Local Solutions for Individual Customers Worldwide - Oil Solutions

Local Solutions for Individual Customers Worldwide - Oil Solutions

Local Solutions for Individual Customers Worldwide - Oil Solutions

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Maintenance<br />

Accumulators and Accessories<br />

General In<strong>for</strong>mation<br />

The condition of the accumulator is primarily determined by periodic checking of gas pre-charge pressure. Only<br />

qualifi ed personnel should per<strong>for</strong>m any maintenance on accumulators. Nitrogen gas pre-charge pressure should<br />

be checked at least once during the fi rst week of operation to ensure that no leak has developed. The pre-charge<br />

pressure and ambient temperature should be recorded at installation and checking done at the same temperature if<br />

possible. If there is no loss of gas pre-charge pressure, it should be rechecked in approximately 4 months. Thereafter,<br />

it should be checked annually. Check pre-charge if the system is acting sluggishly. If pre-charge is low, check gas<br />

valve <strong>for</strong> leakage and recharge.<br />

Bladder Accumulators<br />

1 Use appropriate valving in the hydraulic system to discharge all hydraulic fl uid from accumulator.<br />

2 To check or adjust pre-charge pressure, HYDRAULIC PRESSURE MUST BE REDUCED TO ZERO.<br />

Pre-charge pressure should be checked periodically.<br />

3 Charging and checking should be done with an accumulator charge kit similar to Stauff Part # STA-CK-1.<br />

4 Remove gas valve protection cap and valve cap as per pre-charge procedure instructions (B) on page 14<br />

5 Attach gauge assembly to accumulator gas valve.<br />

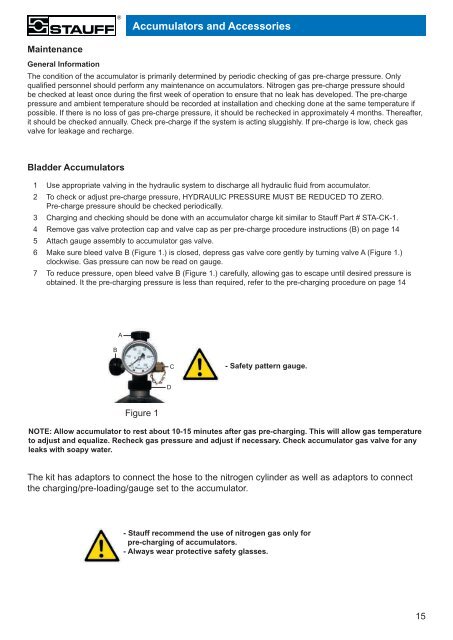

6 Make sure bleed valve B (Figure 1.) is closed, depress gas valve core gently by turning valve A (Figure 1.)<br />

clockwise. Gas pressure can now be read on gauge.<br />

7 To reduce pressure, open bleed valve B (Figure 1.) carefully, allowing gas to escape until desired pressure is<br />

obtained. It the pre-charging pressure is less than required, refer to the pre-charging procedure on page 14<br />

B<br />

A<br />

Figure 1<br />

D<br />

C<br />

- Safety pattern gauge.<br />

NOTE: Allow accumulator to rest about 10-15 minutes after gas pre-charging. This will allow gas temperature<br />

to adjust and equalize. Recheck gas pressure and adjust if necessary. Check accumulator gas valve <strong>for</strong> any<br />

leaks with soapy water.<br />

The kit has adaptors to connect the hose to the nitrogen cylinder as well as adaptors to connect<br />

the charging/pre-loading/gauge set to the accumulator.<br />

- Stauff recommend the use of nitrogen gas only <strong>for</strong><br />

pre-charging of accumulators.<br />

- Always wear protective safety glasses.<br />

15