the issues raised in Dame Judith Hackitt’s report<br />

‘Building A Safer Future’, following the Grenfell<br />

Tower fire. The CPA was tasked by Dame Judith<br />

Hackitt and the Government with tackling the<br />

shortcomings identified in Chapter 7 of the report<br />

relating to product information.<br />

The consultation opened on the 1st February <strong>2021</strong><br />

with an official closing date of the 31st March<br />

<strong>2021</strong>. This was extended to the end of May to urge<br />

everyone who had a view to submit them, and to<br />

encourage the widest representation from across<br />

the industry. The highly-publicised consultation was<br />

undertaken for the CPA by MRA Research. It invited<br />

trade associations, manufacturers, distributors,<br />

specifiers and users of product information to<br />

comment on the proposed new CCPI and its eleven<br />

Clauses.<br />

A key requirement of the consultation was that<br />

respondents read the new Code before completing<br />

their respective questionnaire or providing<br />

feedback. A number of additional and insightful<br />

comments were said to be also submitted by<br />

provider and user organisations alongside their<br />

completed questionnaires. The CPA says the<br />

feedback from the trade associations was detailed,<br />

expert and extensive, providing in-depth comments<br />

and suggestions on behalf of their members.<br />

The findings, the CPA says, confirm that the<br />

industry welcomes and supports the Code, and<br />

considers it a crucial step in the right direction,<br />

whilst comments confirmed that more clarity was<br />

needed in some areas of the Code, particularly<br />

around the training and competence requirements,<br />

and on what exactly was required to comply with<br />

the different Clauses. The MIG is said to have spent<br />

a further two months analysing and working<br />

through the Code so it reflects the massive amount<br />

of expert feedback from the consultation.<br />

Adam Turk, Chair of the CPA’s Marketing Integrity<br />

Group and CEO of Siderise, said: “We are delighted<br />

with the breadth and depth of response received.<br />

The published results are slightly later than planned<br />

but given the importance of the Code, we wanted to<br />

make sure all responses were included in the<br />

analysis. Strenuous efforts were also made in<br />

reaching out to organisations directly to ensure<br />

everyone across the industry had the opportunity to<br />

comment.<br />

“The overwhelming support and constructive<br />

feedback has reassured us that the Code is<br />

absolutely the right step forward for the industry,<br />

while also giving us a lot of insightful input to enable<br />

the MIG to review the wording of the Clauses in line<br />

with these detailed responses,” continued Adam.<br />

“Whilst changes have been made around the clarity<br />

and detail within the Code, I can confirm that the<br />

eleven Clauses remain principally close to those<br />

presented in the report.”<br />

Peter Caplehorn, Chief Executive of the CPA, added:<br />

“We are extremely pleased with the progress that<br />

has been made with the CCPI and the enormous<br />

efforts of the MIG in driving it through. I truly believe<br />

the Code will achieve meaningful and permanent<br />

change in our industry, providing users of<br />

construction products with accurate information<br />

they can trust.<br />

“The CPA is incredibly focussed on improving<br />

building safety and driving cultural change in our<br />

industry. We are involved in a wide range of<br />

initiatives to ensure tragedies like Grenfell never<br />

happen again, and the CCPI is just one of those. An<br />

essential counterpart to the Code is the activity of<br />

the Working Group 12 (WG12) – a sub-group of the<br />

IRG’s Competence Steering Group (CSG), led by the<br />

CPA. WG12 focuses specifically on the competency<br />

of those interacting with products and accessing<br />

construction product information. The CSG<br />

recognises that good product information on its own<br />

is not enough; those that use it must be competent<br />

to do so, to understand what they are reading and to<br />

be able to apply the performance information<br />

appropriately.”<br />

Find out more:<br />

www.cpicode.org.uk<br />

www.buildingsafely.co.uk<br />

18 TC SEPTEMBER <strong>2021</strong>

Same size. Even more product.<br />

We’ve further upgraded<br />

our compression technology<br />

so you get even more<br />

product per pack or pallet.<br />

That means more efficient storage,<br />

handling and transport, and less<br />

packaging too.<br />

Just one of the changes we’ve made<br />

to our range this year to make it<br />

better for you, better for the world.<br />

Find out more:<br />

knaufinsulation.co.uk/the-best-keeps-getting-better<br />

THE BEST KEEPS<br />

GETTING BETTER

NFRC Roofing Focus<br />

MY PLANS FOR THE NFRC<br />

COMPETENT PERSON SCHEME<br />

By Tanya Cooper, Managing Director of the NFRC CPS.<br />

Itook over as the Managing<br />

Director of NFRC Competent<br />

Person Scheme (NFRC CPS) in<br />

March <strong>2021</strong>, having worked<br />

alongside the team during my time<br />

as Chief Operating Officer for NFRC.<br />

Since joining, I have been focused on<br />

guaranteeing the best service to both<br />

contractors and clients.<br />

NFRC CPS – formerly known as Competent<br />

Roofer – was established almost ten years ago in<br />

2012. At the time of writing, we are still the only<br />

active Competent Person Scheme for the roofing<br />

industry in the country.<br />

Guaranteeing workmanship<br />

Competent Person Schemes play an important<br />

role in the repair, maintenance and improvement<br />

sector, allowing contractors to self-certify that<br />

works comply with certain elements of the<br />

building regulations without having to go through<br />

Building Control. They also provide a robust<br />

mechanism for guaranteeing the workmanship of<br />

the registered contractor, providing peace of mind<br />

to clients and stakeholders alike.<br />

For roofing, this means roofers can self-certify<br />

that work meets energy efficiency standards<br />

under Approved Document L1B of the Building<br />

Regulations, where 50 per cent or more of a roof<br />

is being refurbished.<br />

We have hundreds of contractors using our<br />

scheme every week, and over a year we will issue<br />

thousands of Building Regulation Compliance<br />

Certificates (BRCCs), on a wide range of jobs<br />

from domestic, to commercial, to social housing.<br />

However, we believe there are many more roofing<br />

contractors out there who could be benefitting<br />

from the scheme but are missing out. If you think<br />

this may be you, I<br />

would love to<br />

hear from you.<br />

I started with<br />

NFRC CPS<br />

soon after it<br />

became an<br />

entirely independently run<br />

business. Prior to that, we co-managed it<br />

with a third-party provider. We managed the<br />

technical side of the programme, such as<br />

standards, inspections and reporting to UKAS,<br />

and our partners handled the administration, the<br />

customer relationship management (CRM)<br />

system and the insurance protection part of the<br />

scheme. This relationship worked well, but since<br />

we became fully independent at the end of last<br />

year, we have been able to take the scheme in a<br />

new direction.<br />

Since then, we have designed and created a<br />

brand new bespoke CRM system, introduced a<br />

new interactive Contractor’s Portal to make it<br />

much easier to manage registered works, and<br />

have given contractors a much greater choice<br />

over which insurance provider to choose from. Of<br />

course, as with any new system, there are always<br />

hiccups in the beginning, but since I took over, I<br />

have been laser-focused on driving efficiencies<br />

and making improvements to our customer<br />

service. I hope contractors who use the scheme<br />

have noticed the difference and would welcome<br />

any feedback on how the Contractor’s Portal can<br />

be further developed to suit your needs.<br />

Now our new systems and processes are bedding<br />

in, we are able to start looking to the future. I<br />

hope to grow the scheme, ensuring a wider<br />

number of contractors and clients know about<br />

and can benefit from the scheme. We will be at<br />

Housing <strong>2021</strong> in Manchester in <strong>September</strong>,<br />

speaking to local authorities,<br />

housing associations, and<br />

developers from across the<br />

country, promoting the scheme,<br />

and educating them on the benefits of<br />

using a NFRC CPS contractor. If you will be<br />

there, come and find us at Stand F45.<br />

Widening the scope of the scheme<br />

We also plan to soon be able to widen the scope<br />

of the scheme to include PAS2030:2019<br />

accreditation. This will be known to many readers<br />

due to the infamous Green Homes Grant Voucher<br />

Scheme. Whilst that particular scheme is now for<br />

the history books, there are still several<br />

government schemes available that require<br />

PAS2030, notably work done through the Energy<br />

Company Obligation (ECO) scheme, Local<br />

Authority Delivery (LAD) scheme, or the Social<br />

Housing Decarbonisation Scheme (SHDS). Further<br />

to this, it is likely that any replacement programme<br />

to the Green Homes Grant will also require this. Our<br />

application is still being processed by UKAS, but if<br />

successful, we hope to be able to certify<br />

contractors to do both flat and pitched roof<br />

insulation to this standard in the very near future.<br />

Over the last few months, I have laid the<br />

foundations for a more improved, robust and<br />

reliable Competent Person Scheme for the roofing<br />

industry and have ambitious plans for the future.<br />

If you operate in the roofing refurbishment market<br />

and are not currently benefitting from the<br />

scheme, you should be asking yourself, why not?<br />

Find out more about NFRC CPS<br />

www.nfrccps.com/<br />

@NFRCcps<br />

Left: Tanya Cooper, Managing Director of<br />

NFRC Competent Person Scheme.<br />

22 TC SEPTEMBER <strong>2021</strong>

We’ve been busy with some<br />

building of our own.<br />

Historically and globally the EJOT Group policy has always been to<br />

reinvest success into achievable, manageable growth.<br />

EJOT in the UK is no different. Last autumn we began a reinvestment<br />

programme that will not only increase our manufacturing, logistics and<br />

R&D capability, but will focus on our people – not least the engineers,<br />

developers and technicians of tomorrow.<br />

It’s a milestone that can only be maintained by building on the foundations<br />

of service and product quality that have brought us this far.<br />

Manufacturing in Yorkshire and exporting to the world, EJOT UK is proud to<br />

support innovation and ambition in a unique way.<br />

Tomorrow’s challenges, solved today.<br />

www.ejot.co.uk<br />

EJOT® The Quality Connection

Perfectly Pitched<br />

AN UPDATE ON CONTROLLING<br />

CONDENSATION IN BUILDINGS<br />

Following BSI’s recent update to BS 5250, Technical Roofing Consultant<br />

John Mercer addresses some of the more regular condensation-related issues<br />

he comes across on projects…<br />

On July 31st, BSI Standards published a<br />

major revision to BS 5250: Code of<br />

Practice for Management of moisture in<br />

buildings. So, it is an opportune time to discuss<br />

some of the condensation-related issues I come<br />

across.<br />

During my years of carrying out roof surveys and<br />

dealing with roof-related complaints and<br />

enquiries, the issue of condensation control is<br />

certainly one of the most commonly<br />

misunderstood roofing topics I come across. I<br />

have lost count of the number of times I have<br />

dealt with complaints of condensation on<br />

underlay, soaked loft insulation and soiled<br />

ceilings. All too often, the problem is blamed on<br />

the occupants for drying their clothes inside, not<br />

opening windows, or keeping the house too warm;<br />

all may be true, but these reflect actual lifestyles.<br />

Building Regulation C2 requires that the walls,<br />

floors and roof of a building adequately protect<br />

the building and the people who use the building<br />

from harmful effects caused by interstitial and<br />

surface condensation. Interstitial condensation<br />

can cause damage to the structure of a building,<br />

whilst surface condensation can cause moulds to<br />

grow which pose a health hazard to the<br />

occupants.<br />

Approved Document C states that a roof will meet<br />

the requirement of Building regulation C2 if it is<br />

designed and constructed in accordance with BS<br />

5250. However, it is important to remember that<br />

a British Standard Code of Practice takes the<br />

form of recommendations and guidance, and is<br />

not a firm specification. Alternative solutions can<br />

be used, provided the designer can justify their<br />

use as compliant with the Building<br />

Regulation.<br />

The latest revision<br />

In addition to a general<br />

update to all parts of the<br />

previous version, the latest<br />

revision to BS 5250 contains new<br />

guidance on moisture risks other than<br />

condensation, a whole building approach to<br />

moisture-safe design, building context, the<br />

coherence of design and detailing interactions, as<br />

well as capacity and in-service conditions. It also<br />

covers the management of moisture risks in<br />

buildings undergoing energy saving measures.<br />

The revision acknowledges key changes in<br />

modern building design, such as reduced air<br />

permeability of the building fabric and higher<br />

thermal insulation, both of which have the<br />

potential to increase the risk of condensation. It<br />

also considers changes in lifestyle and the<br />

greater use of moisture-generating appliances<br />

such as showers and internal clothes drying.<br />

Climate change is also predicted to add to the<br />

moisture risk through milder, more humid winters<br />

and more frequent and heavier incidents of<br />

driving rain events.<br />

The differences between ‘as designed’, ‘as built’<br />

and ‘in service’ conditions are now more clearly<br />

understood, as is the way occupants use the<br />

building, which may not always be in the manner<br />

intended, as well as the residual moisture held in<br />

the building fabric from the construction<br />

processes. This all means that the moisture risk<br />

evolves and changes over time and during the<br />

lifetime of the building, and designers are<br />

Left: John Mercer, Technical Roofing<br />

Consultant.<br />

“There must<br />

be a clear<br />

airway from<br />

the eaves<br />

ventilators<br />

through to the roof<br />

space”<br />

encouraged to allow for the worst-case scenario.<br />

As well as providing guidance developed through<br />

modelling, BS 5250 gives prescriptive guidance<br />

based on the evidence of many years of<br />

successful use. This particularly applies to cold<br />

roof construction, where there is plenty of data<br />

and evidence to provide practical<br />

recommendations for the use of ventilation to<br />

prevent moisture risk.<br />

Common faults<br />

One of the most common faults I come across is<br />

a lack of ventilation provided into the roof space,<br />

usually because there was a misconception that<br />

the use of a permeable underlay means<br />

ventilation is not necessary.<br />

There are different types of permeable underlays,<br />

all with their own methods of installation.<br />

Although there are some air-permeable underlays<br />

which can be used without additional ventilation,<br />

most vapour permeable underlays require a level<br />

of additional ventilation when used in a cold roof<br />

structure, i.e. where the insulation is laid across<br />

24 TC SEPTEMBER <strong>2021</strong>

a horizontal ceiling.<br />

Another common fault is roof space<br />

ventilation being ineffective due to<br />

the way it is installed or because it<br />

is incompatible with the building<br />

design or with other materials. For<br />

example, there must be a clear<br />

airway from the eaves ventilators<br />

through to the roof space; though all<br />

too often, the ventilation path is<br />

blocked because rafter trays have<br />

been omitted or are ineffectually<br />

installed, causing the insulation to<br />

be laid tight against the underlay.<br />

Ridge ventilation can play an important role in<br />

preventing excess condensation by drawing fresh<br />

air in through the eaves ventilators as air passes<br />

over the ridge. This can be particularly effective if<br />

the residents have partially blocked the cross<br />

flow of air from eaves to eaves by stacking items<br />

in the loft space.<br />

Above: Warm to cold illustration.<br />

Ideally, excessive moisture transfer from the<br />

living areas of a building into the roof voids<br />

should be avoided by sealing gaps at junctions<br />