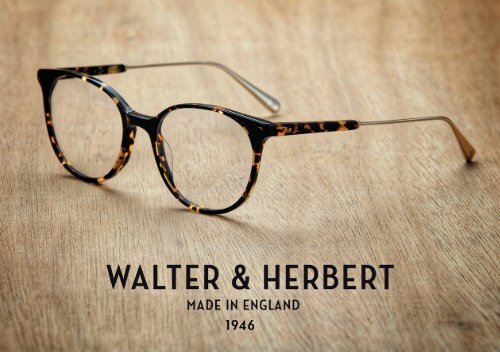

Walter & Herbert Brand Book

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

FROM THE<br />

BEGINNING<br />

In September 1946, two young entrepreneurs partnered to<br />

create Optoplast Manufacturing Company Limited.<br />

In the 40 years that followed, <strong>Walter</strong> Conway and <strong>Herbert</strong><br />

Thorn enjoyed great success as they developed technology<br />

such as the PIMO machine, an innovation that would shape<br />

the way spectacles were manufactured worldwide.<br />

Today, James Conway and Daniel Thorn are continuing this<br />

legacy. Using seven decades of industry experience, they<br />

have created their own collection of frames using materials<br />

and techniques that would make <strong>Walter</strong> and <strong>Herbert</strong> proud.

1946<br />

<strong>Walter</strong> Conway and <strong>Herbert</strong> Thorn<br />

established the headquarters for Optoplast<br />

Manufacturing Co.Ltd.<br />

1967<br />

<strong>Walter</strong> & <strong>Herbert</strong>’s flourishing business<br />

relocated to a new, larger factory in<br />

Surbiton, spanning over 10,000 square<br />

feet.<br />

1948<br />

<strong>Walter</strong> and <strong>Herbert</strong> worked with the National<br />

Health Scheme to launch the first range of<br />

optical frames for the NHS, whilst <strong>Walter</strong> began<br />

work on the PIMO Machine.<br />

1982<br />

<strong>Walter</strong>’s eldest son Gary joined the<br />

company and over the next year, Optoplast<br />

became the largest producer of spectacle<br />

frame sides in England<br />

1951<br />

The PIMO machine was launched. Inserting<br />

metal reinforcements into acetate spectacle<br />

sides with absolute precision, changed the<br />

way spectacles were manufactured worldwide.<br />

<strong>Walter</strong> & <strong>Herbert</strong> were now able to produce<br />

2 temples a second, exporting more than 5<br />

million a year to 11 countries.<br />

W&H<br />

1985<br />

Following <strong>Herbert</strong>’s retirement, his son<br />

Daniel joined the company.<br />

TIMELINE

1992<br />

The business relocated to Liverpool and<br />

set up manufacturing in Manchester. Gary<br />

and Daniel were appointed Joint Chief<br />

Executives. The company was now in the<br />

hands of the second generation of Conways<br />

and Thorns.<br />

1999<br />

Gary’s son James joined the company. 21<br />

years old and fresh from university he quickly<br />

demonstrated his father’s entrepreneurial<br />

spirit and a passion for optics.<br />

2006<br />

A new design office opens. With innovation<br />

and creativity at the heart of every design,<br />

the dedicated team of in-house designers<br />

skilfully create eyewear that maintains<br />

the fundamentals of comfort, quality and<br />

wearability.<br />

2012<br />

Newly appointed Joint Chief Executives James and<br />

Daniel set up Optolab, a UKAS accredited testing<br />

lab. This gave the company a unique competitive<br />

advantage ensuring the quality, performance and<br />

safety of every frame they produced.<br />

2014<br />

The first production machines arrived allowing<br />

Optoplast to make eyewear in Liverpool, England.<br />

2015<br />

<strong>Walter</strong> & <strong>Herbert</strong> Made in England eyewear is<br />

launched signifying a new era for the company.<br />

Deeply engrained in heritage, the brand benefits<br />

from three generations of industry experience and<br />

expertise. Paying homage to its heritage, <strong>Walter</strong><br />

& <strong>Herbert</strong> frames deliver a versatile and original<br />

range of styles that are beautifully designed and<br />

crafted in England.

DESIGNED WITH LOVE<br />

Our design team have lovingly developed a beautiful<br />

collection of frames, inspired by heritage shapes and<br />

colours that draw on our history with a modern twist.<br />

Each frame boasts striking colour combinations of<br />

the best globally sourced acetates.<br />

Bell, C2 Raspberry

NEW TRADITIONS<br />

Each of our frames have been carefully considered<br />

and undergo a lengthy design and development<br />

process. The design team embrace a combination of<br />

classic techniques and modern technologies to take<br />

their ideas from sketch to finished frame.<br />

Ayrton, C3 Pinot Blush<br />

Using 3D printed prototypes, the designers are able<br />

to create the best styles and ensure the ideal fit.<br />

Churchill, C1 Light Tort

MANUFACTURED<br />

WITH CARE<br />

Skilfully crafted in our factory in England,<br />

specialist technicians ensure every frame is worthy of<br />

the <strong>Walter</strong> & <strong>Herbert</strong> stamp.<br />

Each frame is thoroughly tested in our own laboratory to<br />

certify that each frame not only looks and feels beautiful,<br />

but exceeds the British Standards of quality, performance<br />

and safety.

QUALITY<br />

We make sure that our frames are of the highest standard, using the finest<br />

acetate such as Mazzucchelli and the use of OBE hinges. These frames are<br />

made to last.<br />

We believe attention to detail and an unyielding pursuit of perfection are what<br />

make our frames so special.<br />

The W&H logo features on every frame and has been used in various ways to<br />

make bespoke vintage inspired patterns along the temples and core.<br />

Cook, C2 Tort

SIMMONS, C 3 BLACK<br />

TEALBY, C2 TURQUOISE TORT

HUXLEY, C3 BLUE & TORT<br />

WALLIS, C3 CRYSTAL

Email: info@walterandherbert.com<br />

printed on fsc certifi ed paper<br />

Address: 83 Sefton Lane, Liverpool, L31 8BU @walterandherbert