Opportunity Issue 106

Opportunity magazine is a niche business-to-business publication that explores various investment opportunities within Southern Africa’s economic sectors. The publication is endorsed by the South African Chamber of Commerce and Industry (SACCI).

Opportunity magazine is a niche business-to-business publication that explores various investment opportunities within Southern Africa’s economic sectors. The publication is endorsed by the South African Chamber of Commerce and Industry (SACCI).

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ENERGY INNOVATION<br />

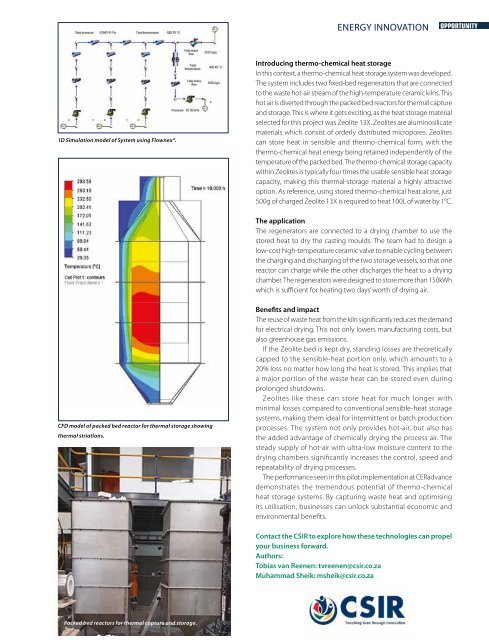

1D Simulation model of System using Flownex®.<br />

Introducing thermo-chemical heat storage<br />

In this context, a thermo-chemical heat storage system was developed.<br />

The system includes two fixed-bed regenerators that are connected<br />

to the waste hot-air stream of the high-temperature ceramic kilns. This<br />

hot air is diverted through the packed bed reactors for thermal capture<br />

and storage. This is where it gets exciting, as the heat storage material<br />

selected for this project was Zeolite 13X. Zeolites are aluminosilicate<br />

materials which consist of orderly distributed micropores. Zeolites<br />

can store heat in sensible and thermo-chemical form, with the<br />

thermo-chemical heat energy being retained independently of the<br />

temperature of the packed bed. The thermo-chemical storage capacity<br />

within Zeolites is typically four times the usable sensible heat storage<br />

capacity, making this thermal-storage material a highly attractive<br />

option. As reference, using stored thermo-chemical heat alone, just<br />

500g of charged Zeolite 13X is required to heat 100L of water by 1°C.<br />

The application<br />

The regenerators are connected to a drying chamber to use the<br />

stored heat to dry the casting moulds. The team had to design a<br />

low-cost high-temperature ceramic valve to enable cycling between<br />

the charging and discharging of the two storage vessels, so that one<br />

reactor can charge while the other discharges the heat to a drying<br />

chamber. The regenerators were designed to store more than 150kWh<br />

which is sufficient for heating two days’ worth of drying air.<br />

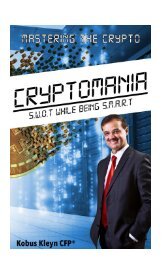

CFD model of packed bed reactor for thermal storage showing<br />

thermal striations.<br />

Benefits and impact<br />

The reuse of waste heat from the kiln significantly reduces the demand<br />

for electrical drying. This not only lowers manufacturing costs, but<br />

also greenhouse gas emissions.<br />

If the Zeolite bed is kept dry, standing losses are theoretically<br />

capped to the sensible-heat portion only, which amounts to a<br />

20% loss no matter how long the heat is stored. This implies that<br />

a major portion of the waste heat can be stored even during<br />

prolonged shutdowns.<br />

Zeolites like these can store heat for much longer with<br />

minimal losses compared to conventional sensible-heat storage<br />

systems, making them ideal for intermittent or batch production<br />

processes. The system not only provides hot-air, but also has<br />

the added advantage of chemically drying the process air. The<br />

steady supply of hot-air with ultra-low moisture content to the<br />

drying chambers significantly increases the control, speed and<br />

repeatability of drying processes.<br />

The performance seen in this pilot implementation at CERadvance<br />

demonstrates the tremendous potential of thermo-chemical<br />

heat storage systems. By capturing waste heat and optimising<br />

its utilisation, businesses can unlock substantial economic and<br />

environmental benefits.<br />

Contact the CSIR to explore how these technologies can propel<br />

your business forward.<br />

Authors:<br />

Tobias van Reenen: tvreenen@csir.co.za<br />

Muhammad Sheik: msheik@csir.co.za<br />

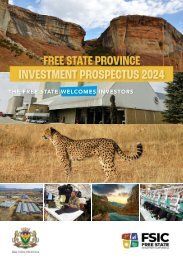

Packed bed reactors for thermal capture and storage.