Water & Wastewater Asia November/December 2022

Water & Wastewater Asia is an expert source of industry information, cementing its position as an indispensable tool for trade professionals in the water and wastewater industry. As the most reliable publication in the region, industry experts turn this premium journal for credible journalism and exclusive insight provided by fellow industry professionals. Water & Wastewater Asia incorporates the official newsletter of the Singapore Water Association (SWA).

Water & Wastewater Asia is an expert source of industry information, cementing its position as an indispensable tool for trade professionals in the water and wastewater industry. As the most reliable publication in the region, industry experts turn this premium journal for credible journalism and exclusive insight provided by fellow industry professionals. Water & Wastewater Asia incorporates the official newsletter of the Singapore Water Association (SWA).

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

NOVEMBER / DECEMBER <strong>2022</strong><br />

www.waterwastewaterasia.com<br />

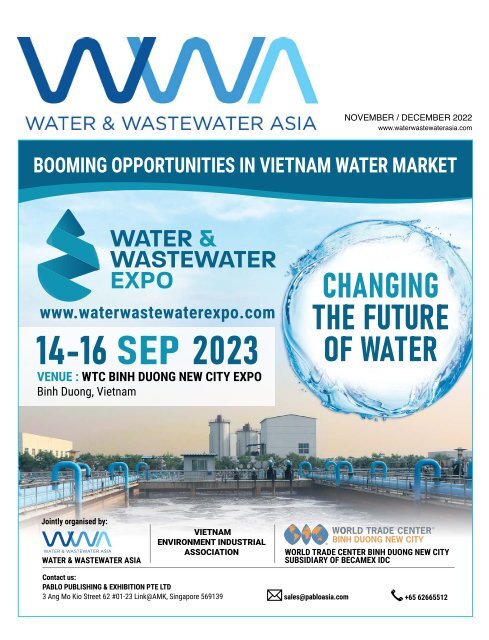

BOOMING OPPORTUNITIES IN VIETNAM WATER MARKET<br />

www.waterwastewaterexpo.com<br />

14-16 SEP 2023<br />

VENUE : WTC BINH DUONG NEW CITY EXPO<br />

Binh Duong, Vietnam<br />

CHANGING<br />

THE FUTURE<br />

OF WATER<br />

Jointly organised by:<br />

WATER & WASTEWATER ASIA<br />

VIETNAM<br />

ENVIRONMENT INDUSTRIAL<br />

ASSOCIATION<br />

WORLD TRADE CENTER BINH DUONG NEW CITY<br />

SUBSIDIARY OF BECAMEX IDC<br />

Contact us:<br />

PABLO PUBLISHING & EXHIBITION PTE LTD<br />

3 Ang Mo Kio Street 62 #01-23 Link@AMK, Singapore 569139<br />

sales@pabloasia.com<br />

+65 62665512

Solutions for a<br />

Sustainable Future<br />

Bringing sustainability to wastewater<br />

management with Energy Recovery<br />

From the industry-leading PX Q300 and Ultra PX to our line of pumps and<br />

turbochargers, we’ve been a leader in the desalination industry for 30 years.<br />

energy with little to no scheduled maintenance, our proven technologies can help<br />

emerging markets with wastewater management as they transform into global<br />

manufacturing leaders.<br />

Find out how countries like India that are seeking to balance economic ambition<br />

with rising water needs can utilize our technologies to help meet discharge<br />

regulations and maximize water reuse while minimizing brine discharge in a<br />

recent article by Satish Shaligram, Sales Manager, <strong>Asia</strong> Pacific.<br />

Ultra PX <br />

Scan the code or read the article<br />

on our LinkedIn page:<br />

bit.ly/energyrecoveryiww<br />

Currently seeking manufacturer representatives and distributors in <strong>Asia</strong>.<br />

For more information, email IWW@energyrecovery.com.

@tsurumiavant

CONTENTS<br />

06 18<br />

16<br />

CONTENTS<br />

04 Editor’s Note<br />

06 News<br />

53 SWA Newsletter<br />

63 What’s Next?<br />

64 Advertisers’ Index<br />

SINGAPORE FOCUS<br />

16 Cleanedge <strong>Water</strong> covers all bases<br />

IN CONVERSATION WITH<br />

18 SUEZ embarks on 2027 goals<br />

20<br />

22<br />

The collective call for sustainable action<br />

“Good for business, good for community”:<br />

What sustainability could look like in<br />

South East <strong>Asia</strong><br />

IN THE FIELD<br />

24 Reducing leaks in Jakarta’s water<br />

networks<br />

26 Fits like a glove: Veolia supports<br />

Mölnlycke’s sustainable network<br />

FOCUS<br />

29<br />

The future for pumps, IIoT and Industry<br />

4.0<br />

32 <strong>Wastewater</strong> treatment: A deep dive into<br />

new technologies<br />

35 Basics of drinking water hygiene <br />

2 WATER & WASTEWATER ASIA | NOVEMBER/DECEMBER <strong>2022</strong>

CONTENTS<br />

60<br />

38<br />

38<br />

Digitalisation as a critical enabler for<br />

water sustainability<br />

40 Cutting energy consumption through<br />

remote leak detection<br />

42<br />

How <strong>Asia</strong>n governments can reduce<br />

physical and commercial water losses<br />

44 How India can balance manufacturing<br />

and access to clean water<br />

46 GoDigital <strong>Water</strong>: The digital<br />

transformation of a local water<br />

authority<br />

HOTSEAT<br />

49 <strong>Water</strong>-energy-food-material nexus:<br />

The next frontier<br />

ON OUR RADAR<br />

57 Tsurumi’s AVANT MQC slices away<br />

inefficient wastewater treatment<br />

58<br />

59<br />

Energy Recovery launches PX Q400<br />

Pressure Exchanger<br />

Yokogawa releases new magnetic<br />

flow series<br />

60 The smart RTU dedicated to the<br />

water industry<br />

61 Bridging big to small dimensions:<br />

The new COOL-FIT 2.0 Push System<br />

SNEAK PEEK & SHOW REVIEW<br />

62 Indo<strong>Water</strong> Expo & Forum sets the<br />

stage for 2023<br />

52<br />

<strong>Water</strong> technologies company Solenis<br />

chooses Delaware state for US$40m<br />

expansion<br />

WATER & WASTEWATER ASIA | NOVEMBER/DECEMBER <strong>2022</strong> 3

FROM THE EDITOR<br />

IS THE GLASS HALF<br />

EMPTY OR HALF FULL?<br />

The answer: the glass is always full. It is filled<br />

half with water, and half with air. Similarly, as<br />

individual players in the water industry might<br />

not be sufficient to solving the most immediate<br />

issues of this day and age, organisations<br />

from the private, public, and academia<br />

sector should come together to create a<br />

comprehensive plan for the rocky years ahead.<br />

Where one falls short in certain aspects,<br />

others must step forward to fill in possible<br />

shortcoming.<br />

It goes without saying that <strong>2022</strong> has seen<br />

significant highs and lows for the water<br />

industry. From recording-breaking heatwaves<br />

and extended droughts, to the emergence<br />

of a new normal in a post-pandemic realm,<br />

companies, utilities and governments around<br />

the world have dipped their toes into the<br />

uncharted waters of dealing with a rapidly<br />

changing world. While we continue to navigate<br />

this unpredictable realm, it has become<br />

evident that working together towards a<br />

common goal is the only way forward.<br />

Take Veolia <strong>Water</strong> Technologies, for example:<br />

in collaboration with Mölnlycke, a medical<br />

products provider, the company has<br />

formulated sustainable wastewater treatment<br />

solutions for their recently inaugurated plant<br />

in Kulim, Malaysia. By taking stock of the<br />

demands in medical glove manufacturing<br />

and keeping abreast of sustainable goals in<br />

the country, Veolia was able to integrate a<br />

treatment designed to further the company’s<br />

green targets.<br />

Similarly, Grundfos recently signed a<br />

memorandum of understanding with<br />

Singapore Polytechnic to develop water and<br />

energy efficient solutions across various<br />

industries. The former will utilise its experience<br />

in smart technology to bring sustainable<br />

savings, while the latter will draw relevant<br />

networks between academia and industry.<br />

Altogether, this partnership will enhance the<br />

grid of sustainable models, allowing more<br />

companies in Singapore to benefit from a<br />

green transformation.<br />

Elsewhere, India must juggle the needs of<br />

rising manufacturing industry and ensure<br />

its people have access to clean, unpolluted<br />

water. Enter Energy Recovery, whose, as<br />

their names suggests, have enabled the<br />

country to reap the benefits of industrial<br />

wastewater treatment at low cost. With this,<br />

India is one step closer to reducing water<br />

pollution and enhancing the quality of life of<br />

her people.<br />

Regardless of nation, regardless of<br />

industry, everyone plays an important<br />

role in securing the future of our water<br />

resources. As ice caps are melting at an<br />

unprecedented pace in the most extreme<br />

corners of the globe, while lakes are<br />

shrinking in others, the path towards a<br />

more sustainable road is paved by all<br />

parties involved. And here at <strong>Water</strong> &<br />

<strong>Wastewater</strong> <strong>Asia</strong>, we will continue to bring<br />

you provoking stories from all corners of<br />

the industry, in hopes that it can inspire our<br />

readers to take the charge forward towards<br />

a better, greener future.<br />

In the final issue of this year, let us reflect<br />

on the progress we made this past year,<br />

and look boldly into the future ahead. The<br />

glass is, after all, always full.<br />

Agatha Wong<br />

Assistant Editor<br />

Published by<br />

PABLO PUBLISHING & EXHIBITION PTE LTD<br />

3 Ang Mo Kio Street 62,<br />

#01-23 Link@AMK Singapore 569139<br />

Tel: (65) 6266 5512<br />

E-mail: info@pabloasia.com<br />

Company Registration No: 200001473N<br />

Singapore MICA (P) No: 102/12/2021<br />

REGIONAL OFFICES (CHINA)<br />

PABLO BEIJING<br />

Tel: +86 10 6509 7728<br />

Email: pablobeijing@163.com<br />

PABLO SHANGHAI<br />

Tel: +86 21 5238 9737<br />

Email: pabloshanghai@163.net<br />

All rights reserved. Views of writers do not necessarily reflect the views<br />

of the Publisher and the Singapore <strong>Water</strong> Association. No part of this<br />

publication may be reproduced in any form or by any means, without prior<br />

permission in writing from the Publisher and copyright owner. Whilst every<br />

care is taken to ensure accuracy of the information in this publication, the<br />

Publisher accepts no liability for damages caused by misinterpretation<br />

of information, expressed or implied, within the pages of the magazine.<br />

All advertisements are accepted on the understanding that the Advertiser<br />

is authorised to publish the contents of the advertisements, and in this<br />

respect, the Advertiser shall indemnify the Publisher against all claims or<br />

suits for libel, violation of right of privacy and copyright infringements.<br />

<strong>Water</strong> & <strong>Wastewater</strong> <strong>Asia</strong> is a controlled-circulation bi-monthly magazine.<br />

It is mailed free-of-charge to readers who meet a set of criteria. Paid<br />

subscription is available to those who do not fit our terms of control. Please<br />

refer to subscription form provided in the publication for more details.<br />

Printed by Times Printers Pte Ltd<br />

PABLO SINGAPORE<br />

William Pang • Publisher<br />

williampang@pabloasia.com<br />

Agatha Wong • Assistant Editor<br />

agatha@pabloasia.com<br />

Kimberly Liew • Assistant Editor<br />

kimberly@pabloasia.com<br />

Pang YanJun • Business Development Manager<br />

yanjun@pabloasia.com<br />

let's connect!<br />

Goh Meng Yong • Graphic Designer<br />

mengyong@pabloasia.com<br />

Shu Ai Ling • Circulation Manager<br />

circulation@pabloasia.com<br />

PABLO BEIJING<br />

Ellen Gao • General Manager<br />

pablobeijing@163.com<br />

PABLO SHANGHAI<br />

Daisy Wang • Editor<br />

pabloshanghai@163.net<br />

@waterwastewaterasia<br />

<strong>Water</strong> & <strong>Wastewater</strong> <strong>Asia</strong><br />

incorporates the official newsletter<br />

of Singapore <strong>Water</strong> Association<br />

4 WATER & WASTEWATER ASIA | NOVEMBER/DECEMBER <strong>2022</strong>

Elektra<br />

Connecting you to your chemical<br />

dosing pumps, wherever you are<br />

The Elektra digital dosing pump controller from SEKO allows<br />

you to monitor and manage your dosing equipment 24/7<br />

via smartphone for a new standard in operational efficiency<br />

and accessibility in water-treatment applications.<br />

www.seko.com<br />

SekoWeb<br />

Data on demand<br />

• Access data and system status via<br />

smartphone or PC<br />

• Adjust programming instantly<br />

• Discover the true cost of your application<br />

• Identify anomalies and prevent<br />

unplanned downtime<br />

Find out more<br />

Find out more

NEWS<br />

XYLEM SINGAPORE AND GROSS-WEN TECHNOLOGIES TO<br />

COLLABORATE ON BOOSTING SUSTAINABILITY AND EFFICIENCY<br />

OF ALGAE-BASED WASTEWATER TREATMENT TECH<br />

process to help Singapore and water<br />

utilities achieve net zero emissions.”<br />

Gross said: “Our partnership with<br />

Xylem in Singapore is an exciting step<br />

forward in the global deployment of<br />

GWT’s RAB treatment technology. Our<br />

R&D project with PUB will serve as<br />

a showcase for how algae treatment<br />

can be leveraged to decarbonise the<br />

wastewater treatment industry.”<br />

The project was one of the Proposal<br />

Phase winners of PUB’s Carbon<br />

Zero Grand Challenge, which seeks<br />

to incentivise innovative solutions<br />

that can help PUB achieve net-zero<br />

emissions by 2050 and scale to<br />

water facilities around the globe.<br />

If successful in the proof-of-<br />

GWT’s algae-based<br />

treatment uses<br />

algae to capture<br />

atmospheric CO2<br />

and will be later<br />

used to make<br />

various sustainable<br />

products like<br />

fertilisers, bioplastics<br />

and biofuels<br />

(Image: Gross-Wen<br />

Technologies)<br />

Xylem <strong>Water</strong> Solutions Singapore<br />

and Gross-Wen Technologies (GWT)<br />

have announced a memorandum of<br />

understanding (MoU) for a new joint<br />

R&D project to deploy algae-based<br />

wastewater treatment solutions in<br />

Singapore. The project will focus<br />

on the development of GWT’s<br />

existing revolving algal biofilm<br />

(RAB) technology, an algae-based<br />

wastewater treatment solution that<br />

promotes nutrient recovery while<br />

reducing the carbon footprint of water<br />

utilities.<br />

The project will feature GWT’s algaebased<br />

treatment of anaerobic digestor<br />

(AD) effluent for carbon footprint<br />

reduction and nutrient recovery. This<br />

includes atmospheric CO2 capture<br />

by algae, low-energy nitrogen and<br />

phosphorus recovery, and reduced<br />

nitrous oxide emissions from the<br />

concentrated AD effluent. The algae<br />

produced during the process will<br />

be harvested and used to make<br />

fertilisers, bioplastics and biofuels.<br />

As part of the project, the R&D<br />

team led by Luo Rongmo, senior<br />

development engineer at Xylem<br />

Singapore Technology Hub, and<br />

Martin Gross, president and CEO of<br />

GWT, was awarded up to S$247,000<br />

to implement a small-scale RAB<br />

system at Xylem’s Singapore<br />

facility during the proof-of-concept<br />

phase of the Carbon Zero Grand<br />

Challenge. If successful, this will<br />

be piloted in a full-scale system for<br />

PUB, Singapore’s National <strong>Water</strong><br />

Agency.<br />

Luo said: “We are pleased to<br />

be partnering with Gross-Wen<br />

Technologies and combining our<br />

strengths in the industry to develop<br />

a sustainable wastewater treatment<br />

concept phase, Xylem Singapore<br />

could be awarded a further $2.5m<br />

to demonstrate an approximate<br />

one kilotonne-scale version of<br />

their solution at a PUB facility in<br />

Singapore.<br />

If the small-scale RAB system at Xylem<br />

Singapore’s facility is successful, it will be<br />

launched for a full system pilot for PUB<br />

(Image: Gross-Wen Technologies)<br />

6 WATER & WASTEWATER ASIA | NOVEMBER/DECEMBER <strong>2022</strong>

NEWS<br />

NX FILTRATION TO BE PART OF ACCIONA-<br />

LED INITIATIVE TO ELIMINATE EMERGING<br />

POLLUTANTS FROM WATER SOURCES<br />

NX Filtration, a provider of direct water<br />

nanofiltration technology, has announced<br />

its participation in the European innovation<br />

project LIFE PRISTINE. The project’s<br />

objective is to eliminate emerging<br />

contaminants in the integral water cycle,<br />

which is one measure to promote alternative<br />

water resources in the face of water scarcity.<br />

The LIFE PRISTINE project has a budget<br />

of €4m and is coordinated by Acciona, the<br />

Spanish sustainable infrastructure solutions<br />

group. Other project partners include Eurecat,<br />

Xylem Services, the Regional Entity for<br />

<strong>Wastewater</strong> Sanitation and Treatment of the<br />

Murcia Region (ESAMUR) and the water utility<br />

provider Bilbao Bizkaia <strong>Water</strong> Consortium<br />

(CABB). The project hopes to combine water<br />

treatment processes, such as NX Filtration’s<br />

hollow fibre nanofiltration membranes, with<br />

artificial intelligence (AI)-based digital tools to<br />

develop a solution that removes the emerging<br />

pollutants.<br />

The project was launched in light of various<br />

forums being alerted to the urgent need to<br />

take steps in protecting water resources.<br />

Such an outcome can be achieved through<br />

reducing water consumption, but also by<br />

promoting alternative resources and reuse.<br />

One key issue that has been raised in efforts<br />

to encourage water reuse is the presence<br />

of pollutants and microplastics in water<br />

supplies. These substances of anthropogenic<br />

origin are difficult to eliminate when using<br />

existing treatment systems and they may end<br />

up in seas and rivers, or even enter the food<br />

chain. Their presence may create hazards.<br />

There is thus an increasing emphasis on<br />

regulating the use of these substances and<br />

developing solutions to remove them from the<br />

environment.<br />

LIFE PRISTINE thus aims to eliminate up to<br />

80% of emerging pollutants in the endto-end<br />

water cycle, particularly per and<br />

polyfluoroalkyl (PFAS) substances. These<br />

are typically found in flame retardants,<br />

pesticides, pharmaceutical and personal<br />

care products, toxins microplastics and<br />

genes of microorganisms that are resistant<br />

to antibiotics. The project aims to strengthen<br />

the existing legislation and promote the reuse<br />

of water with the highest possible quality and<br />

safety standards.<br />

The PRISTINE solution involves the<br />

processes of adsorption, nanofiltration and<br />

advanced oxidation using virtual sensors,<br />

process modelling and decision-making<br />

support tools. The machine is said to be<br />

capable of reducing emerging pollutants from<br />

water sources and wastewater effluent. The<br />

PRISTINE project is set to be demonstrated<br />

in a representative operating environment:<br />

namely, the secondary effluent of a treatment<br />

plant in Murcia, Spain, and supporting<br />

drinking water pre-treatment in the Bilbao<br />

Bizkaia Advanced <strong>Water</strong> Treatment Centre<br />

(CATABB).<br />

WAVIN ACQUIRES DUTCH START-UP METROPOLDER<br />

Wavin has acquired Dutch start-up<br />

MetroPolder, against the backdrop of<br />

increasingly extreme weather events and long<br />

periods of drought that have been affecting<br />

the liveability of cities around the world.<br />

With the acquisition, Wavin is expected to<br />

incorporate MetroPolder’s knowledge to<br />

close the water cycle in cities and make cities<br />

“future-proof”.<br />

MetroPolder has developed a technology<br />

to capture water on roofs and reuse it for<br />

cooling, irrigation and recycling. The bluegreen<br />

roofs are equipped with a buffer<br />

system, an internet-connected valve and<br />

an online dashboard. The valves sensors<br />

and rain radars control the water level and<br />

discharge real-time. This smart connection<br />

enables dynamic water storage. The<br />

technology has been implemented in projects<br />

over several locations worldwide, including<br />

the Netherlands, Guatemala, France the UK<br />

and US.<br />

Friso Klapwijk, CEO of MetroPolder said:<br />

“Wavin sees rainwater as a resource, not a<br />

problem. That’s where we found each other.<br />

We want to make cities future-proof, by<br />

applying smart water management. Think<br />

of reusing rainwater for for cooling cities to<br />

combat heat stress. We are pleased and<br />

proud to be part of the Wavin family from now<br />

on.”<br />

Maarten Roef, CEO of Wavin, said: “The<br />

green/blue roof solution of MetroPolder<br />

is a proven successful, international,<br />

application that puts Wavin as a company in<br />

an even better position to make cities more<br />

climate resilient. Supplemented with the<br />

knowledge and expertise of MetroPolder,<br />

we are convinced that we will succeed in<br />

getting more and more cities to look at the<br />

applications of water differently. Because the<br />

opportunities are plentiful.”<br />

WATER & WASTEWATER ASIA | NOVEMBER/DECEMBER <strong>2022</strong> 7

NEWS<br />

PERISTALTIC PUMPS GAIN IMPROVED COVERAGE IN WIMES<br />

Watson Marlow Fluid Technology Solutions<br />

(WMFTS) has helped with a revision of the<br />

<strong>Water</strong> Industry Mechanical & Electrical<br />

Specifications (WIMES), opening up<br />

peristaltic pumps to more potential<br />

customers in the UK water industry.<br />

Peristaltic pumps, such as WMFTS’ range<br />

of Qdos chemical metering pumps for water<br />

and wastewater treatment applications,<br />

had not previously had the benefits of their<br />

technology explained in the specifications.<br />

The revised WIMES now contains<br />

comprehensive dosing pump specifications,<br />

with a number of the benefits of peristaltic<br />

pumps now more apparent and explicitly<br />

covered in the latest version.<br />

WIMES is a collaborative project managed<br />

by the Pump Centre, aimed at providing<br />

common mechanical and electrical<br />

specifications for the UK water industry.<br />

Seventeen of the UK’s largest water<br />

companies are involved in WIMES, which<br />

enables them to procure equipment which<br />

is fit for purpose and provides the lowest<br />

lifecycle costs at a competitive purchase<br />

price.<br />

The intention of WIMES is that the<br />

specifications should be unambiguous and<br />

allow individual suppliers to compete on<br />

an equal footing, so buyers can accurately<br />

compare and contrast suppliers.<br />

Dale Kavanagh, industrial sales & business<br />

development manager at WMFTS UK, said:<br />

“The specification has been rewritten so<br />

there is more detail about peristaltic pumps,<br />

and their benefits compared to other pump<br />

types. It is a huge result and has helped<br />

develop the business this year.<br />

“For the last two years Watson Marlow have<br />

been working hard to ensure that the latest<br />

version of the specifications would have a<br />

fairer balance, showing the advantages of<br />

WMFTS Qdos 60 and<br />

30 peristaltic pumps<br />

are now included in<br />

the <strong>Water</strong> Industry<br />

Mechanical & Electrical<br />

Specifications (WIMES)<br />

peristaltic pump technology. This ongoing<br />

work has resulted in large orders from several<br />

water companies in England.<br />

“Watson-Marlow were able to get a seat at the<br />

table and collaborated with water regulators,<br />

putting the case forward on why peristaltic<br />

pumps are beneficial. The success was a<br />

result of a lot of hard work, in particular from<br />

sales skills training manager Bruce Quilter<br />

and former UK industrial sales engineer Eddie<br />

Smeaton.”<br />

GREATER RELIABILITY<br />

WMFTS’ Qdos range of peristaltic pumps can<br />

handle flow rates from 0.1 to 2,000 megalitres<br />

a minute at pressures up to 7 bar as well<br />

as offering repeatable chemical metering<br />

accuracy of ±1%.<br />

With a Qdos pump, the flow remains the same<br />

at any pressure, providing greater dosing<br />

control and leading to measurable chemical<br />

and energy savings — a key difference to<br />

other equipment on the market. The low<br />

maintenance design also means process<br />

uptime is maximised with no-tools, and quick<br />

and easy pumphead replacement in situ.<br />

A reverse function enables the operator to<br />

drain the line before maintenance and, once<br />

in operation, there is an integral leak detector<br />

to eliminate the risk of exposure to chemicals.<br />

Integration of the Qdos pump range is easier<br />

than traditional dosing pump types as they<br />

eliminate the need for foot valves, strainers,<br />

degassing valves and loading valves, along<br />

with all the relevant joints, simplifying<br />

maintenance and enabling dosing skid<br />

manufacturers to reduce the size of their<br />

skids.<br />

Roger Marlow, principal consultant at the<br />

Pump Centre, commented on the more<br />

comprehensive dosing pump specification<br />

in the updated WIMES: “<strong>Water</strong> managers<br />

and engineers of large water infrastructure<br />

projects are looking to alternative pumping<br />

technologies for many reasons. The<br />

landscape of chemical metering pump<br />

manufacturing and innovation in the water<br />

industry is changing and it is important for<br />

WIMES documents to reflect that.<br />

“It has been a very positive experience<br />

working with Watson-Marlow and we will<br />

continue the collaboration between all parties<br />

in the future.”<br />

Reflecting on the current landscape of<br />

chemical dosing equipment, Kavanagh<br />

said: “The scale of the rollout of new<br />

equipment makes now an ideal time for<br />

utilities to consider the whole-life benefit of<br />

the chemical dosing equipment they select.<br />

As such, it is believed that Qdos pumps an<br />

ideal solution to meet companies’ water<br />

management challenges.”<br />

8 WATER & WASTEWATER ASIA | NOVEMBER/DECEMBER <strong>2022</strong>

NEWS<br />

renews Grundfos’ profound commitment to<br />

the UN Sustainability Development Goals, a<br />

commitment that underpins its core business<br />

strategy.<br />

GRUNDFOS CHANGES BUT THEIR<br />

STORY CONTINUES<br />

Grundfos has announced its upcoming vision<br />

for the world’s water, energy and climate<br />

challenges, with a new brand promise that<br />

reaffirms and strengthens its commitment to<br />

pioneering solutions to the worlds water and<br />

climate challenges and improve quality of life<br />

for people.<br />

Underpinned by the endline “Possibility in<br />

every drop”, Grundfos’ new promise is to<br />

“respect, protect and advance the flow of<br />

water” in these following strategies:<br />

• To respect and take responsibility for water<br />

for the benefit of everybody on the planet<br />

• To protect water wherever it exists from<br />

waste, shortage and inaccessibility<br />

• To advance water through relentless<br />

innovation for the sake of efficiency,<br />

energy and the future<br />

Grundfos’ new endline,<br />

which is meant to<br />

symbolise the infinite<br />

possibilities of using<br />

water to change the world<br />

The new brand promise encapsulates<br />

Grundfos’ duty and responsibility to people<br />

and the planet, committing the organisation<br />

to apply its expertise in identifying new<br />

possibilities for innovations and solutions<br />

that are more efficient, save more energy,<br />

save more water and help make the world<br />

a better place for future generations. It also<br />

The new endline “Possibility in every drop”<br />

expresses Grundfos’ belief in the infinite<br />

power of water to change the world; that<br />

possibilities exist to heat or cool a home<br />

without warming the planet, to give access<br />

to clean and safe water wherever needed,<br />

and that people’s quality of life can still be<br />

improved with solutions that save energy and<br />

are more efficient.<br />

Poul Due Jensen, CEO of Grundfos, said:<br />

“Our services go beyond water, but our<br />

credibility is rooted in it. Through the flow<br />

of water, Grundfos products and services<br />

touch millions and millions of people every<br />

day without most of them even knowing it.<br />

<strong>Water</strong> is and has always been at the heart<br />

and soul of Grundfos, and we want to make<br />

a positive difference and help solve the<br />

world’s water and climate challenges and<br />

improve the quality of life for people. That is<br />

why we give this promise to the world: We<br />

respect, protect, and advance the flow of<br />

water.”<br />

FADY JUEZ ELECTED PRESIDENT OF THE<br />

INTERNATIONAL DESALINATION ASSOCIATION<br />

FOR <strong>2022</strong> – 2024 TERM<br />

The International Desalination Association<br />

(IDA) announced that Fady Juez, managing<br />

director of Metito Overseas, has been<br />

elected president by the Term 20 IDA board.<br />

Shannon McCarthy has been re-appointed<br />

as the secretary general of the association.<br />

“I aim to ensure IDA continues the<br />

tremendous global recognition and financial<br />

turnaround accomplished in term 19, under<br />

the leadership of Shannon McCarthy and<br />

Carlos Cosin, with the board’s full support.<br />

The IDA will celebrate its 50th anniversary<br />

in 2023, and it is my honour to lead the<br />

board of directors in this important term.<br />

Considering the growing need for nonconventional<br />

water solutions to offset the<br />

effects of climate change, population growth,<br />

and industry needs, the board and I will<br />

continue the work to engage with the global<br />

stakeholder community to bring solutions<br />

to meet UN SDG6 water for all. The special<br />

imitative to ensure a water-positive world,”<br />

stated Juez.<br />

Juez has been an active member serving the<br />

International Desalination Association board<br />

of directors for the last 20 years.<br />

Fady Juez was<br />

elected president<br />

of the International<br />

Desalination<br />

Association after 20<br />

years of being on its<br />

board of directors<br />

In addition to Juez serving as president,<br />

Alejandro Sturniolo, global head of water reuse<br />

& strategic partnerships, H20 Innovations, has<br />

been named 1st vice president, and Jantje<br />

Johnson, CEO, Orangeboat, has been named<br />

2nd vice president.<br />

The full slate of officers and committee chairs<br />

will be finalised during the <strong>2022</strong> World Congress,<br />

“Charting Resilient <strong>Water</strong> Solutions.”<br />

10 WATER & WASTEWATER ASIA | NOVEMBER/DECEMBER <strong>2022</strong>

NEWS<br />

ANAERGIA ANNOUNCES EXPANSION OF LEADERSHIP<br />

TEAM TO “SUPPORT AND ACCELERATE GLOBAL GROWTH”<br />

Anaergia Inc. Has announced the<br />

appointments of Paula Myson as chief<br />

financial officer (CFO), and Hani Kaissi<br />

as chief development officer (CDO), both<br />

effective Oct 17 <strong>2022</strong>.<br />

Myson has over 25 years of senior<br />

leadership experience in financing and<br />

operating businesses in the energy,<br />

natural resources, and financial services<br />

industries. Most recently, she was the<br />

CFO of a renewable energy company with<br />

an international portfolio of projects and<br />

operations. Prior to that, she was the CFO of<br />

a public-listed gold producer. In addition to<br />

providing financial leadership, she has been<br />

responsible for corporate development,<br />

investor relations, risk management, and<br />

information technology. She holds a Master<br />

of Business Administration degree from<br />

the University of Alberta, is a Chartered<br />

Financial Analyst (CFA) charterholder, and<br />

holds a Certified Professional in Investor<br />

Relations (CPIR) designation.<br />

Kaissi joined Anaergia in 2010 and had been<br />

CFO of Anaergia since 2019. He has over<br />

25 years of experience in the water and<br />

waste industries. He started his career in<br />

the engineering and project management<br />

of large-scale infrastructure projects<br />

and has since held senior operations,<br />

strategy, product management, corporate<br />

development, M&A, and finance positions at<br />

ZENON Environmental and General Electric<br />

(GE <strong>Water</strong> & Process Technologies). Kaissi<br />

has a Bachelor of Engineering degree from<br />

the American University of Beirut and holds<br />

a Master of Business Administration degree<br />

from McGill University.<br />

“We are very excited to announce these<br />

appointments which enhance Anaergia’s<br />

team,” said Andrew Benedek, Chief<br />

Executive Officer of Anaergia. “Paula<br />

Myson’s CFO experience and wide-ranging<br />

business expertise with publicly traded<br />

companies and companies that engage<br />

in international development projects will<br />

be a huge asset to Anaergia. Furthermore,<br />

with Hani Kaissi in the newly created CDO<br />

position, Anaergia is now better positioned<br />

to capitalize on growth opportunities around<br />

the world,” added Dr Benedek.<br />

SUCCESSFUL HANDOVER OF THE ANAEROBIC<br />

BIODIGAT SB SYSTEM TO DEVELEY IN GERMANY<br />

Develey Senf & Feinkost, an international<br />

manufacturer of mustard, sauces and<br />

dressings, commissioned Wehrle in March<br />

2021 with the design and implementation<br />

of a wastewater treatment plant with biogas<br />

generation. Just one year later, in the summer<br />

of <strong>2022</strong>, the biological commissioning of the<br />

industrial water treatment plant took place<br />

at 100% capacity at the company’s largest<br />

German production site in Dingolfing.<br />

The Wehrle plant reduces the wastewater<br />

pollution load in such a way that the discharge<br />

values fixed by local authorities for indirect<br />

discharge into the downstream municipal<br />

sewage treatment plant are safely fulfilled.<br />

The industrial wastewater treatment plant is<br />

also an example for the synergetic integration<br />

of modern environmental technology and<br />

supports the customer’s overall sustainability<br />

initiative by reducing production emissions.<br />

Wehrle worked together with their customer<br />

to develop an overall concept, including<br />

sophisticated wastewater treatment and<br />

reliable purification of the water during peak<br />

loads in accordance with official requirements.<br />

Furthermore, the integrated biogas generation<br />

of the wastewater treatment plant together<br />

with a modern combined heat and power<br />

plant allows the direct conversion of the<br />

generated biogas into electricity, which can<br />

be used on site. The used technology is the<br />

anaerobic high-performance BIODIGAT SB<br />

process. With its three-phase separation<br />

system incorporating highly efficient biogas<br />

utilisation as well as heat pump technology<br />

with maximised overall energy efficiencies, the<br />

process meets all customer requirements.<br />

The successful commissioning of the new<br />

wastewater treatment plant was completed<br />

almost on time, despite the difficult conditions<br />

caused by the pandemic. The capacity was<br />

reportedly at 100%, four weeks after inoculation<br />

of the plant with biomass. The cleaning<br />

result and the gas yield showed an increase<br />

of approximately 20-30% compared to the<br />

expected values. Intelligent control technology<br />

enables continuous operation of the biology<br />

and the combined heat and power plant 24/7.<br />

Mr Reiter, technical director of Develey in<br />

Dingolfing, was satisfied: “The robustness of<br />

the biological process has clearly exceeded our<br />

expectations. The high-performance system<br />

reliably purifies our wastewater, which varies<br />

greatly in quantity and quality, in continuous<br />

operation. In fact, the biogas production is<br />

so good that we are considering another<br />

combined heat and power plant for electricity<br />

generation.”<br />

With this project, Wehrle claims that it has<br />

expanded its references for anaerobic<br />

wastewater treatment and showed its reliability<br />

as partner in the field of environmental<br />

technology. “We are proud to be part of this<br />

innovative and future-oriented project as an<br />

important system supplier and to be able to<br />

support the customer in its long-standing<br />

claim to sustainable operation with innovative<br />

products, clever engineering, drive and on-time<br />

implementation,” said Frank Natau, business<br />

development, water processes at Wehrle.<br />

WATER & WASTEWATER ASIA | NOVEMBER/DECEMBER <strong>2022</strong> 11

NEWS<br />

SOFTWARE ASSET FOR WATER<br />

INVESTMENT PLANNING LAUNCHES<br />

The latest version of Probit’s asset<br />

investment manager (AIM) software aims<br />

to help water companies in England and<br />

Wales save time and cost in planning<br />

works to optimise geographical synergies.<br />

AIM4 also makes web service interfacing<br />

and more localised analysis available to<br />

water companies and other organisations<br />

managing large asset bases.<br />

AIM4 is said to have set a precedent for<br />

analysing water and wastewater assets<br />

together. Historically, water companies<br />

that manage both water and wastewater<br />

infrastructure were unable to do so, as<br />

software with the capacity to process such<br />

vast numbers of assets was not available.<br />

This meant work stream management<br />

teams were not working collaboratively and<br />

modelling was siloed.<br />

Increasing demand for cost efficiencies<br />

in investment programmes means asset<br />

management challenges are being given<br />

greater strategic importance and becoming<br />

more complex. Ageing infrastructure,<br />

climate change, increasing regulation, and a<br />

growing population can all impact on asset<br />

life.<br />

IMPROVED FUNCTIONALITY<br />

Reflecting on the advances of AIM4, Philip<br />

Jonkergouw, managing director at Probit,<br />

said: “The biggest improvements have<br />

been to functionality, optimisation set-up<br />

capability, and adaptability. AIM4’s greatest<br />

strength lies in its ability to respond to the<br />

unknown and develop accordingly.<br />

“AIM4 has a high level of adaptability and<br />

flexibility when clients are facing new<br />

requirements, especially during water<br />

utility price reviews or asset management<br />

modelling transitions. As a result, it can<br />

now be used to answer more and more<br />

complicated questions for clients.”<br />

Using the AIM software, asset intensive<br />

organisations in water and other sectors<br />

can model the complete lifecycle of assets,<br />

anticipating changes and how they will<br />

impact on services. This results in better<br />

business decision-making that helps make<br />

assets more resilient and reduces service<br />

disruption and the risk of regulatory fines.<br />

AIM4 also delivers improvements in<br />

software functionality, such as the ability<br />

to analyse risk per region and per asset<br />

base. This allows users to examine factors<br />

such as planning constraints, along with<br />

the associated risks of not commencing<br />

work at specific points in the future, at a<br />

granular level.<br />

In addition, AIM4 introduces the option of<br />

web services, meaning AIM is no longer a<br />

standalone piece of software with limited<br />

client interaction. Third party systems<br />

can now connect directly to AIM to enter,<br />

extract, and link up data, creating an allround<br />

tool.<br />

AMP7 PLANNING<br />

The regulatory asset management<br />

period 2020-2025, AMP7, requires water<br />

companies in England and Wales to<br />

calculate investment needs and provide<br />

evidence on expenditure over a five-year<br />

period. By allowing asset managers to<br />

explicitly model what happens to assets<br />

under various conditions, certain questions<br />

can be asked such as how assets will<br />

deteriorate with how much risk and the<br />

associated costs due to failures in the<br />

network.<br />

Reflecting on the growth of the AIM<br />

software, Jonkergouw said: “Initially, AIM<br />

was used for underground linear assets<br />

such as sewer and water pipes, water<br />

mains and trunk mains. Then, clients<br />

wanted to do more types of modelling to<br />

Probit’s asset investment manager (AIM) software is<br />

helping water companies in England and Wales save<br />

time and cost in planning works<br />

include above-ground assets, such as<br />

wastewater treatment plants and pump<br />

stations.<br />

“Now it can be used to synchronise works<br />

across the whole water and wastewater<br />

asset base, and potentially with other<br />

sectors too. This is a perfect example of<br />

the adaptability and flexibility of the AIM<br />

software to meet new client requirements<br />

and we hope to continue these strong<br />

working relationships with AIM4 and<br />

beyond.”<br />

FUTURE OF AIM<br />

AIM software also delivers digital<br />

solutions and asset management across<br />

other infrastructure intensive sectors<br />

including power and transportation. The<br />

next step is to bring other utilities into<br />

the cross-sector optimisation work. For<br />

example, synchronising gas works to<br />

be done at the same location and at the<br />

same time as planned roadworks.<br />

“There has been ambition for this in the<br />

past,” said Jonkergouw, “but until now<br />

the tools, technology and processing<br />

power were not available nor did the<br />

sectors have the datasets needed. Now<br />

that asset management streams have<br />

the potential to come together in a single<br />

optimisation investment framework in<br />

AIM, this could start to drive cross-sector<br />

collaboration and trials.”<br />

12 WATER & WASTEWATER ASIA | NOVEMBER/DECEMBER <strong>2022</strong>

NEWS<br />

BENTLEY’S DR DRU CRAWLEY<br />

RECEIVES IBPSA-USA AWARD<br />

Bentley Systems has announced that Dr<br />

Dru Crawley, Bentley fellow and director of<br />

building performance research, has received<br />

the IBPSA-USA Award for Distinguished<br />

Achievement in Building Simulation. It will<br />

be presented at the IBPSA-USA SimBuild<br />

conference.<br />

IBPSA-USA is the United States regional<br />

affiliate of the International Building<br />

Performance Simulation Association (IBPSA).<br />

It advances and promotes the science of<br />

building simulation to improve the design,<br />

construction, operation, and maintenance<br />

of new and existing buildings in the United<br />

States. IBPSA was founded to advance and<br />

promote the science of building performance<br />

simulation to improve the design,<br />

construction, operation, and maintenance of<br />

new and existing buildings worldwide. IBPSA<br />

has more than 5,000 members worldwide in<br />

34 affiliates representing 42 countries.<br />

Dr Crawley was elected president of IBPSA<br />

on 10 Sept <strong>2022</strong>. He is the previous president<br />

of IBPSA-USA and has been part of the<br />

organisation since 1987. Dr Crawley has<br />

published more than 125 papers and articles,<br />

testified before the US Congress on zeroenergy<br />

and green buildings, lectured at more<br />

than 30 universities, and made more than 500<br />

presentations on building energy efficiency,<br />

sustainability, and renewable energy<br />

throughout the world.<br />

“Presented every two years, this award<br />

recognises an individual who has a<br />

distinguished record in the field of building<br />

performance simulation for 15 or more years,”<br />

said Carrie Brown, president of IBPSA-USA.<br />

“With an exemplary record of software<br />

development, high calibre research, and<br />

educational efforts, Dr Crawley has been an<br />

extremely influential champion of BPS. The<br />

breadth and depth of Dru’s expertise has<br />

made him an industry leader throughout his<br />

career, and our field is categorically better<br />

due to his contributions.”<br />

Dr Dru Crawley was<br />

awarded the IBPSA-<br />

USA Award for his<br />

achievements in the<br />

industry after 35<br />

years of experience<br />

SMART WATER NETWORK MANAGEMENT<br />

Optimize resOurces - ensure water quality - reduce cOsts<br />

SOFREL DL4W<br />

4G LTE-M/NB-IoT<br />

Data logger<br />

Flow and pressure monitoring<br />

Night flow analysis<br />

Flow rate alerts<br />

Leak detection<br />

CSO monitoring & detection<br />

learn mOre:<br />

SOFREL ChlorIN<br />

Autonomous chlorine<br />

level measurements<br />

Real-time monitoring<br />

Easy to install<br />

Immediate notification in<br />

case of threshhold breach<br />

learn mOre:<br />

www.lacroix-environment.com<br />

WATER & WASTEWATER ASIA | NOVEMBER/DECEMBER <strong>2022</strong> 13

NEWS<br />

RESEARCH FROM ABB SHOWS HOW<br />

CITIES CAN TACKLE WATER STRESS<br />

BY REDUCING CARBON EMISSIONS<br />

AND COST OF WASTEWATER<br />

TREATMENT FOR REUSE<br />

ABB published the first in a series<br />

of new reports for the energy and<br />

wastewater sectors to highlight the<br />

impact that technology can have<br />

in enabling industrial customers to<br />

reduce carbon emissions and manage<br />

the energy transition for a more<br />

sustainable future.<br />

With the United Nations predicting a<br />

40% water deficit by 2040, ABB has<br />

conducted research to reveal how<br />

better use of wastewater could relieve<br />

pressure on water supplies.<br />

When treated effectively, wastewater<br />

can be returned to the water cycle for<br />

reuse, proving a valuable but often<br />

untapped resource in tackling water<br />

scarcity. Importantly, it also lowers the<br />

levels of untreated sewage pumped<br />

into rivers and oceans, which have<br />

hugely negative impacts on public<br />

health, the environment and marine life.<br />

“Global data shows that only half of<br />

our wastewater is properly treated,”<br />

said Brandon Spencer, president,<br />

ABB Energy Industries. “Allowing<br />

untreated wastewater back into<br />

our water courses not only has a<br />

disastrous effect on fisheries, animals,<br />

marine biodiversity, and public health,<br />

but it is also a terrible ‘waste’ of this<br />

commodity. We need to be doing<br />

more.”<br />

Treating wastewater, however, requires<br />

a lot of power, with the industry at large<br />

consuming up to 3% of the world’s<br />

total energy output and contributing<br />

over 1.5% to global greenhouse gas<br />

emissions.<br />

Seeking to redress this balance, ABB<br />

has conducted nine months of research<br />

and modelling with an independent<br />

economist, to demonstrate how greater<br />

adoption and integration of process<br />

automation technologies, can deliver<br />

both carbon and cost savings to enable<br />

more efficient treatment of wastewater.<br />

The findings reveal that in wastewater<br />

sites, utilities could reduce carbon<br />

emissions by up to 2,000 tonnes per<br />

annum, the equivalent volume of CO2<br />

responsible for 30,000 tonnes of glacier<br />

mass lost every year. With over 50,000<br />

existing wastewater plants worldwide,<br />

the opportunity, if scaled, is upwards of<br />

100 million tonnes of CO2 saved.<br />

Furthermore, in applying a robust<br />

package of process control and digital<br />

solutions, water companies could reap<br />

annual operational savings of up to<br />

US$1.2m (9.5%) per plant, opening<br />

revenue streams to ensure higher<br />

volumes of wastewater are treated and<br />

less is discarded in our rivers and seas.<br />

“ABB is committed to leading with<br />

technology to preserve precious<br />

resources such as water and energy,<br />

and ultimately enable a low-carbon<br />

society and a more sustainable world.<br />

In 2021, we have reduced our own CO2<br />

emissions by 39%, compared with the<br />

baseline year of 2019, and as part of<br />

our Sustainability Strategy 2030, we<br />

are working with our customers with<br />

the aim of reducing their annual CO2<br />

emissions by at least 100 megatons by<br />

2030,” said Spencer.<br />

The global wastewater market, driven<br />

by the need for more freshwater,<br />

population increase, and stringent<br />

environmental regulations, is projected<br />

to grow from $300bn in <strong>2022</strong> to $490bn<br />

by 2029.<br />

The reports’ economic modelling<br />

was undertaken by independent<br />

economist Steve Lucas of Development<br />

Economics in conjunction with ABB<br />

Energy Industries and supported with<br />

desktop research of academic and<br />

industry sources. ABB will publish<br />

further economic reports focused on<br />

the offshore, power and chemicals<br />

markets across <strong>2022</strong> and 2023.<br />

ABB’s infographic<br />

detailing their<br />

findings in their<br />

newest report<br />

14 WATER & WASTEWATER ASIA | NOVEMBER/DECEMBER <strong>2022</strong>

SINGAPORE FOCUS<br />

CLEANEDGE WATER<br />

covers all bases<br />

With operations in the region, CleanEdge<br />

offers a comprehensive water treatment<br />

experience centered on sustainability and<br />

waste minimisation.<br />

optimises overall plant cost. This system is a<br />

suitable solution for areas facing acute shortage<br />

of water.<br />

Sewage treatment plants<br />

As pre-fabricated plug-and-play systems for<br />

sewage treatment, Lars offer these ready-to-use<br />

containerised plants for a range of capacities.<br />

Minimal to zero work onsite with a short lead<br />

time remains the main attraction of this product<br />

Zero liquid discharge and multi-effect<br />

evaporator<br />

Understanding the industries’ need for a<br />

complete ZLD solution to meet voluntary<br />

environmental or statutory standards, Lars<br />

completes the full ZLD cycle by incorporating<br />

different type of evaporators and drying<br />

system further to their high recovery<br />

membrane solutions. Here, the capex and<br />

opex are optimised by providing MVR and TVR<br />

technologies.<br />

The National Dairy Development Board in India worked together with Lars to provide better<br />

management of dairy wastewater<br />

CleanEdge <strong>Water</strong> offers technologies for<br />

treating industrial wastewater, focusing<br />

on resource recovery and sustainability.<br />

Headquartered in Singapore, and founded<br />

and managed by a group of professionals<br />

dedicated to the environment, development<br />

and sustainability, the company aims to solve<br />

complex problems and design integrated<br />

solutions to increase recovery, sustainability<br />

and profitability, with a focus on technical<br />

upgrades with disruptive technologies.<br />

CleanEdge <strong>Water</strong>’s group company, Lars<br />

Enviro, is an environmental engineering<br />

organisation in India with more than 25<br />

years in the field of water, raw water and<br />

wastewater, with emphasis on industrial<br />

wastewater, recycling systems, sewage<br />

treatment and waste to energy.<br />

LARS ENVIRO<br />

Biogas/Bio-methanation through effluent<br />

treatment plants<br />

Via generating energy from the feed-stock<br />

such as press mud and cow manure, the<br />

biogas generation of anaerobic digestion<br />

can manage energy supply and waste<br />

management issues. This solution avoids<br />

contaminating groundwater and the emission<br />

of greenhouse gases, while also recovering<br />

energy in the form of steam, biogas, power,<br />

CBG, and more. The generated digestate can<br />

sustainably substitute synthetic or chemical<br />

fertilisers and strengthen the farm ecosystem.<br />

<strong>Wastewater</strong> recycling plants<br />

Lars aims towards simplifying industrial<br />

wastewater recycling. The company’s<br />

WWRP solution use available resources and<br />

Condensate polishing units<br />

Distillery condensate is generated as a byproduct<br />

of multi-effect evaporation of spent<br />

wash, while grain wash generated as wastewater<br />

stream from alcohol production process. The<br />

effluent contains organic load and can have<br />

a detrimental effect on the environment. Lars<br />

has developed technologies considering PCB<br />

stringent norms and implementation of ZLD.<br />

Together with the recycling plant, the CPU treats<br />

condensate and makes it reusable by offering a<br />

combination of anaerobic, aerobic technologies<br />

along with tertiary (sand filters, UF, RO) and<br />

disinfection (UV) treatment. This recycled water<br />

reduces fresh water demand.<br />

WTE plants<br />

Solid waste management through anaerobic<br />

digestion can provide customers with renewable<br />

energy and address waste management<br />

issues. Energy can be recovered in the form of<br />

steam, biogas, power, bio CNG, and more. The<br />

digestate can substitute synthetic fertilisers and<br />

strengthen the farm ecosystem.<br />

The decentralised WTE Plants can minimise<br />

solid waste at the source. Lars’ technology-<br />

16 WATER & WASTEWATER ASIA | NOVEMBER/DECEMBER <strong>2022</strong>

SINGAPORE FOCUS<br />

based solutions can strengthen solid waste<br />

management. manage health risks and<br />

environmental pollution through plug-and-play<br />

digesters.<br />

Biogas to renewable energy<br />

Lars Enviro’s anaerobic digestion can handle<br />

different organic substrates from food waste<br />

to sewage sludge, to produce renewable<br />

energy. This can be used as an alternative,<br />

renewable automotive fuel through gas<br />

grid/cascades and also to replace LPG for<br />

industrial needs.<br />

From pre-treatment techniques required<br />

ahead of anaerobic fermentation, right up<br />

to the required post-treatment of digestate,<br />

composting and biogas upgrading, Lars<br />

possesses one of the highest design and<br />

operating experience of biogas plants,<br />

producing about 1000MT CBG per day,<br />

or 226MWH equivalent of potential power<br />

generation.<br />

CLEANEDGE WATER<br />

CleanEdge also offers a range of water<br />

treatment systems, ranging from raw water<br />

treatment plants, UF and RO plants, DM<br />

plants, and desalination solutions.<br />

LESMAT<br />

LESMAT is an anaerobic solution for<br />

seasonal industries generating high strength<br />

wastewater. It is an optimal solution<br />

when footprint is a constraint. Here, a bio<br />

film of desired bacteria is attached to a<br />

structural media to facilitate reduction and<br />

better treatment. CleanEdge has so far<br />

commissioned 56 LEMSAT units.<br />

LESBAR<br />

LESBAR is a biodigester for the treatment of<br />

low- and medium- strength wastewater across<br />

breweries, and sugar and food processing,<br />

etc. Equipped with an in-house design offering<br />

a three-tier GLSS (gas liquid solid separator)<br />

system, LESBAR comes in different materials<br />

like stainless steel, mild steel with epoxy/FRP,<br />

complete FRP, and more. Thus far, 164 units<br />

of LESBAR have been commissioned.<br />

CleanEdge offers<br />

raw water treatment<br />

plants, UF and RO<br />

plants, DM plants, and<br />

desalination solutions<br />

LESAR<br />

A better engineered version of the<br />

conventional continuously stirred tank<br />

reactor, LESAR is an optimal solution for<br />

biogas recovery or treatment of highstrength<br />

industrial wastewater. With over<br />

100 installations across industries and<br />

continents, LESAR can be applied a wide<br />

range of industries, from distilleries to<br />

manure and sludge digestion. Till date, 106<br />

units of LESAR have been commissioned.<br />

KOOLL COMPANY, THE PHILIPPINES<br />

Lars Enviro was contacted to design,<br />

supply, and commission a fermented wash<br />

(raw spent wash) biogas plant for the Kooll<br />

Company, in Talisay City, The Philippines.<br />

The company is one of the largest<br />

producers of alcohol- and beverage-grade<br />

liquid carbon dioxide, supplying to major oil<br />

and beverage companies in the country with<br />

a flow of 980m 3 /day at a COD of 120,000mg<br />

per litre. The plant Lars constructed thus<br />

generated about 34,500m 3 of biogas per<br />

day, which was utilised as fuel in boiler.<br />

With the plant, Lars enabled the reduction<br />

of highly pollutant wastewater and the<br />

ability to handle shock loads. With one<br />

seeding and commissioning required,<br />

there was no need for specialised culture<br />

and nutrients for further operations, and<br />

no need for chemicals once the plant had<br />

stabilised<br />

The plant was also capable of handling<br />

a higher volume of wastewater and can<br />

restart rapidly after a shutdown. The<br />

biogas produced can be utilised in boilers,<br />

canteens, furnaces, CBG, for electricity<br />

generation. The treated wastewater, which<br />

contains high nutrient, can be used as<br />

organic compost to improve soil fertility,<br />

reducing water demand and the economic<br />

burden (inorganic fertilisers) of farmers.<br />

THE NATIONAL DAIRY DEVELOPMENT<br />

BOARD<br />

The National Dairy Development Board was<br />

set up by the Parliament of India. With its<br />

main office located in Anand, Gujarat, with<br />

regional offices throughout the country, the<br />

board was created to finance, support and<br />

support producer-owned and controlled<br />

organisations. Its programmes and activities<br />

seek to strengthen farmer cooperatives and<br />

support national policies that are favourable to<br />

the growth of such institutions.<br />

The dairy industry is the most polluting food<br />

industry in terms of water use during the<br />

production of milk and milk products. The<br />

wastewater contains dissolved sugars, proteins<br />

and fats, which is organic and biodegradable.<br />

Dairy wastewater is thus considered as<br />

possessing high concentrations of organic<br />

matter and BOD. It is estimated that dairy<br />

industries generate 2.5-3 litres of wastewater<br />

per litre of milk processed.<br />

If left untreated, dairy wastewater will pollute<br />

land and river systems. Hence, proper<br />

treatment of dairy wastewater is necessary<br />

before disposal in the environment, as per the<br />

Maharashtra pollution control board (MPCB)<br />

standards.<br />

With experience in managing dairy waste from<br />

companies such as Etika Dairy from Malaysia,<br />

and Hatsun Agro Products from India, LARS<br />

had supplied preliminary, anaerobic, aerobic<br />

treatment, alongside tertiary treatment like<br />

MGF and ACF. Lars provided a single point<br />

solution to treat liquid waste water generated<br />

from the plant, and treated water was used for<br />

irrigation purposes.<br />

WATER & WASTEWATER ASIA | NOVEMBER/DECEMBER <strong>2022</strong> 17

IN CONVERSATION WITH<br />

SUEZ EMBARKS<br />

on 2027 goals<br />

As the water industry is poised for significant<br />

changes in climate, smart solutions, and more,<br />

Agatha Wong speaks with Sabrina Soussan, chairman<br />

and CEO of SUEZ, to find out more about the<br />

company’s strategy in the years to come.<br />

To begin with, can you share with us your<br />

experience as CEO of SUEZ since your<br />

appointment earlier this year?<br />

Soussan: The first months have been filled<br />

with much listening, interacting and getting<br />

to know as many colleagues, from across 40<br />

countries we operate in, as possible. I have<br />

been particularly impressed by our Chinese<br />

Team which has been working under very<br />

difficult conditions due to lockdowns<br />

imposed as countermeasures to COVID-19.<br />

Over that period, we have also achieved a<br />

number of significant milestones. We have<br />

completed three acquisitions: hazardous<br />

waste in France; EnviroServ, the leader in<br />

waste treatment in Southern Africa; and<br />

our former recycling and recovery (R&R)<br />

assets in the UK. These moves highlight<br />

the optimism and confidence of our<br />

shareholders in SUEZ’s future. Once the<br />

acquisitions are finalised, the SUEZ global<br />

team would have grown from 35,000 to<br />

44,000 employees and our annual revenue<br />

risen from €7.5 to €9bn.<br />

Can you comment on SUEZ’s new<br />

strategy? What are some of the changes<br />

that customers can expect from it moving<br />

forward?<br />

Soussan: Our plan is an ambitious one,<br />

in line with the increasingly important<br />

environmental challenges facing our world.<br />

My ambition for SUEZ is that we become the<br />

trusted partner of industrial companies and<br />

local authorities for circular solutions in water<br />

and waste. This strategy will progress SUEZ<br />

towards its goals through three pillars: focus,<br />

differentiation and enhanced value creation.<br />

• We will focus on our core business: the<br />

complete waste and water value chains,<br />

including related services, and concentrate<br />

our efforts on certain particularly buoyant<br />

markets, such as <strong>Asia</strong>, the United<br />

Kingdom, Italy, India, Australia, the Middle<br />

East and Africa.<br />

• We will differentiate by offering a unique<br />

value proposition to our customers, built on<br />

our proven infrastructure, on our expertise<br />

with a recognised leadership in smart and<br />

digital solutions, on end user experience,<br />

and on innovation.<br />

• We will offer enhanced value creation by<br />

being more selective with our projects,<br />

making digitalisation and service<br />

excellence our drivers for competitiveness.<br />

By 2027, this strategy will enable us to be<br />

a benchmark in our industry, recognised<br />

for our agility, capacity to create value, and<br />

innovation.<br />

SUEZ will invest an additional €860m<br />

compared to the previous period to<br />

address new environmental and energy<br />

challenges. What do you think are the most<br />

pressing issues in the industry, and how<br />

will SUEZ continue to create differentiated<br />

solutions to meet these needs?<br />

Soussan: Our industry currently faces<br />

historic challenges, characterised by<br />

strong momentum for green transition from<br />

governments, industries and customers.<br />

SUEZ has been part of this evolution by taking<br />

the lead in action and expanding its expertise.<br />

We will continue to devote our efforts in<br />

addressing environmental challenges<br />

regionally in this fast-changing world. True<br />

to our partnership culture, we will double<br />

our investments, alongside our customers,<br />

mobilising an additional €860m compared to<br />

the previous period for the digitalisation of<br />

water networks, decarbonisation and energy<br />

efficiency, for example. We will also increase<br />

our innovation capacity, with a 50% increase<br />

in our R&D budget by 2027 to develop<br />

differentiated solutions for preserving water<br />

resources, combating pollutants, recycling,<br />

producing green energy from waste; and<br />

reducing our own carbon footprint, as well<br />

as that of our customers. Digital technology<br />

is also an important lever for improving<br />

performance and agility and for developing<br />

new solutions. We will continue to invest<br />

in this area, with the goal of doubling our<br />

revenues from these activities in five years.<br />

18 WATER & WASTEWATER ASIA | NOVEMBER/DECEMBER <strong>2022</strong>

IN CONVERSATION WITH<br />

How will SUEZ work towards its strategic<br />

objectives and maintain its position for the<br />

future?<br />

Soussan: As we grow strategically and<br />

reposition ourselves to be a leading, fullservice<br />

provider across the entire water<br />

and waste value chains, we will have to be<br />

selective with where we invest our resources<br />

and which projects we undertake. Pursuing<br />

strategic opportunities requires efficient<br />

decisions and strong capital support. We<br />

are fortunate to have a strong backing from<br />

our consortium of shareholders, with ample<br />

capital and strategic alignment.<br />

Second, we will also need to maintain our<br />

leadership in sustainable development.<br />

By the end of <strong>2022</strong>, SUEZ will unveil its<br />

sustainable development roadmap, outlining<br />

our contribution, ambitions, and quantified<br />

targets for climate, nature conservation, and<br />

social matters.<br />

Third, we need to engage all stakeholders.<br />

We have made a commitment for employees<br />

to hold 10% of the capital within the next<br />

five to seven years through an employee<br />

shareholding plan. We are promoting diversity<br />

and equal opportunity, and we are renewing<br />

our social commitments through inclusion<br />

initiatives, notably through our social inclusion<br />

subsidiaries, such as Rebond in France.<br />

SUEZ will also be focusing on both mature<br />

and emerging markets. On that vein,<br />

what are your goals for South East <strong>Asia</strong> in<br />

particular? What unique opportunities for<br />

growth and investment do you see in this<br />

region?<br />

Soussan: South East <strong>Asia</strong> is an important<br />

region for SUEZ because of our historic<br />

presence in this region and the rising demand<br />

for environmental improvements and the<br />

need to supply top class water and waste<br />

services to the growing populations. As part<br />

of our desire to focus our activities, we will<br />

keep concentrating our efforts, notably in the<br />

Philippines, Indonesia, Vietnam and Thailand,<br />

as well as others. We have numerous projects<br />

in these nations, managed by strong local<br />

SUEZ’s plan for 2027<br />

will see the company<br />

leveraging its knowledge<br />

of the water industry to<br />

serve more customers<br />

(Image: SUEZ/Antoine<br />

Meyssonnier)<br />

teams. Additionally, we provide them with<br />

technical and financial support from our<br />

worldwide SUEZ organisation. Our goal<br />

is to expand further by working with our<br />

partners and clients. By 2027, SUEZ aims at<br />

generating approximately 40% of its revenue<br />

in international markets.<br />

Can you share with us more on the<br />

new, simplified, and customer-focused<br />

organisation that will be structured<br />

around water and waste? How will this<br />

organisation further benefit SUEZ’s<br />

customers and deliver a more robust<br />

commercial and operational experience?<br />

Soussan: We plan to become a more<br />

agile and customer-focused organisation<br />

structured around our two core businesses,<br />

water and waste. Globally, we will organise<br />

our businesses as one “<strong>Water</strong>” and one<br />

“Waste” division. Our new structure and<br />

operating model will enable us to better<br />

put the customer at the forefront of our<br />

activities.<br />

What are your hopes and visions for<br />

SUEZ as it works towards its strategic<br />

plans? What are you most excited about<br />

for SUEZ’s journey in the next five years?<br />

Soussan: I’m looking forward to seeing<br />

this ambitious, yet realistic, strategic plan,<br />

which is rooted in a purpose of making key<br />

contributions to society, progressing step<br />

by step. I’m convinced that SUEZ, through<br />

its water and waste activities, has been<br />

playing and will play a vital role everywhere<br />

it operates in improving people’s quality of<br />

life on a day-to-day basis.<br />

WATER & WASTEWATER ASIA | NOVEMBER/DECEMBER <strong>2022</strong> 19

IN CONVERSATION WITH<br />

THE COLLECTIVE CALL<br />

for sustainable action<br />

Cooperation with government bodies, private<br />

companies, and academic institutions will be vital<br />

in ensuring the longevity of green strategies.<br />

By Agatha Wong<br />

The announcement of the Environmental<br />

Sustainability & Energy Efficient Centre (ESEE)<br />

by Singapore Polytechnic (SP) at the “Values-<br />

Based Green Transition – For Singapore<br />

Businesses” event brought together key<br />

players ranging from government agencies,<br />

private companies, trade associations and<br />

chambers, demonstrating a united resolve in<br />

supporting the green transition of companies<br />

across various sectors.<br />

Serving as a one-stop provider of services and<br />

counsel for sustainable practices, companies<br />

can expect the knowledge and expertise<br />

of participating members as they tackle<br />

common teething issues such as operational<br />

costs and administrative process. Similarly,<br />

companies like Grundfos will be tapping<br />

into their portfolios to support firms across<br />

various industries. The end result: a symbiotic<br />

arrangement where all parties benefit mutually<br />

from the expansion of greener strategies.<br />

“The MOU with SP will allow us tap into higher<br />

learning institutions, where Grundfos comes in<br />

with vast knowledge and applications; as well<br />

as experience in bringing about sustainability<br />

solutions. SP will also provide us a platform<br />

to also enter more ecosystems and connect<br />

with more industries, policy makers and<br />

higher-learning institutions, and get things off<br />

the ground,” said Eric Lai, regional managing<br />

director of Industry – APAC, and country<br />

director for Singapore, at Grundfos.<br />

On that front, Grundfos will be able to offer its<br />

portfolio of services and products, designed<br />

for water and energy efficiency, to a wider<br />

audience. Humphrey Lau, former<br />

group senior vice-president of global<br />

industry business at Grundfos, shared<br />

at the conference the six projects<br />

which the company has planned,<br />

drawing from the reduction of Grundfos’<br />

carbon footprint by energy consumption<br />