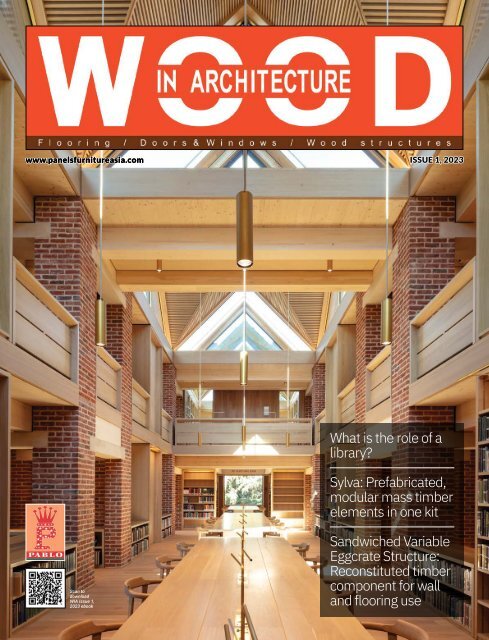

Wood In Architecture Issue 1, 2023

First published in 2017, Wood in Architecture (WIA) is a bi-annual trade magazine devoted to the international timber construction sector. The newest addition to the Panels & Furniture Group of wood magazines, WIA features in-depth insights to the latest industry news, incredible projects and leading trade events. WIA is an advocate for timber as a material of choice for today’s built environment, and is the perfect source of inspiration for architects, builders, engineers and interior designers across the globe.

First published in 2017, Wood in Architecture (WIA) is a bi-annual trade magazine devoted to the international timber construction sector. The newest addition to the Panels & Furniture Group of wood magazines, WIA features in-depth insights to the latest industry news, incredible projects and leading trade events. WIA is an advocate for timber as a material of choice for today’s built environment, and is the perfect source of inspiration for architects, builders, engineers and interior designers across the globe.

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

www.panelsfurnitureasia.com<br />

ISSUE 1, <strong>2023</strong><br />

What is the role of a<br />

library?<br />

Sylva: Prefabricated,<br />

modular mass timber<br />

elements in one kit<br />

Scan to<br />

download<br />

WIA <strong>Issue</strong> 1,<br />

<strong>2023</strong> ebook<br />

Sandwiched Variable<br />

Eggcrate Structure:<br />

Reconstituted timber<br />

component for wall<br />

and flooring use

We Know<br />

<strong>Wood</strong>.<br />

And we want to share<br />

what we know about some<br />

of the most beautiful,<br />

sustainably-grown species<br />

in the world.<br />

Softwood Export Council<br />

is your go-to resource<br />

for information on U.S.<br />

wood products, and we’re<br />

invested in creating and<br />

maintaining relationships<br />

world-wide. With industry<br />

connections across the<br />

United States, there’s<br />

no better avenue into<br />

importing the highest<br />

quality American species.<br />

For more information, visit<br />

www.americansoftwoods.com

sales@pabloasia.com

CONTENTS<br />

34<br />

12<br />

32<br />

2 WOOD IN ARCHITECTURE • ISSUE 1 – <strong>2023</strong>

CONTENTS<br />

04 Editor’s Note<br />

06 News<br />

THE BIG PICTURE<br />

12 What is the role of a library?<br />

MARKET REPORT<br />

26 Timber construction<br />

business: How to make it a<br />

success story<br />

SUSTAINABILITY<br />

30 Compliance with North<br />

American composite wood<br />

formaldehyde emission rules<br />

32 EDGE Suedkreuz Berlin<br />

MATERIALS AND<br />

TECHNOLOGY<br />

34 Aurum: Modern, sustainable<br />

architecture embraced by<br />

historic surroundings<br />

36 Sylva: Prefabricated,<br />

modular mass timber<br />

elements in one kit<br />

ENGINEERED WOOD<br />

39 Communicating with mass<br />

timber: <strong>Wood</strong>en telecom<br />

towers by EcoTelligent<br />

42 Glulam columns for a<br />

veranda<br />

DESIGN<br />

44 Escapes – The landscapes of<br />

the soul: <strong>Wood</strong>-dye veneers by<br />

TABU<br />

46 Paseo Mallorca 15<br />

STRUCTURAL<br />

ELEMENTS<br />

49 Sandwiched Variable Eggcrate<br />

Structure: Reconstituted<br />

timber component for wall and<br />

flooring use<br />

52 The Circus<br />

FLOORING<br />

54 Harder than hardwood:<br />

<strong>Wood</strong>ura by Välinge Flooring<br />

56 2022: Challenging year for<br />

global laminate flooring sector<br />

FIT-OUTS<br />

57 Sycamore tree hung in hotel<br />

lobby<br />

59 Yamagiwa Osaka showroom<br />

and office<br />

SHOW PREVIEW<br />

61 Workspace Design Show <strong>2023</strong><br />

62 BEX Asia <strong>2023</strong><br />

63 Events Calendar<br />

64 <strong>In</strong>dex of Advertisers<br />

42<br />

46<br />

36<br />

WOOD IN ARCHITECTURE • ISSUE 1 – <strong>2023</strong> 3

EDITOR’S NOTE<br />

When will the mass<br />

timber revolution hit<br />

South East Asia?<br />

It is not often for somebody who lives in South<br />

East Asia to see mass timber structures.<br />

<strong>Wood</strong>en buildings, maybe — depending on<br />

which country you stay. <strong>Wood</strong>en cabins or<br />

small houses are probably plenty in rural<br />

regions, but for urbanised Singapore you get a<br />

steel and concrete jungle everywhere.<br />

Mass timber has taken hold of many western<br />

countries and in some parts of Asia-Pacific,<br />

but it is slow on the uptake for South East<br />

Asia. Familiar arguments in support of mass<br />

timber, such as its inexpensiveness in terms of<br />

material and labour, might not apply in South<br />

East Asian context. Specific to Singapore,<br />

architects and designers need to import<br />

timber from EU countries or New Zealand, and<br />

that marks up the cost of building with mass<br />

timber. They need to install sprinkler systems<br />

as well, and that increases costs.<br />

That does not mean that mass timber is a<br />

lost cause for South East Asia, of course.<br />

Mass timber still is a worthy investment for<br />

our environment and the carbon-intensive<br />

construction industry, although the caveat to<br />

this is that the timber used to create mass<br />

timber elements must be sustainably<br />

harvested and sourced. After all,<br />

deforestation, land conversation and illegal<br />

forestry are also culprits of increasing<br />

greenhouse gas emissions.<br />

<strong>In</strong> this issue, we interviewed architect<br />

and creative director Pan Yi Cheng,<br />

who invented the Sandwiched Variable<br />

Eggcrate Structure, a flooring and wall<br />

module prototype (p.49). This prototype<br />

aims to decarbonise the construction<br />

industry by targeting low-storey houses<br />

in Singapore, as well as address the<br />

aforementioned expensiveness of<br />

importing timber from western countries<br />

by using reconstituted timber from<br />

Malaysia to build the prototype.<br />

We also talked to global sawnwood<br />

producer Stora Enso about their new kit for<br />

prefabricated, mass timber elements, Sylva<br />

(p.36). With manpower in the construction<br />

industry getting scarcer and the demand<br />

for green buildings growing, Sylva aims to<br />

be the answer to these two issues, tailormade<br />

for various building typologies.<br />

Libraries are our central theme for this<br />

issue’s Big Picture column. When we think of<br />

libraries, we think of books. However, a closer<br />

look at the projects we feature — and many<br />

others out there in the world — tell a different<br />

story: How can libraries become communal<br />

spaces as well? And what is the effect of<br />

using wood in such spaces?<br />

We hope to continue bringing everyone<br />

inspiring and beautiful projects of wooden<br />

architecture and interior design in the new<br />

year. And if ever you come across new<br />

projects, don’t hesitate to reach out to us and<br />

let us know. We will be happy to showcase<br />

them.<br />

EDITOR | YAP SHI QUAN<br />

WOOD IN ARCHITECTURE<br />

PABLO SINGAPORE<br />

Publisher<br />

William Pang • williampang@pabloasia.com<br />

Editor<br />

Yap Shi Quan • shiquan@pabloasia.com<br />

Business Development Manager<br />

Pang YanJun • yanjun@pabloasia.com<br />

Graphic Designer<br />

Goh Meng Yong • mengyong@pabloasia.com<br />

Circulation Manager<br />

Shu Ai Ling • circulation@pabloasia.com<br />

PABLO BEIJING<br />

General Manager<br />

Ellen Gao • pablobeijing@163.com<br />

PABLO SHANGHAI<br />

Editor<br />

Kresly Shen • pabloshanghai@163.net<br />

HEAD OFFICE<br />

PABLO PUBLISHING & EXHIBITION PTE LTD<br />

3 Ang Mo Kio Street 62, #01-23, Link@AMK,<br />

Singapore 569139<br />

Tel : +65 6266 5512<br />

Email: info@pabloasia.com<br />

www.panelsfurnitureasia.com<br />

Company Registration No: 200001473N<br />

Singapore MICA (P) No: 084/12/2022<br />

REGIONAL OFFICES (CHINA)<br />

PABLO BEIJING<br />

Tel : +86 10 6509 7728<br />

Email : pablobeijing@163.com<br />

PABLO SHANGHAI<br />

Tel : +86 21 5238 9737 / 36<br />

Email : pabloshanghai@163.net<br />

let's connect!<br />

@wood.ia<br />

All rights reserved. Views of writers do not necessarily reflect the views<br />

of the Publisher. No part of this publication may be reproduced in any<br />

form or by any means, without prior permission in writing from the Publisher<br />

and copyright owner. Whilst every care is taken to ensure accuracy<br />

of the information in this publication, the Publisher accepts no liability for<br />

damages caused by misinterpretation of information, expressed or implied,<br />

within the pages of the magazine. All advertisements are accepted on the<br />

understanding that the Advertiser is authorised to publish the contents of<br />

the advertisements, and in this respect, the Advertiser shall indemnify the<br />

Publisher against all claims or suits for libel, violation of right of privacy and<br />

copyright infringements. Panels & Furniture Asia is a controlled-circulation<br />

magazine with two issues a year. It is mailed free-of-charge to readers who<br />

meet a set of criteria. Paid subscription is available to those who do not<br />

fit our terms of control. Please refer to subscription form provided in the<br />

publication for more details.<br />

Printed by Times Printers Pte Ltd<br />

Scan to subscribe<br />

to WIA’s enewsletter<br />

Front cover image: Nick Kane<br />

4 WOOD IN ARCHITECTURE • ISSUE 1 – <strong>2023</strong>

in conjunction with<br />

SFS & MT VIETNAM <strong>2023</strong><br />

www.sfsmtwoodexpo.com<br />

30 JUNE TO 03 JULY <strong>2023</strong><br />

VENUE :<br />

TRUNG TÂM TRIỂN LÃM HỘI NGHỊ<br />

QUỐC TẾ VIỆT NAM VISKY EXPO<br />

QUANG TRUNG SOFTWARE CITY, ĐƯỜNG SỐ<br />

2, TÂN HƯNG THUẬN, QUẬN 12,<br />

THÀNH PHỐ HỒ CHÍ MINH 70000, VIETNAM<br />

IMAGES: LEITZ TOOLING<br />

Organised by:<br />

PABLO<br />

PUBLISHING<br />

& EXHIBITION<br />

PTE LTD<br />

Official Media:<br />

Contact us:<br />

sales@pabloasia.com<br />

+65 62665512<br />

WECHAT<br />

CONTACT

NEWS<br />

US IMPORTS OF ENGINEERED<br />

WOOD FLOORING RISE BY 11%<br />

According to the Decorative Hardwoods<br />

Association, imports of multi-layered<br />

wood flooring into the US rose by<br />

more than 11% in value to more than<br />

US$1.3bn and 7% in volume to more<br />

than 761 million square feet in 2022.<br />

Data from the US <strong>In</strong>ternational Trade<br />

Commission showed that there were<br />

strong increases that followed growth<br />

of more than 31% in volume in 2021<br />

compared to 2020.<br />

Asia, in particular South East Asia,<br />

swept the top few positions. Imports<br />

from Vietnam rank first, increasing by<br />

nearly one-third in 2022 from 2021,<br />

with approximately 209 million square<br />

feet imported and $311m in value.<br />

Cambodia, China, Malaysia, Thailand<br />

and <strong>In</strong>donesia followed after, although<br />

Cambodia and China saw a fall in<br />

volume compared to 2021, with 4.1%<br />

and 20.4% decrease respectively, and a<br />

fall in value with 2.6% and 16.2%.<br />

<strong>In</strong> contrast, Malaysia, Thailand and<br />

<strong>In</strong>donesia recorded robust increases<br />

in volume and value. Malaysia<br />

experienced a 34.4% increase in<br />

volume and 39.8% in value, Thailand<br />

with 46% and 53.4% increases, and<br />

<strong>In</strong>donesia with 31.5% and 24.1%<br />

increases. WIA<br />

SUMITOMO FORESTRY ESTABLISHES JOINT VENTURE<br />

FOR ENTRY INTO UK REAL ESTATE MARKET<br />

Sumitomo Forestry has announced it<br />

has jointly established three companies<br />

— Bywater SFC Holdings, Bywater SFC<br />

Management and Bywater SFC <strong>In</strong>vestments,<br />

or collectively known as Bywater SFC —<br />

with British real estate developer Bywater<br />

Properties.<br />

With a shared business vision to realise<br />

decarbonisation, Sumitomo Forestry and<br />

Bywater are developing a six-storey mass<br />

timber office building in London, UK.<br />

The establishment of Bywater SFC will<br />

serve to further strengthen the relationship<br />

of these two companies. It also marks<br />

Sumitomo Forestry’s full-scale entry into<br />

the UK real estate development market<br />

to promote environmentally conscious<br />

properties and mass timber constructions in<br />

Europe.<br />

Bywater specialises in the development,<br />

planning and management of real estate<br />

properties, primarily offices. It has developed<br />

mass timber and environmentally conscious<br />

properties in UK cities such as London,<br />

Manchester, Glasgow and Belfast.<br />

Sumitomo Forestry Group is engaged in a range<br />

of businesses revolving around wood, including<br />

forest management, timber and building<br />

material procurement and manufacturing,<br />

wooden construction, and wood biomass power<br />

generation.<br />

Within the construction industry, it is currently<br />

involved in the development of 4,000 mass<br />

timber build-to-rent housing units per year<br />

using 2×4 construction, as well as numerous<br />

medium- to large-scale mass timber<br />

constructions both in Japan and abroad, such<br />

as a 15-storey office building in Melbourne,<br />

Australia, a six-storey office building in London,<br />

UK, a seven-storey office building in Dallas, US,<br />

and a three-storey office building in Atlanta, US.<br />

<strong>In</strong> February 2022, Sumitomo Forestry<br />

established Sumirin UK which has been<br />

collaborating with Bywater to develop the<br />

London office building.<br />

Bywater SFC will develop real estate properties<br />

under the Bywater brand name. Its expansion<br />

into the European market is planned to<br />

include developing mass timber multi-family<br />

dwellings, refurbishing buildings, and several<br />

environmentally conscious projects using<br />

existing construction methods.<br />

According to Sumitomo Forestry, demand for<br />

environmentally conscious real estate is high<br />

in Europe, which leads the world in terms of<br />

climate change policies.<br />

Under the UK’s Assessment of Environmental<br />

Performance of Buildings (BS EN15978),<br />

for buildings constructed of wood from<br />

sustainable forests and designed so that<br />

the wood is reused after demolition, wood<br />

carbon sequestration can be subtracted in the<br />

calculation of the building’s Whole Lifecycle<br />

Carbon (WLC) emissions.<br />

The UK ranks number one in Europe in terms<br />

of commercial real estate investments and the<br />

number of residential transactions, as reported<br />

by the European Mortgage Federation.<br />

Recent advances in wood fireproofing and<br />

other technologies have led to the streamlining<br />

of building certification and administrative<br />

licensing systems, resulting in an increase in<br />

the number of medium- to large-scale mass<br />

timber construction projects. WIA<br />

6 WOOD IN ARCHITECTURE • ISSUE 1 – <strong>2023</strong>

NEWS<br />

MORE OPPORTUNITIES FOR WOOD IN<br />

CHINA’S CONSTRUCTION INDUSTRY<br />

Back in October 2022, the municipal government<br />

of Shanghai began to promote low-carbon,<br />

zero-carbon and even negative carbon emission<br />

technology innovations to support the carbon<br />

peak and carbon neutrality strategies for the city.<br />

According to Canada <strong>Wood</strong> Group, Shanghai<br />

officials are reportedly working on positioning<br />

the city as an exemplary model for the national<br />

double carbon goals, to reach carbon peak by<br />

2030 and carbon neutrality by 2060.<br />

Ten action plans were formulated to support<br />

the goals, which includes the zero-carbon<br />

technologies of urban and rural construction<br />

and transportation areas.<br />

The government published an official notice<br />

for the Carbon Peak and Carbon Neutrality<br />

Implementation Plan with Science and<br />

Technology Backing, which has been<br />

announced with the participation of six<br />

municipal authorities.<br />

The implementation plan sets specific<br />

targets, such as the R&D of low-carbon<br />

related technology systems covering energy,<br />

industry, construction, and transportation<br />

areas; completion of demonstration projects;<br />

and establishment of carbon neutralityrelated<br />

laboratories and green technological<br />

innovation centres.<br />

To promote the green and low-carbon<br />

construction of urban areas, communities and<br />

rural areas, the plan promotes the R&D of key<br />

technologies for carbon reduction throughout<br />

the lifecycle of buildings.<br />

It specifically lists low-carbon or zerocarbon<br />

building materials for design and<br />

construction, calling for action on the<br />

R&D of new building materials as well as<br />

structural systems with natural materials<br />

that can sequester carbon, including wood<br />

structures.<br />

During the China-Canada Green Low Carbon<br />

Construction Exchange organised by<br />

Forestry <strong>In</strong>novation <strong>In</strong>vestment (FII) China,<br />

the Shanghai Management Commission of<br />

Housing and Urban-Rural Development also<br />

reiterated the importance of the inclusion of<br />

wood in the plan.<br />

China’s carbon peak and carbon neutrality<br />

strategy are creating more opportunities for<br />

wood construction development across the<br />

country, with the carbon advantages of wood<br />

gaining more awareness among Chinese<br />

government stakeholders. WIA<br />

WOOD IN ARCHITECTURE • ISSUE 1 – <strong>2023</strong> 7

NEWS<br />

CANADA WOOD KOREA KICKS OFF<br />

SECOND NLT DEMONSTRATION IN KOREA<br />

According to Canada <strong>Wood</strong> Korea, South<br />

Korea envisions timber as the key construction<br />

material to reach its carbon neutrality target.<br />

The trend of building with wood using mass<br />

timber technology in larger and taller public<br />

buildings has been reinforced by repeated<br />

statements from various levels of government<br />

in recent years.<br />

Canada aims to take advantage of this market<br />

opportunity, particularly in the public building<br />

sector, by promoting the use of nail-laminated<br />

timber (NLT), a cost-effective substitute<br />

to cross-laminated timber (CLT) products.<br />

For cost-sensitive public building projects<br />

funded by the government, the simplicity and<br />

aesthetic quality of NLT have a unique catch.<br />

To generate meaningful impact, Canada <strong>Wood</strong><br />

has pivoted their demonstration efforts in<br />

this direction to showcase the use of NLT in<br />

public buildings such as a community centre<br />

and enable the Korean industry to get through<br />

the learning curve when it comes to design,<br />

manufacturing and installation.<br />

Their inaugural project was a community<br />

building in Jinju city focused on introducing<br />

various NLT roof configurations in a gable roof<br />

design.<br />

The second NLT demonstration is underway<br />

now. The project is located in Seungsan Village,<br />

a historic settlement featuring classic Korean<br />

wooden dwellings, and is famous for being<br />

the hometown of several corporate founders<br />

of large conglomerates like GS and LG Group.<br />

As a popular tourism destination, the demo<br />

project will be home to many travellers.<br />

Drawing upon knowledge gleaned from the<br />

first project, this building has incorporated<br />

The second NLT demonstration is underway in<br />

Seungsan Village (Image: Canada <strong>Wood</strong> Korea)<br />

various design components that improve<br />

manufacturing and construction cost. For<br />

example, its shed roof layout facilitates simpler<br />

and consistent NLT roof setup, resulting in<br />

cheaper production and no need for the steel<br />

columns seen in the first project.<br />

The Jinju municipality is encouraging the<br />

utilisation of wood and is the host city of the<br />

inaugural <strong>Architecture</strong> Festival in 2022, which<br />

explicitly recognised wood structures for their<br />

ability to maintain carbon neutrality. WIA<br />

LUNAWOOD TO INCLUDE FIRE PROTECTION<br />

TREATMENT IN THEIR PRODUCTS<br />

Lunawood has entered into a partnership<br />

agreement with Nordic Timber Labs for the fire<br />

protection of planed Lunawood Thermowood<br />

products at their production facility in Nastola,<br />

Lahti, Finland.<br />

Lunawood is the producer of Lunawood<br />

Thermowood, a range of thermally treated<br />

wood products for facades, interiors and<br />

landscaping. Nordic Timber Labs is a provider<br />

of fire impregnation services.<br />

Himmelbyen, 2017-2019 by The Seasons (Image:<br />

Terkel Bo Grum-Schwensen/Bergsten Timber)<br />

The use of wood materials in facades has<br />

increased around the world, especially in<br />

growth centres where architects want to use<br />

natural wood products to bring warmth and<br />

soften modern architecture, and help replace<br />

fossil building materials with wood products<br />

that act as carbon stores.<br />

Without fire protection treatment,<br />

Thermowood belongs to the same fire<br />

class D as untreated wood. Using the<br />

fire impregnation method, Lunawood<br />

Thermowood will reportedly meet the<br />

required fire class B of the facade structures<br />

of P1 and P2 buildings.<br />

The used technology and method for fire<br />

protection is a documented, CE-marked<br />

treatment process which enables consistent<br />

quality in fire protection.<br />

“The cornerstone of Lunawood strategy is<br />

sustainability. Thanks to the fire impregnation<br />

technique we are able to bring our sustainable<br />

Thermowood to new heights in larger projects,<br />

replacing fossil-based materials. <strong>In</strong> addition,<br />

working with a local impregnation partner<br />

helps us minimise the overall climate footprint<br />

of the final product,” explained Maija Masalin,<br />

vice-president of marketing and product<br />

management at Lunawood.<br />

“We are happy that such specialised<br />

expertise has been established in Finland.<br />

This co-operation increases the degree<br />

of domesticity and both usability and<br />

competitiveness of sustainable wood<br />

products manufactured entirely in Finland in<br />

the international market.”<br />

Vincent Parasnis, CEO of Nordic Timber Labs,<br />

concluded: “We are proud to be teaming up<br />

with such a competent and well-respected<br />

innovator in the Thermowood space, and it<br />

is exciting bringing novel technology to the<br />

Finnish timber market. The global commercial<br />

footprint of Lunawood products helps us<br />

enable fire safe wood construction all around<br />

the world.” WIA<br />

8 WOOD IN ARCHITECTURE • ISSUE 1 – <strong>2023</strong>

NEWS<br />

BEST USE OF CERTIFIED TIMBER PRIZE<br />

WINNER AWARDED BY PEFC AND WAF<br />

Paseo Mallorca 15, designed by OHLAB<br />

architects, has won the Best Use of Certified<br />

Timber prize, supported by the Programme for<br />

the Endorsement of Forest Certification (PEFC)<br />

at the 2022 World <strong>Architecture</strong> Festival (WAF).<br />

The prize recognises architects for their use<br />

of certified timber as a key element of their<br />

project and something that makes it stand out<br />

in terms of sustainability, innovation, quality<br />

and aesthetics.<br />

The judges praised the project for its<br />

“masterful control of light” and “timeless<br />

beauty and technical innovation”.<br />

“The building shows the many ways that PEFCcertified<br />

material can deliver sustainability to<br />

global building design,” said Fabienne Sinclair,<br />

head of marketing of PEFC, who presented the<br />

award.<br />

CELEBRATING LOCAL TRADITION<br />

AND SUSTAINABILITY<br />

Set on a tree-lined promenade in the heart of<br />

the Spanish city of Palma de Mallorca, Paseo<br />

Mallorca 15 is a new residential complex has<br />

sustainability and energy efficiency at heart.<br />

The facade, supplied by GRUPO GUBIA, is<br />

made of PEFC-certified Scots pine that has<br />

been thermally modified due to the building’s<br />

close proximity to the sea. This treatment<br />

gives the timber minimal contractions and<br />

expansion movements. Vertical timber slats<br />

are brushed on all sides, with different sections<br />

and separations, then fixed to an anodised<br />

aluminium frame.<br />

According to PEFC, more than 350 fixed and<br />

sliding timber panels change the vision of the<br />

building continually and act as a solar filter or<br />

brise soleil.<br />

The design reflects traditional Majorcan<br />

carpentry and according to OHLAB is a<br />

“re-reading of the island’s traditional<br />

materials and systems…carried out in an<br />

abstract and contemporary key, creating a<br />

building that seeks to be totally efficient and<br />

sustainable as well as creating a pleasant<br />

and stimulating sensory experience for its<br />

inhabitants”.<br />

The project has been designed according to<br />

Passivhaus standards to achieve maximum<br />

energy efficiency and to provide a healthy,<br />

comfortable living environment.<br />

To know more about Paseo Mallorca 15, flip to<br />

page 46. WIA<br />

WOOD IN ARCHITECTURE • ISSUE 1 – <strong>2023</strong> 9

NEWS<br />

AHEC PARTICIPATES IN MADRID DESIGN FESTIVAL<br />

WITH TWO WOOD DESIGN SHOWCASES<br />

1<br />

1 The mentors of SLOW Spain, as well as designers for the workpieces<br />

showcased for Natural Connections. From left: Jorge Penadés,<br />

Álvaro Catalán de Ocón, <strong>In</strong>ma Bermúdez and Moritz Krefter<br />

2 The furniture pieces showcased for SLOW Spain<br />

2<br />

The American Hardwood Export Council<br />

(AHEC) has presented two wood design<br />

projects at the Madrid Design Festival<br />

<strong>2023</strong>, held from 7 Feb-12 Mar <strong>2023</strong>.<br />

The first is ‘SLOW Spain: Slow design for<br />

fast change’, a project in collaboration<br />

with nine Spanish design schools that<br />

showcases the talent and ideas of<br />

the emerging design generation while<br />

exploring the material possibilities<br />

of four sustainable but underused<br />

American hardwoods for furniture<br />

design.<br />

The projects have been mentored by<br />

designers <strong>In</strong>ma Bermúdez and Moritz<br />

Krefter from Studio <strong>In</strong>ma Bermúdez,<br />

Álvaro Catalán de Ocón from studio<br />

ACdO, and Jorge Penadés from Oficina<br />

Penadés.<br />

Together with the students, they<br />

have worked to refine and shape the<br />

students’ ideas using red oak, maple,<br />

cherry and tulipwood.<br />

The exhibition aims to show the<br />

importance of ‘slow design’ and how<br />

this philosophy can be applied<br />

in furniture creation. As well as<br />

being an opportunity to learn<br />

more about the importance of<br />

sustainability in furniture design,<br />

the ‘slow’ approach can contribute<br />

to a positive change in the current<br />

culture of fast furniture.<br />

Each of the pieces has been<br />

handcrafted in the La Navarra<br />

carpentry in Madrid. The final<br />

designs mix aesthetics with<br />

functionality, and range from side<br />

tables to a bookcase-screen, a desk<br />

or the reinvention of a chair.<br />

“SLOW is about education and<br />

opportunity. We have attempted<br />

to fill the gap in design education<br />

which often does not provide an<br />

in-depth experience for design<br />

students to learn about and work<br />

with hardwood materials,” said<br />

David Venables, European director<br />

of AHEC.<br />

The second project is ‘Natural<br />

Connections’, which reportedly<br />

aims to connect materials and people in<br />

a playful, conscious and nature-focused<br />

way.<br />

The aforementioned mentor-designers<br />

were invited to create three pieces of<br />

furniture for public spaces, designed to<br />

help people encounter and rediscover<br />

nature, using red oak, maple or cherry.<br />

The result is a collection of pieces that<br />

promote fun and interaction.<br />

“Our collaboration with the Madrid<br />

Design Festival, Matadero Madrid and<br />

three of the most important design<br />

studios in Spain has provided an amazing<br />

opportunity to connect the public with<br />

the worlds of design, craft, and wood,”<br />

said Venables.<br />

“The design teams worked with<br />

maple, cherry, and red oak to create<br />

playful, original, and highly innovative<br />

installations that we hope will provide<br />

engagement, excitement and a<br />

connection for visitors to these wonderful<br />

natural materials.” WIA<br />

Images: AHEC<br />

10 WOOD IN ARCHITECTURE • ISSUE 1 – <strong>2023</strong>

NEWS<br />

PUBLIC HOUSES IN SOUTH AUSTRALIA<br />

TO ONLY USE LOCAL MATERIALS<br />

The state government of South Australia has<br />

announced that public houses built in South<br />

Australia must use products manufactured<br />

in the state.<br />

This means the state government requires<br />

core products used in construction, including<br />

bricks, timber frames, concrete, reinforcing<br />

steel, steel frames, windows, security doors<br />

and steel for roofing, fencing and rainwater<br />

tanks, to be manufactured locally in South<br />

Australia.<br />

house framing timber and about 25% of the<br />

nation’s particleboard, and it is great news<br />

that this policy will support our domestic<br />

manufactured product over imported product,<br />

thereby support local jobs.”<br />

Furthermore, the cross-laminated timber<br />

(CLT) and glue-laminated timber (glulam)<br />

expansion by Timberlink is expected to help<br />

secure the southeast region of Australia as one<br />

of Australia’s leading timber manufacturing<br />

regions, unlocking further economic activity for<br />

the region. WIA<br />

Source: Timberbiz<br />

According to Timberbiz, this announcement<br />

came after government reforms, where the<br />

new government has made promises to<br />

make policy changes that will benefit local<br />

businesses, manufacturers and workers.<br />

The state government will also commit<br />

AU$177.5m to build 400 new homes and<br />

refurbish another 350, which will benefit<br />

local manufacturers and South Australia<br />

businesses, especially in times of a stressed<br />

housing market.<br />

The government is further targeting an<br />

increase of $425m per year in work awarded<br />

to South Australia businesses.<br />

“This is a big win for manufacturing<br />

industries in South Australia, particularly<br />

the forest industries, giving such sectors<br />

a boost of confidence and recognition by<br />

the state government,” said Nathan Paine,<br />

CEO of South Australian Forest Products<br />

Association.<br />

“Timber frames are a core manufactured<br />

product in South Australia that supports<br />

our residential construction and building<br />

industries, and we are please that locally<br />

grown trees [will help in] building and<br />

refurbishing affordable public homes for<br />

South Australians.<br />

“The South Australian forest industries<br />

process about 35% of Australia’s structural<br />

WOOD IN ARCHITECTURE • ISSUE 1 – <strong>2023</strong> 11

BIG PICTURE<br />

What is the role<br />

of a library?<br />

12 WOOD IN ARCHITECTURE • ISSUE 12 – <strong>2023</strong> 2022

BIG PICTURE<br />

Libraries have long developed past their sole purpose of<br />

collecting books for use. As public spaces where<br />

the community can gather to work, play, and<br />

socialise, and as models for sustainability,<br />

the following projects showcase timber<br />

libraries in all their versatility, encapsulating<br />

not only culture, but also enjoyment,<br />

neighbourliness, and warmth.<br />

WOOD IN ARCHITECTURE • ISSUE 1– <strong>2023</strong> 13

BIG PICTURE<br />

2<br />

1<br />

Climate-conscious<br />

design<br />

PROJECT: Microlibrary Warak Kayu<br />

LOCATION: Semarang, <strong>In</strong>donesia<br />

ARCHITECTURE FIRM: SHAU <strong>In</strong>donesia<br />

STRUCTURAL ENGINEER: Joko Agus Catur Wibowo<br />

RESEARCH AND PREFABRICATION:<br />

Kayu Lapis <strong>In</strong>donesia<br />

CONTRACTOR: RAH Contractor<br />

PHOTOGRAPHY: KIE & team<br />

A NEIGHBOURHOOD ICON<br />

The Microlibrary Warak Kayu is<br />

the fifth built project within the<br />

Microlibrary series, an <strong>In</strong>donesian<br />

initiative to increase reading interest<br />

by creating socially-performative<br />

multifunctional community spaces<br />

with environmentally conscious<br />

design and materials, which aim to<br />

serve low-income neighbourhoods in<br />

<strong>In</strong>donesia. Designed by architecture<br />

firm SHAU and prefabricated by<br />

Kayu Lapis <strong>In</strong>donesia, an integrated<br />

wood manufacturing company, this<br />

project is a community, private sector<br />

and government collaboration. The<br />

microlibrary charges no entry fee and<br />

is run by Harvey Centre, a locallyembedded<br />

charity group in Semarang,<br />

the <strong>In</strong>donesian capital of Central<br />

Java, in coordination with the local<br />

government.<br />

Architecturally it represents SHAU’s<br />

passive climate design, material,<br />

and typology experimentation for<br />

the tropical context. After numerous<br />

design iterations, the most favourable<br />

design concept was the one with<br />

the whole building being elevated,<br />

like a traditional rumah panggung —<br />

which translates to house on stilts —<br />

because it does not only function as a<br />

library but adds value by becoming a<br />

neighbourhood and community centre,<br />

at the same time being used to promote<br />

<strong>In</strong>donesian engineered wood products<br />

and manufacturing capabilities. By<br />

elevating the library, various spatial<br />

configurations, multiple programmes<br />

and a range of activities can be offered.<br />

On the ground is a large semi-outdoor<br />

area which can be used for workshops,<br />

as well as a wide tribune seating at the<br />

entrance for watching presentations or<br />

movies, and to grab children’s attention,<br />

a wooden swing. The ground area is<br />

framed by a ring of planter boxes to<br />

create a more intimate atmosphere.<br />

Upstairs in the library itself, there is a<br />

net where kids can lie down, relax and<br />

read but also directly communicate<br />

14 WOOD IN ARCHITECTURE • ISSUE 1 – <strong>2023</strong>

BIG PICTURE<br />

2 3<br />

1 The library has a net where kids can lie down,<br />

relax and read but also directly communicate<br />

with people underneath<br />

2 Bangkirai-based finger joint laminate was<br />

used for columns and beams<br />

3 A wide tribune seating at the entrance for<br />

watching presentations or movies<br />

with parents and friends in the space<br />

underneath. It is important to have this multiprogrammatic<br />

approach to make the library a<br />

popular place, since reading alone is not yet<br />

considered a fun activity in the country.<br />

The Microlibrary Warak Kayu is the latest<br />

addition to the architecture landscape of<br />

Semarang. It is built at Taman Kasmaran, a<br />

public square in the city centre with direct<br />

proximity with a river and has a view to<br />

Kampung Pelangi, or Rainbow Village, a local<br />

tourist attraction. The square has a cafeteria<br />

with warungs, also known as small vendors,<br />

underneath, and there is a local school nearby.<br />

The library will be part of the city’s tourism<br />

route where the bus tour will stop. <strong>In</strong> that<br />

sense, the library serves not only the local<br />

neighbourhood but is embedded in the larger<br />

city network and thus has an increased reach.<br />

A MODEL FOR FSC-CERTIFIED<br />

CONSTRUCTION<br />

The building can be seen as a living<br />

educational spot for wood material and<br />

construction techniques and is <strong>In</strong>donesia’s<br />

first Forest Stewardship Council (FSC)<br />

project certified building. This is possible<br />

with the donor and client, Arkatama<br />

Isvara Foundation. A variety of Kayu Lapis<br />

<strong>In</strong>donesia’s available materials and products<br />

for construction are used and only the<br />

foundation, footings and roof cladding are not<br />

wood-based materials.<br />

The design process includes a bottom-up<br />

process, where all available products in the<br />

factory were first evaluated, and the design<br />

was developed from that. As one of the<br />

design-exploration results, the brise soleil<br />

was based on the Zollinger Bauweise, a<br />

construction system developed in the 1920s<br />

in Germany. It is a form of reciprocal system,<br />

resulting in a distinctive slightly shifted<br />

diamond pattern. This pattern happens to<br />

resemble a local mythical creature, Warak<br />

Ngendog, and its dragon-like skin, displayed<br />

during annual festivals in Semarang. Hence<br />

the name Warak Kayu in <strong>In</strong>donesian,<br />

meaning wooden Warak, which is a positive<br />

narrative for communicating the design to a<br />

wider audience.<br />

CLIMATE DESIGN, MATERIAL AND<br />

CONSTRUCTION<br />

The Microlibrary Warak Kayu is designed<br />

around passive climatic design aspects: No air<br />

conditioning is used, and therefore no energy is<br />

spent. Semarang has a tropical monsoon climate<br />

according to Köppen climate classification with<br />

temperatures up to 34°C during the end of dry<br />

season. The building is cooled down by means<br />

of cross ventilation and solar heat is prevented<br />

from entering using shading elements. The roof<br />

overhang provides shading around noon. The<br />

longer facades are oriented north-west and<br />

south-east due to site restrictions. Therefore, an<br />

eggcrate-like deep screen is designed to block<br />

the lower sun altitude angles in the mornings and<br />

afternoons. That means direct sunlight cannot<br />

enter the building in an unobstructed way. As a<br />

result, the diffuse-reflected sunlight is sufficient<br />

to read books without artificial lighting. <strong>In</strong><br />

addition, the depth requirement of the Zollinger<br />

brise soleil was determined by the angular<br />

relationship between the sun path and building<br />

rotation. The cross ventilation aspect also helps<br />

to drag moisture out of the building and prevent<br />

books from getting mouldy or damaged.<br />

WOOD IN ARCHITECTURE • ISSUE 1– <strong>2023</strong> 15

BIG PICTURE<br />

1<br />

4<br />

5<br />

4 Only bangkirai<br />

is used for the<br />

main structure of<br />

columns, beams<br />

and secondary<br />

beams<br />

5 The Zollinger<br />

brise soleil,<br />

eggcrate design<br />

blocks the lower<br />

sun altitude<br />

angles in the<br />

mornings and<br />

afternoons<br />

<strong>Wood</strong> as construction material<br />

outperforms many other materials<br />

regarding embodied energy, water and<br />

air pollution, carbon footprint, and<br />

it is also a re-growing material. For<br />

the Microlibrary Warak Kayu all wood<br />

materials are in compliance to the SVLK<br />

Timber Legality Verification for certified<br />

timber, and almost all according to<br />

FSC certification. <strong>Wood</strong> is sustainably<br />

logged in Central Kalimantan, then<br />

shipped from Sampit over the Java<br />

Sea southwards to Semarang and<br />

the factory. The whole process also<br />

includes nursery, replanting and<br />

harvesting time planning to maintain<br />

sustainability for the coming years.<br />

Various types of wood products and<br />

wood species were used. For the main<br />

structural components like columns<br />

and beams, bangkirai-based finger joint<br />

laminate — a tropical hardwood with<br />

high weather resistance often used for<br />

outdoor furniture and decks — was<br />

used. For decking and the Zollinger<br />

brise soleil, different meranti-based<br />

plywood types in various thicknesses<br />

were employed.<br />

The main structure of columns, beams<br />

and secondary beams has the highest<br />

volume of all materials. Here, only<br />

bangkirai is used. The by-products of<br />

this manufacturing in form of leftover<br />

and small-cut wood pieces are<br />

trimmed and processed for finger joint<br />

strip elements. That means the whole<br />

structural elements also make use of<br />

factory leftovers.<br />

Apart from the concrete foundation all<br />

wooden elements are prefabricated at<br />

the Semarang factory and transported<br />

within 20km to the site. Prefabrication<br />

of the elements at the factory, on-time<br />

delivery and on-site assembly mean<br />

less noise, dust and generally less<br />

harmful impacts on the direct<br />

environment during assembly, and at<br />

the same time, faster construction time.<br />

<strong>In</strong> addition, with prefabrication at the<br />

factory, due to better trained workers,<br />

modern tools, higher safety standards,<br />

a safer construction process but also<br />

higher degree of precision is reached,<br />

and with that, fewer mistakes are made.<br />

This in return produces less waste.<br />

<strong>In</strong> general, wooden waste material<br />

produced at the factory can be collected<br />

more easily because no sorting is<br />

needed. Also, there is minimal distance<br />

involved in transporting waste for<br />

recycling, and valuable leftovers from<br />

cutting can be used for other products<br />

consisting of smaller pieces also made<br />

at the factory. The construction of<br />

the main structural elements uses a<br />

mixture of engineered connections and<br />

carpenter joints — most notably scarf<br />

joints — for prolonging the main beams<br />

due to manufacturing practicality.<br />

16 WOOD IN ARCHITECTURE • ISSUE 1 – <strong>2023</strong>

BIG PICTURE<br />

1<br />

1<br />

A hybridised<br />

public space<br />

PROJECT: Lea Bridge Library Pavilion<br />

LOCATION: Leyton, London, UK<br />

ARCHITECTURE FIRM: Studio Weave<br />

CLIENT: London Borough of Waltham Forest<br />

STRUCTURAL ENGINEER: Timberwright<br />

FURNITURE AND CARPENTRY:<br />

Sebastian Cox<br />

PHOTOGRAPHY: Jim Stephenson<br />

COMPLETION: October 2021<br />

2<br />

London-based architecture practice Studio Weave has<br />

extended the Lea Bridge Library in east London, adding<br />

a cafe and adaptable community space with improved<br />

connection to the library’s gardens, resulting in a revived<br />

civic heart for the Borough of Waltham Forest.<br />

1 The Lea Bridge Library<br />

2 A library can offer places to work, learn,<br />

socialise, and gather, beyond just reading<br />

To connect the local and future community as the<br />

neighbourhood undergoes a period of cultural growth and<br />

WOOD IN ARCHITECTURE • ISSUE 1– <strong>2023</strong> 17

BIG PICTURE<br />

3<br />

regeneration, Studio Weave explored the<br />

changing role of a library in modern civic<br />

infrastructure conceiving a new wing that<br />

offers places to work, learn, socialise, and<br />

gather.<br />

Je Ahn, director of Studio Weave said: “We<br />

envisaged the Lea Bridge Library extension<br />

as a hybridised public space; a new town<br />

hall with wider opportunities for citizens to<br />

participate more fully in public life. Hybridised<br />

public spaces combine and maximise<br />

collective resources, and are unexpected<br />

engine rooms for community connection.<br />

“Since completing the new library extension,<br />

as locals we have witnessed first-hand the<br />

impact it has had on the community. The<br />

extension is always brimming with occupants:<br />

children’s parties on weekends, students,<br />

mother’s groups, and workshop attendees<br />

each week. We are proud to have contributed<br />

an environmentally-focused space for Leyton’s<br />

social and cultural growth.”<br />

The new 250m 2 wing sits to the rear of the<br />

Edwardian red brick library and occupies the<br />

western boundary of the site, designed to<br />

lightly touch the existing heritage building and<br />

its green space, Friendship Gardens. Studio<br />

Weave utilised the existing western garden<br />

wall as a structural spine, anchoring the<br />

structure and bulk of the building to one side,<br />

ensuring a seamless, open connection to the<br />

gardens. Cantilevered beams of high-strength<br />

laminated veneer lumber (LVL) support a<br />

length of overhead glazing and floating ceiling<br />

of timber battens. Floor-to-ceiling glazing<br />

along the entire east elevation invites the<br />

outdoors in, creating a visual and physical<br />

connection to Friendship Gardens.<br />

Studio Weave designed the new Lea Bridge<br />

Library extension to sit harmoniously in<br />

between existing mature trees in Friendship<br />

Gardens, resulting in a rectangular floor<br />

plan punctuated by a semi-circular glass cut<br />

out. The pavilion curves in and steps up at a<br />

central pinch point to protect the root system<br />

4<br />

18 WOOD IN ARCHITECTURE • ISSUE 1 – <strong>2023</strong>

BIG PICTURE<br />

of a neighbouring mature Common Lime<br />

tree. The architects used this momentary<br />

squeeze in the plan created by the sweeping<br />

concave glass as an opportunity to divide the<br />

pavilion. A pivoting timber door hangs flush<br />

with wall joinery and swings across to create<br />

a flexible private events space, offering a<br />

community asset while also future-proofing a<br />

further revenue stream for the library. A long<br />

colonnade stretches the length of the new<br />

extension, featuring a gently graded natural<br />

stone walkway to ensure level access to the<br />

rear event space. A facade of zig-zagging red<br />

precast concrete panels and columns nods<br />

to the tone of the brick used in the existing<br />

library, and conceal drainage which captures<br />

and redirects water down to the tree roots<br />

below the building.<br />

Accessibility is central to the success and<br />

popular use of the Lea Bridge Library Pavilion.<br />

Studio Weave designed two new access points<br />

to draw visitors in through the gardens at<br />

the side and rear of the site, bypassing the<br />

library’s quiet zone. The main entrance and<br />

foyer on Lea Bridge Road were refurbished to<br />

include new wash facilities, buggy parking and<br />

an upstairs staff room. From the foyer, the new<br />

cafe welcomes visitors before opening into the<br />

main space. A continuous wall of fluted timber<br />

joinery connects bookshelves with in-built<br />

banquette seating, creating interspersed open<br />

reading rooms. The open plan layout can be<br />

adapted for a range of cultural, recreational<br />

and community activities and be used at<br />

different times of day by different local groups<br />

and library users.<br />

The architects’ approach to sustainability<br />

can be felt throughout the building. Studio<br />

Weave balanced a light, open-plan community<br />

space that benefits from a considered passive<br />

cooling strategy supported by mechanical<br />

heat recovery ventilation (MVHR). The ceiling<br />

is positioned to protect the exposed aggregate<br />

floor from direct sunlight, and the continuous<br />

glass wall opens at intervals to allow for<br />

natural cross ventilation.<br />

Reuse is a strong theme throughout the new<br />

pavilion. All internal joinery and furniture<br />

timber were salvaged from trees felled across<br />

the publicly owned streets and parks across<br />

London in an effort to reduce the carbon<br />

footprint of the pavilion and reuse existing<br />

waste materials. The species of trees salvaged<br />

include London plane, poplar, sycamore, ash,<br />

holm oak, turkey oak, sequoia, horse chestnut<br />

and more, and add a variety of textures and<br />

tones to the custom-designed fitted and<br />

loose furniture. Studio Weave worked closely<br />

with local furniture maker Sebastian Cox,<br />

designing an in-built banquette with fluted<br />

timber shelving that stretches along the<br />

pavilion, reinforcing the link to the library<br />

while creating a natural visual language which<br />

is echoed by the trees outside in Friendship<br />

Gardens. Sebastian Cox also designed custom<br />

tables, chairs and sofas for the new space, all<br />

crafted from 25m 3 of waste timber.<br />

The project is a community element of<br />

the Borough of Waltham Forest’s cultural<br />

regeneration, supported by £411,000 from<br />

the Greater London Authority’s Good Growth<br />

Fund. Studio Weave is now working on the<br />

second phase of the library’s development,<br />

re-landscaping the garden and adding in play<br />

facilities to be delivered by summer <strong>2023</strong>.<br />

The extension has revived the library as a key<br />

cultural and community hub through which<br />

social cohesion is fostered, offering events,<br />

activities and opportunities to empower<br />

local residents. Where the library offers<br />

access to a wealth of knowledge, Studio<br />

Weave’s architecture offers an open public<br />

asset and space for the community to share<br />

experiences.<br />

5<br />

3 All internal joinery<br />

and furniture timber<br />

was salvaged from<br />

trees felled across<br />

London streets and<br />

parks<br />

4 Large windows<br />

for users to enjoy<br />

the fresh air and<br />

sunshine<br />

5 Cantilevered beams<br />

of high-strength LVL<br />

Alpa Depani, head of strategic planning and<br />

design at Waltham Forest Council, concluded:<br />

“The Lea Bridge Library extension is a warm<br />

and generous addition that responds with<br />

care to both the existing historic building,<br />

and the garden with its mature trees. It<br />

embeds sustainable principles and has been<br />

transformative in terms of opening up the<br />

possibilities for community life and activity,<br />

as proved by its popularity with a range of our<br />

residents.”<br />

WOOD IN ARCHITECTURE • ISSUE 1– <strong>2023</strong> 19

BIG PICTURE<br />

20 WOOD IN ARCHITECTURE • ISSUE 1 – <strong>2023</strong><br />

1

BIG PICTURE<br />

Durable and sustainable<br />

1 The New Library at Magdalene College<br />

2 The timber gable pitched roof<br />

PROJECT: New Library at Magdalene College<br />

ARCHITECTURE FIRM: Niall McLaughlin Architects<br />

CLIENT: Magdalene College<br />

TIMBER SUPPLIER: James Latham<br />

TIMBER EXTERNAL DOORS, WINDOWS, SHUTTERS AND CLADDING:<br />

Piper Joinery<br />

CLT STRUCTURE: Eurban<br />

CLT SUPPLY: Stora Enso<br />

GLULAM STRUCTURE: Neue Holzbau<br />

INTERNAL TIMBER DOORS AND SCREENS: Trojanwood Joinery<br />

TIMBER FLOORING: Pica Floorings<br />

PHOTOGRAPHY: Nick Kane<br />

COMPLETION: January 2021<br />

The new building at Magdalene College<br />

replaces cramped and poorly equipped<br />

facilities in the adjacent Pepys Building<br />

with a larger library, incorporating an<br />

archive facility and a picture gallery.<br />

The New Library is sited at a sensitive<br />

historic setting, along the boundary<br />

wall between the enclosed space of<br />

the Master’s Garden and the more<br />

open space of the Fellows’ Garden. Its<br />

placement extends the quadrangular<br />

arrangement of buildings and courts<br />

that developed from the monastic<br />

origins of the college site.<br />

2<br />

The library is approached from Second<br />

Court, through a little doorway and<br />

out under an old yew tree. From this<br />

corner visitors can sense the presence<br />

of the river opening out at the edge of<br />

the lawn. Niall McLaughlin Architects<br />

wanted to make the building a journey<br />

that gradually rose up towards the<br />

light. On the way up there would be<br />

rooms, galleries and places to perch<br />

with a book. At the top, there would<br />

be views out over the lawn towards<br />

the water. The architects wanted to<br />

create a variety of ways for someone to<br />

situate themselves depending on their<br />

WOOD IN ARCHITECTURE • ISSUE 1– <strong>2023</strong> 21

BIG PICTURE<br />

inclination. Visitors might sit in a grand hall,<br />

a small room, or tuck themselves into a tiny<br />

private niche.<br />

For the architects, good architecture plays<br />

variety of experience against the underlying<br />

order to produce harmony. The new library<br />

is based upon a logical latticework of<br />

interrelated elements. A regular grid of<br />

brick chimneys supports the floors and<br />

bookstacks and carries warm air up to<br />

ventilate the building. Between each set of<br />

four chimneys there is a roof lantern bringing<br />

light down into the spaces below: air rising<br />

and light falling. This regular array produces<br />

a natural hierarchy with narrow zones for<br />

circulation and wide zones for reading<br />

rooms. The delineation of load-bearing<br />

brick vertical structure, supporting spanning<br />

engineered timber horizontal structure is<br />

used to reinforce the organisational scheme.<br />

This creates an underlying pattern of warp<br />

and weft that the architects hope can be<br />

understood intuitively by people using the<br />

building.<br />

3<br />

3 Horizontal timber<br />

structure to reinforce<br />

the organisational<br />

scheme<br />

4 Engineered timber<br />

was used to reduce<br />

embodied carbon<br />

dioxide in the<br />

construction<br />

5 The timber window<br />

tracery will weather<br />

over time to become<br />

silvery grey<br />

The materiality and form of the new library<br />

are derived both from its context and from<br />

the college’s brief to make a highly durable<br />

and sustainable building. The older college<br />

buildings are of load-bearing brick, with<br />

timber floors and gabled pitched roofs<br />

structures. Brick chimneys animate the<br />

skyline and stone tracery picks out the<br />

fenestration. Niall McLaughlin Architects<br />

tried to make the new building from this set<br />

of architectural elements. They used timber<br />

instead of stone for the window tracery,<br />

which will weather over time to become<br />

silvery grey like stone colour. They worked<br />

carefully with their builders to find a variety<br />

of bricks that would match the tapestry-like<br />

quality of the older College buildings. At the<br />

same time, the New Library at Magdalene<br />

College is a modern building that employs<br />

passive ventilation strategies to minimise<br />

energy in use, and engineered timber<br />

structure to reduce carbon embodied in its<br />

construction.<br />

The New Library won the 26th RIBA Stirling<br />

Prize in 2022.<br />

4 5<br />

22 WOOD IN ARCHITECTURE • ISSUE 1 – <strong>2023</strong>

BIG PICTURE<br />

Warm,<br />

peaceful,<br />

tranquil<br />

PROJECT: Tonami Public Library<br />

LOCATION: Toyama, Japan<br />

ARCHITECTURE FIRM:<br />

MIKAMI Architects and<br />

Oshita Architects & Engineers<br />

AREA: 3,342.62m 2<br />

PHOTOGRAPHY: Kouji Horiuchi<br />

COMPLETION: November 2020<br />

1 1 A nighttime view of the<br />

library’s huge roof<br />

WOOD IN ARCHITECTURE • ISSUE 1– <strong>2023</strong> 23

BIG PICTURE<br />

The Tonami Public Library is a public<br />

library located in Tonami city, Toyama<br />

prefecture in Japan, facing the Sea<br />

of Japan. The countryside of Tonami<br />

has inherited a breathtaking rural<br />

landscape known as the ‘scattered<br />

villages’. The exterior of the main<br />

building conveys the reality of<br />

azumadachi there, a term which refers<br />

to a traditional Japanese house style.<br />

The concept of a ‘one-room library<br />

under a big roof’ was born from this<br />

image.<br />

The massive roof, like the large,<br />

gentle waves depicted, is a modern<br />

interpretation of azumadachi and a new<br />

landmark for Tonami city. The building<br />

is also positioned so that the road on<br />

the west side is parallel to the low<br />

eaves and the interior of the building<br />

is visible. The ceiling of this gently<br />

undulating main roof is approximately<br />

1,900m 2 and is finished with a design<br />

consisting of slender cedar planks.<br />

The total length of the cedar planks<br />

is 42km. The library is enveloped in<br />

the scent and warmth of dense wood,<br />

giving visitors a sense of peace and<br />

tranquility in a forest of books.<br />

<strong>In</strong>side the building, the ceiling inverts<br />

with the gentle waves of the main roof,<br />

connecting the two levels as one. The<br />

sloping ceiling on the north side of the<br />

building evokes a sense of liveliness.<br />

As one moves toward the back, the<br />

slope of the ceiling becomes gentler,<br />

and everyone, from children to the<br />

elderly, is enveloped by the warmth of<br />

1<br />

24 WOOD IN ARCHITECTURE • ISSUE 1 – <strong>2023</strong>

BIG PICTURE<br />

dense wood and natural light pouring<br />

in through the high windows. The<br />

facing staircase leading to the upper<br />

floor connects the upper and lower<br />

spaces, allowing visitors to freely view<br />

the entire interior from the second<br />

floor.<br />

<strong>In</strong> the interior, the combination of<br />

wood and poured concrete creates<br />

a calm reading space, while the<br />

tulip-patterned carpet — the flower<br />

representing Tonami city — and the<br />

tulip design evokes refreshment after<br />

studying.<br />

<strong>In</strong> addition, when sitting on a sofa-type<br />

reading chair while facing the street, the<br />

wooden ceiling can rest visitors’ eyes<br />

after a long day of reading. The ceiling,<br />

which extends to the eaves, leads the<br />

eye outside, allowing the viewer to enjoy<br />

the glass-paned windows. Meanwhile,<br />

a kids space allows the interior to be<br />

shared with the exterior world through<br />

the windows. WIA<br />

2 The one-room library under a big<br />

roof concept<br />

3 The wooden ceiling rests visitors’<br />

eyes after a long day of reading<br />

4 The library is enveloped in the<br />

scent and warmth of dense wood<br />

2 3<br />

4<br />

WOOD IN ARCHITECTURE • ISSUE 1– <strong>2023</strong> 25

MARKET REPORT<br />

Timber<br />

construction<br />

business:<br />

How to make<br />

it a success story<br />

By Peter Hartmann, South East Asia market responsible,<br />

and Michael Postulart, senior consultant, Schuler Consulting<br />

navigate through the jungle of project<br />

requirements, and implement<br />

construction projects from design to<br />

production.<br />

OUT OF THE NICHE, INTO THE<br />

MARKET<br />

Many entrepreneurs have recognised<br />

that the future lies in timber<br />

construction. Both investors who come<br />

from the classical object construction<br />

with mineral building materials as<br />

well as non-industry stakeholders are<br />

looking for their place in the market.<br />

Those who build with wood now are<br />

moving with the trend, for timber<br />

construction offers answers to modern<br />

man’s question of sustainable and<br />

affordable living space. By 2050, more<br />

than two billion additional individuals<br />

are expected to seek a roof over their<br />

heads. With the housing industry<br />

coping with this major task, wood can<br />

help to go the extra mile. <strong>In</strong> housing<br />

densification, wood as a building<br />

material is already better than other<br />

materials due to its properties, such as<br />

lower weight and higher stability.<br />

The race is on: One prestigious<br />

project follows the next. The current<br />

tallest timber building at 85.4m-tall,<br />

Mjøstårnet, based in the town of<br />

Brumunddal, <strong>In</strong>nlandet, Norway, will<br />

soon surrender its place to the next<br />

record chaser, the Rocket in the city<br />

of Winterthur, Switzerland, which is<br />

scheduled to reach the 100m mark in<br />

2026. With timber construction, many<br />

want to reach new heights. Multi-storey<br />

buildings are often intended not only<br />

to set new construction standards,<br />

but also to serve as an example of<br />

urban living. The wooden giants are<br />

unique, but they have one thing in<br />

common: They are complex. From<br />

vision to implementation, there are<br />

several hurdles to overcome. Schuler<br />

Consulting can help companies<br />

But it is not only the building material<br />

itself that is appealing. Strengthened by<br />

the social demand for green building,<br />

timber construction is developing out<br />

of its niche and into a real movement.<br />

<strong>Wood</strong> is also a showcase candidate in<br />

terms of climate friendliness. While<br />

conventional construction emits<br />

up to 600kg of CO2 per tonne of<br />

cement, the wood used in multi-storey<br />

buildings in timber construction saves<br />

more CO2 than is emitted during the<br />

construction project. <strong>In</strong> the case of<br />

hybrid construction methods, with<br />

a combination of elements made of<br />

wood and wood-based materials as<br />

well as elements made of, for instance,<br />

concrete, it is the ratio that counts —<br />

every component that is not made of<br />

concrete saves CO2 emissions.<br />

For example, a single-family house<br />

binds about 40 tonnes of CO2 and<br />

26 WOOD IN ARCHITECTURE • ISSUE 1 – <strong>2023</strong>

MARKET REPORT<br />

requires only half as much CO2 in production<br />

as a concrete building. This already makes<br />

timber construction attractive today, but<br />

especially in the long term, also from a<br />

business perspective, since lower CO2<br />

emissions consequently mean less CO2 tax.<br />

The possibilities of timber construction are<br />

expanding step by step. Even bigger, even<br />

higher or even more sustainable: There are<br />

always new benchmarks. Building with wood<br />

is attractive for many, such as for residents<br />

and for politicians, who must also set new<br />

framework conditions in the building sector to<br />

comply with the agreed climate agreements,<br />

not least for economic reasons. However, in<br />

timber construction, there have so far been few<br />

standards to fall back on when implementing<br />

complex projects such as multi-storey<br />

buildings or housing developments reports. On<br />

the one hand, this makes the market attractive,<br />

as there is a lot of design scope for architects,<br />

investors and engineers. It invites investors to<br />

think big and, of course, to build high. On the<br />

other hand, due to their complexity, projects in<br />

multi-storey construction place high demands<br />

on project management and project execution.<br />

This is noticeable, among other things, in<br />

the fact that companies from the timber<br />

construction sector are increasingly looking for<br />

strategic advice. As such, Schuler Consulting’s<br />

task as project engineers is then to look<br />

for lean ways in the project to implement<br />

the visions of the timber constructors<br />

economically and efficiently. To approach<br />

the question of how to become successful in<br />

timber construction, especially in large-scale<br />

projects, we share a few practical tips from our<br />

own experience.<br />

SEVEN PROJECT MANAGEMENT<br />

TIPS FOR MULTI-STOREY<br />

CONSTRUCTION<br />

Know your product: Every project starts with<br />

an idea, which can quickly grow in complexity.<br />

It is important to define the building project<br />

clearly from the beginning. Firstly, this means<br />

knowing your product and what you want<br />

to get out of it at the end of the project, and<br />

secondly, making a detailed business case.<br />

A business case is necessary to make one’s<br />

The great timber construction boom is also due to the possibilities of automation and a higher degree<br />

of prefabrication<br />

vision economically tangible and to place it on<br />

a firm foundation that will try to withstand all<br />

risk assessments in the best-case scenario.<br />

At the beginning of the project there is always<br />

the question of the product: What is to be<br />

built, how high, what is the vision in terms of<br />

sustainability and economic viability, and more.<br />

Then there is risk assessment by the project<br />

management. These are many questions that<br />

have to be clarified at the beginning to start the<br />

project cleanly.<br />

Know your stakeholders: It is also necessary<br />

to have a top-down view of the goal at the<br />

beginning and not lose sight of it throughout<br />

the entire project course. This means knowing<br />

the requirements of all the people involved,<br />

such as architects, the building physicists<br />

and technical building planners, logisticians<br />

and buyers. Each of them brings a catalogue<br />

of requirements and wishes that need to<br />

be sorted, structured and prioritised. Often,<br />

classic conflicting goals between the different<br />

technical planners — fire protection, sound<br />

insulation, thermal insulation, statics, building<br />

services, architecture — have to be coordinated<br />

and aligned with the project goal. Also, new<br />

on board here is the production planner, who<br />

wants a product that can be manufactured<br />

as highly automated as possible to an<br />

economically feasible extent.<br />

As project managers, Schuler plays a kind<br />

of conductor in a construction and factory<br />

planning project, bringing together or<br />

‘orchestrating’ the concerns of the different<br />

planners in such a way that the end result is a<br />

product that can be produced smartly.<br />

Small changes, big impact: Team size is<br />

crucial for successful project management.<br />

While small teams create a fast and agile<br />

working environment that also delivers results<br />

and implements changes at short notice, large<br />

teams can bring the necessary manpower to<br />

check changes down to the last detail. Even<br />

small changes in construction have a great<br />

impact in other areas: If the thickness of the<br />

timber frame construction is changed, this<br />

WOOD IN ARCHITECTURE • ISSUE 1 – <strong>2023</strong> 27

MARKET REPORT<br />

Defining the building<br />

project clearly<br />

from the beginning,<br />

knowing your<br />

product, make one’s<br />

vision economically<br />

tangible<br />

impacts on the statics; if another<br />

layer is added to the wall structure,<br />

such as to improve the building’s<br />

physical properties, the additional<br />

work steps and thus the entire cycle<br />

time in the coordinated prefabrication<br />

must be adjusted. Such changes also<br />

have a further impact on fire and<br />

noise protection, as well as thermal<br />

insulation — for example, if the dew<br />

point slips into an unfavourable range<br />

as a result of the change.<br />

<strong>In</strong> large teams, there are enough<br />

specialist planners who can produce<br />

comprehensive designs for this. The<br />

challenge is to keep the threads<br />

in hand and bring them together<br />

properly. The more players there<br />

are in the game, the more views and<br />

opinions from different disciplines<br />

come up. This brings opportunities and<br />

risks. The project manager’s task is to<br />

choose the right path, to develop the<br />

most target-oriented idea, and to take<br />

the entire team along on this path.<br />

Logistics planning: The crucial<br />

question in all projects is logistics. It is<br />

often easier to manufacture the timber<br />

elements on-site, in the production<br />

environment, than to transport the<br />

elements to the construction site.<br />

The larger the projects, the greater<br />

the advantages of sophisticated<br />

logistics. Thus, a marginal topic that<br />

is inconspicuous at the beginning<br />

often gains a lot of attention in the<br />

projects. One of the reasons for this is<br />

that logistics is one of the major cost<br />

drivers in the value chain. With the<br />

progressive increase in CO2 taxation<br />

and the associated rise in transport<br />

costs, the pressure for optimised<br />

logistics is growing. Particularly large<br />

production volumes will result in a<br />

high number of loading cycles, which<br />

require smart and often individual<br />

loading concepts. Here, Schuler<br />

can develop concepts tailored to<br />

the customer with the surrounding<br />

logistics in the production and<br />

warehouse environments.<br />

Certificates do not just hang on the<br />

wall: The issue of sustainability is<br />

becoming increasingly important in<br />

construction projects. Many insurance<br />

companies, funds and investors attach<br />

importance to building certification.<br />

Through certification, builders<br />

and investors hope for greater<br />

competitiveness in the real estate<br />

market and higher returns over<br />

the entire lifecycle of the property.<br />

Over the last decades, various<br />