BAUER CENTERSTAR with BDS 3.0

BAUER CENTERSTAR with BDS 3.0

BAUER CENTERSTAR with BDS 3.0

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

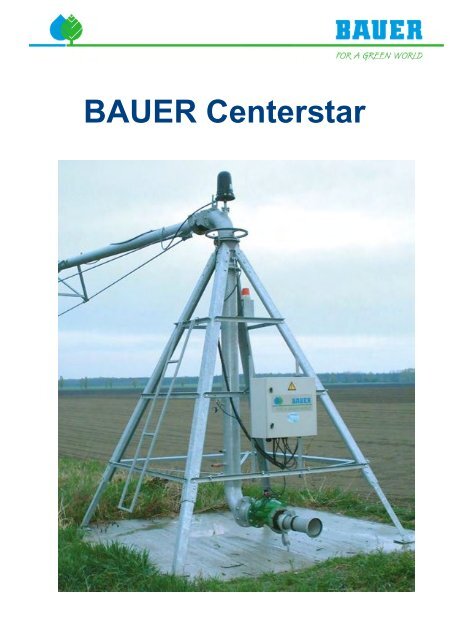

<strong>BAUER</strong> Centerstar

3,7 m<br />

4,2 m<br />

5,0 m<br />

4,2 m<br />

0,7 m<br />

0,7 m<br />

5,2 m<br />

4,3 m<br />

L<br />

<strong>CENTERSTAR</strong> 5000 168EL / 203EL<br />

0,7 m<br />

3,1 m<br />

L L<br />

L<br />

Rohrdurchmesser 168 / 203 mm<br />

Pipe diameter<br />

Diamètre du tube<br />

0,7 m<br />

Span<br />

Span<br />

Span<br />

Länge<br />

Length L m<br />

Longueur<br />

Überhang<br />

Overhang<br />

Porte-a`-faux<br />

Länge<br />

Length<br />

Longueur<br />

Sandfang<br />

Sand trap<br />

Dessableur<br />

Sprühdüsenverlängerung<br />

Spray nozzle extension<br />

Rallonge de buse atomiseur<br />

3,9 m<br />

L L<br />

Rohrdurchmesser 168 / 203 mm<br />

Pipe diameter<br />

Diamètre du tube<br />

O m<br />

S m<br />

Nm<br />

* Centerstar 203EL nicht verfügbar<br />

Centerstar 203EL not available<br />

Centerstar 203EL non disponible<br />

0,7 m<br />

*<br />

59,8 54,0 48,1 42,3<br />

59,80 53,95 48,10 42,25<br />

O S N<br />

23,4 17,6 11,7 5,9 0<br />

24,1 18,3 12,4 6,6 0,7<br />

0,15<br />

<strong>CENTERSTAR</strong> 5000 168E / 203E<br />

Span<br />

Span<br />

Span<br />

Länge<br />

Length L m<br />

Longueur<br />

Überhang<br />

Overhang<br />

Porte-a`-faux<br />

Länge<br />

Length<br />

Longueur<br />

Sandfang<br />

Sand trap<br />

Dessableur<br />

Sprühdüsenverlängerung<br />

Spray nozzle extension<br />

Rallonge de buse atomiseur<br />

*<br />

Centerstar 203E nicht verfügbar<br />

Centerstar 203E not available<br />

Centerstar 203E non disponible<br />

O m<br />

S m<br />

N m<br />

36,4<br />

36,40<br />

0,15 0,15 0,15 0,15<br />

1,2 1,2 1,2 1,2 1,2<br />

3,0 3,0 3,0 3,0 3,0<br />

*<br />

59,8 54,0 48,1 42,3<br />

0,7 m<br />

59,80 53,95 48,10 42,25<br />

O S N<br />

23,4 17,6 11,7 5,9 0<br />

24,1 18,3 12,4 6,6 0,7<br />

0,15<br />

36,4<br />

36,40<br />

0,15 0,15 0,15 0,15<br />

1,2 1,2 1,2 1,2 1,2<br />

3,0 3,0 3,0 3,0 3,0

Erforderlich<br />

Nicht erforderlich<br />

<strong>CENTERSTAR</strong> 5000<br />

Zentralturmkupplung / Flexible tower coupling<br />

Required<br />

Not required<br />

Spanlänge Abstand a<br />

Span length Distance a<br />

( m )<br />

42,3<br />

48,1<br />

54,0<br />

59,8<br />

( m )<br />

0,74<br />

0,84<br />

0,94<br />

1,04<br />

a<br />

Abstand a<br />

03.2003

TECHNICAL DESCRIPTION OF<br />

<strong>CENTERSTAR</strong> 5000 203/168EL<br />

1. PIVOT CENTRAL TOWER<br />

Tower Structure:<br />

- Sturdy, torsionfree tower construction consisting of 4 tower supports, braced <strong>with</strong><br />

steplike arranged cross-struts<br />

- Hydraulically optimized design of pivot inlet and outlet, swivelling through 360°<br />

- Sealing of pivot pipe <strong>with</strong> 1 lip seal and gasket<br />

- Pivot rising pipe 194 x 2,5 mm of steel according to OE-NORM M 3124 ST12FZ <strong>with</strong><br />

welded-on bend 90° DIN 2605, 194 x 4,5 , for inlet and outlet<br />

- Rising pipe <strong>with</strong> pressure gauge and connection facility for fertigation<br />

- Inlet <strong>with</strong> flange DN 200/PN 10 (8")<br />

- Cable entry on the bottom side of the rising pipe <strong>with</strong> packing of the conduit gland and<br />

collector exit for power cable <strong>with</strong> 11 wires for full circle operation<br />

Corrosion protection:<br />

- Hot dip zinc coating according to DIN 50976 for all structural members<br />

Profile dimensions:<br />

- 4 tower legs: angle sections 100 x 100 x 5 mm<br />

- braces: angle sections 45 x 45 x 5 mm<br />

Coupling of tower:<br />

30° articulation for application on uneven grounds<br />

Foundation - to be provided locally:<br />

Reinforced concrete slab <strong>with</strong> cast-in stone bolts for simple tightening of central tower<br />

Size of foundation: minimum 3,10 x 3,10 m<br />

Control panel: UNIVERSAL<br />

Design and materials according to OEVE and VDE Standards (Austrian and German<br />

electrical standards)<br />

Built-in equipment according to IEC Standards and to VDE regulations.<br />

../2

- 2 -<br />

Control panel consisting of:<br />

- Sheet steel casing <strong>with</strong> lockable front door<br />

- Swivelling control panel to be opened only when not under voltage<br />

- Water-tight steel casing (type of protection IP54) <strong>with</strong> corrosion resistant varnish<br />

- Installed power current: 3 x 400 V/50Hz + PEN<br />

source of current <strong>with</strong> earthed neutral<br />

- Control voltage: 220 V single phase<br />

- Control voltage transformer<br />

- Commercial industrial contactors and disconnecting switch<br />

- Cable connections equipped <strong>with</strong> cable bracket<br />

Standard built-in equipment:<br />

- Main switch for power supply <strong>with</strong> door latch<br />

- Earth-leakage circuit breaker (e.l.c.b.)<br />

- Working hour meter<br />

- Voltmeter for measuring a phase voltage<br />

- Percentage timer for setting the rotation speed<br />

- Run / Stop switch for Pivot System<br />

- Illuminated button for START FORWARD<br />

- Illuminated button for START BACKWARD<br />

- Switch for bridging the safety circle<br />

- change-over switch “AUTO-REVERSE ON-OFF”<br />

- Safety shut-down of system at malfunction<br />

- signalling contat - PIVOT running<br />

- Connection facility for electric shut-off valve<br />

- 4-pole socket, 16 Amp<br />

- Earthing: the central tower has to be connected to a suitable earth connection<br />

Options:<br />

- Automatic shut-down of system in a chosen position resp. parking position <strong>with</strong><br />

short-out switch<br />

- Automatic reverse or automatic sector stop (change-over switch in standard<br />

extent of supply)<br />

- Low pressure shut-off <strong>with</strong> short-out switch<br />

The control panel is completely wired by using different colours for the main circuit and<br />

the control circuit.<br />

Wiring diagram for each control desk.<br />

Collector (slip rings for full circle operation)<br />

External collector installed under an insolated shield. Main and control cables are led<br />

through the collector. 11 spring-loaded sliding contacts, brush type.<br />

../3

2. Spans<br />

- 3 -<br />

Bow string type truss <strong>with</strong> stabilizers<br />

Span-length: 59,8m ; 54,0m; 48,1m and 42,3m for diam. 168<br />

54,0m; 48,1m and 42,3m for diam. 203<br />

Coating:<br />

High performance hot dip zinc coating according to DIN 50976 for all steel components<br />

including main pipes<br />

Pipes:<br />

Steel pipes according to OENORM M 3123 ST 37 FZ<br />

Straight bead welded, <strong>with</strong> flanges<br />

Dimension: 203mm x 2,5mm wallthickness<br />

Dimension: 168 mm x 2,75 mm wall thickness<br />

Length of the individual pipes:Mainpipes 5,85 m; Endpipes 0,55m<br />

Flange thickness: 10 mm<br />

Outlets:<br />

Spaced every 2,925mm, 3/4" female thread<br />

Power cable:<br />

Jacketed 11-wires cable, oil- and UV-resistant<br />

Cross-sections of conducting wire: 4 x 6 mm² copper<br />

7 x 1,5 mm² copper<br />

Cable fixed <strong>with</strong> clamps and special holding device<br />

Truss braces:<br />

Bolted angle sections, dimension 45 x 45 x 5 mm<br />

<strong>with</strong> 7 bracing struts at a span length of 48,1 m<br />

<strong>with</strong> 8 bracing struts at a span length of 54,0 m<br />

<strong>with</strong> 9 bracing struts at a span length of 59,8 m<br />

Truss rods:<br />

High-tensile steel, ø 20 mm<br />

REMARK: The Pivot main line, the bracing struts and the undertruss structure are<br />

made up by a maximum possible quantity of identical parts. Thus it is easily<br />

possible to adapt different span lengths.<br />

Bolts:<br />

DIN-grade 8.8 <strong>with</strong> lock nuts<br />

Tower coupling:<br />

The sturdy ball joint allows optimal adaptation to the different torsional strains caused by<br />

unevenness of ground and different span lengths. The coupling mounted outside of the<br />

pipe causes no necking and allows the irrigation water to pass <strong>with</strong>out any hindrance.<br />

Both coupling elements are vertically flexible up to 16°<br />

Pipe connection <strong>with</strong> hose collar, made out of finest quality, weather proof, UV- and<br />

ozone resistant material. ../4

Alignment control:<br />

The alignment control ensures maximum control exactitude and operation safety.<br />

Control angle ± 0,15 degree from neutral position.<br />

<strong>BAUER</strong> as the only manufacturer supplies a switch lever which is directly coupled to the<br />

flexible articulation (<strong>BAUER</strong> patent) securing an exact transfer of movement to the tower<br />

switch box. Hence the impulses are not influenced by uneven ground.<br />

Monitoring system <strong>with</strong> high performance electric elements, <strong>with</strong>standing tropical<br />

condtions.<br />

The ample dimensioned circuit elements are protected by a solid plastic shield which is<br />

fastened by spring vices, suitable also for high wind velocities.<br />

Admissible gradient: up to 30 %<br />

Tower switch box:<br />

- Manufacturer: <strong>BAUER</strong> Ges.m.b.H., Austria<br />

- Design and materials according to OEVE or VDE (Austrian and German electrical<br />

standards)<br />

- Built-in equipment according to IEC Standards and to VDE regulations<br />

- Construction: 400 V/50 Hz three phase voltage<br />

230 V - single phase control voltage 50/Hz<br />

- Ample dimensioned switch elements<br />

- Electro-mechanic microswitch for alignment control and safety shut-down (special<br />

design for pivot systems, scrutinized for maximum exactitude, safe operation and<br />

resistance)<br />

- The tower switch box is completely installed and tested in <strong>BAUER</strong> Factory; no further<br />

installation needs to be done in the project terrain.<br />

- IC safety joint for protection against voltage spikes for longlasting durability of the<br />

switch elements.<br />

3. Towers<br />

Structure:<br />

Heavy angle iron structure, <strong>with</strong> 4 tower supports, braced <strong>with</strong> steplike arranged crossstruts<br />

Dimension:<br />

Tower supports: 100 x 75 x 7 mm<br />

Cross-struts: 45 x 45 x 5 mm<br />

../5

- 5 -<br />

Coating:<br />

Lasting hot dip zinc coating according to DIN 50976 for all structural members including<br />

rims.<br />

Wheel base:<br />

Wheel base of 4,26 m for maximum stability. Ample dimensioned wheel bases made out<br />

of steel pipe ø 168 mm x 2,75 mm <strong>with</strong> welded-on brackets for drive motor and wheel<br />

gear.<br />

Drive:<br />

- Geared motor POWER SAVER ¾ HP<br />

- Enclosed motor, insulation class F, special moisture proof for electric connections<br />

- High torque drive motor ¾ HP, 400 V/50 Hz <strong>with</strong> thermal overload protection<br />

- High efficiency spur gear <strong>with</strong> flame-hardened gearwheels<br />

- Gear ratio: 40:1<br />

- Expansion chamber integrated in the housing<br />

- Shaft seals <strong>with</strong> special dirt-repelling profile<br />

- Corrosion protection by special varnish coat<br />

Wheel gear:<br />

- Wheel gear type UMC 740 U, ration 50:1<br />

- Heavy duty transmission <strong>with</strong> sturdy bevel gear bearings for high torques<br />

- Hub shaft ø 57,2 mm <strong>with</strong> protected shaft seals<br />

- Expansion chamber <strong>with</strong> membrane<br />

- Entry shaft seals <strong>with</strong> special dirt-repelling profile<br />

- Corrosion protection by special varnish coat<br />

Drive shaft:<br />

Ample dimensioned, galvanized square pipes 25 x 3 mm<br />

Coupling parts <strong>with</strong> elastic element for troublefree start<br />

Drive shaft <strong>with</strong> protecting pipe against corrosion and to avoid accidents, meeting the<br />

international safety regulations.<br />

Tyres:<br />

High-flotation tyres for irrigation<br />

Dimension: 14,9 – 24; 8 Ply<br />

New tyres<br />

Rim size: W 12 x 24 for 8 wheel studs<br />

Hole circle diameter: 8"<br />

Rims hot dip galvanized<br />

../6

4. Overhang:<br />

- 6 -<br />

Complete <strong>with</strong> struts, pipe diameter 133 x 3 mm wall thickness<br />

Length: 5,9 m, 11,7 m, 17,6 m and 23,4 m<br />

Sand trap:<br />

Sand trap <strong>with</strong> flush out, including valve in operation height<br />

5. Spray Nozzle Equipment<br />

Low pressure spray nozzles type Senninger: LDN<br />

For the low pressure spray nozzles, <strong>BAUER</strong> propose a minimum nozzle pressure of 1,0<br />

bar to enable fine drop resolution. The spray nozzles are mounted on the main pipe.<br />

All spray nozzles have different colours to distinguish more easily the sizes. The nozzles<br />

are inserted simply by hand by turning them in - no tools necessary - especially<br />

advantageous when nozzles are blocked.<br />

The tough and high quality Thermoplast spray nozzle has a longlasting durability and is<br />

highly wear resisting.<br />

The nozzles are equipped <strong>with</strong> interchangeable, grooved rebounding plates.<br />

To secure uniform water distribution in hilly terrain, all spray nozzles are equipped <strong>with</strong><br />

pressure reducing valves.<br />

Distance between the spray nozzles: 2,925 mm<br />

To avoid excessive irrigation in the driving tracks, half-circle nozzles of 180° are used on<br />

both sides of the tower.<br />

For the hydraulic calculation of the Pivot supply pressure, please refer to the computer<br />

prints.<br />

6. Flexible Drop -pipes<br />

Steel bend 180° galvanized -both sides <strong>with</strong> threads 3/4"<br />

Flexible hose 3/4" , 2,5m length<br />

Stabilizer pipes 0,5m length<br />

(drop pipes supplied in parts for local assambling)

Technical Advantages of <strong>BAUER</strong><br />

Compared to other Pivot Suppliers.<br />

1. Bauer uses main pipe lengths of 5,85m. The competitors use up to 3<br />

different pipe lengths ranging up to 13,4m.<br />

Advantage: Easier for manufacture, less inventory for dealer, less<br />

complications during erection.<br />

2. By using a pipe lengths of only 5,85m, the weight is low which makes<br />

the handling during the installation much easier.<br />

Advantage: 2 people can lift the main pipe by hand. With the larger<br />

pipes offered by competitors, a crane is needed to support the weight.<br />

3. <strong>BAUER</strong> uses only one truss rod length; Competitor are using different<br />

length and different diameters.<br />

Advantage: <strong>BAUER</strong> makes it easy; a simple construction and saves<br />

inventory space for storage of parts.<br />

4. Bauer uses 5 different truss angle packages. Other suppliers use up to<br />

7 different angle packages.<br />

Advantage: There are less components needed on stock and the<br />

erection of machines is less complicated.<br />

5. Bauer offers the most universal parts of all the suppliers.<br />

Advantage: Stock is reduced, less spare parts, less training for service<br />

people easier installation..<br />

6. Bauer flexible span connection <strong>with</strong> ball and socket coupling offers a<br />

large angle for undulating ground (uneven surfaces).<br />

Advantage: Span coupling is used for both; flat and uneven surfaces<br />

but some competitors (Lindsay type) have a standard and special<br />

coupling for rough surfaces.<br />

7. The Bauer uses the largest wheel base of 4,3 m for drive towers<br />

Advantage: The span is more stable than competitors. An example is<br />

in France during massive storms, competitor pivots were overturned<br />

while the Bauer machines were unaffected.<br />

8. Crop clearance for <strong>BAUER</strong> Pivots are 3,1m<br />

Advantage: American producer are offering 2,8m for long<br />

spans; crops like maize can be damaged.<br />

9. All of Bauer components are hot dipped galvanized according to<br />

DIN 50976 which is a higher standard than that used in the<br />

United States.<br />

Advantage: American based companies galvanizing is<br />

therefore of lower quality.<br />

Page 1 of 2

10. Bauer always uses new tires <strong>with</strong> a dimension of 14,9-24 and<br />

galvanized rims as standard. Competitors use a tire dimension<br />

of 11,2-24 and mostly use retread tires. Some of the rims are<br />

only painted and not galvanized.<br />

Advantage: greater corrosion protection and higher quality<br />

11. Tower alignment between spans is measured from very close<br />

to the flexible join and so the angle deviation reading is as<br />

accurate as possible.<br />

12. The Bauer alignment control box is not effected by torsion<br />

caused when travelling over uneven surfaces or obstacles.<br />

This means that a true angle reading is always given.<br />

13. The cams in the alignment control box are larger in dimension<br />

than all of the competitors.<br />

Advantage: Switching points for angle alignment are easily<br />

set and very accurate even <strong>with</strong> small variations over time.<br />

14. Alignment control boxes are delivered <strong>with</strong> a standard setup which has been tested<br />

before leaving the company.<br />

Advantage :Easy to install, no settings of micro switches.<br />

15. The Bauer tower control boxes contain specially treated micro switches for completely<br />

safe operation even under extreme climate conditions<br />

Advantage: Guarantees a accurate trouble-free operation under worst climate<br />

conditions. .<br />

16. The main control box from Bauer is manufactured in accordance to the strict ISO<br />

regulation necessary for Austria, Germany and other European countries. The US<br />

standard for electricity safety is much less strict.<br />

Advantage: Bauer control boxes have a much higher electrical safety,<br />

17. The components used in a Bauer control boxes are from high quality and well know<br />

manufactures such as Siemens, Schrack, Schneider<br />

Advantage: replacement parts can be easily found from local suppliers of electrical<br />

goods.<br />

18. <strong>BAUER</strong> offers the highest possible<br />

comfort in packing. All important parts of<br />

the towers are packed in wooden boxes.<br />

Small parts, such as bolts or nuts, are<br />

vacuum-packed in special plastic bags<br />

Advantage: Saves time for erection and<br />

prevents loosing small parts in the field<br />

19. The cables for Pivots are pre-assembled, which<br />

means that they are trimmed to the right length and<br />

equipped <strong>with</strong> cable eyes,<br />

Clear advantage: Facilitates the assembly of the<br />

plant, and this saves time<br />

Page 2 of 2

Control panel<br />

UNIVERSAL

<strong>BAUER</strong> UNIVERSAL PRO<br />

The Innovative Irrigation Control System<br />

Accurate Control and Monitoring of the Centerstar 5000<br />

� The crops are delivered<br />

precisely the precipitation<br />

needed due to the<br />

microprocessor control<br />

� Efficient and economical<br />

irrigation management<br />

� User-friendly<br />

� Clear display of the operating<br />

status<br />

� Recording of up to 20 operating<br />

processes<br />

� Multilingual operating menu<br />

� SMS control <strong>with</strong> the cellular<br />

service

Subject to change / Universal Pro / 11 2004 e<br />

Benefi ts and Conveniences of the<br />

Centerstar Control System<br />

• Input of the precipitation rate in mm<br />

• Programming of different precipitation rates for forward<br />

and reverse run<br />

• Input of the number of rotations<br />

• Preselection of the date and time for the start<br />

• Input of an operating intermission<br />

• Start retardation – until pressure is built up in the system<br />

• Start-up retardation at Start and Sector switch-over<br />

• Restart after pressure and voltage drop<br />

• Alarm indication and recording of the last 20 processes<br />

• Individual setting of the clock phase for a uniform irrigation<br />

• Recording of the operating hours (wet – dry)<br />

• System stop at the occurrence of an error<br />

• Pump start signal<br />

• Control of the shut-off valve<br />

• Emergency operation, if the electronic system fails<br />

Option<br />

• SMS control by fitting in a GSM modem<br />

• Power supply package onsisting of a solar panel and a<br />

buffer battery<br />

UNIVERSAL PRO<br />

SMS Control <strong>with</strong> the Mobile<br />

Telephone<br />

The control of the <strong>CENTERSTAR</strong> by SMS offers optimal operational<br />

comfort to the user. By just entering control commands,<br />

the <strong>CENTERSTAR</strong> can be controlled from any location.<br />

A wide range of replies <strong>with</strong> regard to the operating status can<br />

be programmed individually.<br />

Examples of input:<br />

Messages:<br />

ERROR<br />

Start/forward <strong>with</strong> a precipitation height of 15 mm<br />

Start/reverse <strong>with</strong> a precipitation height of 15 mm<br />

Stop the system<br />

Requesting info on the operational status<br />

Malfunction, operating status message<br />

Power Supply Package<br />

With the solar panel and the buffer battery as a supplementary<br />

equipment, SMS messaging is possible also after<br />

power failure, e.g. after a thunderstorm.<br />

Röhren- und Pumpenwerk<br />

<strong>BAUER</strong> GmbH<br />

8570 Voitsberg, Austria<br />

Tel. +43 3142 200-0<br />

Fax +43 3142 200-320 / -340<br />

sales@bauer-at.com<br />

www.bauer-at.com

Large display <strong>with</strong> clearly arranged readout<br />

<strong>BAUER</strong> <strong>BDS</strong> <strong>3.0</strong> –<br />

digitally programmed<br />

control center<br />

● 8 menu keys for simple input of system data, position<br />

parameters and schedule steps<br />

● cursor keys for quickly calling up different menus and<br />

input screens<br />

● number keys for precise data input in numerical values<br />

● function switches for turning important functions ON/OFF<br />

instantaneously (e.g. endgun, WET/DRY etc.)<br />

<strong>with</strong>out programming

Subject to change / <strong>CENTERSTAR</strong> <strong>BDS</strong> <strong>3.0</strong> / 09 2005 e<br />

<strong>BAUER</strong> <strong>CENTERSTAR</strong> <strong>with</strong> <strong>BDS</strong> <strong>3.0</strong><br />

System options<br />

● Communication<br />

<strong>with</strong> <strong>CENTERSTAR</strong> through radio modem for<br />

system control and monitoring by means of PC<br />

control center, radio set or GSM cellular.<br />

● CAN bus control<br />

(additional control p.c.b. in the tower box)<br />

guarantees automatic <strong>CENTERSTAR</strong> alignment<br />

as well as detailed error logging of every<br />

tower.<br />

Your Dealer:<br />

Precise positioning<br />

A rotary position transducer<br />

<strong>with</strong> an integrated<br />

CAN bus transmits the<br />

exact position of the<br />

<strong>CENTERSTAR</strong> <strong>with</strong> 0.2°<br />

accuracy.<br />

Precision-controlled irrigation <strong>with</strong><br />

permanent monitoring<br />

Two status screens <strong>with</strong> 24 information blocks display<br />

the operational status of the system in 6 optional languages.<br />

Benefits:<br />

● Four irrigation segments<br />

Up to four segments can be programmed <strong>with</strong><br />

different precipitation. Allows ideal system<br />

adjustment to varying soil and crop conditions.<br />

● 4 ON/OFF points<br />

For every system rotation it is possible to determine<br />

up to four different start and stop points<br />

for endgun, fertilizer injection, etc.<br />

● 10 irrigation programs – for efficient irrigation<br />

management<br />

<strong>with</strong> individually programmable precipitation<br />

heights, start times, breaks and numbers of rotation.<br />

Irrigation is perfectly adjusted to existing<br />

site and crops.<br />

● Outputs<br />

for remote pump start and electric shut-off<br />

valve allow the pivot system to be run automatically.<br />

● Precise recordings<br />

of running hours (wet/dry), total water discharge<br />

and error logging provide comprehensive<br />

system details.<br />

● Restart<br />

for continued irrigation after interruptions<br />

caused by pressure drop, voltage drop, and<br />

excessively high winds etc.<br />

● Emergency operation<br />

in case of electronic failure.<br />

Additional benefits:<br />

● Software storage on EPROMS<br />

● Simple software upgrading<br />

● Overvoltage protection for electronics<br />

Röhren- und Pumpenwerk<br />

<strong>BAUER</strong> Gesellschaft m. b. H.<br />

8570 Voitsberg, Austria<br />

Tel. 03142/200-0, Fax 03142/200-320<br />

www.bauer-at.com<br />

E-Mail: sales@bauer-at.com

Bauer CAN-BUS System<br />

-Continuous communication between<br />

control panel <strong>BDS</strong> <strong>3.0</strong>, absolute encoder<br />

and pivot tower<br />

ABSOLUTE ENCODER<br />

- Transmits exact position of pivot<br />

- 13 bit accuracy<br />

- Permanent data check<br />

CAN BUS<br />

- Located in alignment control box<br />

- Each span separately controlled<br />

- Easy to programme<br />

Röhren- und Pumpenwerk <strong>BAUER</strong> GmbH., A-8570 Voitsberg/Austria<br />

Tel. +43 / 3142 / 200-0, Fax +43 / 3142 / 200-320<br />

e-mail: sales@bauer-at.com, www.bauer-at.com

BENEFITS<br />

DATA TRANSFER<br />

- With 2-core cable to alignment control boxes<br />

- Standard pivots using 7-core cables for pivot control<br />

- Continuous data check<br />

MOTOR START<br />

- No simultaneous starts of drive motors<br />

- Low amperage peak<br />

- Smaller gensets and supply cables<br />

ALIGNMENT<br />

- Auto-alignment<br />

- No time-consuming settings for alignment<br />

- Important for towable systems<br />

REPORT<br />

- Detailed failure report<br />

- Reason, location (span, sensor etc.)<br />

- Easy troubleshooting<br />

Röhren- und Pumpenwerk <strong>BAUER</strong> GmbH., A-8570 Voitsberg/Austria<br />

Tel. +43 / 3142 / 200-0, Fax +43 / 3142 / 200-320<br />

e-mail: sales@bauer-at.com, www.bauer-at.com

Power Saver III<br />

Ratios:<br />

30:1 ratio 1 ½hp<br />

40:1 ratio .75hp<br />

50:1 ratio .75hp<br />

Evaluation Specification<br />

· All aluminum gearcase and motor housing for cooler running, longer life, and increased<br />

Corrosion resistance.<br />

· Proven reliability.<br />

· Dual bolt mounting pattern 5"x6", 3 3/8" x 6 3/8".<br />

· Voltage: 460V 60 Hz, 380V 50 Hz.<br />

· Type: Helical gear design. High strength steel shafting for long life and dependability.<br />

· Thermally protected <strong>with</strong> automatic reset.<br />

· All gears are heat treated.<br />

· Shipped <strong>with</strong> gear oil.<br />

· Specially designed input and output seals.<br />

· Top fill plug positioned to set correct oil level.<br />

· All critical electrical connections are encapsulated to resist penetration of moisture.<br />

· Class F insulation and materials are used throughout.<br />

· CSA approved.<br />

· Efficiency 95%.<br />

· Makes possible the use of smaller generators and smaller incoming wire sizes.<br />

Röhren- und Pumpenwerk <strong>BAUER</strong> Ges.m.b.H.; A-8570 Voitsberg / Austria<br />

Tel. +43/3142-200-0, Fax: +43/3142-23095; www.bauer-at.com; E-Mail: sales@bauer-at.com

Gearbox 740 U 50:1<br />

Evaluation Specification<br />

· New Dual output seals standard.<br />

· Larger input bearings and reinforced housing.<br />

· Stainless steel expansion chamber.<br />

· Universal mount bolt pattern.<br />

· Full cycle expansion chamber; bellows-type expansion diaphragm.<br />

· Tapered roller bearings.<br />

· 50:1 worm gear ratio, Various over-hung load capacities,<br />

Peak torque in excess of 75,000 in./lbs & 4,400 ft./lbs output torque.<br />

High strength cast iron bolt-on end caps.<br />

· Input shafts fitted <strong>with</strong> external UV resistant dust seals.<br />

· Dual input seals.<br />

· Includes rib neck carriage bolts <strong>with</strong> wheel nuts.<br />

· Each gearbox filled <strong>with</strong> extreme pressure, multi-purpose gear oil.<br />

· Top oil fill provision.<br />

· Each unit date stamped.<br />

· High strength steel worm and output shaft.<br />

· I.P. shaft guard included.<br />

Röhren- und Pumpenwerk <strong>BAUER</strong> Ges.m.b.H.; A-8570 Voitsberg / Austria<br />

Tel. +43/3142-200-0, Fax: +43/3142-23095; www.bauer-at.com; E-Mail: sales@bauer-at.com

Gearbox 725 TNT tow 50:1<br />

Evaluation Specification<br />

· Easily disengage bale and tow your pivot to its working location, then simply<br />

re-engage bale and you are ready to run.<br />

· Patented concentric gear engagement design.<br />

· Simple bale engagement lever makes for quick, easy, and trouble free operation.<br />

· Efficient and reliable alternative to BT-4B and 725-UT applications.<br />

· Available in 50:1 and 52:1 ratios<br />

· Lighter weight and more economical cost than standard towable gearboxes.<br />

· Universal bolt pattern mount fits most pivot and lateral / linear towable irrigation systems.<br />

· Positive lock in both tow and non-tow positions.<br />

· Compatible <strong>with</strong> most standard tires sizes.<br />

· Uses the proven heavy duty gearing as our 725-U gearbox.<br />

Röhren- und Pumpenwerk <strong>BAUER</strong> Ges.m.b.H.; A-8570 Voitsberg / Austria<br />

Tel. +43/3142-200-0, Fax: +43/3142-23095; www.bauer-at.com; E-Mail: sales@bauer-at.com

LDN ® LDN<br />

Low-Drift Nozzle<br />

®<br />

Low-Drift Nozzle<br />

The Senninger Low-Drift Nozzle (LDN ® ) fea-<br />

tures a unique multiple deflector pad design.<br />

This allows it to produce uniform sized droplets<br />

through the wide range of nozzle flows found<br />

on center pivots. The result is extremely efficient<br />

water application <strong>with</strong> minimized losses to<br />

wind drift, evaporation and runoff.<br />

• Multiple-level deflector pads to handle the higher<br />

flows on the middle to outer spans<br />

• Mini deflector pads available for smaller nozzles<br />

• Chemigate pads available: Corn (58° upward throw)<br />

and Cotton (15° - 30° multi-level upward throw)<br />

• Hosebarb adapter available for direct furrow<br />

water application<br />

• Color coded nozzles for easy size identification<br />

• 3/4" NPT male thread<br />

• Two-year warranty on materials, workmanship<br />

and performance<br />

As nozzle 0.5 sizes to 5.25 increase gpmalong the length of a pivot, 4.0 extra to deflector 9.5 gpmpads are added to accommodate 6.75 to the 14.5 higher gpmflow.<br />

The<br />

increased area of coverage provided by this multi-pad system aids in the reduction of instantaneous application rate, reducing<br />

runoff and surface compaction.<br />

Page 10 — Senninger Irrigation Inc. (407) 293-5555 — Pivot Catalog<br />

New Weight and<br />

Bubbler Pad<br />

The LDN is now available<br />

<strong>with</strong> a new slip-over<br />

weight for better stability<br />

in high wind and a bubbler<br />

pad for gentle<br />

direct-to-furrow water<br />

delivery.<br />

3/4 & 1 lb.<br />

sizes<br />

available

i-Wob ® i-Wob ®<br />

The Senninger i-Wob uses a unique off-center<br />

rotary action to provide outstanding uniformity<br />

at low pressures. Its new below-the-nozzle<br />

weight creates less stress on flexible drops.<br />

Three models available<br />

Standard<br />

• black deflector<br />

• 9-grooves<br />

• largest area of coverage<br />

Low-Angle - 6<br />

• white deflector<br />

• 6-grooves<br />

• large droplets/<br />

fights wind<br />

Low-Angle - 9<br />

• blue deflector<br />

• 9-grooves<br />

• gentler application/<br />

fights wind<br />

Page 8 — Senninger Irrigation Inc. (407) 293-5555 — Pivot Catalog<br />

• Off-center rotary action for outstanding spray pattern<br />

• Exclusive below-the-nozzle weight eliminates the<br />

need for heavier, conventional drop weights<br />

• Easy to change nozzles - color coded for size<br />

identification<br />

• Resilient wear sleeve cushions contact surfaces<br />

resulting in a longer wearing, more reliable product<br />

• Standard-angle and two low-angle models available<br />

• 3/4" NPT male thread or hosebarb base<br />

• Two-year warranty on materials, workmanship<br />

and performance<br />

Excellent distance of throw<br />

37.7' 57'<br />

Spray Nozzle i-Wob<br />

The action of its wobbling shroud allows the i-Wob to<br />

throw water much farther than spray nozzles <strong>with</strong><br />

stationary deflector pads. (In this example, nozzles are<br />

at 20 psi, a 6' height, using a 11/32” nozzle, <strong>with</strong> a flow of<br />

14.3 gpm in no-wind conditions.)<br />

Lowest instantaneous application rate<br />

Ordinary spray nozzles place water in a ring at the outer<br />

edge of their wetted circle. This causes higher<br />

application rates, soil compaction<br />

and an increased chance of runoff.<br />

The i-Wob uniformly covers<br />

the inside of its wetted circle.<br />

This means it is wetting a much<br />

larger area at a much lower<br />

instantaneous application rate.<br />

In this example,<br />

the i-Wob is wetting<br />

over four and a half<br />

times the area of the<br />

spray nozzle.<br />

(Nozzles are at<br />

20 psi, a 6' height,<br />

using a 11/32" nozzle,<br />

<strong>with</strong> a flow of 14.3 gpm<br />

in no-wind conditions.)<br />

513<br />

square feet<br />

2,552<br />

square feet<br />

Five foot<br />

wetted band<br />

Spray Nozzle<br />

i-Wob<br />

overhead view

Pressure Regulators<br />

Pivot Special<br />

Regulator (PSR)<br />

• 10 factory preset<br />

operating pressures<br />

(6, 10, 12, 15, 20, 25, 30,<br />

35, 40 & 50 psi)<br />

• Flow range from<br />

1/2 to 15 gpm<br />

Senninger introduced the first<br />

high-quality in-line pressure<br />

regulator to the irrigation industry<br />

back in 1966. Since then,<br />

Senninger Regulators have<br />

become an integral part of modern<br />

irrigation systems. They set<br />

the standards by which all regulators<br />

are judged.<br />

Water Application Without Pressure Regulators<br />

Underwatering<br />

Desired Application Level<br />

Water Application With Senninger Regulators<br />

Page 18 — Senninger Irrigation Inc. (407) 293-5555 — Pivot Catalog<br />

Pressure-Master Regulator ®<br />

Low-Flow (PMR-LF)<br />

Pressure-Master Regulator ®<br />

Medium-Flow (PMR-MF)<br />

• 10 factory preset operating pressures<br />

(6, 10, 15, 20, 25, 30, 35, 40, 50 & 60 psi)<br />

• Flow range from 2 to 20 gpm<br />

Overwatering<br />

Application remains uniform<br />

even as elevation changes<br />

• Maintain a constant preset outlet pressure while<br />

handling inlet pressures up to 150 psi<br />

• Withstand severe water hammer<br />

• 100% water tested for accuracy, no adjustments<br />

ever needed<br />

• Strong, durable construction<br />

• 9 factory preset operating pressures<br />

(6, 10, 12, 15, 20, 25, 30, 35 & 40 psi)<br />

• Flow range from 1/10 to 8 gpm<br />

• Very low hysteresis and friction losses<br />

• 3/4" NPT female x 3/4" NPT female thread<br />

• Two-year warranty on materials, workmanship<br />

and performance<br />

Restriction through a<br />

Senninger Regulator is<br />

negligible until the exact<br />

operating pressure is<br />

reached. At this point,<br />

the regulator goes into<br />

action and automatically<br />

maintains its designed<br />

downstream pressure<br />

and flow to the spray<br />

nozzle or sprinkler head.

PIVOT /LINEAR Systems<br />

8519400 BOOMBACK one sided -for 1moving direction<br />

8519420 BOOMBACK double sided -for forward and reverse<br />

•for dry wheel tracks<br />

•adjustable nozzleheigth<br />

•onesided or double sided<br />

•for Ø168 mmpivot pipes<br />

•easy to install<br />

onesided<br />

double sided<br />

Röhren-und Pumpenwerk<strong>BAUER</strong> GmbH.,A-8570Voitsberg/Austria<br />

Tel. +43 /3142 /200-0, Fax +43 /3142 / 23095<br />

e-mail: sales@bauer-at.com, www.bauer-at.com<br />

Voitsberg 18.10.2004