HMI software for CNC controls

HMI software for CNC controls

HMI software for CNC controls

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>HMI</strong> <strong>software</strong> <strong>for</strong><br />

<strong>CNC</strong> <strong>controls</strong><br />

4/2 Operator control and programming<br />

4/2 <strong>HMI</strong>-Embedded<br />

4/3 <strong>HMI</strong>-Advanced<br />

4/4 AutoTurn<br />

4/5 ManualTurn<br />

4/6 ShopMill<br />

4/8 ShopTurn<br />

4/10 Technology cycles<br />

4/11 Measuring functions/<br />

measuring cycles<br />

4/12 CAD reader<br />

4/13 TRANSLINE <strong>HMI</strong><br />

4/14 Open Architecture<br />

4/14 <strong>HMI</strong> Open Architecture<br />

4/16 CardWare<br />

4/17 EasyMask<br />

4/17 EasyTrans<br />

4/18 HotWin<br />

4/18 EasyMon<br />

4/19 Motion Control In<strong>for</strong>mation<br />

System MCIS<br />

4/19 DNC – Direct Numeric Control<br />

4/20 DNC Machine<br />

4/21 DNC Cell<br />

4/23 DNC IFC SINUMERIK<br />

4/23 DNC IFC Serial<br />

4/24 DNC IFC Dialog<br />

4/24 DNC IFC Filesystem<br />

4/25 DNC Compare<br />

4/26 DNC Plant<br />

4/28 DNC <strong>HMI</strong><br />

4/28 TDI – Tool Data In<strong>for</strong>mation<br />

4/30 TDI Overview<br />

4/31 TDI Toolhandling<br />

4/32 TDI Planning<br />

4/33 TDI Statistic<br />

4/34 TDI IFC<br />

4/34 TDI Cell<br />

4/36 TDI Plant<br />

4/37 TDI Machine<br />

4/38 TDI Toolplan Generation<br />

4/39 TDI Ident Connection<br />

Motion Control In<strong>for</strong>mation<br />

System MCIS (continued)<br />

4/40 MDA – Machine Data Acquisition<br />

4/41 MDA Cell<br />

4/43 MDA IFC<br />

4/44 MDA Machine<br />

4/46 RPC – Remote Procedure Call<br />

(computer coupling)<br />

4/47 TPM – Total Productive Maintenance<br />

4/48 RCS – Remote Control System<br />

4/49 RCS @Event<br />

4/50 RCS Host/RCS Viewer<br />

4/51 RCS Host/RCS Viewer<br />

Embedded<br />

4/52 RCS remote diagnosis<br />

4/54 ADDM – Data Management<br />

4/55 ePS Network Services<br />

4/56 Supplementary hardware <strong>for</strong><br />

<strong>HMI</strong> <strong>software</strong><br />

4/56 MOBY E tool identification system<br />

4/57 MOBY I identification system<br />

4/58 Mobile data memories MDS<br />

4/59 Write/read devices SLG<br />

4/60 SIMATIC RF300<br />

4/61 Tools<br />

4/61 SIMATIC STEP 7 <strong>for</strong><br />

SINUMERIK hardware<br />

4/62 Ghost<br />

4/62 SinuCom<br />

4/64 SinuCom Update Agent<br />

4/65 SINUMERIK Solution Partners<br />

4/65 Solution Partners Automation –<br />

Machine Tools SINUMERIK<br />

Siemens NC 60 · 2006

4<br />

<strong>HMI</strong> <strong>software</strong> <strong>for</strong> <strong>CNC</strong> <strong>controls</strong><br />

Operator control and programming<br />

<strong>HMI</strong>-Embedded<br />

■ Overview<br />

The <strong>HMI</strong>-Embedded <strong>software</strong> is technology-independent, multichannel<br />

operating <strong>software</strong> <strong>for</strong> machine tools and executes on<br />

an "embedded operating system". The <strong>software</strong> supports convenient<br />

and complete window-oriented operation of machines. The<br />

generation of parts programs is assisted by a text editor which<br />

provides easy-to-use, screen <strong>for</strong>m-based support. The powerful<br />

contour calculator enables programming and graphic display of<br />

complex workpiece contours.<br />

■ Function<br />

Part programs can be rapidly checked using the 2D simulation<br />

<strong>for</strong> turning. An easy-to-use milling simulation option is available.<br />

The graphical user interface can be extended in the basic version<br />

by up to 20 pictures via predefined softkeys without additional<br />

<strong>software</strong>.<br />

Using these softkeys it is possible to import machine-specific<br />

screen <strong>for</strong>ms, pictures or function trees. Programming support,<br />

such as cycle support, can be altered and intensified with the<br />

"Supplement user interface" function. Configuring takes place<br />

using simple text files.<br />

The user interface can be optionally expanded by more than<br />

20 pictures using the integral editor at specific predefined softkeys<br />

(with a SINUMERIK <strong>HMI</strong> copy license OA).<br />

4/2<br />

Siemens NC 60 · 2006<br />

■ Selection and Ordering Data<br />

Designation Order No.<br />

<strong>HMI</strong>-Embedded<br />

<strong>for</strong> PCU 20 and PC/PG on<br />

CD-ROM<br />

Languages: English, French,<br />

German, Italian, Simplified<br />

Chinese 1) ,Spanish<br />

• Single license <strong>for</strong><br />

6FC5253-0BX00-0AG0<br />

current <strong>software</strong> version<br />

• Single license <strong>for</strong><br />

6FC5253-7BX00-7AG0<br />

specific <strong>software</strong> version<br />

• Single license<br />

6FC5253-0BX00-0AG1<br />

without data carrier<br />

• Software update service 6FC5253-0BX00-0AG2<br />

• Update on order of<br />

6FC5253-7BX00-7AG3<br />

specific <strong>software</strong> version<br />

Additional languages 2) 3)<br />

on CD-ROM<br />

Languages: Czech, Danish,<br />

Dutch, Finnish, Hungarian,<br />

Japanese, Korean, Polish,<br />

Portuguese/ Brazilian, Russian,<br />

Simplified Chinese, Swedish,<br />

Traditional Chinese, Turkish<br />

• Single license <strong>for</strong><br />

6FC5253-7BX10-7XG0<br />

specific <strong>software</strong> version<br />

• Single license<br />

6FC5253-0BX10-0XG1<br />

without data carrier<br />

Milling Simulation<br />

6FC5253-0AE02-0AA0<br />

<strong>for</strong> <strong>HMI</strong>-Embedded<br />

Software option<br />

SINUMERIK <strong>HMI</strong><br />

6FC5253-0AF00-0AA0<br />

copy license OA<br />

Software option<br />

Example of "specific <strong>software</strong> version", e.g. 6.5:<br />

6FC5253-6....-5...<br />

1) <strong>HMI</strong>-Embedded SW Version 6.5 and higher.<br />

2) CD-ROM also contains the languages: Eng, Fr, Ger, It, Sp.<br />

3) Please enquire about <strong>software</strong> versions available.

■ Overview<br />

The <strong>HMI</strong>-Advanced <strong>software</strong> is a universal, multi-channel user<br />

interface <strong>software</strong> <strong>for</strong> machine tools. The <strong>software</strong> supports convenient<br />

and complete window-oriented operation of machines.<br />

The text editor provides easy-to-use, screen <strong>for</strong>m-based support.<br />

The powerful contour calculator enables programming and<br />

graphic display of complex workpiece contours. Part programs<br />

can be rapidly checked using the integral 2D/3D simulation <strong>for</strong><br />

turning and milling.<br />

■ Function<br />

You can modify or redesign the graphical user interface easily:<br />

• Using the integral editor, the graphical user interface can be<br />

extended in the basic version by up to 20 pictures via predefined<br />

softkeys.<br />

Using these softkeys it is possible to import machine-specific<br />

screen <strong>for</strong>ms, pictures or function trees. Programming support,<br />

such as cycle support, can be intensified with the "Supplement<br />

user interface" function. Configuring takes place using simple<br />

text files.<br />

• Using the SINUMERIK <strong>HMI</strong> configuration package ProTool/Pro,<br />

you can configure displays graphically, quickly and easily.<br />

• The SINUMERIK <strong>HMI</strong> programming package (with extensive<br />

online documentation) permits you to develop your own operating<br />

ideas and concepts using the Microsoft Visual Studio<br />

6 development tool and the <strong>HMI</strong> basic <strong>software</strong>.<br />

In order to use one or more of these possibilities, it is necessary<br />

to have the "SINUMERIC <strong>HMI</strong> copy license OA" option <strong>for</strong> each<br />

PCU. When using the integral editor, this is only necessary from<br />

the 21st picture onwards.<br />

■ Integration<br />

The SINUMERIK <strong>software</strong> <strong>HMI</strong>-Advanced can be used with:<br />

• SINUMERIK 840Di with Windows XP<br />

• SINUMERIK 810D powerline/840D powerline: SINUMERIK<br />

PCU 50/PCU 70 with Windows XP or PCU 50.3<br />

Preconditions <strong>for</strong> <strong>HMI</strong>-Advanced on PC/PG:<br />

• IBM-compatible PC, Pentium 1.2 GHz or better<br />

• RAM: at least 512 MB<br />

• Windows XP operating system<br />

• Vacant PCI slot/PCMCIA CP 5512/CP 5611<br />

<strong>HMI</strong> <strong>software</strong> <strong>for</strong> <strong>CNC</strong> <strong>controls</strong><br />

Operator control and programming<br />

■ Selection and Ordering Data<br />

Designation Order No.<br />

Example of "specific <strong>software</strong> version", e.g., 7.2:<br />

6FC5253-7....-2...<br />

1) <strong>HMI</strong>-Advanced <strong>software</strong> version 6.4 and higher.<br />

2) Please enquire about <strong>software</strong> versions available.<br />

Siemens NC 60 · 2006<br />

<strong>HMI</strong>-Advanced<br />

<strong>HMI</strong>-Advanced<br />

incl. technology cycles<br />

<strong>for</strong> drilling, milling and turning<br />

and the startup tool <strong>for</strong><br />

SIMODRIVE 611 digital<br />

on CD-ROM<br />

Languages: English, French,<br />

German, Italian, Simplified<br />

Chinese, Spanish<br />

For PCU 50/PCU 70 or<br />

PCU 50.3 1)<br />

• Single license<br />

6FC5253-7BX10-7AG0<br />

<strong>for</strong> specific <strong>software</strong> version<br />

• Single license<br />

6FC5253-0BX10-0AG1<br />

without data carrier<br />

• Software update service 6FC5253-0BX10-0AG2<br />

• Update on order of<br />

6FC5253-7BX10-7AG3<br />

specific <strong>software</strong> version<br />

For PC/PG<br />

• Single license<br />

6FC5253-7BX40-7AG0<br />

<strong>for</strong> specific <strong>software</strong> version<br />

• Single license<br />

6FC5253-0BX40-0AG1<br />

without data carrier<br />

• Software update service 6FC5253-0BX40-0AG2<br />

• Update on order of<br />

6FC5253-7BX40-7AG3<br />

specific <strong>software</strong> version<br />

Additional languages 2)<br />

on CD-ROM<br />

Languages: Czech, Danish,<br />

Dutch, Finnish, Hungarian,<br />

Japanese, Korean, Polish,<br />

Portuguese/Brazilian, Russian,<br />

Simplified Chinese, Swedish,<br />

Traditional Chinese, Turkish<br />

• Without license 6FC5253-7BX10-7XG8<br />

• Single license<br />

6FC5253-7BX10-7XG0<br />

<strong>for</strong> specific <strong>software</strong> version<br />

• Single license<br />

6FC5253-0BX10-0XG1<br />

without data carrier<br />

Multi-channel step sequence 6FC5253-0AF03-0AA0<br />

programming<br />

Software option<br />

SINUMERIK <strong>HMI</strong><br />

6FC5253-0AF00-0AA0<br />

copy license OA<br />

Software option<br />

4/3<br />

4

4<br />

<strong>HMI</strong> <strong>software</strong> <strong>for</strong> <strong>CNC</strong> <strong>controls</strong><br />

Operator control and programming<br />

AutoTurn<br />

■ Overview<br />

In the context of workshop-oriented programming, the AutoTurn<br />

graphic programming <strong>software</strong> <strong>for</strong> turning provides a fast and<br />

convenient means of compiling the data required by the NC program<br />

from a workpiece drawing. AutoTurn guides the operator<br />

from the blank input to the finished part simulation.<br />

AutoTurn contains a comprehensive technology database and<br />

automatically creates a work schedule which can be changed or<br />

extended. Complex turned parts can be machined extremely<br />

easily and quickly in this manner.<br />

The AutoTurn PC versions are available in conjunction with the<br />

training <strong>software</strong> SinuTrain Plus. The programs created on the<br />

PC can be directly transferred to the turning machine in the<br />

workshop and executed from there if the turning machine has<br />

been adapted <strong>for</strong> SinuTrain Plus. For further in<strong>for</strong>mation, see<br />

"Services" - "Components <strong>for</strong> <strong>CNC</strong> basic and further training".<br />

■ Benefits<br />

■ More in<strong>for</strong>mation<br />

7 Free definition of the blank and finished part<br />

Additional in<strong>for</strong>mation is available in the Internet under:<br />

7 High-per<strong>for</strong>mance contour computer<br />

7 Comprehensive technology database (tools, cutting parameters,<br />

materials, chucks)<br />

7 Interactive programming (<strong>for</strong> manual intervention outside automatic<br />

work schedule generation)<br />

7 Graphic simulation with display of tools and finished part<br />

http://www.siemens.com/automation/jobshop<br />

7 Connection to CAD systems via the DXF interface<br />

http://www.siemens.com/sinutrain<br />

■ Function<br />

• End face and generated surface machining (boring, tapping,<br />

grooves, and free contours can be programmed on any of the<br />

contour planes).<br />

• Construction geometry <strong>for</strong> calculating unknown contour points.<br />

Use this function to create free pocket contours and then construct<br />

the contour you want to machine by selecting geometry<br />

elements.<br />

• Automatic work schedule generation (one touch)<br />

• Identification and processing of residual material<br />

• Y-axis, toolholder double assignment<br />

4/4<br />

Siemens NC 60 · 2006<br />

■ Integration<br />

The <strong>software</strong> AutoTurn can be used with:<br />

• SINUMERIK PCU 50/PCU 70<br />

• SINUMERIK 810D powerline/840Di/840D powerline<br />

■ Selection and Ordering Data<br />

Designation Order No.<br />

AutoTurn<br />

on CD-ROM<br />

• Single license <strong>for</strong><br />

6FC5253-0GX00-0AG0<br />

current <strong>software</strong> version<br />

• Single license <strong>for</strong><br />

6FC5253-7GX00-7AG0<br />

specific <strong>software</strong> version<br />

• Single license<br />

6FC5253-0GX00-0AG1<br />

without data carrier<br />

• Software update service 6FC5253-0GX00-0AG2<br />

• Service Pack<br />

6FC5253-7GX00-7AG3<br />

<strong>for</strong> specific <strong>software</strong> version<br />

AutoTurn Plus<br />

on CD-ROM<br />

• Single license <strong>for</strong><br />

6FC5253-0GX01-0AG0<br />

current <strong>software</strong> version<br />

• Single license <strong>for</strong><br />

6FC5253-7GX01-7AG0<br />

specific <strong>software</strong> version<br />

• Single license<br />

6FC5253-0GX01-0AG1<br />

without data carrier<br />

• Software update service 6FC5253-0GX01-0AG2<br />

• Service Pack<br />

6FC5253-7GX01-7AG3<br />

<strong>for</strong> specific <strong>software</strong> version<br />

Example of "specific <strong>software</strong> version", e.g. 5.3:<br />

6FC5253-5....-3...

■ Overview<br />

The ManualTurn operator control <strong>software</strong> is designed <strong>for</strong> cyclecontrolled<br />

turning machines primarily used <strong>for</strong> conventional<br />

operations including step by step machining of turned parts with<br />

manual intervention capabilities and easy programming <strong>for</strong> the<br />

machine operator.<br />

With ManualTurn, you enter the traverse commands using simple<br />

input <strong>for</strong>ms in a dialog that provides plain text and graphic<br />

support. The following modes are possible: manual, straight,<br />

angular, circular, cycles, cutting, contour and program.<br />

A PC version is available <strong>for</strong> ManualTurn (see "SinuTrain/<br />

Jobshop").<br />

■ Benefits<br />

7 Simple introduction to <strong>CNC</strong> technology up to a true <strong>CNC</strong><br />

plat<strong>for</strong>m with DIN operation<br />

7 Manual intervention into machining process at any time,<br />

e.g. using contour handwheel<br />

7 Dynamic input graphics <strong>for</strong> contour elements and cycles<br />

7 Open to the customer: customer’s own cycles can be<br />

integrated<br />

7 Any blanks<br />

■ Function<br />

• Simultaneous recording<br />

• Sequencer with program management<br />

• Free input of contour with high-per<strong>for</strong>mance contour computer<br />

(option)<br />

• Stock removal parallel to contour<br />

• Residual material identification and machining <strong>for</strong> free stock<br />

removal (option)<br />

■ Integration<br />

The SINUMERIK <strong>software</strong> ManualTurn can be used with:<br />

• SINUMERIK 810D powerline/840D powerline with<br />

SINUMERIK PCU 20/PCU 50.<br />

<strong>HMI</strong> <strong>software</strong> <strong>for</strong> <strong>CNC</strong> <strong>controls</strong><br />

Operator control and programming<br />

■ Selection and Ordering Data<br />

Designation Order No.<br />

ManualTurn<br />

incl. export system <strong>software</strong> <strong>for</strong><br />

SINUMERIK 810D/840D and<br />

Toolbox <strong>for</strong><br />

SINUMERIK 810D/840D on CD-<br />

ROM<br />

Display switchover online:<br />

English/German<br />

• Single license <strong>for</strong><br />

6FC5463-0GA00-0AG0<br />

current <strong>software</strong> version<br />

• Single license <strong>for</strong><br />

6FC5463-7GA00-7AG0<br />

specific <strong>software</strong> version<br />

• Single license<br />

6FC5463-0GA00-0AB1<br />

without data carrier<br />

• Software update service 6FC5463-0GA00-0AB2<br />

• Update on order of<br />

6FC5463-7GA00-7AG3<br />

specific <strong>software</strong> versions<br />

1) 2)<br />

Additional languages<br />

on CD-ROM<br />

Languages:<br />

Czech, Finnish, Hungarian,<br />

Japanese, Korean, Dutch, Polish,<br />

Portuguese/Brazilian, Russian,<br />

Simplified Chinese, Swedish,<br />

Traditional Chinese, Turkish<br />

• Single license <strong>for</strong><br />

6FC5253-7BX10-7XG0<br />

specific <strong>software</strong> version<br />

• Single license<br />

6FC5253-0BX10-0XG1<br />

without data carrier<br />

Free contour input<br />

6FC5463-0GA00-0AA0<br />

with free stock removal along<br />

the contour<br />

Software option<br />

Residual material identification 6FC5463-0GA01-0AA0<br />

and machining <strong>for</strong> free<br />

stock removal<br />

(prerequisite: <strong>software</strong> option<br />

"Free contour input")<br />

Software option<br />

Siemens NC 60 · 2006<br />

ManualTurn<br />

For the SINUMERIK 840D powerline the appropriate single<br />

license without a data carrier must be purchased <strong>for</strong> each NCU<br />

be<strong>for</strong>e using the system <strong>software</strong>.<br />

Example of "specific <strong>software</strong> version", e.g. 6.2:<br />

6FC5463-6....-2...<br />

■ More in<strong>for</strong>mation<br />

Additional in<strong>for</strong>mation is available in the Internet under:<br />

http://www.siemens.com/automation/jobshop<br />

1) CD-ROM also contains the languages: Eng, Fr, Ger, It., Sp.<br />

2) On request.<br />

4/5<br />

4

4<br />

<strong>HMI</strong> <strong>software</strong> <strong>for</strong> <strong>CNC</strong> <strong>controls</strong><br />

Operator control and programming<br />

ShopMill<br />

■ Overview<br />

ShopMill is operating and programming <strong>software</strong> <strong>for</strong> milling<br />

machines that makes it easy <strong>for</strong> you to operate the machine and<br />

to program workpieces.<br />

With ShopMill, you get a complete <strong>CNC</strong> control solution <strong>for</strong><br />

milling in the workshop area. You can use ShopMill on singlechannel<br />

versions of vertical or universal milling machines with up<br />

to 12 axes (including rotary axes and spindles). Of the 12 axes,<br />

3 linear and 2 rotary axes plus 1 spindle can be displayed simultaneously.<br />

In addition to an extensive cycle package, it offers a<br />

host of practice-oriented setup functions (e.g. workpiece or tool<br />

measurement) and functions <strong>for</strong> data handling.<br />

ShopMill’s tool management function is transparent and userfriendly.<br />

To use this function, it must be integrated into the PLC<br />

program of the machine.<br />

ShopMill supports three different programming methods:<br />

• G code programs that are generated externally,<br />

e.g. mold making programs imported from CAD/CAM systems.<br />

• G code programs that are created directly on the machine.<br />

All technology cycles are available with G-code programming.<br />

• Machining step programs that are created directly on the<br />

machine (available as an option).<br />

The workpiece can be programmed easily because programming<br />

is graphically supported and no knowledge of G codes is<br />

required. ShopMill displays the program as a clearly understandable<br />

work plan and presents the individual cycles and<br />

contour elements in a dynamic graphical display.<br />

With the PCU 20/PCU 50, ShopMill can access the flash card or<br />

hard disk and the Ethernet (option). Consequently, even large<br />

mold making programs can be executed with ShopMill. With the<br />

PCU 50, the <strong>HMI</strong>-Advanced areas "Utilities", "Parameters",<br />

"Diagnostics" and "Start-up" are permanently integrated into<br />

ShopMill. The solutions <strong>for</strong> Open Architecture, MCIS or Solution<br />

Provider applications from ShopMill can there<strong>for</strong>e be used.<br />

A PC version is available <strong>for</strong> ShopMill (see "SinuTrain/Jobshop").<br />

4/6<br />

Siemens NC 60 · 2006<br />

■ Benefits<br />

7 Clear program presentation in the machining step program<br />

(option)<br />

7 Dynamic input graphics <strong>for</strong> contour elements and cycles<br />

7 Adaptation of the traversing paths of the tool while taking<br />

account of the workpiece contour and obstacles<br />

7 High-per<strong>for</strong>mance contour computer <strong>for</strong> the input of a free<br />

contour<br />

7 Networking and diskette drive connection with<br />

PCU 20/PCU 50<br />

7 Support of swivel heads and swiveling tables<br />

7 Individual cycles and user displays can be integrated.<br />

■ Function<br />

• Machining step programming (option)<br />

• ShopMill tool management<br />

• Simultaneous recording (option)<br />

• Residual material identification and machining in the contour<br />

pocket cycle (option)<br />

• 3D graphics of the finished part<br />

• Multiple clamping of identical workpieces with optimization of<br />

the tool sequence<br />

• Multiple clamping of different workpieces with optimization of<br />

the tool sequence (option)<br />

• Remote diagnosis (option)<br />

• A swivel cycle supports multiface machining and machining of<br />

sloping surfaces independently of the machine kinematics<br />

(swivel table/swivel head)<br />

• Access to external programs through network interfacing or<br />

disk drive (option)<br />

■ Integration<br />

The SINUMERIK <strong>software</strong> ShopMill can be used with:<br />

• SINUMERIK 840Di<br />

• SINUMERIK 810D powerline/840D powerline with<br />

SINUMERIK PCU 20/PCU 50

■ Selection and Ordering Data<br />

Designation Order No.<br />

ShopMill <strong>HMI</strong><br />

without machining step programming,<br />

incl. tool boxes, tool<br />

management on CD-ROM<br />

Languages:<br />

English, German, French, Italian,<br />

Simplified Chinese, Spanish<br />

• Single license <strong>for</strong><br />

6FC5463-0FA20-0AG0<br />

current <strong>software</strong> version<br />

• Single license <strong>for</strong><br />

6FC5463-7FA20-7AG0<br />

specific <strong>software</strong> version<br />

• Single license<br />

6FC5463-0FA20-0AB1<br />

without data carrier<br />

• Software update service 6FC5463-0FA20-0AB2<br />

• Update on order of<br />

6FC5463-7FA20-7AG3<br />

specific <strong>software</strong> versions<br />

Additional languages 1)<br />

on CD-ROM<br />

Languages:<br />

Czech, Danish, Dutch, Finnish,<br />

Hungarian, Japanese, Korean,<br />

Polish, Portuguese/ Brazilian,<br />

Russian, Swedish, Traditional<br />

Chinese, Turkish<br />

• Single license <strong>for</strong><br />

6FC5253-7BX10-7XG0<br />

specific <strong>software</strong> version<br />

• Single license<br />

6FC5253-0BX10-0XG1<br />

without data carrier<br />

ShopMill machining step<br />

6FC5463-0FA21-0AA0<br />

programming<br />

Software option<br />

Automatic residual material<br />

detection and machining<br />

in contour pocket cycle 2)<br />

6FC5463-0FA01-0AA0<br />

Software option<br />

Simultaneous recording<br />

6FC5463-0FA02-0AA0<br />

(real-time simulation<br />

of current machining)<br />

Software option<br />

Network/disk drive<br />

management 3)<br />

6FC5463-0FA03-0AA0<br />

Software option<br />

Multiple clamping of different<br />

workpieces 2)<br />

6FC5463-0FA04-0AA0<br />

Software option<br />

For the SINUMERIK 840D powerline the appropriate single<br />

license without a data carrier must be purchased <strong>for</strong> each NCU<br />

be<strong>for</strong>e using the system <strong>software</strong>.<br />

Example of "specific <strong>software</strong> version", e.g. 6.4:<br />

6FC5463-6....-4...<br />

1) On request.<br />

2) Prerequisite: Software option "ShopMill machining step programming".<br />

3) Contains the <strong>software</strong> option "Network/disk drive management <strong>for</strong> PCU 20".<br />

<strong>HMI</strong> <strong>software</strong> <strong>for</strong> <strong>CNC</strong> <strong>controls</strong><br />

Operator control and programming<br />

■ More in<strong>for</strong>mation<br />

Additional in<strong>for</strong>mation is available in the Internet under:<br />

http://www.siemens.com/jobshop<br />

Siemens NC 60 · 2006<br />

ShopMill<br />

4/7<br />

4

4<br />

<strong>HMI</strong> <strong>software</strong> <strong>for</strong> <strong>CNC</strong> <strong>controls</strong><br />

Operator control and programming<br />

ShopTurn<br />

■ Overview<br />

ShopTurn is an operating and programming <strong>software</strong> program<br />

<strong>for</strong> single-slide turning machines that makes it easy <strong>for</strong> you to<br />

operate the machine and to program workpieces.<br />

With ShopTurn, you get a complete <strong>CNC</strong> control solution <strong>for</strong><br />

turning in the workshop area. In addition to an extensive cycle<br />

package, it offers a host of practice-oriented setup functions<br />

(e.g. workpiece or tool measurement) and functions <strong>for</strong> data<br />

handling.<br />

You can use ShopTurn on single-channel versions of single-slide<br />

turning machines with up to 12 axes (including rotary axes and<br />

spindles). Of the 12 axes, 5 axes plus 1 spindle can be displayed<br />

simultaneously. ShopTurn also supports machine extensions<br />

with C axes, Y axes and counterspindle.<br />

ShopTurn's tool management function is transparent and userfriendly.<br />

To use this function, it must be integrated into the PLC<br />

program of the machine.<br />

ShopTurn supports three different programming methods:<br />

• G code programs that are generated externally,<br />

e.g. imported from CAD/CAM systems<br />

• G code programs that are created directly on the machine.<br />

All technology cycles are available with G-code programming.<br />

• Machining step programs that are created directly on the<br />

machine (available as an option)<br />

The workpiece can be programmed easily because programming<br />

is graphically supported and no knowledge of G codes is<br />

required. ShopTurn displays the program as a clearly understandable<br />

work plan and presents the individual cycles and<br />

contour elements in a dynamic graphic.<br />

With the PCU 20/PCU 50, ShopTurn can access the flash card or<br />

hard disk and the Ethernet (option). Consequently, even large<br />

programs can be executed with ShopTurn.<br />

With the PCU 50, the <strong>HMI</strong>-Advanced areas "Utilities", "Parameters",<br />

"Diagnostics" and "Start-up" are permanently integrated<br />

into ShopTurn. The solutions <strong>for</strong> Open Architecture, MCIS or<br />

Solution Provider applications from ShopTurn can there<strong>for</strong>e be<br />

used.<br />

A PC version is available <strong>for</strong> ShopTurn (see "SinuTrain/Jobshop").<br />

4/8<br />

Siemens NC 60 · 2006<br />

■ Benefits<br />

7 Clear program presentation in the machining step program<br />

(option)<br />

7 Dynamic input graphics <strong>for</strong> contour elements and cycles<br />

7 High-per<strong>for</strong>mance contour computer <strong>for</strong> the input of a free<br />

contour<br />

7 Automatic generation of the approach and departure<br />

movements depending on the tool position and the type of<br />

machining<br />

7 Individual cycles and user pictures can be integrated<br />

7 User pictures and example cycles <strong>for</strong> bar store, part collector<br />

and tailstock are also supplied.<br />

■ Function<br />

• Machining step programming (option)<br />

• ShopTurn tool management<br />

• Simultaneous recording (option)<br />

• Residual material identification and machining when cutting<br />

(option)<br />

• 3D simulation of the finished part (option)<br />

• Traverse to fixed stop (option) when using the counterspindle<br />

• Synchronous spindle (option) when using the counterspindle<br />

• Transmit/Tracyl (option) when using rotating tools<br />

• Access to external programs through network interfacing or<br />

disk drive (option)<br />

• Remote diagnosis (option)<br />

■ Integration<br />

The SINUMERIK <strong>software</strong> ShopTurn can be used with:<br />

• SINUMERIK 840Di<br />

• SINUMERIK 810D powerline/840D powerline with<br />

SINUMERIK PCU 20/PCU 50

■ Selection and Ordering Data<br />

Designation Order No.<br />

ShopTurn <strong>HMI</strong><br />

without machining step programming,<br />

incl. tool boxes, tool<br />

management on CD-ROM<br />

Languages:<br />

English, French, German, Italian,<br />

Simplified Chinese, Spanish<br />

• Single license <strong>for</strong><br />

6FC5463-0GA20-0AG0<br />

current <strong>software</strong> version<br />

• Single license <strong>for</strong><br />

6FC5463-7GA20-7AG0<br />

specific <strong>software</strong> version<br />

• Single license<br />

6FC5463-0GA20-0AB1<br />

without data carrier<br />

• Software update service 6FC5463-0GA20-0AB2<br />

• Update on order of<br />

6FC5463-7GA20-7AG3<br />

specific <strong>software</strong> versions<br />

Additional languages 1)<br />

on CD-ROM<br />

Languages:<br />

Czech, Danish, Dutch, Finnish,<br />

Hungarian, Japanese, Korean,<br />

Polish, Portuguese/ Brazilian,<br />

Russian, Swedish, Traditional<br />

Chinese, Turkish<br />

• Single license <strong>for</strong><br />

6FC5253-7BX10-7XG0<br />

specific <strong>software</strong> version<br />

• Single license<br />

6FC5253-0BX10-0XG1<br />

without data carrier<br />

ShopTurn machining<br />

6FC5463-0GA21-0AA0<br />

step programming<br />

Software option<br />

Residual material detection<br />

and machining<br />

during cutting 2)<br />

6FC5463-0GA10-0AA0<br />

Software option<br />

3D simulation<br />

6FC5463-0GA11-0AA0<br />

of the finished part<br />

Software option<br />

Simultaneous recording<br />

6FC5463-0GA12-0AA0<br />

(real-time simulation<br />

of current machining)<br />

Software option<br />

Travel to fixed stop<br />

6FC5255-0AB02-0AA0<br />

when using counterspindle<br />

Software option<br />

Synchronous spindle<br />

6FC5255-0AB01-0AA0<br />

when using counterspindle<br />

Software option<br />

Transmit/peripheral surface 6FC5251-0AB01-0AA0<br />

trans<strong>for</strong>mation<br />

when using driven tools<br />

Software option<br />

Network/disk drive<br />

management 3)<br />

6FC5463-0FA03-0AA0<br />

Software option<br />

For the SINUMERIK 840D powerline the appropriate single<br />

license without a data carrier must be purchased <strong>for</strong> each NCU<br />

be<strong>for</strong>e using the system <strong>software</strong>.<br />

Example of "specific <strong>software</strong> version", e.g. 6.4:<br />

6FC5463-6....-4...<br />

1) On request.<br />

2) Prerequisite: Software option "ShopTurn work step programming".<br />

3) Contains the <strong>software</strong> option "Network/disk drive management <strong>for</strong> PCU 20".<br />

<strong>HMI</strong> <strong>software</strong> <strong>for</strong> <strong>CNC</strong> <strong>controls</strong><br />

Operator control and programming<br />

■ More in<strong>for</strong>mation<br />

Additional in<strong>for</strong>mation is available in the Internet under:<br />

http://www.siemens.com/jobshop<br />

Siemens NC 60 · 2006<br />

ShopTurn<br />

4/9<br />

4

4<br />

<strong>HMI</strong> <strong>software</strong> <strong>for</strong> <strong>CNC</strong> <strong>controls</strong><br />

Operator control and programming<br />

Technology cycles<br />

■ Overview<br />

Technology cycles<br />

Example: Swiveling to any surface<br />

Technology cycles (standard cycles) <strong>for</strong> drilling/milling and turning<br />

are available <strong>for</strong> frequently repeated machining tasks.<br />

Standard cycles are generally applicable technology sub<br />

routines, with which you can implement specific machining processes<br />

such as tapping a thread or milling a pocket. The cycles<br />

are adapted to a concrete machining task by means of defining<br />

parameters.<br />

■ Function<br />

The following standard cycles are available:<br />

• Drilling:<br />

Drilling/centering, drilling/counterboring, deep-hole drilling,<br />

tapping with and without compensating chuck, boring 1 to 5,<br />

row of holes circle of holes grid of holes, machining on inclined<br />

surfaces<br />

• Milling:<br />

Thread milling, elongated holes in a circle, groove in a circle,<br />

circumferential groove, rectangular/circular pocket, face milling,<br />

path milling, rectangular/circular spigot, pocket milling<br />

with islands (option), machining on inclined surfaces, highspeed<br />

settings <strong>for</strong> optimized HSC machining, engraving<br />

• Turning:<br />

Groove, undercut, cutting with relief cut, extended cutting with<br />

residual material recognition (option), thread undercut, thread<br />

cutting, chaining of threads, thread recutting<br />

The parameters are set via graphically supported input screen<br />

<strong>for</strong>ms in plain text.<br />

■ Integration<br />

Technology cycles are already included in the <strong>HMI</strong>-Advanced<br />

<strong>software</strong>.<br />

4/10<br />

Siemens NC 60 · 2006<br />

Technology cycles<br />

Example: Circular pocket milling<br />

■ Selection and Ordering Data<br />

Designation Order No.<br />

Technology cycles<br />

<strong>for</strong> drilling/milling and turning<br />

on 3.5" floppy disks<br />

For languages/additional languages,<br />

see <strong>HMI</strong>-Advanced and<br />

<strong>HMI</strong>-Embedded<br />

• Single license <strong>for</strong><br />

6FC5250-0AX00-0AB0<br />

current <strong>software</strong> version<br />

• Single license <strong>for</strong><br />

6FC5250-7AX00-7AB0<br />

specific <strong>software</strong> version<br />

• Single license<br />

6FC5250-0AX00-0AB1<br />

without data carrier<br />

• Software update service 6FC5250-0AX00-0AB2<br />

• Update on order of<br />

6FC5250-7AX00-7AB3<br />

specific <strong>software</strong> versions<br />

Example of "specific <strong>software</strong> version", e.g. 6.5:<br />

6FC5250-6....-5...

■ Overview<br />

Measuring cycles<br />

Example: Measuring a shaft<br />

Measuring functions can execute either channel-specifically including<br />

all axes programmed in the measuring set as well as<br />

axially from the parts program or from synchronous actions<br />

beyond NC block limits.<br />

Measuring cycles are subroutines <strong>for</strong> solving specific measuring<br />

tasks. They are easy to use by entering values <strong>for</strong> predefined<br />

parameters. A general distinction is made between tool measurement<br />

and workpiece measurement. For this purpose, we<br />

provide you with a complete range of measuring cycles<br />

■ Benefits<br />

7 2 probes can be connected simultaneously<br />

7 Measurement in the solid with frame<br />

7 Adaptable measuring modes with/without deletion of residual<br />

distance<br />

7 Display and logging of measuring parameters and results<br />

(with measuring cycles)<br />

7 Results can be read in the machine or workpiece coordinate<br />

system<br />

7 Cyclic measurement with synchronous actions parallel to<br />

workpiece machining<br />

7 Measurement in jog mode <strong>for</strong> milling machines<br />

With the advantages of the SINUMERIK measurement functions<br />

and measuring cycles, you ensure machining accuracy, shorten<br />

idle times, and eliminate sources of faults, thus making a significant<br />

contribution to further automation of the manufacturing process.<br />

<strong>HMI</strong> <strong>software</strong> <strong>for</strong> <strong>CNC</strong> <strong>controls</strong><br />

Operator control and programming<br />

■ Function<br />

Measuring functions/measuring cycles<br />

Measuring cycles<br />

Example: Two angle measurement <strong>for</strong> determining the position of a plane<br />

in space<br />

In the case of tool measuring, the loaded tool (typically in the<br />

revolver on turning machines) is moved toward the probe which<br />

is either in a fixed position or swiveled into the working range by<br />

a mechanical device. The automatically derived tool geometry is<br />

entered in the relevant tool offset data record.<br />

In the case of workpiece measuring, a probe is moved towards<br />

the clamped workpiece like a tool. The flexible selection of measuring<br />

cycles means that you can handle practically every measuring<br />

task associated with turning or milling.<br />

The principle of "on-the-fly measurement" is implemented in<br />

SINUMERIK <strong>controls</strong>. The advantage of this principle is that processing<br />

of the probe signal is carried out directly in the <strong>CNC</strong>.<br />

The measuring parameters and the results of the measurements<br />

are output extremely clearly in separate displays which are either<br />

automatically deselected at the end of the cycle, or can be acknowledged<br />

when starting the <strong>CNC</strong>.<br />

The result of the workpiece measurement can either include<br />

automatic offset of the zero point or a correction of the tool wear<br />

by the difference between the actual value and the setpoint.<br />

The measured results can be logged in a file. The Siemens<br />

measuring cycles offer a standard log which you can adapt as<br />

required.<br />

In order to measure tool and workpiece dimensions, a touchtrigger<br />

probe is required that supplies a constant signal (rather<br />

than a pulse) when deflected. The probe should switch bouncefree,<br />

and mechanical adjustment may be necessary.<br />

Multidirectional probes can be used <strong>for</strong> all tool and workpiece<br />

measurements on turning and milling machines. Bidirectional<br />

probes are treated like a mono probe <strong>for</strong> workpiece measurements<br />

on milling and machining centers, but are not suitable <strong>for</strong><br />

tool measurements.<br />

Monodirectional probes can be used on milling machines and<br />

machining centers with slight restrictions in workpiece measurements,<br />

but are not suitable <strong>for</strong> tool measurements or <strong>for</strong> workpiece<br />

measurements on turning machines.<br />

Siemens NC 60 · 2006<br />

4/11<br />

4

4<br />

<strong>HMI</strong> <strong>software</strong> <strong>for</strong> <strong>CNC</strong> <strong>controls</strong><br />

Operator control and programming<br />

Measuring functions/measuring cycles<br />

■ Function (continued)<br />

We offer:<br />

• Measuring Cycles <strong>for</strong> Turning Machines<br />

- Tool measurements (calibration/measurement) <strong>for</strong> turning<br />

tools<br />

- Tool measurements <strong>for</strong> milling tools and drills on turning<br />

machines<br />

- Calibrating workpiece probes<br />

- 1-point workpiece measurement<br />

- 2-point workpiece measurement<br />

• Measuring cycles <strong>for</strong> milling machines and machining centers<br />

- Tool measurements (calibration/measurement) <strong>for</strong> milling<br />

tools<br />

- Calibrating workpiece probes<br />

- Paraxial workpiece measurement on hole/shaft/slot/web/<br />

rectangle<br />

- 1-point workpiece measurement on area<br />

- Workpiece measurement at any angle on hole/shaft/slot/web<br />

- Workpiece measurement at angular position (1-/2-angle measurement)<br />

- Automatic set-up corner internal and external<br />

- Measurement of workpiece sphere and automatic correction<br />

of work offset<br />

■ Integration<br />

General (channel-specific) measuring functions are included as<br />

standard in the basic version of the SINUMERIK 810D powerline/840Di/840D<br />

powerline <strong>CNC</strong>s.<br />

Axial measuring, measuring from synchronous actions and continuous<br />

measuring can be implemented as options with "Measuring<br />

Stage 2".<br />

The optional measuring cycles are included as standard in version<br />

6.4 and higher of the <strong>HMI</strong>-Advanced <strong>software</strong>. A license<br />

(CoL) must be acquired to provide proof of authorization to use<br />

the <strong>software</strong>.<br />

■ Selection and Ordering Data<br />

Designation Order No.<br />

Measuring cycles 1)<br />

<strong>for</strong> drilling/milling and turning<br />

on 3.5" floppy disks<br />

For languages/additional<br />

languages,<br />

see <strong>HMI</strong>-Advanced and<br />

<strong>HMI</strong>-Embedded<br />

• Single license <strong>for</strong><br />

6FC5250-0BX00-0AB0<br />

current <strong>software</strong> version<br />

• Single license <strong>for</strong><br />

6FC5250-7BX00-7AB0<br />

specific <strong>software</strong> version<br />

• Single license<br />

6FC5250-0BX00-0AB1<br />

without data carrier<br />

• Software update service 6FC5250-0BX00-0AB2<br />

• Update on order of<br />

6FC5250-7BX00-7AB3<br />

specific <strong>software</strong> versions<br />

Example of "specific <strong>software</strong> version", e.g. 6.3:<br />

6FC5...-6....-3...<br />

1) When used with OP 030, without input displays.<br />

4/12<br />

Siemens NC 60 · 2006<br />

CAD reader<br />

■ Overview<br />

The CAD Reader program converts DXF files into contours or<br />

hole drilling templates.<br />

■ Function<br />

• Importing of DXF files<br />

• Suppressing of graphic layers<br />

• Automatic contour tracing<br />

• Any workpiece zero per extracted contour/drilling pattern<br />

• Several contours/drilling patterns can be extracted simultaneously<br />

• Conversion into contours or drilling patterns <strong>for</strong> ShopMill,<br />

ShopTurn, ManualTurn, <strong>HMI</strong>-Advanced or <strong>HMI</strong>-Embedded<br />

• Display of extracted contours/drilling patterns in the geometric<br />

processor/cycle support<br />

■ Integration<br />

The "CAD Reader" program can be used with:<br />

• SINUMERIK 810D powerline/840Di/840D powerline<br />

• SINUMERIK 840Di sl/840D sl<br />

Preconditions:<br />

• Windows 95/98/Me/NT 4.0/2000/XP operating system<br />

•Mouse<br />

■ Selection and Ordering Data<br />

Designation Order No.<br />

CAD Reader <strong>for</strong> PC<br />

incl. documentation<br />

Languages: English, German<br />

• Single license<br />

6FC5260-0AY00-0AG1<br />

without data carrier<br />

• Single license with CD-ROM 6FC5260-0AY00-0AG0<br />

of current <strong>software</strong> version<br />

• Single license with CD-ROM 6FC5260-7AY00- 7AG0<br />

of specific <strong>software</strong> version<br />

• Software update service 6FC5260-0AY00-0AG2<br />

• ServicePack on order of<br />

6FC5260-7AY00- 7AG8<br />

specific <strong>software</strong> version<br />

Example of "specific <strong>software</strong> version", e.g., 6.2:<br />

6FC5260-6....-2...

■ Overview<br />

<strong>HMI</strong> <strong>software</strong> <strong>for</strong> <strong>CNC</strong> <strong>controls</strong><br />

Operator control and programming<br />

Siemens NC 60 · 2006<br />

TRANSLINE <strong>HMI</strong><br />

■ Function (continued)<br />

<strong>HMI</strong> Lite CE<br />

<strong>HMI</strong> Lite CE contains a sample project that can be expanded<br />

with machine-specific or project-specific images by using<br />

WinCC flexible. A diagnostic display is available <strong>for</strong> the optional<br />

ProAgent process error diagnostics. It can be used in combination<br />

with S7-PDIAG, S7-GRAPH and S7-HiGraph.<br />

<strong>HMI</strong> Lite CE can be expanded with interactive screens that<br />

access SINUMERIK data provided that the SINUMERIK<br />

Copy License CE is available <strong>for</strong> each operator panel.<br />

■ Selection and Ordering Data<br />

Designation<br />

<strong>HMI</strong> PRO RT<br />

Runtime <strong>software</strong><br />

Order No.<br />

• Single license <strong>for</strong><br />

current <strong>software</strong> version<br />

6FC5263-0PY50-0AG0<br />

• Single license <strong>for</strong><br />

6FC5263-7PY50-7AG0<br />

TRANSLINE <strong>HMI</strong> is the machine user interface <strong>for</strong> operator<br />

specific <strong>software</strong> version<br />

control and visualization tasks in large-scale production, <strong>for</strong><br />

example in transfer lines, machining centers and assembly lines.<br />

• Single license<br />

without data carrier<br />

6FC5263-0PY50-0AG1<br />

This <strong>HMI</strong> system ensures uni<strong>for</strong>mity in the operation of machines<br />

with diverse tasks and technologies by means of standardized<br />

operator displays and a parameterizable navigation menu.<br />

The technology-specific operator displays are assembled into<br />

function groups, such as machine functions (workpiece counting,<br />

cycle times, workpiece overview), help texts, overviews, tool<br />

change functions and manual operating functions. Prepared<br />

diagnostic screen <strong>for</strong>ms support rapid fault localization in the<br />

event of a machine fault.<br />

<strong>HMI</strong> PRO CS<br />

Configuration <strong>software</strong><br />

• Single license <strong>for</strong><br />

current <strong>software</strong> version<br />

• Single license <strong>for</strong><br />

specific <strong>software</strong> version<br />

• Single license<br />

without data carrier<br />

6FC5263-0PY80-0AG0<br />

6FC5263-7PY80-7AG0<br />

6FC5263-0PY80-0AG1<br />

■ Function<br />

<strong>HMI</strong> Lite CE<br />

Runtime <strong>software</strong><br />

Diverse target hardware <strong>HMI</strong>s are supported to ensure the best<br />

possible price/per<strong>for</strong>mance ratio <strong>for</strong> different applications.<br />

<strong>HMI</strong> PRO RT runtime <strong>software</strong> can run on the standard-hardware<br />

PCU 50/PCU 70 and is equivalent to the PC plat<strong>for</strong>m solution.<br />

• Single license <strong>for</strong><br />

current <strong>software</strong> version<br />

• Single license <strong>for</strong><br />

specific <strong>software</strong> version<br />

6FC5263-0PY11-0AG0<br />

6FC5263-7PY11-7AG0<br />

<strong>HMI</strong> Lite CE is available <strong>for</strong> the Windows CE-based OP/TP 277 • Single license<br />

6FC5263-0PY11-0AG1<br />

and OP/TP 177B SIMATIC Panels.<br />

without data carrier<br />

The standard application is easy to adapt or expand and is<br />

there<strong>for</strong>e ideally suited <strong>for</strong> implementing customized versions <strong>for</strong><br />

project-specific use.<br />

Example of "specific <strong>software</strong> version", e.g.: <strong>HMI</strong> Pro CS 6.3:<br />

6FC5263-6PY80-3AG0<br />

<strong>HMI</strong> PRO<br />

■ More in<strong>for</strong>mation<br />

<strong>HMI</strong> PRO CS configuration <strong>software</strong> can run on PGs/PCs. It can<br />

be used to parameterize and configure images <strong>for</strong> <strong>HMI</strong> PRO RT<br />

and load them into the target hardware. Two diagnostic displays<br />

are available <strong>for</strong> the process error diagnostics integrated into<br />

<strong>HMI</strong> PRO RT. Process error diagnostics are used in combination<br />

with S7-PDIAG, S7-GRAPH and S7-HiGraph.<br />

The basic scope of supply can be expanded by images that are<br />

configured by the user with WinCC flexible and/or applications<br />

written in high-level languages (e.g. Visual Basic).<br />

<strong>HMI</strong> PRO RT can be expanded with WinCC flexible images provided<br />

that the SINUMERIK <strong>HMI</strong> configuration package<br />

WinCC flexible is installed on the configuration device.<br />

<strong>HMI</strong> PRO can be expanded with WinCC flexible and/or highlevel<br />

language applications provided that the SINUMERIK <strong>HMI</strong><br />

Copy License OA is available on the target hardware.<br />

For further details, see "SIMATIC WinCC flexible" or "SIMATIC<br />

ProAgent".<br />

4/13<br />

4

4<br />

<strong>HMI</strong> <strong>software</strong> <strong>for</strong> <strong>CNC</strong> <strong>controls</strong><br />

Open Architecture<br />

<strong>HMI</strong> Open Architecture<br />

■ Overview<br />

■ Function<br />

SINUMERIK <strong>HMI</strong> programming package<br />

The "SINUMERIK <strong>HMI</strong> programming package" enables highlevel<br />

language applications based on the programming<br />

languages Visual Basic and Visual C++ to be integrated into<br />

<strong>HMI</strong>-Advanced with PCU 50/PCU 70 and PCU 50.3.<br />

Note:<br />

To develop your own applications, you need to run the <strong>software</strong><br />

version of the "SINUMERIK <strong>HMI</strong> programming package" that<br />

matches the <strong>HMI</strong>-Advanced on the target hardware.<br />

Example: <strong>HMI</strong>-Advanced V7.1.x requires SINUMERIK <strong>HMI</strong><br />

programming package V7.1.<br />

"<strong>HMI</strong> openness" provides OEMs with the option of achieving their Benefits:<br />

own look and <strong>for</strong> implementing their own operating and display<br />

functions.<br />

• Integration of user interfaces in <strong>HMI</strong>-Advanced with<br />

PCU 50/PCU 70 and PCU 50.3<br />

This openness is available in combination with the "SINUMERIK • User interfaces <strong>for</strong> stand-alone execution (without <strong>HMI</strong>-<br />

<strong>HMI</strong> programming package", the "SINUMERIK <strong>HMI</strong> configuring Advanced)<br />

package" and the "SINUMERIK <strong>HMI</strong> add-in package".<br />

• Supports Microsoft COM and OPC interfaces<br />

■ Application<br />

SINUMERIK <strong>HMI</strong> configuring package<br />

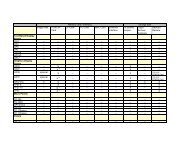

Can execute on Preconditions<br />

With the "SINUMERIK <strong>HMI</strong> configuring package", any skilled<br />

worker with basic technical experience can create technology-<br />

PCU 20 PCU 50/PCU 70 SINUMERIK related modules <strong>for</strong> programming, operation and visualization,<br />

SINUMERIK<br />

<strong>HMI</strong><br />

programming<br />

–<br />

PCU 50.3<br />

(Windows XP)<br />

✓<br />

<strong>HMI</strong><br />

copy license<br />

OA<br />

without the need <strong>for</strong> high-level language expertise.<br />

It is then possible to generate user interfaces, which can be<br />

integrated into <strong>HMI</strong>-Advanced, or which can be used<br />

autonomously, i.e., executed without <strong>HMI</strong>-Advanced, and which<br />

use the communications interfaces of the SINUMERIK.<br />

package<br />

The graphics-supported engineering tool "SIMATIC WinCC flexible"<br />

(Advanced) is used as the basis <strong>for</strong> configuration. You are<br />

there<strong>for</strong>e able to create stand-alone user interfaces <strong>for</strong> operating<br />

and visualizing plant and machine tools. The "SINUMERIK <strong>HMI</strong><br />

WinCC flexible configuring package" is additionally required to<br />

permit that the SINUMERIK 810D powerline/840Di/840D powerline<br />

or the operating systems of these <strong>controls</strong> can be configured.<br />

Benefits:<br />

• Integration of user interfaces in <strong>HMI</strong>-Advanced with<br />

PCU 50/PCU 70 and PCU 50.3<br />

✓ possible<br />

– not possible<br />

• User interfaces <strong>for</strong> stand-alone execution (without<br />

<strong>HMI</strong>-Advanced)<br />

• One SINUMERIK <strong>HMI</strong> copy license CE is required per control<br />

in order to use OEM applications on the SIMATIC CE Panels.<br />

• Integration of user interfaces in SIMATIC <strong>HMI</strong> panels of the<br />

170 or 270 series and the MP370 on a SINUMERIK control<br />

• Always subject to conclusion of an OEM contract.<br />

Note:<br />

"SIMATIC WinCC flexible" (Advanced) is not included in the<br />

"SINUMERIK <strong>HMI</strong> WinCC flexible configuring package" and<br />

must be ordered separately if required.<br />

SINUMERIK <strong>HMI</strong> add-in package<br />

The "SINUMERIK <strong>HMI</strong> add-in package" is a subcomponent of<br />

the SINUMERIK <strong>HMI</strong> programming package. It allows users to<br />

incorporate their own Windows applications in the SINUMERIK<br />

or a standard PC/PG with MPI card. A prerequisite is that the<br />

Windows application does not require a communication link to<br />

the SINUMERIK.<br />

Extensive documentation is included with the "SINUMERIK <strong>HMI</strong><br />

add-in package" that describes how to integrate applications<br />

into <strong>HMI</strong>-Advanced. The tool is available from the Customer<br />

Support online shop.<br />

Benefits:<br />

• Open <strong>for</strong> Windows applications without a communication link<br />

to the SINUMERIK<br />

1) ✓<br />

SINUMERIK – ✓ ✓<br />

<strong>HMI</strong> WinCC<br />

flexible<br />

configuring<br />

package<br />

SINUMERIK – ✓ ✓<br />

<strong>HMI</strong> add-in<br />

package<br />

SINUMERIK<br />

<strong>HMI</strong> expanded<br />

user interface<br />

✓ ✓ from the 21st<br />

screen<br />

1) SINUMERIK <strong>HMI</strong> configuring package 7.x only in conjunction with<br />

PCU 50.3 or PC/PG.<br />

4/14<br />

Siemens NC 60 · 2006

<strong>HMI</strong> <strong>software</strong> <strong>for</strong> <strong>CNC</strong> <strong>controls</strong><br />

Open Architecture<br />

<strong>HMI</strong> Open Architecture<br />

■ Function (continued)<br />

■ Selection and Ordering Data<br />

SINUMERIK <strong>HMI</strong> copy license OA<br />

Designation Order No.<br />

The runtime license "SINUMERIK <strong>HMI</strong> copy license OA" permits<br />

the execution of the user’s own <strong>HMI</strong> Open Architecture applications<br />

on the PCU 20, PCU 50/PCU 70, PCU 50.3 or on a PC/PG<br />

on the SINUMERIK control that were created using the<br />

SINUMERIK <strong>HMI</strong><br />

Programming package<br />

incl. <strong>HMI</strong>-Advanced <strong>for</strong> PC/PG<br />

<strong>for</strong> SINUMERIK 810D/840Di/840D<br />

on CD-ROM<br />

• SINUMERIK <strong>HMI</strong> programming package<br />

• SINUMERIK <strong>HMI</strong> WinCC flexible configuring package<br />

Runtime system languages:<br />

Simplified Chinese<br />

• SINUMERIK <strong>HMI</strong> add-in package<br />

• Expanded user interface > 20 configured displays<br />

(integrated into <strong>HMI</strong>-Advanced and <strong>HMI</strong>-Embedded)<br />

• OPC (OLE <strong>for</strong> Process Control) openness to higher-level<br />

systems thanks to standardized OPC interface<br />

An expansion of the TRANSLINE 2000 <strong>HMI</strong> PRO user interface<br />

with individual applications that have been created with Pro-<br />

Tool/Pro or WinCC flexible also requires the "SINUMERIK <strong>HMI</strong><br />

copy license OA" on the SINUMERIK control.<br />

SINUMERIK <strong>HMI</strong> copy license CE<br />

The runtime license "SINUMERIK <strong>HMI</strong> copy license CE" allows<br />

users to run their own <strong>HMI</strong> Open Architecture applications on the<br />

SIMATIC CE panels on the SINUMERIK control. The engineering<br />

<strong>software</strong> "SIMATIC WinCC flexible" and the "SINUMERIK <strong>HMI</strong><br />

configuring package WinCC flexible" are needed to create these<br />

applications.<br />

When the SINUMERIK <strong>HMI</strong> copy license CE is added, the functions<br />

can be used in conjunction with:<br />

• NC variable dialog (symbolic presentation)<br />

• NC file management (e.g., selection of part programs)<br />

• NC functions (e.g. apply tool, NC Start/Stop and other<br />

PI utilities, ...)<br />

• Alarms and messages in plain text<br />

The SIMATIC Panels listed below can be connected over MPI<br />

or PROFIBUS to the SINUMERIK 810D powerline/840Di/840D<br />

powerline.<br />

• OP 170B, OP 177B, OP 270 (6” and 10”)<br />

• TP 170B, TP 177B, TP 270 (6” and 10”)<br />

• Mobile Panel 170, Mobile Panel 177<br />

• MP 270B, MP 370<br />

■ Integration<br />

Preconditions:<br />

• SINUMERIK 810D powerline/840Di/840D powerline<br />

• SINUMERIK PCU 20 (only to supplement the user interface)<br />

• SINUMERIK PCU 50/PCU 70/PCU 50.3<br />

• SINUMERIK operator panels:<br />

OP 010/OP 010S/OP 010C/OP 012/OP 015/OP 015A/TP 012/<br />

TP 015A<br />

• SIMATIC CE panels: OP 170B/TP 170B/Mobile Panel<br />

170/OP 270/TP 270/MP 270B/MP 370<br />

Windows NT/XP<br />

• To configure SINUMERIK operator panels, the engineering<br />

<strong>software</strong> "SIMATIC WinCC flexible Advanced" is required in<br />

addition to the "SINUMERIK <strong>HMI</strong> configuring package WinCC<br />

flexible".<br />

• One "SINUMERIK <strong>HMI</strong> copy license OA" is required per control<br />

in order to use supplementary <strong>software</strong> on the PCU.<br />

• One "SINUMERIK <strong>HMI</strong> copy license CE" is required per control<br />

in order to use OEM applications on the SIMATIC CE Panels.<br />

• Always subject to conclusion of an OEM contract.<br />

Example of "specific <strong>software</strong> version", e.g. 7.2:<br />

6FC5253-7....-2...<br />

1) , English,<br />

French, German, Italian, Spanish<br />

Engineering system languages:<br />

English, German<br />

incl. Automation Value Card with<br />

400 credits<br />

• Single license <strong>for</strong><br />

current <strong>software</strong> version<br />

6FC5253-0BX20-0AG0<br />

• Single license <strong>for</strong><br />

specific <strong>software</strong> version<br />

• Single license<br />

without data carrier<br />

6FC5253-7BX20-7AG0<br />

6FC5253-0BX20-0AG1<br />

• Software update service 6FC5253-0BX20-0AG2<br />

• Upgrade/power pack<br />

6FC5253-7BX20-7AG3<br />

<strong>for</strong> specific <strong>software</strong> version<br />

SINUMERIK <strong>HMI</strong><br />

WinCC flexible configuring<br />

package<br />

incl. <strong>HMI</strong>-Advanced <strong>for</strong> PC/PG<br />

<strong>for</strong> SINUMERIK 810D/840Di/840D<br />

on CD-ROM<br />

Runtime system languages:<br />

supports all <strong>HMI</strong> runtime system<br />

languages;<br />

Engineering system languages:<br />

English, French, German, Italian,<br />

Spanish<br />

incl. Automation Value Card with<br />

400 credits<br />

• Single license <strong>for</strong><br />

current <strong>software</strong> version<br />

• Single license <strong>for</strong><br />

specific <strong>software</strong> version<br />

6FC5253-0CX25-0AG0<br />

6FC5253-7CX25-7AG0<br />

• Single license<br />

6FC5253-0CX25-0AG1<br />

without data carrier<br />

• Software update service 6FC5253-0CX25-0AG2<br />

• Upgrade/power pack<br />

<strong>for</strong> specific <strong>software</strong> version<br />

6FC5253-7CX25-7AG3<br />

SINUMERIK <strong>HMI</strong><br />

copy license OA<br />

6FC5253-0AF00-0AA0<br />

<strong>for</strong> SINUMERIK 810D/840Di/840D<br />

SINUMERIK <strong>HMI</strong><br />

6FC5253-0AG03-0AA0<br />

copy license CE<br />

<strong>for</strong> SINUMERIK 810D/840Di/840D<br />

SINUMERIK <strong>HMI</strong><br />

add-in package<br />

incl. documentation on CD-ROM<br />

6FC5253-0AF02-0AA0<br />

1) <strong>HMI</strong>-Advanced SW Version 6.4 and higher.<br />

Siemens NC 60 · 2006<br />

4/15<br />

4

4<br />

<strong>HMI</strong> <strong>software</strong> <strong>for</strong> <strong>CNC</strong> <strong>controls</strong><br />

Open Architecture<br />

<strong>HMI</strong> Open Architecture<br />

■ Selection and Ordering Data (continued)<br />

Designation Order No.<br />

Visualization systems<br />

SIMATIC WinCC flexible<br />

6AV6611-0AA01-1CA5<br />

Compact<br />

SIMATIC WinCC flexible<br />

6AV6612-0AA01-1CA5<br />

Standard<br />

SIMATIC WinCC flexible<br />

6AV6613-0AA01-1CA5<br />

Advanced<br />

■ More in<strong>for</strong>mation<br />

You will find further in<strong>for</strong>mation in the "Updates" at<br />

http://www.siemens.com/automation/csinfo<br />

You can obtain technical support and advice from:<br />

Siemens AG<br />

Automation and Drives<br />

NL Stuttgart<br />

Dept. RD SDW STG A&D CoC NC<br />

Competence Center Stuttgart<br />

Germany<br />

Fax: +49(0)711-137-2838<br />

E-mail: info.mc-hmi-oa@siemens.com<br />

4/16<br />

Siemens NC 60 · 2006<br />

CardWare<br />

■ Overview<br />

The <strong>software</strong> "CardWare 6.00 (V06.00.00)" permits use of the<br />

PCMCIA slot on the SINUMERIK PCU 50/PCU 70 <strong>for</strong> specific<br />

PC cards.<br />

■ Function<br />

The <strong>software</strong> has been tested with the following PC cards:<br />

• PCMCIA network card 3Com Megahertz 589E<br />

• PCMCIA card Xircon RealPort Ethernet 10/100 +<br />

Modem 56 REM56G-100<br />

• PCMCIA flash card Toshiba TH6SS160402A (40 MB)<br />

- SanDisk 32 MB flash disk PCMCIA/PC CARD ATA<br />

- Callunacard 1040 MB type III hard disk drive<br />

■ Integration<br />

Preconditions:<br />

PCU 50/PCU 70 with Windows NT 4.0 operating system and<br />

basic <strong>software</strong> versions of 06.01.09 or later<br />

■ Selection and Ordering Data<br />

Designation Order No.<br />

CardWare V6.00<br />

6FC5264-6BX10-0AG0<br />

<strong>for</strong> PCU 50/PCU 70 with<br />

Windows NT 4.0<br />

on CD-ROM<br />

Language: English

■ Overview<br />

EasyMask is a simple configuring tool <strong>for</strong> generating operating<br />

screens. EasyMask is configured using inputs in INI and text files<br />

entered with an ASCII editor. This permits you to easily generate<br />

your own operating screens.<br />

■ Selection and Ordering Data<br />

Designation Order No.<br />

EasyMask<br />

<strong>for</strong> <strong>HMI</strong>-Advanced 7.x<br />

• Single license<br />

6FC5263-0AY00-0AB1<br />

without data carrier<br />

• Floppy disk 6FC5263-7AY00-0AB0<br />

EasyMask<br />

<strong>HMI</strong> <strong>software</strong> <strong>for</strong> <strong>CNC</strong> <strong>controls</strong><br />

Open Architecture<br />

■ Overview<br />

Siemens NC 60 · 2006<br />

EasyTrans<br />

EasyTrans is a simple tool <strong>for</strong> administration of data blocks.<br />

Various parameter areas (R parameters, PLC data blocks and<br />

PLC bit memories) can be saved in a backup file on the <strong>HMI</strong>, and<br />

downloaded back into the control. EasyTrans can create, read<br />

and delete several backup files in a directory. It is configured<br />

using entries in an INI file.<br />

■ Selection and Ordering Data<br />

Designation Order No.<br />

EasyTrans<br />

<strong>for</strong> <strong>HMI</strong>-Advanced 7.x<br />

• Single license<br />

6FC5263-0AY10-0AB1<br />

without data carrier<br />

• Floppy disk 6FC5263-7AY10-0AB0<br />

■ More in<strong>for</strong>mation<br />

You can obtain further in<strong>for</strong>mation on EasyMask and EasyTrans<br />

from:<br />

Siemens AG<br />

Automation and Drives<br />

NL Stuttgart<br />

Dept. A&D ES1<br />

Competence Center <strong>for</strong> Machine Tools and Special Machines<br />

Germany<br />

Fax: +49(0)711-137-2838<br />

E-mail: info.mc-hmi-oa@siemens.com<br />

4/17<br />

4

4<br />

<strong>HMI</strong> <strong>software</strong> <strong>for</strong> <strong>CNC</strong> <strong>controls</strong><br />

Open Architecture<br />

HotWin<br />

■ Overview<br />

HotWin is an application which enables the user to configure up<br />

to 32 input/output windows on the human-machine interface.<br />

These windows can be activated via the PLC or using NCK signals<br />

(signal 0: window cannot be seen, signal 1: window can be<br />

seen).<br />

The contents of the windows can be configured in EasyMask<br />

syntax.<br />

■ Selection and Ordering Data<br />

Designation Order No.<br />

HotWin<br />

<strong>for</strong> <strong>HMI</strong>-Advanced 7.x<br />

• Single license<br />

6FC5263-0AY20-0AB1<br />

without data carrier<br />

• Floppy disk 6FC5263-7AY20-0AB0<br />

4/18<br />

Siemens NC 60 · 2006<br />

EasyMon<br />

■ Overview<br />

EasyMon is an application which facilitates online monitoring of<br />

traverse paths (tool center point) at a selected level on the operator<br />

interface.<br />

The display is also active during program testing (PRT). The<br />

monitoring window is configured using parameterization<br />

displays.<br />

■ Selection and Ordering Data<br />

Designation Order No.<br />

EasyMon<br />

<strong>for</strong> <strong>HMI</strong>-Advanced 7.x<br />

• Single license<br />

6FC5263-0AY30-0AG1<br />

without data carrier<br />

• CD-ROM 6FC5263-7AY30-0AG0<br />

■ More in<strong>for</strong>mation<br />

You can obtain further in<strong>for</strong>mation on HotWin and EasyMon from:<br />

Siemens AG<br />

Automation and Drives<br />

NL Stuttgart<br />

Dept. A&D ES1<br />

Competence Center <strong>for</strong> Machine Tools and Special Machines<br />

Germany<br />

Fax: +49(0)711-137-2838<br />

E-mail: info.mc-hmi-oa@siemens.com

■ Overview<br />

Introduction<br />

With the Motion Control In<strong>for</strong>mation System you will increase the<br />

productivity and reliability of your machine tools by integrating<br />

the machines perfectly into the process chain.<br />

For your production area, this means:<br />

7 Smooth coordination of planning and execution<br />

7 Shorter setup times and enhanced efficiency<br />

7 Reduced machine downtimes<br />

7 Simplified fault analyses<br />

<strong>HMI</strong> <strong>software</strong> <strong>for</strong> <strong>CNC</strong> <strong>controls</strong><br />

Motion Control In<strong>for</strong>mation System MCIS<br />

■ Overview<br />

DNC - Direct Numeric Control<br />

DNC<br />

Machine<br />

DNC Cell DNC Plant<br />

NC program management DNC<br />

The NC program management DNC supports handling of the<br />

NC programs, and reduces the costs <strong>for</strong> NC data organization.<br />

As a result of the convenient electronic NC program management<br />

and archiving, the NC programs are always available in<br />

their latest version <strong>for</strong> the machines of the complete production<br />

area. This is particularly relevant in production areas with a high<br />

degree of flexibility and variation and where NC data frequently<br />

change, <strong>for</strong> example in machining centers, special machines<br />

and flexible production lines.<br />

The NC program management DNC consists of <strong>software</strong> modules<br />

which can be applied depending on the functional<br />

requirements.<br />

DNC Machine<br />

DNC Machine is the <strong>software</strong> module <strong>for</strong> NC program transfer<br />

between the SINUMERIK control and an NC programming workstation<br />

(over the network file system).<br />

DNC Cell<br />

DNC Cell is the <strong>software</strong> module as a single-user solution <strong>for</strong><br />

DNC networking of a small production area.<br />

DNC Plant<br />

DNC Plant is the <strong>software</strong> module as a multi-user solution <strong>for</strong><br />

DNC networking throughout a factory.<br />

Siemens NC 60 · 2006<br />

���������������<br />

4/19<br />

4

4<br />

<strong>HMI</strong> <strong>software</strong> <strong>for</strong> <strong>CNC</strong> <strong>controls</strong><br />

Motion Control In<strong>for</strong>mation System MCIS<br />

DNC – Direct Numeric Control<br />

DNC Machine<br />

■ Overview<br />

DNC Machine is used to connect the SINUMERIK <strong>controls</strong> over<br />

the standard Ethernet network to a file system, <strong>for</strong> example, to<br />

transfer NC programs between the NC programming system<br />

and the <strong>CNC</strong> machine.<br />

■ Benefits<br />

■ Selection and Ordering Data<br />

7 Cost reduction in NC data management<br />

Designation Order No.<br />

7 Increased useful machine life thanks to shorter set-up times DNC Machine<br />

7 Fast, reliable provision of program<br />

7 The latest NC programs are always available <strong>for</strong> the<br />

SINUMERIK control<br />

7 Simple integration of the SINUMERIK control into a standard<br />

Software <strong>for</strong><br />

NC program transfer<br />

on CD-ROM<br />

Languages:<br />

English, French, German, Italian,<br />

Ethernet network<br />

Spanish<br />

7 NC program input by the programmer and automatic transfer • Single license <strong>for</strong><br />

6FC6000-0AC00-0AA0<br />

to the SINUMERIK control mean that handling of the program current <strong>software</strong> version<br />

on the machine by the operator is unnecessary.<br />

• Single license <strong>for</strong><br />

6FC6000-0AC07-7AA0<br />

■ Function<br />

specific <strong>software</strong> version<br />

• Single license<br />

6FC6000-0AF00-0AB0<br />

• Operator interface <strong>for</strong> NC program transfer/uploading on the<br />

without data carrier<br />

SINUMERIK operator panel<br />

• Upgrade on order of<br />

6FC6000-0AC07-7AE0<br />

• Fixed definition, or free navigation in Windows or UNIX network<br />

specific <strong>software</strong> version<br />

directories in which the NC programs have been saved by the<br />

programmer<br />