Piezomechanik

Piezomechanik

Piezomechanik

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

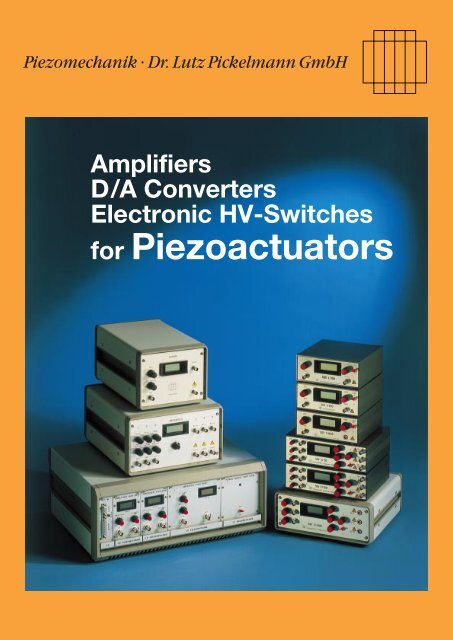

<strong>Piezomechanik</strong> · Dr. Lutz Pickelmann GmbH<br />

Amplifiers<br />

D/A Converters<br />

Electronic HV-Switches<br />

for Piezoactuators

Table of Contents<br />

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3<br />

Electro-Mechanical relations of piezoelectric actuators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4<br />

Practical aspects of dynamically operated piezoactuators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7<br />

Selection guide for amplifiers/supply electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9<br />

Special features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11<br />

Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11<br />

Useful formulas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12<br />

Data of amplifiers<br />

SQV analog amplifiers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13<br />

Low voltage analog power amplifiers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16<br />

High voltage power amplifiers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19<br />

Bimorph amplifiers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24<br />

D/A Converters, Computer-Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26<br />

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28<br />

2 Amplifiers, D/A Converters, Electronic HV-Switches for Piezoactuators http://www.piezomechanik.com

Amplifiers, D/A Converters, Electronic HV-Switches for piezoactuators<br />

1. Introduction<br />

Piezoelectrical actuators are innovative driving systems,<br />

which show increasing application potential for highly sophisticated<br />

driving/positioning tasks in a great variety of technological<br />

fields. The main areas of interest include<br />

• the extreme positioning sensitivity, enabling such<br />

systems to handle dimensions in the atomic scale<br />

• extreme force generation resulting for example in high<br />

acceleration rates during dynamic operation.<br />

For some applications no practicable alternative to piezoactuators<br />

exist<br />

• Piezoelectric actuators are used for the ultraprecise positioning<br />

of components and mechanical setups ranging<br />

from low weight optical elements, up to heavy loads such<br />

as tooling machines. The newest scanning microscope<br />

General considerations for electronic supplies for piezoactuators:<br />

In the simplest case a piezoactuator should move according<br />

to an external signal i.e. from a sinewave generator, or other<br />

source. In most cases, this original signal cannot be applied<br />

directly to the piezoactuator because voltage and power<br />

usually do not match the actuator’s requirements. An amplifier<br />

has to be used to convert the signal to result in sufficient<br />

travel and dynamics of the actuator.<br />

This is an important aspect of actuator’s application:<br />

The adaptation of a piezoelement to a distinct task is determined<br />

only in part by its mechanical properties and geometrical<br />

size. Equally important for the system’s performance<br />

are the properties of the driving electronics.<br />

The same actuator can be used for completely different<br />

operating profiles depending only on the choice of the supply<br />

electronics:<br />

signal<br />

generator<br />

elec. signal<br />

function generator<br />

feedback control electronic<br />

computer<br />

amplifier<br />

pulser<br />

Fig. 1:<br />

Schematic representation of an actuator system<br />

When designing a piezoactuated system the designer<br />

has to deal simultaneously with actuator and supply to<br />

get the optimum matching. A step-by-step definition<br />

whereby the actuator is first-chosen and then a sub-<br />

matching<br />

electronics<br />

technologies such as STMs, AFMs etc. require precise<br />

handling of probe tips with sub-nanometer precision,<br />

which can only done in a reasonable way by using piezomechanical<br />

elements.<br />

• The high acceleration rates/short reaction times predestinate<br />

piezoelements for the control of fast processes in<br />

valve technology, fuel injection application, mechanical<br />

shaking excitation for test purposes with time periods/risetimes<br />

in the microseconds range.<br />

• Piezoactuators are very attractive candidates for active<br />

vibration control and cancellation even in heavy and extended<br />

mechanical structures such as vehicles, airplanes,<br />

helicopters, ships. A special feature is the dual effect of<br />

piezoelectricity, which can be used both for sensing and<br />

actuating. Single element can therefore be used as smart<br />

transducers acting simultaneously as sensor and actuator.<br />

Slow cycling of an actuator requires only a small low power<br />

supply, whereas pulsed operation i.e. generating mechanical<br />

shocks, needs supplies with peakpowers in the kilowatt<br />

range.<br />

Computer control of actuators comprises an additional step:<br />

the computer data has to be converted by a D/A converter of<br />

sufficient speed and resolution, and the low voltage signal is<br />

than amplified to the actuator’s requirements.<br />

piezo<br />

actuator<br />

mechan.<br />

reaction<br />

sequent selection of the supply may lead to costly and<br />

ineffective approaches.<br />

http://www.piezomechanik.com Amplifiers, D/A Converters, Electronic HV-Switches for Piezoactuators<br />

3

2. Electro-Mechanical relations of<br />

piezoelectric actuators<br />

2.1. Principle structures of piezoactuators<br />

Generally, all piezoelectric devices/transducers such as<br />

stacks, bimorphs, tubes can be described as a kind of capacitor<br />

with an electromechanically active dielectric medium:<br />

the PZT ceramic. Therefore, the electrical capacitance of<br />

such devices is an important operating parameter, especially<br />

when adapting the supply electronics for dynamic operation.<br />

The electrical capacitance of piezoactuators is shown in the<br />

data sheet.<br />

The strain within the PZT-medium is related to the internal<br />

electrical field strength when a voltage is applied to the element.<br />

An important consequence for practical consideration<br />

is, that the thinner the PZT-layers are, the lower can be the<br />

driving voltage. Furthermore the degree of lamination determines<br />

the electrical capacitance of piezoactuators.<br />

ceramic endfaces<br />

piezoceramic<br />

layers<br />

electrical<br />

connection<br />

Fig. 2a:<br />

Schematic representation of the capacitive layer structure of a<br />

piezostack<br />

Fig. 2b:<br />

Discretely built-up piezoelectric stack (high voltage type), external<br />

contact electrodes visible<br />

Low voltage actuator types are operated with maximum<br />

voltages ranging from 50 V to 150 V, whereas the high<br />

voltage elements require hundreds of volts up to 1000 V (and<br />

more). For standard stacks the achieved maximum strain is<br />

about 1–1.5‰ of the stack length. There exist highstrain<br />

stacks based on optimized PZT-materials showing a strain of<br />

2‰ and more at fieldstrength of 3 kV/mm.<br />

2.2. Polarity of piezoelectrical elements<br />

For piezoelectrical components an electrical polarity is<br />

usually defined. Piezoelectrical actuators e.g. stacks can only<br />

achieve their maximum response by applying the maximum<br />

voltage with correct polarity. Operation with counterpolarity<br />

voltage although possible is limited to remarkably lower<br />

ratings. A stack actuator shrinks under these conditions,<br />

increasing thereby to some extent the total moving range of<br />

the stack (see brochure “piezomechanical stackactuators”).<br />

Bare piezostacks without casing are usually electrically insulated<br />

at the mechanical mounting points. They are supplied<br />

with pigtails showing the polarity by red(+) and black(–) insulation.<br />

Such elements can be combined therefore with positive<br />

or negative voltage supplies without difficulty. The situation<br />

changes, when actuators with casing are used. Here, the<br />

ground is defined by the coax-cable and therefore the polarity<br />

of the supply voltage is fixed.<br />

Piezoactuators with casing and the supply electronics from<br />

PIEZOMECHANIK are designed for positive polarity both for<br />

low voltage and high voltage actuators. This supports the<br />

easy combination of higher voltage actuators with lower<br />

voltage supplies, which is an important aspect for dynamic<br />

operation of actuators (see section 2.5.).<br />

2.3. Operating characteristics of piezoactuators<br />

The expansion of piezoelectric actuators is illustrated by<br />

voltage/expansion diagrams showing the well-known<br />

hysteresis (fig.3).<br />

rel.<br />

expansion<br />

rel. voltage<br />

Fig. 3:<br />

Relative voltage/expansion diagram of a free running piezoactuator for<br />

different voltage reversal points<br />

4 Amplifiers, D/A Converters, Electronic HV-Switches for Piezoactuators http://www.piezomechanik.com

Actuators are normally classified by the maximum applicable<br />

voltage for maximum stroke, and characterised as low<br />

voltage and high voltage types. For newcomers in piezotechnology,<br />

this sometimes gives the impression, that the voltage<br />

rating of an actuator is the sole criterion for selecting a<br />

proper electronic supply. This is however not correct.<br />

For any application of piezoactuators the electrical power/<br />

current balance for charging and discharging the piezoactuator’s<br />

capacitance has to be kept in mind. The variety of<br />

electrical supplies on offer is due mainly to the different<br />

power/current ratings of these devices.<br />

The charge/current balance during operation is related to<br />

the capacitive nature of actuators as shown below:<br />

Basic capacitor equation<br />

Q(t) = C U(t) C actuator’s capacitance<br />

Q actual electrical charge<br />

U applied voltage<br />

Obviously the expansion of an actuator is also related to<br />

the quantity Q of electrical charge stored in the actuator’s<br />

capacitance C, when a voltage U is applied.<br />

From this charge balance, the kinetic parameters of motion<br />

like speed and acceleration can be derived. These relations<br />

are the base for specifying the necessary current/power for<br />

distinct driving conditions.<br />

Actuator’s position l ~ charge = Q(t)<br />

.<br />

Speed v ~ current I = dQ/dt = Q(t)<br />

..<br />

Acceleration b ~ variation of current = dI/dt = Q(t)<br />

The generation for example of a sine-wave oscillation by<br />

a piezoactuator requires a defined supply current depending<br />

on actuator’s capacitance and moving amplitude.<br />

Therefore an amplifier has to be selected for both criteria:<br />

voltage and current.<br />

Another consequence of the above is that, during a<br />

steady state of the actuator (constant position, constant<br />

force) no current is flowing, therefore no power is required.<br />

When a charged actuator is disconnected from<br />

the supply, it holds its position. This is an important<br />

difference to electromagnetic systems, where a constant<br />

position requires constant electrical power due to the<br />

sustaining current.<br />

The speed of an actuator cannot be increased infinitely even<br />

by very high currents, but is limited by the elastic properties<br />

of the stack. The maximum speed of stacked elements is in<br />

the range of a few m/sec.<br />

Because of the very limited moving range of piezoactuators<br />

the generation of above speeds requires high acceleration<br />

rates up to 10 4 –10 5 g.<br />

During operation of a piezodriven mechanical setup for highly<br />

dynamic application, it has to be verified that the mechanics<br />

coupled to the actuator shows a sufficiently high stiffness/<br />

resonant frequency, otherwise the mechanics cannot follow<br />

actuator’s motion and it is fruitless to optimize the drive for<br />

high speed/acceleration.<br />

2.4. Peak current, average current<br />

Piezoactuators require electrical power/current only during<br />

dynamic operation. Expansion and contraction are characterized<br />

by charging/discharging currents.<br />

The short term available maximum peak current of a supply<br />

determines the minimum risetime/maximum speed of an<br />

actuator. Amplifiers of the series LE provide a special booster<br />

stage for high peak currents to get minimum risetimes.<br />

The average current of a supply determines the longterm<br />

cw-repetition rate of charging/discharging an actuator.<br />

For cw sine oscillation of an actuator, the required peak and<br />

average currents show a fixed ratio of approx. 3:1. Therefore,<br />

the selection of a supply to obtain a distinct cw-actuator frequency<br />

has to consider both, peak and average current data.<br />

2.5. Power efficiency<br />

This section will lead on the first glance to the (surprising)<br />

result, that it is sometimes very reasonable and necessary to<br />

combine a high voltage actuator with a low voltage supply,<br />

where only a fraction of the actuator’s maximum amplitude<br />

can be achieved.<br />

The reason for this strategy are twofold:<br />

• optimizing power efficiency of a dynamically operated<br />

actuator system<br />

• minimizing selfheating of a dynamically operated actuator.<br />

The basic idea is easily demonstrated with the following<br />

example, where the task requires the generation e.g. of a<br />

+/–2,5 µm sine oscillation with a distinct frequency:<br />

The first example uses an actuator type PSt 500/5/5, where<br />

500 V has to be applied to get the full stroke of 5 µm.<br />

A second example is to use the longer stack PSt 500/5/15<br />

capable for a 15 µm motion at 500 V, showing an actuator’s<br />

capacitance 3 times larger than in the 1st case.<br />

The important fact is, that with the longer stack only 150 V<br />

are needed to get the desired 5 µm stroke.<br />

Comparing the actuators’ energy content 1/2 CU 2 respectively,<br />

despite its larger capacitance the longer stack is<br />

favoured regarding power efficiency as only 1/3 of the power<br />

necessary to drive the shorter PSt 500/5/5 with full strain is<br />

required. It is obvious, that a 150 V system’s total power efficiency<br />

is further improved by using a 150 V supply showing<br />

higher current output compared to a 500 V supply operated<br />

at reduced voltage rating.<br />

In the above described strategy, the problem of selfwarming<br />

under dynamic operating conditions is minimized by the<br />

reduced power input and by distribution of the dissipated<br />

energy over a larger volume/surface of the longer actuator.<br />

This is a powerful method to extend the application range of<br />

piezoactuators to high frequency cw-operation without the<br />

risk of overheating.<br />

This strategy of dynamic operation of actuators with reduced<br />

strain shows restrictions in other operating parameters: A<br />

longer stack has a lower stiffness and resonance, and it has<br />

to be determined, whether this is acceptable for a distinct<br />

application.<br />

Finally, an important contribution to the overall power<br />

efficiency of an actuator system is the use of recharger<br />

amplifiers (switched amplifiers).<br />

In most applications, piezoactuators display mainly a reactive<br />

load, where the energy content of a charged actuator flows<br />

back to the amplifier during the discharging cycle. Switched<br />

amplifiers RCV are able to recycle this energy with high efficiency,<br />

so that the needed linepower for a dynamically operated<br />

system has only to cover the (much smaller) active part<br />

of the power balance.<br />

This active power is drawn from the system as mechanical<br />

power or dissipated by the selfheating of the actuators.<br />

This technique shows the optimum of systems’s overall<br />

power efficiency, and favours actuator applications, where<br />

high power levels are required e.g. for active vibration cancellation<br />

in heavy mechanical structures (vehicles, airplanes<br />

etc.) or anywhere, where the power consumption from the<br />

power supply is restricted i.e. battery operated systems.<br />

Power efficiency � is defined as<br />

� = (P r–P al) Pr = reactive power output from amplifier<br />

� = (P r) Pal = active power consumption from line<br />

An ideal amplifier without internal losses shows an efficiency<br />

1.<br />

http://www.piezomechanik.com Amplifiers, D/A Converters, Electronic HV-Switches for Piezoactuators<br />

5

2.6. Frequency response<br />

The performance of an amplifier is characterized by its frequency<br />

response, describing what cw-frequency/amplitude<br />

relations that can be achieved for a defined capacitive load.<br />

The achievable maximum frequencies of an actuator/supplysystem<br />

depend both on the output power of the supply, the<br />

capacitance of the driven actuator and the oscillation amplitude.<br />

To make the selection of an amplifier/actuator combination<br />

with respect to frequency response easier, some response<br />

curves for different capacitive loads are shown in the<br />

data sheet for distinct amplitudes. The response for intermediate<br />

capacitances are achieved by simple interpolation.<br />

An additional figure for an amplifier’s performance is the<br />

achievable minimum risetime, which is tabulated for some<br />

load capacitances (see section 2.4.).<br />

2.7. Voltage stability, noise<br />

One of the most striking features of piezoactuators is their<br />

unlimited positioning sensitivity, which explains the sub-nanometer<br />

resolution for example scanning tunnel microscopes:<br />

A infinitely small voltage step Æ U is transformed into infinitely<br />

small mechanical shift Æ l.<br />

Æ l = l Æ U/U l = actuator’s shift for signal voltage U<br />

Neglecting external influences, the positioning sensitivity of<br />

an actuating system is limited only by the stability of the<br />

electronic supply (noise).<br />

Example:<br />

The amplifiers SQV 150 show a noise of approx. 1 mV equivalent<br />

to a S/N ratio of about 10 5 . A 100 µm actuator such as<br />

the PSt 150/7/100 VS 12 operated with the SQV 150 shows a<br />

variation in position of only 1 nm.<br />

2.8. Pulsed operation of piezoactuators<br />

An important feature of piezoactuators is their capability to<br />

produce extreme forces and acceleration rates, which can be<br />

used for fast switching of valves or to produce mechanical<br />

shocks. In such cases, the actuator should switch in as short<br />

time as possible between 2 distinct levels, whereas the exact<br />

motion profile between these levels is not important.<br />

The minimum risetime of an actuator can derived from its<br />

elastic properties:<br />

A short electrical pulse excites the resonant oscillation of the<br />

actuator and the minimum risetime Tp can be estimated by<br />

Tp Å Tr/3 Tr = period time of actuator’s resonance<br />

Tp = minimum risetime in pulsed operation<br />

Example:<br />

A systems’s resonant frequency of 3 kHz results in a minimum<br />

mechanical risetime of about 100 µsec.<br />

A simple calculation shows, that above shown pulse generation<br />

requires peak powers up to the kilowatts range with currents<br />

of 10 to 100 Amperes. In these cases it is reasonable<br />

not to use analogue amplifiers but electronic pulse switches.<br />

The common design of a HV-pulse generator consists of a<br />

high voltage supply, which continuously charges at a defined<br />

low power (i.e. 50 Watt) a large internal charge storing<br />

capacitor.<br />

This capacitor delivers short term the very high currents to<br />

the external piezoactuator capacitance, when it is switched<br />

by transistors via a load resistor R. The load resistor R acts<br />

as current limiter to avoid electrical overpowering and<br />

defines the time constant RC of the pulser (rise/fall-time)<br />

according the well-known relation<br />

Ua = U o (1-e -t/RC )<br />

R = internal load resistor of switch<br />

C = capacitance of external load (piezoactuator)<br />

Ua = voltage level at actuator<br />

Uo = supply voltage from internal charge storing capacitor<br />

For the operation of the HVP’s 3 time constants have to be<br />

distinguished:<br />

• Switching time of output transistors:<br />

order of magnitude: 1 µsec<br />

defines the minimum electrical pulsewidth<br />

• Time constant RC:<br />

Defines the signal/voltage risetime at the actuator.<br />

Pulsewidths shorter RC lead to a partial charging of the<br />

actuator and thereby to intermediate positions between<br />

“low” and “high”<br />

• Period time of actuator/actuated system (fig. 4.):<br />

This time constant defines the minimum mechanical<br />

rise/fall-time of the system.<br />

To excite the minimum mechanical risetime Tp of an actuator,<br />

the RC time constants of the pulsersystem has to be<br />

shorter than Tp.<br />

voltage step<br />

Fig. 4:<br />

Excitation of a mechanical pulse by a voltage step 0V/Uo; lo final static<br />

position of actuator<br />

2.9. Feedback controlled systems<br />

Piezoelectric actuators are well-suited for setting up electronically<br />

controlled systems for fast and precise handling of<br />

mechanical parameters such as position, speed and force.<br />

Because of the hysteretic and slightly nonlinear behaviour of<br />

piezoactuators, and nonpredictable external influences, this<br />

has to be done by feedback control. A sufficiently fast and<br />

sensitive transducer picks up the actual position or other<br />

parameter of interest and the signal is evaluated by feedback<br />

control electronics, producing the control signal for the<br />

actuator.<br />

The overall efficiency e.g. precision of such a system is<br />

determined by the transducer and electronics and not by the<br />

actuator. The high performance of feedback controlled<br />

systems is demonstrated by the atomic resolution of the<br />

scanning tunnel microscopes (STMs).<br />

6 Amplifiers, D/A Converters, Electronic HV-Switches for Piezoactuators http://www.piezomechanik.com

A further application is the active stabilization of mechanical<br />

arrangements e.g. laser resonators against misalignment due<br />

to thermal drifts or mechanical shocks (see “feedback controlled<br />

stabilization PiStab 2”).<br />

3. Practical aspects of dynamically operated<br />

piezoactuators<br />

3.1. Preloading, reset mechanisms<br />

Piezoceramic is sensitive to tensile stress, it shows a damage<br />

strain of only 1‰.<br />

Note, that this tensile stress can be created externally and<br />

also internally by dynamic operation. This fact is easily seen<br />

in Fig 4/sec. 2.8., where the application of an electric pulse<br />

leads to overshooting of the actuator relative to the steady<br />

state position. This overshooting can cause tensile stress<br />

and thereby damage to the actuator when the relevant forces<br />

are not compensated by other means.<br />

To prevent damage by tensile forces the following strategies<br />

are commonly applied:<br />

• passive preloading/reset of actuators<br />

This technique is mostly applied to stack actuators:<br />

An elastic spring compresses the piezostack with a defined<br />

force shown in fig. 5a, b. A preloaded stack is less sensitive<br />

to externally applied tensile stress for several reasons, i.e. a<br />

reduction in stacklength is achieved by the preload force. A<br />

Fig. 5a:<br />

Mirror tilter with passive prestress/reset<br />

Fig. 5b:<br />

Linear stackactuator with passive prestress/reset<br />

http://www.piezomechanik.com Amplifiers, D/A Converters, Electronic HV-Switches for Piezoactuators<br />

piezostack<br />

tilting<br />

prestress spring<br />

piezostack<br />

mirror surface<br />

prestress/reset<br />

spring<br />

7

eal tensile stress is acting on the ceramic only, when the<br />

external force lengthens the stack beyond the original (loadfree)<br />

state.<br />

Furthermore, the elastic counterforce slows down the moving<br />

mass in the overshoot phase during dynamic operation.<br />

So, the applied preload force can be chosen according the<br />

tilting<br />

Fig. 6a:<br />

Mirror tilter with active (push-pull) reset<br />

piezostack piezostack<br />

Fig. 6b:<br />

Linear push-pull arrangement of piezostacks for active reset<br />

simple mass acceleration law to accommodate the accelerated<br />

masses within the desired short rise/fall-times.<br />

The standard preloading VS of PIEZOMECHANIK actuators<br />

cover a wide range of applications. It is possible to apply<br />

higher preload forces, which can be supplied on request or<br />

can be applied externally (see brochure “piezomechanical<br />

stackactuators”).<br />

• active reset<br />

(push-pull mode, antagonistic configuration)<br />

mirror surface<br />

A more sophisticated reset mechanism for compensating<br />

dynamic forces is the arrangement with two complementary<br />

working actuators shown in fig. 6a, b. The advantages<br />

include a symmetric force balance for both directions of<br />

motion, and higher resonance frequencies compared with<br />

passive preloading.<br />

3.2. Selfheating<br />

Another aspect of dynamically operating piezoactuators is<br />

their selfheating. Due to the ferroelectric nature of PZT ceramics,<br />

the electrical operating power transferred to the actuator<br />

is partially dissipated as heat. For example an actuator<br />

PSt 150/5/15 with full amplitude operation heats up to the<br />

operating temperature limit at about 600 Hz. Higher temperatures<br />

will shorten an actuators lifetime. A further increase of<br />

frequency therefore requires cooling or an equivalent reduction<br />

of amplitude (see sec. 2.5).<br />

Simple surface cooling results in limited success for large<br />

volume actuators, because PZT ceramics have poor thermal<br />

conductivity. Furthermore measuring the actuator’s temperature<br />

on its surface does not reflect the internal conditions. A<br />

good parameter for checking the volume temperature is the<br />

temperature dependence of the electrical capacitance of the<br />

actuator leading to a shift of the current balance.<br />

Fig. 7:<br />

Temperature dependence of the electrical capacitance of a typical<br />

piezoactuator (relative to capacitance at roomtemperature)<br />

8 Amplifiers, D/A Converters, Electronic HV-Switches for Piezoactuators http://www.piezomechanik.com

3.3. Vibration control, acoustical noise<br />

Every dynamic excitation of a piezoactuator attached to a<br />

mechanical structure acts back on this structure. Pulsed or<br />

oscillating actuators generate vibrations in the mechanical<br />

structure. In case of a resonance a large amplitude response<br />

can emerge even for small excitation levels, which can interfere<br />

with the regular function of the structure. Therefore,<br />

dynamically operated structure have to be designed for sufficiently<br />

large resonant frequencies, and include sufficient<br />

damping to avoid these unwanted side effects at the driving<br />

frequency.<br />

Vibration suppression can be done in passive or active ways.<br />

An example for active pulse compensation is shown in fig. 8,<br />

where a counteracting piezostack compensates for the<br />

repulse of the original stack, e.g. shifting a mirror.<br />

Generally, piezoelements are powerful tools for vibration<br />

control, both for generating vibrations (shakers) and for cancellation<br />

(active vibration isolation and damping). Active com-<br />

static suspension<br />

mirror compensating<br />

mass<br />

piezostack piezostack<br />

impulse 0<br />

Fig. 8:<br />

Mechanical impulse compensation<br />

pensation can be done in feedback controlled systems,<br />

where a transducer detects an incoming vibration, and<br />

excites an antivibration with proper amplitude and phase<br />

relation via an actuator.<br />

From ergonomic aspects, it must be kept in mind, that<br />

actuator vibrations can produce acoustical noise which may<br />

be very uncomfortable for the operator.<br />

4. Selection guide for amplifiers/supply electronics<br />

PIEZOMECHANIK offers a wide range of supply electronics<br />

to obtain the optimum solution for different applications<br />

of piezoactuated systems.<br />

For specifying dynamically operated actuator/amplifier<br />

systems the power/current requirements are determined<br />

by the actuator’s capacitance. Note that the actuator’s<br />

capacitance can vary up to 50% (e.g. see section 3.2.)<br />

leading to correspondingly elevated power/current<br />

ratings.<br />

The supply electronics and actuators from PIEZO-<br />

MECHANIK are set to positive polarity for both high<br />

voltage and low voltage components, so that widest<br />

compatibility is achieved e.g. for power efficient<br />

arrangements according sec. 2.5.<br />

On request PIEZOMECHANIK supplies piezocomponents<br />

for negative operating polarity.<br />

4.1. SQV amplifiers<br />

The range of SQV amplifiers comprises the 3 main voltage<br />

ranges, where piezoactuators are offered namely 150 V<br />

(+200 V), 500 V and 1000 V. The output power is a few watts,<br />

which is sufficient for most applications. Smaller volume<br />

actuators can be operated even with higher dynamic/frequencies.<br />

SQV amplifiers show low noise and are therefore<br />

best suited for positioning tasks with highest positioning sensitivity.<br />

SQV amplifiers are available as 3-channel versions e.g. for<br />

optomechanical xyz adjusters.<br />

4.2. LE amplifiers<br />

LE amplifiers are used, when the power/current requirements<br />

cannot be covered by the SQV amplifiers. The LE series<br />

includes current boosters for optimum system power efficiency,<br />

when e.g. a high frequency sinoidal oscillation has to<br />

be excited, or to get short rise/fall-times for a rectangular<br />

signal.<br />

The LE amplifiers are available for power levels up to hundreds<br />

of watts.<br />

Due to these elevated power levels, selfheating of actuators<br />

according sec. 3.2. should be considered.<br />

4.3. RCV recharging amplifiers<br />

The RCV switched amplifiers are designed for driving<br />

large volume/large capacitance piezoactuators with high<br />

currents and powers up to the kilowatt range beyond the<br />

levels of the LE analog amplifiers. This situation occurs for<br />

example with the active excitation and cancellation of<br />

vibrations in heavy mechanical structures e.g. vehicles,<br />

airplanes etc.<br />

Because the design of RCV amplifiers has to be adapted to<br />

some extent to the operated load, there are no standardized<br />

devices. In principle, RCV amplifiers can also be designed for<br />

lower power ratings. Please contact us for details.<br />

4.4. Bipolar amplifiers<br />

Usually piezoactuators such as stacks are operated unipolar<br />

or asymmetrically bipolar to get maximum displacement.<br />

Some applications exist, where piezoelements are operated<br />

symmetrically bipolar, but to avoid depolarization of the PZT<br />

ceramic, the electrical field strength and thereby actuator’s<br />

efficiency has to be held sufficiently low.<br />

Reasons for bipolar operation include simple electrical driving<br />

conditions e.g. of piezobenders (bimorphs), shearmode<br />

actuators or enhancement of stack actuators lifetime e.g.<br />

within feedback control loops for position stabilization. In this<br />

case, the middle position is defined by 0 V, no offset is required<br />

for symmetric positioning range. This leads to long-<br />

http://www.piezomechanik.com Amplifiers, D/A Converters, Electronic HV-Switches for Piezoactuators<br />

9

term low electrical fields preventing materials degradation by<br />

charge carrier diffusion.<br />

Nevertheless, bipolar amplifiers can also generate unipolar or<br />

asymmetric output by applying a proper signal.<br />

4.5. BMT, AGV antagonistic amplifiers<br />

The AGV/BMT amplifiers are designed to drive push-pull<br />

(antagonistic) stack arrangements or piezobenders (“Bimorphs”)<br />

described in section 3.1. By electrical preloading,<br />

the full operating range of the ceramics can be used without<br />

the risk of depolarization which may happen during simple<br />

bipolar operation. The modulation of the antagonistic piezoelements<br />

is done by a single driving signal, complementary<br />

action is achieved by different static offsets shown in fig. 9a,<br />

b, c. This strategy ensures forced synchronization of motion<br />

of the 2 elements even under high dynamic driving conditions.<br />

For an antagonistic setup, the actuators have to show potential<br />

free design, meaning that the operating ground of the<br />

AGV/BMT<br />

Fig. 9a: Push-pull-stack arrangement with schematic electronic supply<br />

configuration<br />

Fig. 9b:<br />

Operation of a parallel-bimorph with electrical preloading<br />

AGV/BMT amplifier<br />

Fig. 9c:<br />

Equivalent circuit to piezoactuator arrangements 9a, 9b<br />

AGV/BMT<br />

amplifier<br />

piezoelements has to be separated from general ground of<br />

the arrangement.<br />

4.6. HVP high voltage switches for pulse operation<br />

HV-pulse generators are used when currents beyond the<br />

level of common amplifiers are necessary and where a<br />

steady movement of an actuator is not required, but only<br />

defined levels should be set within short times or where<br />

mechanical shocks have to be produced.<br />

The HVP high voltage pulse generators from PIEZOMECHA-<br />

NIK show some interesting features enabling the user to<br />

drive piezoactuators in a more sophisticated way than the<br />

simple “high”, “low” procedure with common switches.<br />

Beside the levels “charging = high”, “discharging = low”<br />

there exist a third level “neutral”, where the output is set to<br />

high resistance, so that the charge content (= position) of the<br />

actuator is kept constant. Thus the system can be set and<br />

held in intermediate positions. This is achieved by applying<br />

signal pulses with width less the time constant RC of the<br />

system, leading to only a partial charging of the actuator’s<br />

capacitance corresponding an intermediate position.<br />

A general approach for pulsed actuator operation is not to<br />

oversize current specs for a distinct application, because too<br />

powerful pulses may cause unnecessary mechanical and<br />

electrical stress to the system. On the other hand the<br />

mechanical reaction time cannot be infinitely improved by<br />

increasing the pulsepower (see sec. 2.8.).<br />

4.7. Computer interfaces<br />

For computer control of piezoactuators a lot of designs and<br />

arrangements for interfacing exist. The selection of the<br />

proper interface for a distinct application depends on the<br />

basic hardware/software the user can provide, and the<br />

flexibility he wants to achieve with his setup.<br />

• Computer with internal D/A converter: computer output is<br />

an analog signal<br />

The supplies low voltage analog signal output (e.g. 0 V to<br />

+10 V) is applied directly to the analog amplifiers etc. from<br />

PIEZOMECHANIK.<br />

• HV-PC-card: The computer output is an analog signal. This<br />

card is inserted in the computer and produces immediately<br />

an analog-HV-signal for voltages up to +150 V or +500 V<br />

also in multichannel configuration. The power range is<br />

similar to the SQV or lower power LE amplifiers. This signal<br />

is directly applicable to the piezoactuator. Space saving<br />

configuration.<br />

• External D/A Converters: The computer output is digital<br />

data.<br />

In this case, the digital data has to be transferred via a<br />

serial or parallel interface similar to any other peripheric<br />

device for a computer e.g. a printer.<br />

The data is then converted by a D/A stage into an analog<br />

signal with subsequent amplification by usual analog<br />

amplifiers.<br />

The low voltage D/A converting unit can be a stand-alone<br />

device, or can be integrated to the amplifiers cabinet. In all<br />

these cases, the analog functions of the amplifiers remain<br />

active e.g. a manual setting of an “offset” voltage is possible,<br />

which is useful for adjusting setups before starting<br />

computer control. Multichannel systems are available.<br />

10 Amplifiers, D/A Converters, Electronic HV-Switches for Piezoactuators http://www.piezomechanik.com

5. Special features<br />

Analog amplifiers from PIEZOMECHANIK show some special<br />

features, which are very useful for the operation of piezoactuators:<br />

“Offset”<br />

The amplifiers are provided with a potentiometer where a<br />

DC-output voltage can be manually set over the full operating<br />

range. In this mode, the amplifier can be used as an<br />

adjustable voltage supply without the application of an<br />

external signal.<br />

When an external signal is amplified, the “Offset” voltage is<br />

superimposed automatically. This is useful, when the signal<br />

generator produces only bipolar signals which have to be<br />

shifted to get the unipolar signal required to drive piezoelements<br />

effectively.<br />

“Amplitude”<br />

Using this potentiometer, the input signal can be adapted to<br />

the working range of the amplifier. It is possible to use signal<br />

levels 5 V as well as 10 V (e.g. from standard D/A converting<br />

units).<br />

Current booster<br />

Higher power amplifiers such as the LE types are provided<br />

with a current booster, which enable the amplifier to produce<br />

a much higher current (for a limited time) than the long term<br />

average current. In this mode, the amplifier is optimized for<br />

high power efficiency when a capacitive load such as a<br />

piezoactuator is operated.<br />

The current booster reduces further the risetime, when<br />

rectangular signals are applied.<br />

For these amplifiers the risetimes for a variety of loads are<br />

tabulated in the datasheet.<br />

Monitor output<br />

The average output voltage is shown on the front display of<br />

the amplifiers.<br />

Realtime signal monitoring is done by the “Monitor”-output,<br />

which represents the actual power output status by a 1:100<br />

ratio low power signal. The monitor-output is used for realtime<br />

representation via an oscilloscope. Further it can be<br />

used as a signal source for any control arrangement (feedback<br />

control, voltage limitation), where information about the<br />

current status of the actuator is needed.<br />

6. Safety Instructions<br />

• During operation of piezoactuators voltages and electrical<br />

currents are present which may be harmful to the<br />

operator<br />

• Installation and operation of actuators and electronics<br />

supplies must be carried out by authorized personal<br />

only<br />

• All electrical installation of electric supplies, cables and<br />

connectors must be carried out according to standard<br />

safety regulations<br />

• Piezoactuators can show large electrical capacitances,<br />

and charged actuators can store electrical charge at<br />

high voltage levels, even for long times after being disconnected<br />

from the power supply.<br />

When large volume actuators are not in use, discharge<br />

them carefully, and hold them shortcircuited.<br />

• Piezoactuators can generate electrical charge at high<br />

voltage levels, when varying load or temperature is<br />

acting on actuators with open leads.<br />

When large volume actuators are not in use, discharge<br />

them carefully, and hold them shortcircuited.<br />

• Take care when opening amplifiers and pulsegenerators.<br />

High voltage levels can be held for a long time<br />

after disconnecting the devices from line due to large<br />

capacitance internal capacitors. If these devices must<br />

be opened, wait at least 15 minutes after disconnecting<br />

them from line. Complete discharge of the internal<br />

capacitors has to be ensured by shortcircuiting via a<br />

proper resistor.<br />

http://www.piezomechanik.com Amplifiers, D/A Converters, Electronic HV-Switches for Piezoactuators 11

7. Useful formulas<br />

Notice: the following relations are dealing with ideal capacitors, where the capacitance is invariable under the driving conditions.<br />

But piezoactuators show to some extent deviations from this ideal behaviour due to their ferroelectric nature. Their<br />

capacitances depend on electrical fieldstrength (voltage level), temperature and other parameters and may exceed the nominal<br />

values by 50%, which are stated in the data sheet.<br />

General:<br />

capacitor relation C = Q/U<br />

charging/discharging current<br />

I(t) = C dU/dt<br />

Average current l, t repetition rate, U o maximum voltage<br />

Sinuoidal excitation<br />

Unipolar signal<br />

Current<br />

U o max. supply voltage<br />

f frequency<br />

C actuators capacitance<br />

Peak current<br />

Average current<br />

I a = U oC/t<br />

U(t) = U o/2 (1-cos 2 p ft)<br />

I(t) = U o C p f sin (2 p ft)<br />

I p = p U max C f<br />

I a = U max C f<br />

Peak current exceeds average current by factor p.<br />

Current booster needed for optimum power efficiency.<br />

Symmetric triangular signal<br />

Peak current<br />

Average current<br />

I p = U maxCf<br />

I a = U maxCf<br />

No current booster necessary.<br />

Pulse excitation<br />

Operating voltage Ua(t) of actuator:<br />

Charging current Ic(t)<br />

Ua(t) = U o (1-e –t/RC )<br />

Ic(t) = (U o-Ua(t))/R<br />

R load resistor of pulse generator (see sec.2.8.)<br />

Peak current at pulse onset:<br />

Average current<br />

Ic max = U o/R<br />

I a = U oCw<br />

w repetition rate, U o supply voltage<br />

Power balance<br />

Energy content E of a charged capacitance<br />

E = 1/2 CU o 2<br />

Average power consumption P A during cycling with repetition<br />

rate w<br />

P A = 1/2 CU o 2 w<br />

Dissipated power (selfheating problem)<br />

During the charging/discharging cycles, the transferred<br />

power is partially dissipated into heat according<br />

P dis = tand CU o 2 w<br />

tand dissipation factor<br />

5–10% of total power with common PZT actuator ceramics<br />

12 Amplifiers, D/A Converters, Electronic HV-Switches for Piezoactuators http://www.piezomechanik.com

SQV analog amplifiers (low voltage/high voltage types)<br />

SQV 1/150 single channel amplifier<br />

+150 V output<br />

Special features: see chapter 5.<br />

Potentiometer “Offset”<br />

Potentiometer “Amplitude”<br />

Input<br />

Input: +/–5 V (+/–10 V see chapter 5)<br />

Input resistance: 10 kOhm<br />

Input connector: BNC<br />

Output:<br />

Voltage range: –10 V thru +150 V<br />

Max. peak current/average current: approx. 60 mA<br />

Gain: 30<br />

Noise: approx. 1 mVpp with capacitive load (actuator)<br />

Connector: BNC<br />

Display: LCD, 3 digits<br />

Dimensions: WxDxH 165x210x70 mm<br />

Weight: approx. 1.7 kg<br />

SQV 3/150 triple channel device<br />

3 independent channels<br />

Performance data /channel equiv. SQV 1/150<br />

LC-voltage display, channel selection by dial<br />

Dimensions: WxDxH 215x210x70<br />

Weight: 2.4 kg<br />

Option:<br />

Amplifier for 200 V output: on request<br />

open<br />

output:<br />

U max/2 >20 kHz<br />

Frequency response<br />

Risetimes:<br />

(for square wave input signal)<br />

Load risetime<br />

capacitance to 100 V/150 V<br />

22 µF 40 msec /80 msec<br />

4.2 µF 8 msec /18 msec<br />

1.2 µF 2 msec / 5 msec<br />

330 nF 0.5 msec /1.2 msec<br />

http://www.piezomechanik.com Amplifiers, D/A Converters, Electronic HV-Switches for Piezoactuators 13

SQV 1/500 single channel amplifier<br />

+500 V output<br />

Special features: see chapter 5.<br />

Potentiometer “Offset”<br />

Potentiometer “Amplitude”<br />

Input<br />

Input: +/–5 V (+/–10 V see chapter 5)<br />

Input resistance: 10 kOhm<br />

Input connector: BNC<br />

Output:<br />

Voltage range: 0 V thru +500 V<br />

Max. peak current/average current: approx. 20 mA<br />

Gain: 100<br />

Noise: approx. 1 mVpp with capacitive load (actuator)<br />

Connector: BNC<br />

Display: LCD, 3 digits<br />

Dimensions: WxDxH 165x210x70 mm<br />

Weight: approx. 1.7 kg<br />

SQV 3/500 triple channel device<br />

3 independent channels<br />

Performance data /channel equiv. SQV 1/500<br />

LC-voltage display, channel selection by dial<br />

Dimensions: WxDxH 215x210x70<br />

Weight: 2.4 kg<br />

open<br />

output:<br />

U max/2 >20 kHz<br />

Frequency response<br />

Risetimes:<br />

(for square wave input signal)<br />

Load risetime<br />

capacitance to 300 V/500 V<br />

1.2 µF 20 msec / 42 msec<br />

660 nF 10 msec / 22 msec<br />

330 nF 5 msec / 11 msec<br />

100 nF 1.5 msec / 3.5 msec<br />

30 nF 0.5 msec / 1.2 msec<br />

14 Amplifiers, D/A Converters, Electronic HV-Switches for Piezoactuators http://www.piezomechanik.com

SQV 1/1000 single channel amplifier<br />

+1000 V output<br />

Special features: see chapter 5.<br />

Potentiometer “Offset”<br />

Potentiometer “Amplitude”<br />

Input<br />

Input: +/–5 V (+/–10 V see chapter 5)<br />

Input resistance: 10 kOhm<br />

Input connector: BNC<br />

Output:<br />

Voltage range: 0 V thru +1000 V<br />

Max. peak current/average current: approx. 10 mA<br />

Gain: 200<br />

Connector: LEMOSA OS.250 (BNC adaptor available)<br />

Noise: approx. 5 mVpp with capacitive load (actuator)<br />

Display: LCD, 3 digits<br />

Dimensions: WxDxH 165x210x70 mm<br />

Weight: approx. 1.7 kg<br />

SQV 3/1000 triple channel device<br />

3 independent channels<br />

Performance data /channel equiv. SQV 1/1000<br />

LC-voltage display, channel selection by dial<br />

Dimensions: WxDxH 255x290x115<br />

Weight: 3.5 kg<br />

open output<br />

U max/2 >20 kHz<br />

Frequency response<br />

Risetimes:<br />

(for square wave input signal)<br />

Load risetime<br />

capacitance to 700 V/1000 V<br />

1.2 µF 70 msec /140 msec<br />

330 nF 20 msec /35 msec<br />

100 nF 6 msec /10 msec<br />

30 nF 1.8 msec / 3 msec<br />

http://www.piezomechanik.com Amplifiers, D/A Converters, Electronic HV-Switches for Piezoactuators 15

Low voltage analog power amplifiers<br />

LE 150/025 single channel amplifier<br />

+150 V output<br />

Special features: see chapter 5.<br />

Potentiometer “Offset”, “Amplitude”, Current Booster,<br />

Monitor output<br />

Input<br />

Input: +/–5 V (+/–10 V see chapter 5)<br />

Input resistance: 10 kOhm<br />

Input connector: BNC<br />

Output:<br />

Voltage range: –10 V thru +150 V<br />

Max. peak current: approx. 250 mA<br />

Max. average current: approx. 70 mA<br />

Gain: 30<br />

Noise: approx. 15 mVpp<br />

Connector: BNC<br />

Display: LCD, 3 digits<br />

Dimensions: WxDxH 185x330x150 mm<br />

Weight: approx. 4 kg<br />

Options:<br />

Multichannel arrangements: on request<br />

Amplifier for 200 V output: on request<br />

Computer interfaces:<br />

Optionally, the amplifier LE 150/025 can be equipped by a serial or parallel (CENTRONIX) computer interface (designation as<br />

LE 150/025-S or/-P respectively) for digital control by a fast data transfer and D/A conversion. Up to 3 channels can be operated<br />

simultaneously.<br />

All analog functions of the amplifier remain active. By using ”offset” the amplified signal can be superimposed by a DC-voltage<br />

and the operating voltage range can be varied by ”amplitude” for easy adaption to a distinct application. The resolution is<br />

12 bit.<br />

Order code<br />

LE 150/025 analog amplifier<br />

LE 150/025-S with additional serial interface<br />

LE 150/025-P with additional parallel interface<br />

open<br />

output:<br />

U max/2 >20 kHz<br />

Frequency response<br />

Risetimes:<br />

(for square wave input signal)<br />

Load risetime<br />

capacitance to 100 V/150 V<br />

22 µF 10 msec/50 msec<br />

4 µF 2 msec/ 3 msec<br />

1.2 µF 0.5 msec/ 0.8 msec<br />

330 nF 120 µsec/180 µsec<br />

16 Amplifiers, D/A Converters, Electronic HV-Switches for Piezoactuators http://www.piezomechanik.com

LE 150/100 single channel power amplifier<br />

+150 V output<br />

Special features: see chapter 5<br />

Potentiometer “Offset”, “Amplitude”, Current Booster,<br />

Monitor output<br />

Input<br />

Input: +/–5 V (+/–10 V)<br />

Input resistance: 10 kOhm<br />

Input connector: BNC<br />

Output:<br />

Voltage range: 0 V thru +150 V<br />

Max. peak current: approx. 1200 mA<br />

Max. average current: approx. 350 mA<br />

Gain: 30<br />

Connector: BNC<br />

Noise: approx. 15 mVpp<br />

Display: LCD, 3 digits<br />

Dimensions: WxDxH 330x260xl55<br />

Weight: approx. 7 kg<br />

Options:<br />

Multichannel arrangements: on request<br />

amplifier for 200 V output: on request<br />

Frequency response<br />

Risetimes:<br />

(for square wave input signal)<br />

Load risetime<br />

capacitance to 100 V/150 V<br />

47 µF 3 msec/7 msec<br />

22 µF 1.8 msec/4 msec<br />

4 µF 330 µsec/500 µsec<br />

1.2 µF 90 µsec/130 µsec<br />

330 nF 20 µsec/35 µsec<br />

Computer interfaces:<br />

Optionally, the amplifier LE 150/100 can be equipped by a serial or parallel (CENTRONIX) computer interface (designation as<br />

LE 150/100-S or/-P respectively) for digital control by a fast data transfer and D/A conversion. Up to 3 channels can be operated<br />

simultaneously.<br />

All analog functions of the amplifier remain active. By using “offset” the amplified signal can be superimposed by a DC-voltage<br />

and the operating voltage range can be varied by “amplitude” for easy adaption to a distinct application. The resolution is<br />

12 bit.<br />

Order code<br />

LE 150/100 analog amplifier<br />

LE 150/100-S with additional serial interface<br />

LE 150/100-P with additional parallel interface<br />

open<br />

output:<br />

http://www.piezomechanik.com Amplifiers, D/A Converters, Electronic HV-Switches for Piezoactuators 17

Amplifier system LE 150/200<br />

(formerly LE 150/2)<br />

Modular arrangement of up to 3 independent channels.<br />

For operation of large volume/high capacitance piezoactuators.<br />

The technical data are similar to the LE 150/100 amplifier<br />

except for higher peak current.<br />

Technical data valid per channel.<br />

Special features: see chapter 5<br />

Potentiometer “Offset”, “Amplitude”, Current Booster<br />

Input<br />

Input: +/–5 V (+/–10 V see chapter 5)<br />

Input resistance: 10 kOhm<br />

Input connector: BNC<br />

Output:<br />

Voltage range: –10 V thru +150 V<br />

Max. peak current: 2000 mA<br />

Max. average current: approx. 400 mA<br />

Gain: 30<br />

Connector: BNC<br />

Noise: approx. 50 mVpp<br />

Display: LCD, 3 digits<br />

Dimensions: Single channel version LE 150/200-1<br />

BxWxD 340x350x180<br />

Weight: 10 kg<br />

Options:<br />

Multichannel arrangements: on request<br />

Amplifier for 200 V output: on request<br />

Frequency response<br />

Risetimes:<br />

(for square wave input signal)<br />

Load risetime<br />

capacitance to 100 V/150 V<br />

47 µF 2.4 msec/4 msec<br />

22 µF 1.2 msec/2 msec<br />

4 µF 240 µsec/400 µsec<br />

1.2 µF 60 µsec/150 µsec<br />

330 µF 15 µsec/40 µsec<br />

Computer interface:<br />

The amplifier system LE 150/200 is available with a computer interface module for both types of data transfer serial and parallel<br />

(CENTRONIX). Up to 3 channels can be operated simultaneously. All analog functions of the amplifier modules remain<br />

active. By “offset” the amplified digital signal can be superimposed by a DC-voltage and the operating voltage range can be<br />

varied by “amplitude” for easy adaption to a distinct application. The resolution is 12 bit.<br />

Order code: D/A-LE<br />

Analog amplifier LE 150/300<br />

Single channel power amplifier<br />

Output: Voltage range –10 V thru +150 V<br />

Max. peak current: 3 A<br />

Max. average current: 1 A<br />

open<br />

output:<br />

Analog amplifier LE 150/100 bp<br />

Bipolar amplifier system with +/–150 V output.<br />

Voltage range: –150 V thru +150 V<br />

Max. peak current: 1000 mA<br />

Max. average current: 200 mA<br />

18 Amplifiers, D/A Converters, Electronic HV-Switches for Piezoactuators http://www.piezomechanik.com

High voltage power amplifiers<br />

LE 430/015 single channel amplifier<br />

+430 V output<br />

Special features: see chapter 5<br />

Potentiometer “Offset”, “Amplitude”, Current Booster,<br />

Monitor output<br />

Input<br />

Input: +/–5 V (+/–10 V see chapter 5)<br />

Input resistance: 10 kOhm<br />

Input connector: BNC<br />

Output:<br />

Voltage range: 0 V thru +430 V<br />

Max. peak current: 150 mA<br />

Max. average current: approx. 35 mA<br />

Gain: 85<br />

Noise: approx. 50 mVpp<br />

Connector: LEMOSA 0S.250 (BNC adaptor available)<br />

Display: LCD, 3 digits<br />

Dimensions: WxDxH 185x330x150 mm<br />

Weight: approx. 4 kg<br />

Options:<br />

Multichannel arrangements: on request<br />

Frequency response<br />

Risetimes:<br />

(for square wave input signal)<br />

Load risetime<br />

capacitance to 300 V/430 V<br />

1.2 uF 2 msec/3 msec<br />

660 nF 1 msec/1.4 msec<br />

330 nF 0.5 msec/0.7 msec<br />

100 nF 180 µsec/250 µsec<br />

30 nF 70 µsec/l00 µsec<br />

Computer interfaces:<br />

Optionally, the amplifier LE 430/015 can be equipped by a serial or parallel (CENTRONIX) computer interface (designation as<br />

LE 430/015-S or/-P respectively) for digital control by a fast data transfer and D/A conversion. Up to 3 channels can be<br />

operated simultaneously.<br />

All analog functions of the amplifier remain active. By “offset” the amplified signal can be superimposed by a DC-voltage and<br />

the operating voltage range can be varied by “amplitude” for easy adaption to a distinct application. The resolution is 12 bit.<br />

Order code:<br />

LE 430/015 analog amplifier<br />

LE 430/015-S with additional serial interface<br />

LE 430/015-P with additional parallel interface<br />

open<br />

output:<br />

U max/2 >20 kHz<br />

http://www.piezomechanik.com Amplifiers, D/A Converters, Electronic HV-Switches for Piezoactuators 19

LE 1000/035 single channel amplifier<br />

+1000 V output<br />

Special features: see chapter 5<br />

Potentiometer “Offset”, “Amplitude”, Current Booster,<br />

Monitor output<br />

Input<br />

Input: +/–5 V (+/–10 V see chapter 5)<br />

Input resistance: 10 kOhm<br />

Input connector: BNC<br />

Output:<br />

Voltage range: 0 V thru +1000 V<br />

Max. peak current: 350 mA<br />

Max. average current: approx. 100 mA<br />

Gain: 200<br />

Noise: approx. 50 mVpp<br />

Connector: LEMOSA 0S.250 (BNC adaptor available)<br />

Display: LCD, 3 digits<br />

Dimensions: WxDxH 260x340x160 mm<br />

Weight: approx. 4.5 kg<br />

Options:<br />

Multichannel arrangements: on request<br />

open<br />

output:<br />

Unipolar amplifier LE 500/070<br />

Output voltage 0 V thru +500 V, peak current appr. 700 mA, mean current approx. 250 mA<br />

Bipolar amplifier LE 500/035 bip<br />

Output voltage +/–500 V, peak current approx. 350 mA, mean current approx. 100 mA<br />

Frequency response<br />

Risetimes:<br />

(for square wave input signal)<br />

Load risetime<br />

capacitance to 1000 V<br />

200 nF approx. 0.5 msec<br />

1 µF 3 msec<br />

5 µF 15 msec<br />

20 Amplifiers, D/A Converters, Electronic HV-Switches for Piezoactuators http://www.piezomechanik.com

LE 1000/100 single channel amplifier<br />

+1000 V output<br />

Special features: see chapter 5<br />

Potentiometer “Offset”, “Amplitude”, Current Booster,<br />

Monitor output<br />

Input<br />

Input: +/–5 V (+/–10 V see chapter 5.)<br />

Input resistance: 10 kOhm<br />

Input connector: BNC<br />

Output:<br />

Voltage range: 0 V thru +1000 V<br />

Max. peak current: 1000 mA<br />

Max. average current: approx. 300 mA<br />

Gain: 200<br />

Noise: approx. 50 mVpp<br />

Connector: LEMOSA 0S.250 (BNC adaptor available)<br />

Display: LCD, 3 digits<br />

Dimensions: WxDxH 160x380x210 mm<br />

Weight: approx. 5.5 kg<br />

Options:<br />

Multichannel arrangements: on request<br />

open output:<br />

Unipolar amplifier LE 500/200<br />

Output voltage 0 V thru +500 V, peak current appr. 2000 mA, mean current approx. 700 mA<br />

Bipolar amplifier LE 500/100 bip<br />

Output voltage +/–500 V, peak current approx. 1000 mA, mean current approx. 300 mA<br />

Frequency response<br />

Risetimes:<br />

(for square wave input signal)<br />

Load risetime<br />

capacitance to 1000 V<br />

200 nF approx. 0.2 msec<br />

1 µF 1 msec<br />

5 µF 5 msec<br />

http://www.piezomechanik.com Amplifiers, D/A Converters, Electronic HV-Switches for Piezoactuators 21

High efficiency power recharger amplifiers<br />

RCV<br />

The basic philosophy of switches recharging amplifiers is<br />

described in sec. 4.3.<br />

PIEZOMECHANIK offers recharging amplifiers for average<br />

powers of 500 Watts up to the kWatt range.<br />

Because recharging amplifiers have to be adapted to some<br />

extent to the capacitance of the actuator and the desired<br />

driving conditions, a detailed offer is made after receipt of<br />

specifications and requirements.<br />

Generally, the device can be matched to an application<br />

within the below stated limits:<br />

Example:<br />

E.g. RCV amplifiers have been developed for active vibration<br />

cancellation showing following data<br />

Load capacitance: approx. 20 µF<br />

Operating frequency: up to 400 Hz<br />

Voltage range: +/–200 V<br />

Max. peak current: 10 A<br />

Risetime for a 200 V voltage step at 5 µF load: 100 µsec.<br />

If you are thinking about recharging amplifiers for your<br />

application, contact us.<br />

Voltage range: –600 V to +600 V<br />

Peak currents: up to 10 A<br />

Peak power: 2 kW<br />

Average power: 500 W<br />

Ripple/noise by switching mode: approx. 200 mV<br />

Power efficiency with loss-free capacitive load: > 95 %<br />

(definition see sec. 2.5.)<br />

22 Amplifiers, D/A Converters, Electronic HV-Switches for Piezoactuators http://www.piezomechanik.com

Power pulsers HVP<br />

(see sec. 2.8.)<br />

The HVP switches/pulsers show 3 operational levels<br />

positive square wave = charging of actuator<br />

negative square wave = discharging of actuator<br />

zero level = output neutral: no charge transfer = steady state<br />

of actuator.<br />

The internal supply (source) voltage of the HV pulser can be<br />

set by a potentiometer and is shown on the front panel LC<br />

display. The specified peak currents are achieved for max.<br />

supply voltage setting.<br />

General data<br />

Input:<br />

signal “high” = charging of actuator: > +3 V<br />

signal “low” = discharging of actuator: < –3 V<br />

signal “neutral” no charge transfer: 0 V<br />

Connector: BNC<br />

Output:<br />

Voltage/currents see listing<br />

Average power: 50 Watts<br />

Minimum pulse width: approx. 3 µsec<br />

Repetition rate: up to 50 kHz<br />

Connectors: LEMOSA 0S.250 and 2 banana pin plugs<br />

Types max. voltage peak Load time constant RC/<br />

currents resistors for load capacitance<br />

V A Ohms<br />

HVP 200/50 +200 50 4 40 µsec / 10 µF<br />

HVP 200/100 +200 100 2 20 µsec / 10 µF<br />

HVP 500/20 +500 20 25 25 µsec / 1 µF<br />

HVP 500/50 +500 50 10 10 µsec / 1 µF<br />

HVP 500/100 +500 100 5 5 µsec / 1 µF<br />

HVP 1000/10 +1000 10 100 50 µsec /0.5 µF<br />

HVP 1000/20 +1000 20 50 25 µsec /0.5 µF<br />

HVP 1000/50 +1000 50 20 10 µsec /0.5 µF<br />

Options: HVP can be supplied for altered source voltages<br />

altered current ratings<br />

higher average powers<br />

Power resistor box PRB:<br />

The peak current of a HVP switch can be reduced by using the external resistor box PRB e.g. for adaption to a lower capacitance<br />

actuator. It contains 3 power resistors of different ratings and is connected between HV-switch and actuator.<br />

The resulting peak current is determined by the total resistance of the arrangement:<br />

internal resistor of switch (see listing) + the external resistor.<br />

The box is equipped with one input coax cable/LEMOSA 0S.250 plug. Each resistor has its individual output connector and is<br />

selected thereby.<br />

PRB I: 1 resistor 2 Ohms<br />

1 resistor 5 Ohms<br />

1 resistor 10 Ohms<br />

PRB II: 1 resistor 10 Ohms<br />

1 resistor 20 Ohms<br />

1 resistor 50 Ohms<br />

Input/output connectors: LEMOSA 0S.250 (BNC adaptors<br />

available).<br />

Display: 3 1 /2 digit LCD<br />

Dimensions: WxDxH 260x340x160<br />

Weight: 4.5 kg<br />

http://www.piezomechanik.com Amplifiers, D/A Converters, Electronic HV-Switches for Piezoactuators 23

Amplifiers for push-pull actuator configuration<br />

Bimorph amplifiers<br />

(see sec. 3.1./4.5)<br />

BMT 60 bimorph amplifier<br />

For the philosophy of driving multilayer bimorph actuators<br />

under electrically preloaded conditions check brochure<br />

“piezoelectric bending elements”. In this case, the ceramic is<br />

operated with permanently forward polarized voltage and<br />

thereby prevented from depolarization, so the maximum<br />

mechanical performance is achieved.<br />

The bimorph amplifier BMT 60 has been designed to drive<br />

multilayer-benders elements in the above described optimum<br />

way with high dynamics.<br />

Because of the analogy of the electrical operation of antagonistic<br />

piezostacks configuration and bimorphs, the BMT 60<br />

can also drive complementary acting push-pull stack<br />

arrangements (sec. 3.1.)<br />

Special features:<br />

Potentiometer “Offset”<br />

Potentiometer “Amplitude”<br />

Monitor output<br />

Input<br />

Input: +/–5 V (+/–10 V see chapter 5)<br />

Input resistance: 100 kOhm<br />

Input connector: BNC<br />

Output:<br />

3 pole connector for ground 0 V,<br />

fix voltage U F +60 V<br />

Signal voltage U S 0 V thru +60 V<br />

Max. peak current: 280 mA in each branch<br />

Gain: 12<br />

Noise: approx. 20 mVpp<br />

Connector: 3 pole connector LEMOSA<br />

(1 m cable with suitable plug is included)<br />

Display: LCD, 3 digits<br />

Dimensions: WxDxH 165x210x70 mm<br />

Weight: approx. 1.4 kg<br />

output<br />

connector<br />

24 Amplifiers, D/A Converters, Electronic HV-Switches for Piezoactuators http://www.piezomechanik.com

AGV 150/013 amplifier<br />

This amplifier has been designed to operate low voltage<br />

stack push-pull configurations in the electrically preloaded<br />

mode (see sec. 4.5.). Because of the analogy in the electrical<br />

driving scheme, also bimorph elements can be operated by<br />

this amplifier with high efficiency.<br />

Special features: Potentiometer “Offset”, “Amplitude”,<br />

Current Booster, Monitor output<br />

Input<br />

Input: +/–5 V (+/–10 V see chapter 5)<br />

Input resistance: 100 kOhm<br />

Input connector: BNC<br />

Output:<br />

3 pole connector for ground 0 V,<br />

fix voltage U F +150 V<br />

Signal voltage U S 0 V thru +150 V<br />

Max. peak current: 130 mA in each branch<br />

Max. average current: 70 mA in each branch<br />

Gain: 30<br />

Connector: 3 pole connector LEMOSA<br />

(1 m cable with suitable plug is included)<br />

Noise: approx. 20 mVpp<br />

Display: LCD, 3 digits<br />

Dimensions: WxDxH 185x330x150 mm<br />

Weight: approx. 4 kg<br />

AGV 430/08 amplifier<br />

This amplifier has been designed to operate high voltage<br />

stack push-pull configurations in the electrically preloaded<br />

mode (see sec. 4.5.). Because of the analogy in the electrical<br />

driving scheme, also bimorph elements can be operated by<br />

this amplifier with high efficiency.<br />

Special features: Potentiometer “Offset”, “Amplitude”,<br />

Current Booster, Monitor output<br />

Input<br />

Input: +/–5 V (+/–10 V see chapter 5)<br />

Input resistance: 100 kOhm<br />

Input connector: BNC<br />

Output:<br />

3 pole connector for ground 0 V,<br />

fix voltage U F +430 V<br />

Signal voltage U S 0 V thru +430 V<br />

Max. peak current: 80 mA in each branch<br />

Max. average current: 35 mA in each branch<br />

Gain: 85<br />

Noise: approx. 50 mVpp<br />

Connector: 3 pole connector LEMOSA<br />

(1 m cable with suitable plug included)<br />

Display: LCD, 3 digits<br />

Dimensions: WxDxH 185x330x150 mm<br />

Weight: 4.5 kg<br />

output<br />

connector<br />

output<br />

connector<br />

http://www.piezomechanik.com Amplifiers, D/A Converters, Electronic HV-Switches for Piezoactuators 25

The optionally available interfaces which are integrated to<br />

amplifiers are described in the corresponding data sheet for<br />

the amplifiers e.g. LE 150/025-S.<br />

This basic range of interfaces is completed by the units<br />

described in the following section<br />

1. Stand alone D/A converter DAI-3:<br />

The DAI-3 unit corresponds to the interface option D/A-LE of<br />

the LE 150/200 amplifier system. It shows both serial and<br />

parallel (CENTRONIX) data input for handling up to 3 channels<br />

independently. The analog output is 0 V thru +10 V and<br />

can be plugged directly to the analog amplifiers described in<br />

this catalog. It is obvious, that the DAI-3 unit can be used to<br />

control any other system, requiring an analog input control<br />

signal.<br />

front<br />

D/A converters, Computer-Interfaces<br />

2. PC-plug in cards with analog HV-output<br />

The PC plug in-cards generate the analog HV-signal for<br />

immediate operation of piezoactuators or other loads.<br />

The advantages of the PC-AHV cards are the spacesaving<br />

arrangement within the computer cabinet, where no external<br />

additional amplifiers are needed and the speed and reliability<br />

of data handling. The cards show current boosters for<br />

elevated driving dynamics.<br />

They are available in single and triple channel versions.<br />

General data<br />

• PCI-Bus<br />

• 8 bit data bus<br />

• Setting of port address by a DIL switch<br />

• Voltage resolution 14 bit for unipolar output<br />

13 bit for bipolar output<br />

• Width 1 slot<br />

• PC board dimensions<br />

Interfaces: serial RS 232<br />

parallel (CENTRONIX)<br />

Resolution: 12 Bit<br />

Output signal: 0 V thru +10 V (other settings e.g. bipolar: on<br />

request)<br />

High modulation rate of output: up to kHz with parallel data<br />

transfer e.g. for fast feedback control systems.<br />

Line operation<br />

3 analog independent outputs<br />

26 Amplifiers, D/A Converters, Electronic HV-Switches for Piezoactuators http://www.piezomechanik.com<br />

rear

PC-AHV +150/1 single channel<br />

Output voltage: 0 V thru +150 V<br />

Max. peak current: 75 mA<br />

Max. average current: 25 mA<br />

Resolution: 14 bit<br />

Noise: approx. 5 mV<br />

Output connector: LEMOSA 00.250 (BNC adaptors available)<br />

PC-AHV +150/3 triple channel<br />

Output voltage: 0 V thru +150 V<br />

Max. peak current: 75 mA/channel<br />

Max. average current: 25 mA (total for 3 channels)<br />

Resolution: 14 bit<br />

Noise: 5 mV<br />

Output connector: LEMOSA 00.250 (BNC adaptors available)<br />

PC-AHV 150bp/1 single channel<br />

Bipolar output voltage: –150 V thru +150 V<br />

Max. peak current: 50 mA/channel<br />

Max. average current: 15 mA<br />

Resolution: 13 bit<br />

Noise: approx. 5 mV<br />

Output connector: LEMOSA 00.250 (BNC adaptors available)<br />

Optionen: geänderte Leistungsdaten, Ausgangsbuchsen etc. auf Anfrage<br />

Feedback Control Stabilization PiStab-2<br />

Modern HiTechnologies often use physical effects, which are<br />

extremely sensitive in magnitude to any small deviation from<br />

the correct position of the mechanical components of the<br />

device. Any misalignment e.g. by thermal drifts can diminish<br />

the device performance e.g. the optical output power of a<br />

discretely setup laser resonator). Other examples are the<br />

coupling efficiency of freely coupled optical fibers, interferometers,<br />

sensor/transducer arrangements in microsystems,<br />

biological systems etc.<br />

To ensure a stable optimum operation the task is to detect<br />

the onset of mechanical misalignment and to readjust the<br />

Mirror mount with 2 piezocontrolled degrees of freedom and a PiStab-2<br />

feedback controlled electronics/supply<br />

PC-AHV 150bp/3 triple channel<br />

Bipolar output voltage: –150 V thru +150 V<br />

Max. peak current: 50 mA/channel<br />

Max. average current: 15 mA (total for 3 channels)<br />

Resolution: 13 bit<br />

Noise: approx. 5 mV<br />

Output connector: LEMOSA 00.250 (BNC adaptors available)<br />

PC-AHV +500/1 single channel<br />

Output voltage: 0 V thru +500 V<br />

Max. peak current: 15 mA<br />

Max. average current: 5 mA<br />

Resolution: l4 bit<br />

Noise: approx. 5 mV<br />

Output connector: LEMOSA 0S.250 (BNC adaptors available)<br />

PC-AHV +500/3 triple channel<br />

Output voltage: 0 V thru +500 V<br />

Max. peak current: 15 mA/channel<br />

Max. average current: 5 mA (total for 3 channels)<br />

Resolution: 14 bit<br />

Noise: approx. 5 mV<br />

Output connector: LEMOSA 0S.250 (BNC adaptors available)<br />

components actively. For micro- and nanopositioning purposes,<br />

the first choice include all kinds of piezoactuated<br />

systems such as stacks, bimorphs, hybrid systems etc.<br />

The stabilization electronics PiStab-2 controls up to<br />