October 2022

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

90<br />

110<br />

Tapered Board Thickness<br />

60<br />

160<br />

Tapered Roofs<br />

STEPPING UP TO THE<br />

COMPARTMENTATION CHALLENGE<br />

By Robert Vass, Chief Technical Officer at TaperedPlus.<br />

Currently, fire and compartmentation are<br />

rightly high on the agenda and in the press<br />

within the construction industry. While<br />

building safety should always take precedence, it is<br />

important to remember that when high focus is on<br />

one area of compliance, others are not bypassed.<br />

typically non-combustible insulation needs to be<br />

Whether the aim is to reduce the risk of fire<br />

thicker than combustible insulation to meet the<br />

spreading over a flat roof from one<br />

same thermal performance (See Pic 1 above).<br />

‘compartment’ to another in the domestic setting<br />

as outlined in in Approved Document B (B3), or Creating steps in insulation like this can become<br />

an insurer’s requirement on a data centre to make further complicated when considering roof<br />

a fire break between the main data storage and drainage, as the steps may result in trapped<br />

back up servers, there is often a request to utilise water if upwards steps are created between<br />

combustible insulants such as PIR<br />

ridgelines and outlets or gutters.<br />

(Polyisocyanurate) or EPS (Expanded Polystyrene)<br />

The right mix<br />

in field areas, and non-combustible insulation like<br />

As an independent designer and supplier of flat<br />

Stonewool or Cellular Glass above a partition wall.<br />

and tapered roof insulation, at TaperedPlus we’re<br />

In these scenarios, specifiers run in to the issue not tied to any material type or manufacturer. We<br />

that most insulation manufacturers will readily have the ability to mix insulation products for the<br />

calculate the thermal performance of their own ideal technical solution and the increasingly<br />

product, whether it be flat board insulation or common compartmentation enquiries tie in well<br />

tapered insulation, but are less willing to consider with the skill set we offer.<br />

the effect of the insulation performance of<br />

Our approach to dual product<br />

another manufacturer’s material, even though a<br />

compartmentalisation specifications is to assess<br />

percentage of the roof area is to be covered with<br />

roof areas and how much of the roofs are covered<br />

an alternative material with a differing thermal<br />

with each product before conducting area<br />

performance.<br />

weighted thermal calculations, with the aim to<br />

If each individual manufacturer targets the<br />

use just enough of each insulation material to<br />

specified U-value (W/m²K) in their material only, the create a smooth top surface, avoiding a step in<br />

result would be numerous steps in the insulation as insulation, while achieving the specified U- value<br />

7200<br />

1500 1500<br />

K 11 11 K<br />

K<br />

J 10 10 J<br />

J<br />

I 9 9 I<br />

I<br />

H 8 8 H<br />

6000<br />

8<br />

G 7<br />

7 G<br />

F<br />

F 6 6 F<br />

F<br />

E<br />

E 5 5 E<br />

E<br />

D D 4 4 D D<br />

C<br />

C 3 3 C<br />

C<br />

Pic 2<br />

K<br />

J<br />

I<br />

H<br />

1500 1500<br />

G<br />

6<br />

5<br />

4<br />

3<br />

6 F<br />

F<br />

5 E<br />

E<br />

1500 1500<br />

11 11 K<br />

K<br />

10 10 J<br />

J<br />

9 9 I<br />

I<br />

8 8 H<br />

8<br />

7<br />

7 G<br />

6 6 F<br />

F<br />

5 5 E<br />

E<br />

4 D<br />

D 4 4 D<br />

D<br />

3 C<br />

C 3 3 C<br />

C<br />

6000<br />

as an area weighted performance.<br />

While this calculation is straight forward with flat<br />

board insulation where falls are provided in the<br />

structure, it can become far more complicated<br />

when tapered insulation is needed. As a tapered<br />

insulation specialist, at TaperedPlus we’re able to<br />

perform insulation calculations to BS EN ISO<br />

6946:2017 Annex E for each roof area effected by<br />

the varying insulation types, lean on our<br />

knowledge of material stock profiles to ensure the<br />

insulation thicknesses tie in with one another,<br />

and provide user-friendly drawings to aid site<br />

installation.<br />

The dual insulation approach is typically taken to<br />

try and reduce material costs versus full<br />

coverage of the non-combustible insulant,<br />

however, projects with close neighbouring party<br />

walls can result in practicality issues and added<br />

labour when mixing products in such proximity<br />

(See Pic 2 left).<br />

For this reason, at TaperedPlus we work closely<br />

with tendering installers as well as specifiers to<br />

work towards the best holistic cost option.<br />

B<br />

A<br />

B 2 2 B<br />

A 1 1 A<br />

1500 1500<br />

B<br />

A<br />

2<br />

1<br />

2<br />

1<br />

1500 1500<br />

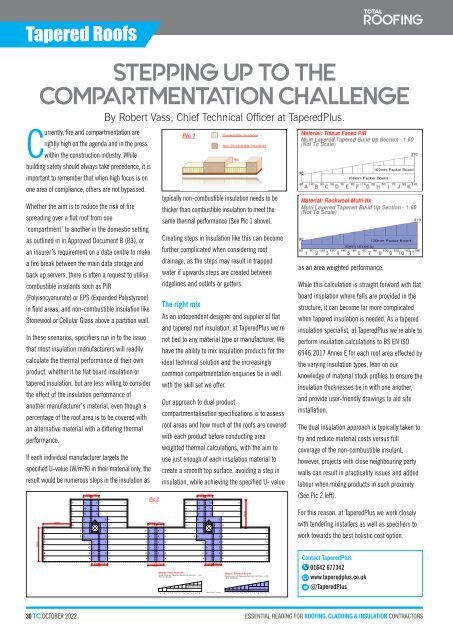

Material: Tissue Faced PIR<br />

Multi Layered Tapered Build Up Section - 1:60<br />

(Not To Scale)<br />

90<br />

B<br />

A<br />

100mm Packer Board<br />

100mm Packer Board<br />

A 110 B 30 C 50 D 70 E 90 F 110 G 30 H 50 I 70 J 90 K<br />

310<br />

B<br />

A<br />

2<br />

1<br />

2<br />

1<br />

1500 1500<br />

B<br />

A<br />

Material: Rockwool Multi-fix<br />

Multi Layered Tapered Build Up Section - 1:60<br />

(Not To Scale)<br />

90<br />

120mm Packer Board<br />

30mm Underlay<br />

1 80 2 100 3 120 4 140 5 160 6 60 7 80 8 100 9 120 10 140 11<br />

B<br />

A<br />

310<br />

Contact TaperedPlus<br />

01642 677342<br />

www.taperedplus.co.uk<br />

@TaperedPlus<br />

30 TC OCTOBER <strong>2022</strong>