Panels & Furniture March/April 2022

Panels & Furniture Asia (PFA) is a leading regional trade magazine dedicated to the woodbased panel, furniture and flooring processing industry. Published bi-monthly since 2000, PFA delivers authentic journalism to cover the latest news, technology, machinery, projects, products and trade events throughout the sector. With a hardcopy and digital readership comprising manufacturers, designers and specifiers, among others, PFA is the platform of choice for connecting brands across the global woodworking landscape.

Panels & Furniture Asia (PFA) is a leading regional trade magazine dedicated to the woodbased panel, furniture and flooring processing industry. Published bi-monthly since 2000, PFA delivers authentic journalism to cover the latest news, technology, machinery, projects, products and trade events throughout the sector. With a hardcopy and digital readership comprising manufacturers, designers and specifiers, among others, PFA is the platform of choice for connecting brands across the global woodworking landscape.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

FURNITURE MANUFACTURING<br />

Left and right edgebanding connection<br />

composed of two NB7PCGM-PC<br />

Nanxing’s NB-Laser 10<br />

as XML, MPR, BAN, among others, thus<br />

optimising the coordination of various<br />

agencies. According to Nanxing, the average<br />

efficiency of the drilling workstation can<br />

reach more than six pieces per minute, and<br />

more than four pieces per minute for slotting<br />

and drilling. Such speed is 2.5 times faster<br />

than the traditional stand-alone machine,<br />

and the whole machine is more compact with<br />

a smaller floor space.<br />

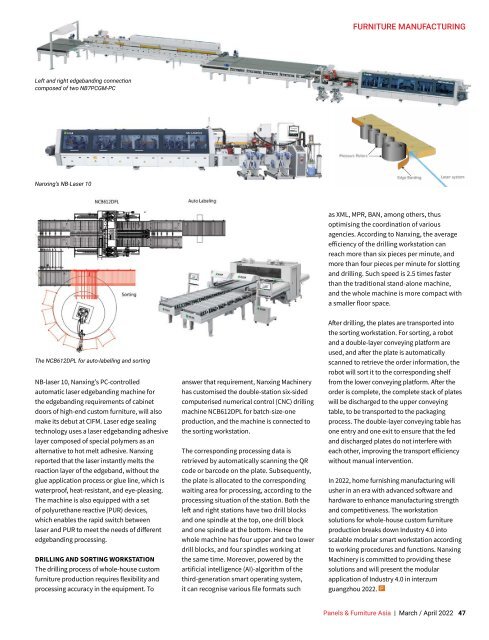

The NCB612DPL for auto-labelling and sorting<br />

NB-laser 10, Nanxing’s PC-controlled<br />

automatic laser edgebanding machine for<br />

the edgebanding requirements of cabinet<br />

doors of high-end custom furniture, will also<br />

make its debut at CIFM. Laser edge sealing<br />

technology uses a laser edgebanding adhesive<br />

layer composed of special polymers as an<br />

alternative to hot melt adhesive. Nanxing<br />

reported that the laser instantly melts the<br />

reaction layer of the edgeband, without the<br />

glue application process or glue line, which is<br />

waterproof, heat-resistant, and eye-pleasing.<br />

The machine is also equipped with a set<br />

of polyurethane reactive (PUR) devices,<br />

which enables the rapid switch between<br />

laser and PUR to meet the needs of different<br />

edgebanding processing.<br />

DRILLING AND SORTING WORKSTATION<br />

The drilling process of whole-house custom<br />

furniture production requires flexibility and<br />

processing accuracy in the equipment. To<br />

answer that requirement, Nanxing Machinery<br />

has customised the double-station six-sided<br />

computerised numerical control (CNC) drilling<br />

machine NCB612DPL for batch-size-one<br />

production, and the machine is connected to<br />

the sorting workstation.<br />

The corresponding processing data is<br />

retrieved by automatically scanning the QR<br />

code or barcode on the plate. Subsequently,<br />

the plate is allocated to the corresponding<br />

waiting area for processing, according to the<br />

processing situation of the station. Both the<br />

left and right stations have two drill blocks<br />

and one spindle at the top, one drill block<br />

and one spindle at the bottom. Hence the<br />

whole machine has four upper and two lower<br />

drill blocks, and four spindles working at<br />

the same time. Moreover, powered by the<br />

artificial intelligence (AI)-algorithm of the<br />

third-generation smart operating system,<br />

it can recognise various file formats such<br />

After drilling, the plates are transported into<br />

the sorting workstation. For sorting, a robot<br />

and a double-layer conveying platform are<br />

used, and after the plate is automatically<br />

scanned to retrieve the order information, the<br />

robot will sort it to the corresponding shelf<br />

from the lower conveying platform. After the<br />

order is complete, the complete stack of plates<br />

will be discharged to the upper conveying<br />

table, to be transported to the packaging<br />

process. The double-layer conveying table has<br />

one entry and one exit to ensure that the fed<br />

and discharged plates do not interfere with<br />

each other, improving the transport efficiency<br />

without manual intervention.<br />

In <strong>2022</strong>, home furnishing manufacturing will<br />

usher in an era with advanced software and<br />

hardware to enhance manufacturing strength<br />

and competitiveness. The workstation<br />

solutions for whole-house custom furniture<br />

production breaks down Industry 4.0 into<br />

scalable modular smart workstation according<br />

to working procedures and functions. Nanxing<br />

Machinery is committed to providing these<br />

solutions and will present the modular<br />

application of Industry 4.0 in interzum<br />

guangzhou <strong>2022</strong>. P<br />

<strong>Panels</strong> & <strong>Furniture</strong> Asia | <strong>March</strong> / <strong>April</strong> <strong>2022</strong> 47