Marvelous Magnetic Machines: Building Model Electric Motors from Scrap

You’re standing in front of an old card table in a driveway at a garage sale. On that table is a one-quart aluminum saucepan, a votive candle holder, pieces of some office machinery, and a wooden awards plaque. What do you see there? If you did not answer “a six-cylinder radial electromagnetic attraction motor,” then you need this book! H.P. Friedrichs (author of The Voice of the Crystal and Instruments of Amplification) returns this time to explore the principles behind the operation and construction of five simple, yet impressive, model electric motors. Aspiring mechanical model makers are often discouraged by their lack of access to machine tools, like mills, lathes, or drill presses. Friedrichs demonstrates that with some basic knowledge, an open eye, and a sharp mind, one can use commonly available (and often discarded) parts and materials to engineer one’s way around any lack of expensive machine tooling. In fact, every motor in this book was built from scrap, and can be assembled with hand tools. You’ll learn where to hunt for and find materials, and where to salvage suitable bearings. You’ll know where useful solenoids can be extracted from scrap, and how to fabricate bobbins to wind your own. You’ll learn how to time your motors, fashion a connecting rod, make a commutator from scratch, use a hall effect sensor to detect magnet position, use a transistor as a switch, and much more. Hardcover, 160 pages,177 photos and illustrations.

You’re standing in front of an old card table in a driveway at a garage sale. On that table is a one-quart aluminum saucepan, a votive candle holder, pieces of some office machinery, and a wooden awards plaque. What do you see there? If you did not answer “a six-cylinder radial electromagnetic attraction motor,” then you need this book!

H.P. Friedrichs (author of The Voice of the Crystal and Instruments of Amplification) returns this time to explore the principles behind the operation and construction of five simple, yet impressive, model electric motors.

Aspiring mechanical model makers are often discouraged by their lack of access to machine tools, like mills, lathes, or drill presses. Friedrichs demonstrates that with some basic knowledge, an open eye, and a sharp mind, one can use commonly available (and often discarded) parts and materials to engineer one’s way around any lack of expensive machine tooling. In fact, every motor in this book was built from scrap, and can be assembled with hand tools.

You’ll learn where to hunt for and find materials, and where to salvage suitable bearings. You’ll know where useful solenoids can be extracted from scrap, and how to fabricate bobbins to wind your own. You’ll learn how to time your motors, fashion a connecting rod, make a commutator from scratch, use a hall effect sensor to detect magnet position, use a transistor as a switch, and much more.

Hardcover, 160 pages,177 photos and illustrations.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Connecting rods made in this fashion have several desirable attributes. They<br />

are cheap and simple to make, they run well with reasonably low friction, and they’re<br />

compliant. In addition, their length can be adjusted over a limited span by advancing or<br />

backing off the standoffs on the threaded rod. This can be very useful when trying to finetune<br />

the Texas Motor.<br />

Wiring and Engine Timing<br />

As is always the case, the Texas Motor relies on proper timing to establish just<br />

when the coils of the electromagnets are to be energized. Like the Peewee, the magnets in<br />

the Texas Motor are fired with a leaf switch, and the basic principles with regard to timing<br />

apply here, as well. However, there are a few details unique to the Texas Motor.<br />

The first consideration has to do with coil polarity. Recall that the polarity of the<br />

field produced <strong>from</strong> the poles of an electromagnet depends upon the direction in which<br />

electrical current circulates through the electromagnet’s windings. The pair of coils in the<br />

Texas Motor are able to exert the most aggressive force on the attraction plate only if the<br />

magnetic polarity of their respective cores is different. In other words, when energized,<br />

one core should produce a north magnetic pole, while the other should be a south pole.<br />

With care, I could have recorded the direction with which each coil was wound,<br />

noting which lead of the coil fed the center, and which was connected to the outermost<br />

winding. With this information, I could have predicted what the pole polarity would be<br />

for any given current applied to the windings.<br />

A simpler method is to prepare the coils without regard to polarity, and then<br />

characterize them later. This can be done with a flashlight cell and a cheap magnetic<br />

compass. To do this, I connected the leads of one of the coils to the flashlight cell and<br />

brought the compass near the pole face. The compass needle is either attracted to or<br />

repelled by the field produced in the coil. I swapped the leads on the cell, as needed,<br />

until I observed that the compass needle was repelled, meaning that the pole of the<br />

electromagnet had assumed a north magnetic polarity. When this condition was achieved,<br />

I labeled the coil lead which was attached to the positive terminal of the cell with a piece<br />

of tape. I repeated this same process with the second coil.<br />

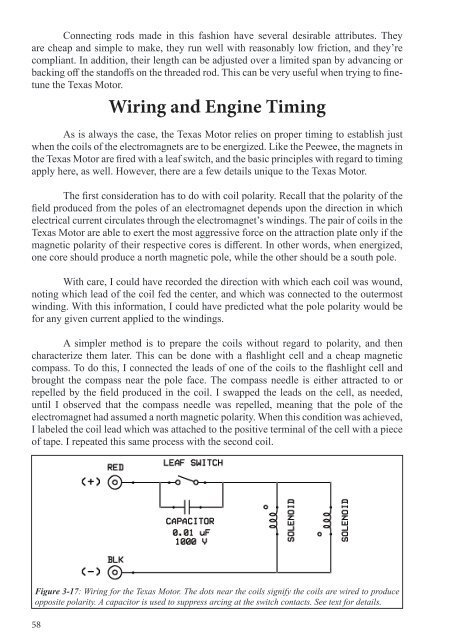

Figure 3-17: Wiring for the Texas Motor. The dots near the coils signify the coils are wired to produce<br />

opposite polarity. A capacitor is used to suppress arcing at the switch contacts. See text for details.<br />

58