Edition 73 (January-March, 2024)

GLASS BULLETIN is a publishing company, managed by a highly experienced editorial and administrative staff. It has a dedicated and responsible team for providing quality journals and related services to its readers. The company publishes GLASS BULLETIN which is the fastest growing top-notch journal of India for the global glass industry. It is published quarterly and circulated among glass manufacturers, glass processors, glass-machinery & tool manufacturers, art glass processors, glass dealers, architects, builders, aluminium fabricators, interior decorators and the automobile industry across the globe. GLASS BULLETIN is the ideal platform, both in the print and digital media, for worldwide exposition of news, reports, products and exhibitions related to the glass industry. It is a one-stop solution for all queries and needs related to glass–machinery and technology, its innovation, product-procession and marketing in India. By its permanent columns, it enjoys the status of highest readership among all Indian glass journals. GLASS BULLETIN is the media partner for international glass exhibitions in Beijing, Shanghai and Guangzhou in China besides in other parts of the world, including Europe, India and the Middle East. GLASS BULLETIN e-magazine, the first glass-related e-magazine of India, is also available online and on mobile phone, free of cost at http://www.glassbulletin.com

GLASS BULLETIN is a publishing company, managed by a highly experienced editorial and administrative staff. It has a dedicated and responsible team for providing quality journals and related services to its readers. The company publishes GLASS BULLETIN which is the fastest growing top-notch journal of India for the global glass industry. It is published quarterly and circulated among glass manufacturers, glass processors, glass-machinery & tool manufacturers, art glass processors, glass dealers, architects, builders, aluminium fabricators, interior decorators and the automobile industry across the globe.

GLASS BULLETIN is the ideal platform, both in the print and digital media, for worldwide exposition of news, reports, products and exhibitions related to the glass industry. It is a one-stop solution for all queries and needs related to glass–machinery and technology, its innovation, product-procession and marketing in India. By its permanent columns, it enjoys the status of highest readership among all Indian glass journals.

GLASS BULLETIN is the media partner for international glass exhibitions in Beijing, Shanghai and Guangzhou in China besides in other parts of the world, including Europe, India and the Middle East.

GLASS BULLETIN e-magazine, the first glass-related e-magazine of India, is also available online and on mobile phone, free of cost at http://www.glassbulletin.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

05

06

07

09

Reliable.<br />

Efficient.<br />

Fully equipped.<br />

The Glaston COMFORT BOX offers high-quality,<br />

gas-filled IG unit manufacturing of rectangular and<br />

shaped formats.<br />

This IG line offers numerous components as<br />

standard, e.g.<br />

• Air cushion conveyors<br />

• Production of 3-sided stepped I.G. units<br />

Get your IG manufacturing business on<br />

the road to success — Download the<br />

IG Manufacturing Line Guide here<br />

www.glastory.net<br />

Meet us at<br />

CHINA GLASS <strong>2024</strong><br />

Shanghai, China<br />

Apr 25-28<br />

Hall N1, Stand #300<br />

Machinery, services and solutions designed with the future in mind for<br />

the architectural, automotive, solar and appliance industries.<br />

info@glaston.net | www.glaston.net | www.glastory.net | www.gpd.fi<br />

11

12

Website<br />

ENTER GLASS INDUSTRIAL 4.0<br />

MACsoft HELPS YOU ONE STEP FORWARD...<br />

MAC is always committed to supply the most professional solutions according to different customer<br />

situations. Our global service and consultancy system will also make the communication easy and timely.<br />

YouTube<br />

Architecture Glass Processing<br />

Ashley +86 13910174313<br />

solution@macglastech.com<br />

Appliance Glass Processing<br />

Shower door Processing<br />

Claire +86 18942463709<br />

export@macglastech.com<br />

Photovoltaic Glass Solution<br />

Furnace and Processing<br />

MACsoft solutions And MES system<br />

Lydia +86 18600<strong>73</strong>5815<br />

global@macglastech.com<br />

13

14

Ψ-Values<br />

of up to<br />

arctic climate<br />

phA+<br />

CERTIFIED<br />

0.029<br />

COMPONENT<br />

Passive House Institute<br />

15

Light Up Your Dream Of Intelligent Glass Factory<br />

HUMAM is the leading manufacturer for glass processing<br />

smart factory solution since 2004. We have more than 300<br />

machines in India including fully automatic shuttle storage<br />

system, CNC cutting machine, laser printing machine, all<br />

type of loading & unloading & conveyor system integrating<br />

with all processing lines for architectural glass, shower<br />

door glass and home appliance glass, solar glass etc…<br />

HUMAM supplies ERP & MES control systems also bus &<br />

car windshield bending furnace, heat soak test furnace.<br />

We continuously work with Saint-Gobain, ASAHI, FUSO,<br />

FG, Tough Glass, Art-N Glass etc…Look forward to<br />

cooperating with you to build up smart factory.<br />

16<br />

WhatsApp<br />

WeChat<br />

We b : w ww. h u m a m g l a s s . c o m<br />

M o b i l e & Wh a t sA p p N o. : + 8 6 1 8 6 6 6 5 8 8 9 6 1<br />

Em a i l : s a l e s 0 5@h u m a m g l a s s . c o m<br />

C o n t a c t P e r s o n : Va n e s s a L u o<br />

H uma m I n t e l l i g e n t M a c h i n e C o . , L t d .

-Molecular sieve<br />

-Our Delta T can reach 40-80 centigrade<br />

Water vapor and gas permeability lower to 0.2g /( m2.d).<br />

Quality is is similar as Germany Kommerling<br />

Rock Well Building Material Hubei Co., Ltd.<br />

India office<br />

Mr. Robin Singh<br />

+919015444697<br />

Mr. Sameer Chandila<br />

+91 844<strong>73</strong> 44321<br />

27 17

TOTAL SOLUTIONS<br />

FOR GLASS GRINDING AND<br />

FINISH<br />

( Iso Certified Company)<br />

Professional manufacturer of<br />

Diamond tools for processing automotive glass<br />

Diamond tools for processing solar glass<br />

Customized high quality diamond tools in glass processing.<br />

Strong R&D team and technical support, reliable and professional.<br />

BEIJING GREATDIA SUPERHARD TOOLS CO.,LTD<br />

ADD: NO 5,FU RONG STREET, XI MA GE ZHUANG CUN, GAO LI YING ZHEN, SHUN YI DISDRICT,<br />

BEIJING CHINA 101318<br />

WEB: WWW.GREATDIATOOL.COM / EMAIL: CHERRY@GREATDIATOOL.COM<br />

MOB / WECHAT / WHAT'S APP: +86 15010660856<br />

19

20

21

22

Take Your<br />

Glass Cutting<br />

To the Next Level<br />

HIGH STABILITY WITH<br />

CONTINUOUS RUNNING<br />

AUTOMATIC PRESSURE<br />

ADJUSTMENT ACCURATELY<br />

60+ INDIAN<br />

CUSTOMERS<br />

23

25

Harmara Road, Industrial Area,<br />

Madanganj, Kishangarh, Rajasthan<br />

India / Pin no. 305801<br />

91 <strong>73</strong>000 68444<br />

sales@aardwolf.co.in<br />

# 9/27, Ground Floor, 5th Main Road,<br />

Ganesha Block, Sultanpalya,<br />

R. T. Nagar Post, Bengaluru-560032<br />

91 99017 24600<br />

raghavendra@aardwolf.co.in

50% ENERGY SAVING<br />

FLEXIBLE HIGH SPEED INTELLIGENT<br />

DOUBLE EDGING MACHINE<br />

Over 15 years of Specialized Knowledge & Experience<br />

Thick Heavy Steel Structure<br />

N04 .Lianfu Road ,Fuan Industrial Zone. Leliu Town, Shunde District Foshan, Guangdong,China<br />

Tel and Whatsapp: +86 176 6563 0001<br />

E-mail: pinglasstechnology@gmail.com, lch_india@pincorp.cn<br />

28

29

1 ST HAND AUTHORIZED SELLER<br />

OF XINFU PvB IN INDIA<br />

XINFU<br />

INTERNATIONAL<br />

3 Production lines in China<br />

with Capacity of 6 Million Square meters<br />

Architecture grade, Automotive grade, Solar grade<br />

Transmittance 91 %<br />

Best Production Facility<br />

Loss in weight feeder<br />

-- Brabender Germany<br />

Screen changers and melt pump -- Maag, Switzerland,<br />

Extrusion die<br />

-- CLOEREN USA,<br />

The online thickness scanner, Automatic gauge control (AGC) systems,<br />

Online scanning moisture tester -- Honeywell USA,<br />

The online surface vision test system -- ISRA Germany.<br />

XINFU CUSTOMER MAIN MARKET<br />

Pilkington China BSG Auto Fuyao Auto Taiwan Glass 40% Oversea Market<br />

Iran<br />

Australia<br />

Turkey<br />

Middle East<br />

South American<br />

India<br />

Korea<br />

BLG International Pvt. Ltd.<br />

FROM THE HOUSE OF<br />

LAKSHMI FLOAT GLASS LTD.<br />

Supply<br />

all over India<br />

Displayed at :<br />

Redg. Office: A-2/30-31, 3rd Floor W.H.S,<br />

DDA Marble Market, Kirti Nagar New Delhi<br />

Mumbai Office: L-135, Midc, Taloja, Raigarh,<br />

Maharashtra, Mumbai-410208, INDIA<br />

Contact us @<br />

adityagupta@blginternational.in,<br />

www.lakshmifloat.com sales@blginternational.in<br />

Whatsapp us:<br />

+91 99562 95454<br />

33

lginternational<br />

Business Leaders in Glass<br />

BEIJING HONGTIANYANG<br />

TRADING CO., LTD<br />

3 Hollow louver production lines in China<br />

Swiss Spacer<br />

Stainless Steel Spacer<br />

Warm Edge Spacer Corner Keys<br />

Aluminum Spacer Stainless Steel Connector<br />

AVAILABLE SIZES: BENDABLE/NON BENDABLE<br />

Thickness (mm)<br />

Colour<br />

5.5, 7.5, 8.5, 9.5, 11.5, 13.5, 15.5,<br />

17.5, 19.5, 23.5, 27.5 & 31.5<br />

Mill Finish, Black Colour &<br />

All Others Colour are Available<br />

Plastic Corner<br />

Steel Straight<br />

Keys<br />

Connectors<br />

FOR DIRECT CONTAINER CONTACT MR. ADITYA GUPTA<br />

blginternational PVT. LTD<br />

FROM THE HOUSE OF<br />

LAKSHMI FLOAT GLASS LTD.<br />

Supply<br />

all over India<br />

Displayed at :<br />

Redg. Office: A-2/30-31, 3rd Floor W.H.S,<br />

DDA Marble Market, Kirti Nagar New Delhi<br />

Mumbai Office: L-135, Midc, Taloja, Raigarh,<br />

Maharashtra, Mumbai-410208, INDIA<br />

Contact us @<br />

adityagupta@blginternational.in,<br />

www.lakshmifloat.com sales@blginternational.in<br />

PLEASE CONTACT 24X7 HOT LINE<br />

+91 99562 95454<br />

34

INTERNATIONAL<br />

Insulating Glass<br />

Silicone Sealant<br />

BUSINESS LEADERS IN GLASS<br />

GLASS PROCESSING, MATERIALS & GLASS PROCESSING MACHINES<br />

Grinding<br />

Wheel<br />

(Resin Diamond<br />

Wheel)<br />

Aluminium<br />

Spacer<br />

Polishing<br />

Wheel<br />

10S60<br />

CNC Cutting<br />

Wheel<br />

EVA<br />

EVA<br />

PVB<br />

Plastic Corner<br />

Keys<br />

Steel Straight<br />

Connectors<br />

Pressure Equaliser<br />

for Insulating Glass<br />

2 Component<br />

Silicone Sealant<br />

Pump<br />

Warm Edge<br />

Spacer<br />

Kevlar Rope<br />

Butyl Tape<br />

Wave / Cloudy<br />

Linio /<br />

Cross Small<br />

Savona /<br />

Bubble<br />

Candi / Sona<br />

Silicon Vacuum Bag<br />

OUR PRODUCTS<br />

PVB | EVA | VACUUM SILICONE BAGS | TEFLON MESH | FABRIC | INSULATING GLASS SILICONE SEALANT | FENZI BUTYL<br />

GRINDING WHEEL | POLISHING WHEEL | CNC CUTTING WHEEL | SWISSPACER | WARM EDGE SPACER | ALUMINIUM SPACERS | CORNER<br />

KEYS STEEL STRAIGHT CONNECTORS | MOLECULAR SIEVE 3A | GLASS BLOCKS | FLOAT GLASS | MIRROR BULLET RESISTANT GLASS<br />

PROCESSED GLASS & PATTERN GLASS | BUTYL TAPE | GLASS SEPARATOR | GLASS PROCESSING TOOLS | GLASS PROCESSING MACHINES<br />

SentryGlas ® | Trosifol ® | ExtraStiff ® | Butacite G ®<br />

blginternational PVT. LTD<br />

FROM THE HOUSE OF<br />

LAKSHMI FLOAT GLASS LTD.<br />

Supply<br />

all over India<br />

Displayed at :<br />

Redg. Office: A-2/30-31, 3rd Floor W.H.S,<br />

DDA Marble Market, Kirti Nagar New Delhi<br />

Mumbai Office: L-135, Midc, Taloja, Raigarh,<br />

Maharashtra, Mumbai-410208, INDIA<br />

Contact us @<br />

adityagupta@blginternational.in,<br />

www.lakshmifloat.com sales@blginternational.in<br />

PLEASE CONTACT 24X7 HOT LINE<br />

+91 99562 95454<br />

35

IMPORTANT<br />

ANNOUNCEMENT<br />

THE FIRST PRIVATE LAB IN INDIA<br />

TO BE BIS RECOGNISED TO TEST<br />

PROCESSED AND FLOAT GLASS.<br />

FOR FURTHER DETAILS, CONTACT US<br />

+91 - 9080992502<br />

harish@winwallindia.com<br />

www.winwallinternational.com/india<br />

37

ALUMINUM SPACERS / PROFILES - PLASTIC CORNERS & STEEL<br />

CONNECTORS - MOLECULAR SIEVES - DOUBLE SIDED TAPES<br />

FENZI 7 Kg. BUTYL SLUGS OF EU ORIGIN FOR INSULATING GLASS<br />

Barakaat Steels Pvt. Ltd., is the first Company in India to start production of Aluminium Profiles/Spacer, used in the manufacture of Insulating Glass. The<br />

Company has been pioneers in the manufacture of Insulating Glass and of trading in Insulating Glass Components for more than four Decades. Keeping in<br />

pace with the latest technologies at worldwide scenario, Barakaat Steels has been diversifying from time to time, by bringing products at par with<br />

International Standards. Barakaat Steels have created a new dimension, by combining customer requirements as prime objectives in offering the right<br />

product mix, a broad knowledge of products & their applications, good business relationships, logistics & financials expertise, proximity to the customer,<br />

and last but not the least, the appropriate range of support service. We are also suppliers to almost all major insulating glass manufacturers in India.<br />

Spacers - 100% Import substitute<br />

No need of Bulk storage<br />

Available as per customers requirement<br />

Minimum processing & supply time<br />

Less financial involvement<br />

Strong logistical support<br />

Double Pane<br />

Triple Pane<br />

ALUMINUM PROFILES<br />

BENDABLE SPACER<br />

PLASTIC CORNER KEYS<br />

STEEL CONNECTORS<br />

MOLECULAR SIEVES<br />

PRIMARY SEALANT<br />

DOUBLE SIDED TAPE<br />

AN ISO 9001:2015 CERTIFIED COMPANY<br />

Admn. & Regd. Office: B-17, Shreyas Industrial Estate, Goregaon (E), Mumbai - 400 063, (India).<br />

Tel.: +91 9768 045 252 / 9768 137 228 • Email: sales@univerglas.com<br />

Works: 1706/1, GIDC Industrial Estate, Sarigam Fansa Road, Sarigam, Gujarat - 396 155, (India).<br />

40

41

45

46<br />

14

avontuffglass.com<br />

WE ARE<br />

GLASS APART!<br />

SERVING GROWING DEMAND<br />

FOR ARCHITECTURAL<br />

GLASSES SINCE A DECADE.<br />

“Avon Tuff Glass has accepted new<br />

challenges and change & we have been<br />

processing High Quality - High Performance<br />

glass for the construction since 2012.<br />

With over 10 years of experience in<br />

architectural glass processing, we bring our<br />

passion for customer, innovation and<br />

dedication to quality.<br />

Join us on the journey as we see the possibilities together:<br />

• SAFETY GLASS<br />

• ACOUSTIC GLASS<br />

• ENERGY GLASS<br />

• SECURITY GLASS<br />

• DECORATIVE PAINTED GLASS<br />

FACTORY & REGD. OFFICE :<br />

S. No. 201-1, Devicha Pada, Sonale, Dist. Thane Bhiwandi - 421 302,<br />

AVON TUFF<br />

AVON TUFF GLASS PVT. LTD.<br />

CREATING BETTER TOMORROW<br />

Sales: +91 8879543317 • Tel: 02522- 282002 /282004<br />

Business (WhatsApp): 8879543316 • E: sales@avontuffglass.com<br />

48

54

57

Company News<br />

Stealth Series by Ozone:<br />

Tailored for modern<br />

architecture<br />

Slim Frame Sliding Systems Designed To Enable<br />

Seamless Clear View<br />

Ozone’s newly launched Stealth<br />

Series is specifically tailored<br />

for internal applications and<br />

is ideal for large, clear structural<br />

openings. In-built with soft open and<br />

close mechanisms, it achieves flawless<br />

gliding along with distinct and clear<br />

views, proving viable for architects and<br />

designers seeking a more integrated<br />

overall look.<br />

These soft-close sliding systems<br />

also come with concealed pneumatics<br />

and a compact soft-close dampener,<br />

thus providing a slim and aesthetically<br />

pleasing appearance. With a 16mm<br />

profile, it plays a key role in setting the<br />

context of the project.<br />

The versatile Stealth Series consists<br />

of sliding systems, swing door systems,<br />

shower systems, and automatic sliding<br />

systems.<br />

Key attributes of this series<br />

include not only cost-effective and<br />

easy-installation solutions but also<br />

adaptability. The complete range<br />

does not require bottom tracks and<br />

includes optional handles with highquality<br />

door-locking mechanisms.<br />

Customization is available for door<br />

height and door panels.<br />

Furthermore, various types of glass<br />

patterns can be configured using a<br />

divider and pasting grid profiles.<br />

But the benefits don’t just stop<br />

there. The series also has an in-built<br />

two-way soft close mechanism for<br />

smooth and silent sliding. This not<br />

only reduces inertial impact but allows<br />

for noiseless day-to-day functioning.<br />

For additional visual appeal,<br />

concealed ceiling tracks and track<br />

covers are offered to match your<br />

interiors. These systems come in<br />

three finishes - Brushed Antique<br />

Brass, Brushed Rose Gold, and Black<br />

Matt and can be installed without<br />

glass holes, saving time and cost.<br />

The advanced combination of<br />

design, quality, and functionality<br />

makes the Ozone Stealth Series ideal<br />

for architects, fabricators, interior<br />

designers, and builders who are<br />

looking for products that add high<br />

quality, maximize glass surfaces, and<br />

result in a design of transparency and<br />

simplified functionality, which are key<br />

aspects of modern architecture.<br />

To learn more about<br />

Ozone’s Stealth Series Range,<br />

scan the QR code.<br />

64 Glass Bulletin | <strong>January</strong> - <strong>March</strong>, <strong>2024</strong>

65

Interview<br />

MR. VISHAL KHANDELWAL<br />

Managing Director,<br />

WINDOW TECHS<br />

Innovating perspectives:<br />

Window Techs’ journey in<br />

glass industry<br />

Pioneering Excellence with Managing Director<br />

Mr. Vishal Khandelwal<br />

GB speaks to the MD of Window Techs, which has<br />

redefined the glass industry since 1993, on its cutting-edge<br />

solutions and commitment to sustainability.<br />

66 Glass Bulletin | <strong>January</strong> - <strong>March</strong>, <strong>2024</strong>

Interview• 2<br />

In an exclusive interview, Glass<br />

Bulletin delves into the journey of<br />

Window Techs, a trailblazer in the<br />

glass industry. Mr. Vishal Khandelwal,<br />

the Managing Director with two<br />

decades of experience, shares<br />

insights into the company’s history,<br />

cutting-edge technologies, and its<br />

commitment to sustainability.<br />

From pioneering the introduction<br />

of Insulated Glass Blinds to staying<br />

ahead in the market with innovative<br />

solutions, Window Techs stands<br />

as a beacon of excellence with Mr.<br />

Khandelwal at the helm.<br />

Excerpts from the interview:<br />

Q: Can you provide an overview<br />

of your company’s history and its<br />

journey in the glass industry?<br />

I founded Window Techs in 1993,<br />

and since then, our transformative<br />

journey has gained momentum,<br />

marked by strategic acquisitions<br />

and the incorporation of cuttingedge<br />

machinery in our Faridabad<br />

production plant. In 2011, the<br />

introduction of Insulated Glass Blinds<br />

was a turning point.<br />

Q: What are the key products or<br />

services offered by your company?<br />

Window Techs offers a diverse range<br />

of innovative solutions, from Insulated<br />

Glass Blinds to Fire Curtains,<br />

Smoke Curtains, Wall Guards,<br />

Corner Guards, Nurse Call Systems,<br />

and ZOHO Plumbing Solutions,<br />

showcasing our commitment to<br />

comprehensive interior solutions.<br />

Q: Give us an overview of<br />

the cutting-edge technologies<br />

employed in the manufacturing<br />

process of insulated glass blinds<br />

for doors and windows?<br />

Our manufacturing process<br />

integrates cutting-edge technologies,<br />

emphasizing excellence and<br />

Glass Bulletin | <strong>January</strong> - <strong>March</strong>, <strong>2024</strong> 67

Interview<br />

innovation. The strategic acquisition<br />

of technology from Denmark<br />

ensures top-notch machinery, and<br />

the integration of smart systems<br />

showcases our commitment to staying<br />

at the forefront of technological<br />

innovation.<br />

Q: How do your insulated glass<br />

blinds contribute to energy<br />

conservation in residential and<br />

commercial spaces?<br />

Window Techs’ Insulated Glass Blinds<br />

significantly contribute to energy<br />

conservation by providing insulation,<br />

reducing heat transfer, and offering<br />

different air gap options. This<br />

enhances energy efficiency, ensuring<br />

a comfortable and eco-friendly<br />

environment in both residential and<br />

commercial spaces.<br />

Q: How would you describe the<br />

current market landscape for<br />

insulated glass blinds for doors<br />

and windows? What trends do you<br />

see emerging, and how will you<br />

capitalise on them?<br />

The current market landscape reflects<br />

a growing demand for energy-efficient<br />

and aesthetically pleasing solutions.<br />

Window Techs, as an internationally<br />

recognized brand, is well-positioned<br />

to capitalise on these trends with its<br />

diverse product offerings.<br />

Q: What is your vision for<br />

insulated glass blinds in the next<br />

5-10 years, and how does your<br />

company plan to contribute<br />

to that? How do you approach<br />

sustainability and environmental<br />

considerations?<br />

Window Techs envisions continued<br />

growth in the insulated glass blinds<br />

market. Our plans include exploring<br />

new markets, aligning with emerging<br />

trends, and staying committed to<br />

sustainability, as evidenced by our<br />

diverse product range adhering to<br />

AGBC/IGBC standards.<br />

Q: How does your company<br />

balance functionality with<br />

aesthetically pleasing designs in<br />

your insulated glass blinds?<br />

Balancing functionality with<br />

aesthetically pleasing designs is a<br />

hallmark of Window Techs’ insulated<br />

glass blinds. We offer customizable<br />

options, allowing customers to achieve<br />

a tailored look that aligns with their<br />

architectural preferences, while<br />

staying attuned to design trends.<br />

Q: What are the unique selling<br />

points and advantages that set<br />

your insulated glass blinds apart<br />

from competitors?<br />

Window Techs’ insulated glass blinds<br />

stand out with their versatility,<br />

energy efficiency, and aesthetic<br />

appeal. Addressing specific needs and<br />

demands of architects, builders, and<br />

end-users, our blinds set themselves<br />

apart from competitors in the market.<br />

Email: info@windowtechs.in<br />

Website: www.windowtechs.co.in<br />

68 Glass Bulletin | <strong>January</strong> - <strong>March</strong>, <strong>2024</strong>

Company News<br />

NorthGlass and<br />

Glasstechnik join forces<br />

to improve services in<br />

Germany<br />

Strategic Partnership Aimed At Achieving<br />

Enhanced Glass Services<br />

Tie-up to elevate glass services in Germany, fostering a<br />

mutually beneficial partnership for enhanced customer<br />

satisfaction and industry advancement.<br />

As one of the world’s leading<br />

manufacturers in the glass<br />

tempering furnace industry,<br />

NorthGlass has sold more than 5,900<br />

tempering furnaces in 112 countries<br />

since 1995 with an average annual<br />

sales quantity of more than 300<br />

furnaces in the last 10 years, thanks<br />

to its advanced technology and rich<br />

professional experience.<br />

Europe has always played an<br />

important role in NorthGlass’s<br />

overseas market and Germany is<br />

definitely one of the key markets in<br />

Europe. To provide more efficient and<br />

convenient services to NorthGlass’s<br />

German customers, NorthGlass<br />

recently signed a strategic cooperation<br />

agreement with Glastechnik Holger<br />

Kramp GmbH, to improve the sales<br />

and after-sales service in Germany.<br />

“After doing serious market<br />

research, we finally decided to invite<br />

Glastechnik Holger Kramp GmbH<br />

working together with NorthGlass, to<br />

bring more benefits to our customers<br />

in Germany. I believe that this<br />

cooperation will create a win-win-win<br />

situation for all involved parties”, said<br />

Mr.Johnny LI, International Sales<br />

Director of NorthGlass.<br />

“Before making this decision,<br />

NorthGlass had terminated the<br />

cooperation with our former agency<br />

ATN Anlagentechnik Naethbohm<br />

GmbH,” he added.<br />

Website: www.northglass.com<br />

Glass Bulletin | <strong>January</strong> - <strong>March</strong>, <strong>2024</strong> 71

Company News<br />

72 Glass Bulletin | <strong>January</strong> - <strong>March</strong>, <strong>2024</strong>

Gutmann PVB• 2<br />

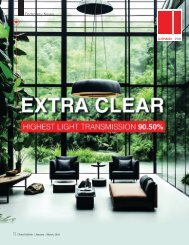

Gutmann launches Extra<br />

Clear PVB in India<br />

Collaborates With Visaar Proact Solutions To<br />

Bring Superior-Quality PVB<br />

Gutmann offers supreme-quality, 100 per cent virgin<br />

Gutmann Extra Clear PVB with high strength, durability and<br />

a high level of transparency.<br />

Gutmann PVB, an affiliate<br />

of Gutmann Middle East,<br />

collaborated with Visaar Proact<br />

Solutions to launch their supremequality<br />

Extra Clear PVB. Based in<br />

the southern part of India, Visaar<br />

Proact Solutions is a key importer<br />

and exporter of quality packing<br />

materials, chemicals and minerals<br />

and the company is now expanding<br />

its business portfolio with the flagship<br />

Available Sizes<br />

Gutmann PVB in India.<br />

Gutmann PVB is an affiliate of<br />

Gutmann Middle East, which is in the<br />

heart of the industrial zone of Dubai.<br />

It specializes in the manufacturing<br />

of superior-quality Polyvinyl butyral<br />

(PVB) for safety laminated glass<br />

interlayers. Gutmann PVB has<br />

successfully positioned itself as the<br />

first and only manufacturer of PVB in<br />

the Middle East and Africa.<br />

Key Specifications<br />

What is Polyvinyl butyral?<br />

PVB is a versatile thermoplastic<br />

that is clear, colourless, and tough.<br />

It is known for its excellent clarity,<br />

flexibility, and adhesion properties.<br />

It is widely used as an interlayer in<br />

laminated glass which helps to hold<br />

the glass shards in place in the event<br />

of breakage, providing a safety barrier<br />

to prevent injury.<br />

Gutmann offers supreme-quality,<br />

100 per cent virgin - Gutmann<br />

Extra Clear PVB with high strength,<br />

durability, a high level of transparency<br />

and exceptional adhesive properties<br />

which demonstrate superior<br />

resistance to thermal and water<br />

damage.<br />

Gutmann Extra Clear PVB<br />

interlayer is a versatile product that<br />

offers high levels of security and<br />

penetration resistance, UV protection,<br />

low thermal conductivity and the<br />

highest level of light transmission<br />

as well. The product complies with<br />

stringent quality standards (BS EN<br />

12600 certified).<br />

Advantages<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

100% Virgin<br />

Blocks 99% of UV radiation<br />

Highest light transmission<br />

Thermal Stability<br />

Water Resistance<br />

Recyclable and reusable<br />

Cut sizes available as per<br />

customer requirement<br />

Post Sales technical support<br />

Off-the-shelf stock facility<br />

(capacity to store more than<br />

100 rolls) in India.<br />

Email: salespvb@visaarps.com,<br />

bdm@visaarps.com<br />

Website: www.gutmannpvb.com<br />

Glass Bulletin | <strong>January</strong> - <strong>March</strong>, <strong>2024</strong> <strong>73</strong>

Company News<br />

Chief Minister of Maharashtra Mr Eknath Shinde (centre) with Group CEO of Aria Holding Mr Suraj Thampi (second from right), along with Maharashtra Minister of Industries<br />

Mr Uday Samant (left) and Principal Secretary of Industries Mr Harshdeep Kamble (right).<br />

Qatar-based Aria Holding<br />

to set up float glass plant<br />

in Maharashtra<br />

Multinational Conglomerate Signs MoU Worth<br />

Rs 2,000 Crore With The State Govt<br />

MoU was signed by Suraj Thampi, Group CEO of Aria<br />

Holding, in the presence of Chief Minister of Maharashtra<br />

Eknath Shinde and Minister of Industries Uday Samant at<br />

the World Economic Forum in Davos.<br />

Aria Holding, a leading global<br />

conglomerate based in Qatar,<br />

and the government of<br />

Maharashtra entered a Memorandum<br />

of Understanding (MoU) at the<br />

World Economic Forum <strong>2024</strong> Annual<br />

Meeting in Davos, Switzerland. As per<br />

the deal, Aria Holding will invest over<br />

Rs 2,000 crore to establish a stateof-the-art<br />

float glass manufacturing<br />

facility in Maharashtra.<br />

The agreement was signed by<br />

Mr Suraj Thampi, Group Chief<br />

Executive Officer of Aria Holding,<br />

74 Glass Bulletin | <strong>January</strong> - <strong>March</strong>, <strong>2024</strong>

Aria Holding• 2<br />

Principal Secretary of Industries, Maharashtra, Mr. Harshdeep Kamble and Group CEO of Aria Holding, Mr. Suraj Thampi,<br />

after signing the MoU.<br />

and Dr Harshdeep Kamble,<br />

Principal Secretary of the Industries<br />

department, in the presence of Chief<br />

Minister of Maharashtra Mr Eknath<br />

Shinde, Minister of Industries Mr<br />

Uday Samant and Mr John Douglas,<br />

Commercial Director, Alutec Facades.<br />

“The government of Maharashtra<br />

welcomes this investment by Aria<br />

Holding, and this MoU marks a<br />

significant milestone in our efforts<br />

to promote the local economy and<br />

attract new investors to the state,” CM<br />

Shinde said.<br />

“We are confident that this<br />

investment by Aria Holding will fortify<br />

the state’s manufacturing sector and<br />

create a spectrum of job opportunities,<br />

from skilled labour for manufacturing<br />

to professionals, and will bring<br />

tangible benefits to our state. We are<br />

committed to providing all necessary<br />

support for successfully establishing<br />

the float glass plant,” he added.<br />

The MoU aligns with the ‘Make<br />

in India’ initiative launched by<br />

Prime Minister Narendra Modi<br />

in 2014, repositioning India as a<br />

critical market to do business in,<br />

attracting unprecedented growth in<br />

foreign investments. Infrastructure<br />

development is core to India’s growth<br />

strategy, and float glass plays a<br />

pivotal role across sectors, including<br />

construction, automotive, and<br />

industries.<br />

A significant amount of float glass<br />

requirements is still met through<br />

imports, and demand continues to<br />

increase. Aria Holding’s investment<br />

will boost the domestic supply of float<br />

glass and is intertwined with India’s<br />

development strategy, supporting<br />

infrastructure expansion, automotive<br />

growth, energy efficiency, employment<br />

generation, and technological<br />

advancements.<br />

“It is rewarding to see our<br />

continued expansion and investment<br />

into new markets through this<br />

MoU,” said His Excellency Sheikh<br />

Ali Bin Hamad Al Thani, who is the<br />

chairman of Aria Holding. “India<br />

is a compelling destination for<br />

investment, and Maharashtra, with<br />

its location, workforce, infrastructure,<br />

and progressive policies, provides us<br />

with a great platform to establish our<br />

factories.”<br />

The strategic partnership<br />

demonstrates the Maharashtra<br />

government’s dedication to fostering<br />

development in the state and<br />

providing a conducive environment<br />

for businesses to thrive and contribute<br />

to its progress.<br />

“Aria Holding is excited to be a part<br />

of India’s growth story through this<br />

strategic investment. Our state-ofthe-art<br />

factories in Maharashtra will<br />

manufacture glass for local, national,<br />

and international demand. India is<br />

going through a massive boom in<br />

infrastructure development nationally,<br />

and we plan to capture a significant<br />

share of that growth. Through our<br />

portfolio companies, we also plan to<br />

establish a robust export strategy for<br />

our products,” ssaid Suraj Thampi,<br />

Group CEO of Aria Holding.<br />

About the company<br />

Aria Holding, a multinational<br />

conglomerate headquartered in<br />

Qatar, operates across diverse sectors,<br />

including engineering, industrial,<br />

technology, business services, and<br />

trading. With a portfolio of industryleading<br />

companies like Alutec (Façade<br />

Engineering) and Vistas Global<br />

(Technology & Business Services),<br />

Aria fosters growth and innovation<br />

within its portfolio while creating<br />

enduring value for its stakeholders,<br />

employees, and the communities it<br />

operates.<br />

Email: info@ariaholding.com<br />

Website: www.ariaholding.com<br />

Glass Bulletin | <strong>January</strong> - <strong>March</strong>, <strong>2024</strong> 75

Company News<br />

Emirates Glass expands its Glaston<br />

fleet with Jumbo Series<br />

New Glaston Line Is Capable Of Processing High-Performance Coated Glass<br />

The investment marks Emirates Glass’ commitment to delivering top-notch architectural<br />

glass solutions to the Middle East and beyond.<br />

Emirates Glass LLC, one of<br />

the leading organizations in<br />

the glass industry and a longtime<br />

advocate of Glaston technology,<br />

continues its journey of innovation<br />

and quality enhancement with the<br />

installation of the Glaston Jumbo<br />

Series flat glass tempering line<br />

featuring Vortex Pro convection<br />

technology.<br />

This investment marks Emirates<br />

Glass’s commitment to delivering topnotch<br />

architectural glass solutions<br />

to the region and beyond. Since its<br />

inception in 1997, Emirates Glass<br />

has been an integral part of Dubai’s<br />

growth and a vital contributor to the<br />

region’s architectural landscape. The<br />

company has supplied glazing and<br />

expertise for many of the most iconic<br />

buildings across the city.<br />

“We can proudly say that 60 per<br />

cent of Dubai is glazed by Emirates<br />

Glass,” says Rizwanulla Khan,<br />

Executive President of Emirates<br />

Glass, who has been associated with<br />

the industry for the past four decades.<br />

Staying ahead of industry trends<br />

According to Khan, the glass industry<br />

in the Middle East has evolved by<br />

leaps and bounds in the last 20 years.<br />

Gone are the days when it was enough<br />

to use uncoated monolithic glasses.<br />

Today, the industry is looking for highperformance<br />

double- and triple-glazed<br />

insulated glass products with the<br />

lowest possible emissivity.<br />

“Another trend globally is toward<br />

oversized glass panels. Some of the<br />

biggest corporations require jumbosized<br />

glasses for their showrooms. And<br />

as a supplier, we are taking the lead,”<br />

Khan says. He also highlights the<br />

need for glass products that prioritize<br />

sustainability and energy efficiency.<br />

Both sustainability and thermal<br />

performance are extremely important.<br />

But while in Europe, the market<br />

wants to retain heat, this part of<br />

the world aims to retain cool air.<br />

76 Glass Bulletin | <strong>January</strong> - <strong>March</strong>, <strong>2024</strong>

Company News<br />

Producing such coatings requires<br />

highly sophisticated machinery and<br />

technology.<br />

Expanding to jumbo glass with a<br />

new line<br />

Emirates Glass has continuously<br />

invested in new machinery to serve<br />

evolving market demands. Their<br />

latest addition is the Glaston Jumbo<br />

Series tempering furnace with Vortex<br />

Pro convection technology. This<br />

new line is capable of processing<br />

high-performance coated glass with<br />

emissivity levels as low as 0.02 and a<br />

maximum glass size of up to 8 m.<br />

This investment complements<br />

the company’s two other Glaston<br />

tempering lines – the Glaston ProE<br />

MAGNUM and Glaston RC200. “Our<br />

Glaston MAGNUM machine dates<br />

back to 2006. We have been running<br />

it round the clock for all these years,<br />

and it still operates perfectly. This<br />

gave us the confidence that our next<br />

machine should be from Glaston, as<br />

well,” Khan says.<br />

Achieving remarkable differences<br />

The new tempering line was delivered<br />

in November 2020 and has since been<br />

a game-changer for Emirates Glass.<br />

“We especially appreciate the Glaston<br />

Jumbo’s convection control and the<br />

Glaston iLooK online quality control<br />

for distortion and anisotropy,” Khan<br />

says.<br />

“Even our customers have noticed<br />

a significant improvement in the<br />

quality of the glass they receive. We<br />

have been able to reach better optical<br />

quality and refined aesthetic glass<br />

characteristics in part thanks to the<br />

anisotropy control. This has elevated<br />

overall customer satisfaction and<br />

bolstered our reputation for delivering<br />

superior glass products,” he adds.<br />

The Glaston Jumbo Series has<br />

brought about considerable savings,<br />

too. “Today, the industry is looking to<br />

reduce energy costs in production.<br />

Glass processors expect their<br />

machinery to efficiently process<br />

large volumes of glass. This is exactly<br />

what we achieved with the Glaston<br />

Jumbo’s effective air and electricity<br />

consumption,” he notes.<br />

Glaston and HEGLA form<br />

partnership in Asia-Pacific<br />

Move Aimed At Strengthening Offering Of Both<br />

Parties For Customer Benefit<br />

With their complementary product offering, the two<br />

companies can meet glass processors’ growing demand<br />

for automation and integration.<br />

Glaston and HEGLA, both<br />

leaders in their respective<br />

areas of business in the glass<br />

machinery industry for architectural<br />

and automotive glass applications have<br />

entered into an exclusive partnership<br />

covering the majority of the Asia-<br />

Pacific region.<br />

The goal of the partnership is to<br />

strengthen the offering of both parties<br />

for the benefit of customers. With the<br />

complementary product offering, both<br />

companies can meet glass processors’<br />

growing demand for automation and<br />

integration providing comprehensive<br />

solutions, faster response and services<br />

to the customers thanks to the broader<br />

network in the region.<br />

Effective <strong>March</strong> <strong>2024</strong>, HEGLA’s<br />

sales and distribution activities in the<br />

area will draw upon the resources<br />

and network of Glaston Group. The<br />

partnership covers the whole region<br />

except for Japan, South Korea and<br />

China.<br />

“In HEGLA, we have the ideal<br />

partner as their complimentary<br />

offering will provide a perfect addition<br />

to our product range. Glaston is now<br />

able to offer the full product range to<br />

those customers who want to combine<br />

our heat treatment and insulated glass<br />

production with highly automated<br />

shop floor logistic solutions thereby<br />

substantially increasing efficiency and<br />

productivity. We are excited to start<br />

this new cooperation,” said CSO Sasu<br />

Koivumäki at Glaston Corporation.<br />

“With Glaston, we are able to<br />

provide highly customized solutions<br />

for clients including the integration<br />

of Glaston’s heat treatment and<br />

insulating glass production into our<br />

highly automated and integrated shop<br />

floor logistic solutions in one of the<br />

largest and fastest growing regions of<br />

the world,” Bernhard Hötger, CEO of<br />

HEGLA Group, added.<br />

About HEGLA Group<br />

Founded in 1976, HEGLA is renowned<br />

for high-quality, high-performance<br />

machines and systems for flat glass<br />

processing. The company is one of<br />

the market and technology leaders<br />

for highly automated and integrated<br />

shop floor solutions and services<br />

covering glass storage, loading, cutting,<br />

remnant sheet handling and sorting as<br />

well as laser marking and processing<br />

machines providing bird protection<br />

and mobile friendly glass.<br />

About Glaston Group<br />

Glaston is the glass processing<br />

industry’s innovative technology<br />

leader supplying equipment, services<br />

and solutions to the architectural,<br />

mobility, display and solar industries.<br />

The company also supports the<br />

development of new technologies<br />

integrating intelligence to glass.<br />

Email: info@glaston.net<br />

Website: www.glaston.net<br />

Email: carsten.koch@hegla.de<br />

Website: www.hegla.com<br />

Glass Bulletin | <strong>January</strong> - <strong>March</strong>, <strong>2024</strong> 77

Company News<br />

With IG2Pieces, HEGLA offers a system solution that can separate glass from an<br />

IGU, cleanly and without damage.<br />

Separating insulated glass:<br />

Utilising imperfect panes<br />

and end-of-life IGUs<br />

Breakthrough In Glass Recycling With HEGLA’s<br />

Innovative Technology<br />

Revolutionizing recycling, HEGLA automates insulated<br />

glass separation, boosting sustainability and resource<br />

efficiency in building materials.<br />

The amount of glass on buildings<br />

continues to increase: be<br />

it transparent facades and<br />

multiple IGUs on new buildings, or<br />

windows and panes that are replaced<br />

on existing properties at the end of<br />

the product life cycle. For many years,<br />

mixed glass containers were the go-to<br />

variant for glass disposal, but rising<br />

energy costs and society’s growing<br />

awareness of sustainability have<br />

increased the incentive to recycle.<br />

With the IG2Pieces assembly line<br />

technology, HEGLA has developed<br />

a solution that can automatically<br />

separate insulated glass.<br />

At the same time, the company<br />

offers a handling concept that retains<br />

the purity of the raw material and<br />

improves revenues or enables panes to<br />

be reused as such.<br />

Dealing with imperfect panes and<br />

used glass sustainably<br />

“Our development work was based<br />

on the question of how it is possible<br />

to deal with imperfect panes and<br />

used glass in a way that conserves<br />

resources and is efficient at the same<br />

time,” said Heinrich Ostendarp,<br />

Managing Director of HEGLA. To<br />

ensure that the glass panes remain<br />

usable for a range of applications,<br />

the aim was to release the individual<br />

panes from the spacers reliably,<br />

cleanly and without damage, while<br />

maintaining high productivity.<br />

“Thanks to a newly developed<br />

separation method, the automated<br />

process leaves only a minimal amount<br />

of sealing compound on the surface of<br />

the pane,” added Dr Ostendarp.<br />

The measurement of the ISO<br />

dimensions and the insulated glass<br />

structure is fully automated. Once<br />

the glass has been removed from the<br />

laminate, it can be recycled without<br />

any loss of raw material quality.<br />

Just like the panes, the unimpaired<br />

spacers, including the intact<br />

desiccant, are conveyed to a separate<br />

system for disposal or recycling.<br />

Type-specific float glass yields<br />

financial advantages<br />

Separated recycling of the individual<br />

types of glass yields advantages,<br />

compared to mixed containers. When<br />

panes are professionally separated,<br />

this generates added financial value.<br />

The impact on the environment is also<br />

positive: the panes find their way back<br />

to the float tank to close the material<br />

circuit while preserving the quality<br />

of the raw material. Further, one<br />

kilogram of floatglass that is produced<br />

from used glass generates around 0.3<br />

kilogram less CO2, compared to a<br />

classic glass mixture.<br />

78 Glass Bulletin | <strong>January</strong> - <strong>March</strong>, <strong>2024</strong>

HEGLA• 2<br />

Once the pane has been removed from the insulated glass laminate, the IGU can either be reformed with the available glass or it can be<br />

used for other orders.<br />

Reuse and repair<br />

Alongside type-specific recycling,<br />

the reuse of undamaged panes is<br />

yet another option that increases<br />

the recycling rate. “Separation and<br />

repair make particular sense for<br />

newly produced, large-surface and<br />

high-quality IGUs, if this is done<br />

productively and safely,” explained the<br />

managing director.<br />

If, despite all precautions, there<br />

are impurities or surface defects in<br />

a freshly produced insulated glass<br />

laminate, the individual pieces can<br />

be cleanly removed and the defective<br />

pane can be disposed of, if necessary.<br />

The remaining glass is available for<br />

further processing. This method<br />

can be economically attractive for<br />

special coatings, toughened glass,<br />

or laminated safety glass panes in<br />

particular, as well as complex and<br />

large attachments. “With our system,<br />

we accelerate and simplify a process<br />

that takes place manually in many<br />

companies and depends on the skill<br />

and know-how of the employees,”<br />

remarked Dr Ostendarp.<br />

If repairs cannot be made during<br />

the ongoing production process or if<br />

no special-purpose cut is available,<br />

there is a third option. The clean<br />

application of butyl and sealing of<br />

separated glass can be planned for<br />

follow-up orders and cut to smaller<br />

dimensions. Applications here include<br />

LSG, high-quality, refined glass, or<br />

special-purpose glass that is no longer<br />

available.<br />

Three questions about separating<br />

insulated glass<br />

Q: The separation of IGUs is a<br />

process that many glass processors<br />

have avoided until now, due to the<br />

time and effort involved. To what<br />

extent has the situation changed?<br />

Dr Ostendarp: Automated<br />

separating technology will change<br />

the initial situation. Alongside higher<br />

productivity and safety, the separation<br />

quality is higher. This results in<br />

cleaner panes, while the spacers and<br />

their desiccant remain unaffected. As<br />

panes are becoming ever larger and<br />

the proportion of special-purpose glass<br />

is growing, the separation of insulated<br />

glass is becoming more financially<br />

attractive in and of itself. For a small<br />

glass unit with two single float panes,<br />

the cost and benefits must still be<br />

individually evaluated.<br />

However, if it contains an LSG<br />

pane, a special coating or toughened<br />

glass, separation is increasingly<br />

attractive. This also applies if the<br />

repair of a unit involves an extra pane,<br />

which would result in longer delivery<br />

times or higher costs. Firstly, the<br />

effectiveness of the system depends<br />

on the cycle. Automated separation<br />

must be done so quickly that both<br />

the environment and the company’s<br />

budget will benefit. With the increase<br />

in carbon pricing, this ratio will<br />

continue to improve. Secondly, repairs<br />

or type-specific recycling saves carbon<br />

and contributes to achieving the<br />

climate goals.<br />

Q: you emphasise the sustainability<br />

and resource conservation aspects.<br />

Would you explain these in more<br />

detail?<br />

Dr Ostendarp: Climate protection<br />

goals are more relevant than ever.<br />

There are now calls for tender in<br />

which concepts for recycling and<br />

improving the climate footprint are<br />

required. As a result, separating<br />

insulated glass can be very attractive<br />

for reasons of corporate image.<br />

Further, recycling saves CO2 and<br />

reduces the costs of the CO2<br />

certificate for float glass producers.<br />

Ultimately, the commitment must<br />

also pay, which can be reinforced by<br />

financial incentives.<br />

Q: While the separation of<br />

insulated glass is not widespread,<br />

the topic is generating considerable<br />

interest. What do you expect for the<br />

future?<br />

Dr Ostendarp: In the future, I<br />

can imagine that new interest groups<br />

will examine the issue. In some cases,<br />

IGUs will then be separated directly<br />

on the construction site. Suppliers<br />

and buyers will come together via<br />

software platforms. I also envision<br />

new glass products, including IGUs<br />

made from fully recyclable panes. In<br />

terms of energy prices, melting will<br />

become more attractive –the demand<br />

for type-specific shards for the float<br />

tank is already high today.<br />

–Carsten Koch<br />

Email: carsten.koch@hegla.de<br />

Website: www.hegla.com<br />

Glass Bulletin | <strong>January</strong> - <strong>March</strong>, <strong>2024</strong> 79

Company News<br />

Sisecam finalises<br />

partnership agreement<br />

with ICRON<br />

Global Glass Major’s Investment In Tech Services<br />

Firm Rises To 15.66 %<br />

Sisecam aims to take its operational excellence and<br />

optimisation approach in its current business activities to<br />

the next level with ICRON.<br />

Sisecam has finalised its<br />

partnership agreement with<br />

ICRON, a Turkish technology<br />

company that provides decision<br />

optimisation services at operational<br />

and strategic levels.<br />

Sisecam Investment BV, a whollyowned<br />

subsidiary of Sisecam,<br />

purchased shares in ICRON at<br />

a closing general meeting held<br />

on <strong>January</strong> 15, <strong>2024</strong>. Sisecam<br />

Investment BV General Meeting<br />

was attended by Sisecam Chairman<br />

and Executive Member of the Board<br />

Professor Dr Ahmet Kırman, Sisecam<br />

CEO Görkem Elverici, ICRON<br />

80 Glass Bulletin | <strong>January</strong> - <strong>March</strong>, <strong>2024</strong>

Sisecam• 2<br />

Founding Partner A Tamer Ünal,<br />

ICRON Chairman and CEO Gürer<br />

Ünal and ICRON Board Member<br />

Ahmet Ertuğrul.<br />

Some three per cent of ICRON’s<br />

total shares were purchased by<br />

Sisecam Investment BV for USD<br />

3 Million. Simultaneously with the<br />

share purchase, it was also decided<br />

to increase ICRON’s total capital by<br />

USD 5 Million, with participation<br />

solely by Sisecam Investment BV. As a<br />

result of this capital increase, Sisecam<br />

Investment BV’s stake in ICRON will<br />

rise to 15.66 per cent.<br />

In the first half of 2023, Sisecam<br />

signed a letter of intent to invest in<br />

ICRON, a provider of operational<br />

and strategic decision optimisation<br />

services to various industries. In<br />

October 2023, Sisecam announced<br />

that it had reached a partnership<br />

agreement with ICRON.<br />

Under the agreement approved by<br />

the Turkish Competition Authority,<br />

Sisecam also holds an option to<br />

purchase additional shares in ICRON<br />

– allowing it to raise its total stake in<br />

the company up to 49 per cent – in<br />

the future.<br />

Sisecam’s goal with this<br />

partnership, its first investment<br />

in software technologies, is to<br />

grow in tandem with ICRON, a<br />

high-potential technology services<br />

provider. In addition, Sisecam aims<br />

to take its operational excellence and<br />

optimization approach in its current<br />

business activities to the next level<br />

with ICRON.<br />

In recognition of its excellence,<br />

ICRON was recognised in Gartner’s<br />

2023 “Magic Quadrant for Supply<br />

Chain Planning Solutions”. This list<br />

of the global top 20 supply chain<br />

technology vendors was compiled by<br />

Gartner, a world-renowned technology<br />

research and consultancy firm.<br />

ICRON is expected to contribute<br />

to Sisecam’s operational and financial<br />

performance with its alreadyestablished<br />

digital infrastructure and<br />

its quality approach that fully meets<br />

today’s evolving technological needs.<br />

About Sisecam<br />

Sisecam was founded in 1935 to<br />

establish Türkiye’s glass industry in<br />

line with the vision of Mustafa Kemal<br />

Atatürk. Today, Sisecam is a major<br />

global player in the fields of glass and<br />

chemicals. Sisecam is the only global<br />

company operating in all core areas of<br />

glass production – including flat glass,<br />

glassware, glass packaging, and glass<br />

fiber.<br />

Website: www.sisecam.com.tr/en<br />

Glass Bulletin | <strong>January</strong> - <strong>March</strong>, <strong>2024</strong> 81

Company Report<br />

Milestone in automated<br />

entrance solutions: AL13<br />

Studio opens in Bengaluru<br />

Sprawled Over 5,000 Square Feet, It Showcases<br />

Cutting-Edge Solutions From Portalp<br />

Ambica Aluminium Company stands as Karnataka’s first<br />

exclusive dealer for Jindal Aluminium Ltd and has now<br />

solidified its pan-India partnership with Portalp.<br />

In a remarkable event celebrating<br />

innovation and excellence in<br />

automatic entrance solutions, the<br />

AL13 Studio by Ambica Aluminium<br />

Company was inaugurated in<br />

Bengaluru.<br />

The studio, sprawled over 5,000<br />

square feet, showcases many cuttingedge<br />

solutions from the French<br />

automatic entrance solution provider,<br />

Portalp. Ambica Aluminium Company<br />

stands as Karnataka’s first exclusive<br />

dealer for Jindal Aluminium Ltd<br />

and has now solidified its pan-India<br />

partnership with Portalp.<br />

The inauguration ceremony<br />

witnessed the esteemed presence<br />

of Mr Laurent Frayssinet, CEO of<br />

Portalp Group, France, and Mr Pragun<br />

Jindal, Vice Chairman and Managing<br />

Director of Jindal Aluminium Ltd.<br />

Other distinguished guests included<br />

Mr Marc Vial Montpellier, Director<br />

for Bangalore and Chennai offices<br />

and head of Industries and Tech<br />

departments, and the founder of<br />

Ambica Aluminium Company Mr<br />

Champalal Nagori.<br />

The event commenced with a<br />

tree-planting ceremony, symbolising<br />

82 Glass Bulletin | <strong>January</strong> - <strong>March</strong>, <strong>2024</strong>

Portalp• 2<br />

Mr Marc Vial Montpellier,<br />

Director for Bangalore and Chennai offices and<br />

head of Industries and Tech Departments<br />

growth and sustainability, followed<br />

by a ribbon-cutting ceremony and<br />

the traditional lighting of the lamp.<br />

The dignitaries were honoured<br />

with mementoes and planters were<br />

presented by the founder of Ambica<br />

Aluminium Company, highlighting the<br />

commitment to eco-friendly practices.<br />

Each dignitary took the stage<br />

to address the gathering, sharing<br />

insightful perspectives on the future<br />

roadmap of their companies and<br />

their collaborative journey with<br />

Ambica Aluminium. The emphasis on<br />

innovation and quality was a recurring<br />

theme in their motivational speeches.<br />

The guests were then guided<br />

through the state-of-the-art studio,<br />

where a diverse range of automatic<br />

entrance solutions was showcased.<br />

From Radial Doors at the entrance<br />

to framed and frameless versions of<br />

single-leaf, double-telescopic, tripletelescopic,<br />

and Breakout systems, the<br />

studio demonstrates the versatility<br />

and advanced features of Portalp’s<br />

offerings, including Hermetic Doors,<br />

Clean Room Doors, and Toilet Doors.<br />

As a symbolic gesture of unity,<br />

guests were invited to sign a blank<br />

memento, leaving behind personalised<br />

messages to commemorate their<br />

presence and wish great success<br />

to Ambica Aluminium. This act<br />

reinforced the sense of community<br />

and collaboration that defines the<br />

ethos of the industry.<br />

The dignitaries were then<br />

ushered into the VIP lounge for<br />

a sumptuous lunch, fostering<br />

networking opportunities and casual<br />

conversations. The event concluded<br />

with the signing of the “Wall of Fame,”<br />

a symbolic gesture that marked<br />

the success of the AL13 Studio<br />

inauguration.<br />

The AL13 Studio stands as a<br />

testament to Ambica Aluminium<br />

Company’s commitment to pushing<br />

the boundaries of innovation and<br />

providing top-notch solutions to its<br />

clientele. The strategic partnership<br />

with Portalp further strengthens the<br />

studio’s position as a pioneer in the<br />

automatic entrance solutions domain<br />

in Bengaluru.<br />

Ambica Aluminium Company<br />

Email: contact@al13.in<br />

Website: www.al13.in<br />

Glass Bulletin | <strong>January</strong> - <strong>March</strong>, <strong>2024</strong> 83

Company Report<br />

Innovators in glass machinery:<br />

Handong’s precision craftsmanship<br />

Company’s Strong Production Capacity Ensures Timely Product Delivery<br />

Handong’s Glass Washing Machine series and Laminated Glass Production Line series<br />

encompass over 100 machine models, showcasing the company’s commitment to diverse<br />

and cutting-edge solutions.<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3 2<br />

1<br />

蒸 压 釜<br />

Autoclave<br />

蒸 压 釜 小 车<br />

Trolley<br />

下 片 台<br />

Unloading Table<br />

过 渡 输 送 台<br />

Conveying Table<br />

预 压 机<br />

Full Forced Convection Furnace<br />

过 渡 输 送 台<br />

Conveying Table<br />

合 片 房<br />

Cleaning Room<br />

清 洗 干 燥 机<br />

Washing & Drying Unit<br />

上 片 台<br />

Loading Table<br />

发 明 专 利 号 :<br />

ZL.2014 10628635.6<br />

Automatic Laminated Glass Production Line<br />

Delving into the realm of<br />

precision and craftsmanship,<br />

Shenzhen Handong Glass<br />

Equipment Manufacturing Company<br />

Limited has evolved into a prominent<br />

glass deep processing machine<br />

manufacturer. The company<br />

seamlessly integrates design and<br />

development, processing and<br />

manufacturing, marketing, and aftersales<br />

service.<br />

Cutting-edge product lines:<br />

Automatic Laminated Glass<br />

Production Line<br />

Handong’s Automatic Laminated<br />

Glass Production Line, centrally<br />

controlled by PLC, embodies<br />

automation and intelligence. With<br />

real-time remote monitoring, glass<br />

positioning, and assembling accuracy<br />

of ±0.5mm, this line exemplifies<br />

precision in every aspect. Its<br />

modular design allows for various<br />

configurations, making it adaptable to<br />

diverse production needs.<br />

Full Forced Convection Furnace<br />

The Full Forced Convection Furnace<br />

is a well-designed marvel, boasting a<br />

stainless steel air circulation system<br />

processed with laser numerical<br />

control for unparalleled precision.<br />

With a focus on energy efficiency,<br />

this furnace operates at low<br />

temperatures, making it ideal for<br />

SGP laminating, low-e laminating,<br />

sheet glass laminating, and reducing<br />

energy consumption by 30% - 50%. Its<br />

low maintenance requirements and<br />

reduced personnel costs set it apart<br />

from traditional equipment.<br />

Glass Autoclave<br />

Handong’s Glass Autoclave adheres<br />

to GB/ASME/CE standards and is<br />

meticulously designed for safety and<br />

efficiency. With multilayer protection,<br />

rigorous manufacturing processes,<br />

and advanced production technology,<br />

it ensures reliable and secure<br />

operations. The autoclave’s internal<br />

insulation board, water-cooled<br />

motor, and efficient heating system<br />

contribute to a production cycle of<br />

Full Forced Convection Furnace<br />

84 Glass Bulletin | <strong>January</strong> - <strong>March</strong>, <strong>2024</strong>

Handong• 2<br />

3.5-6 hours.<br />

Solar Glass Washing Machine<br />

Controlled by PLC and displayed<br />

on a touch screen, the Solar Glass<br />

Washing Machine offers reliable,<br />

long-term operation. It boasts targeted<br />

optimization designs for various<br />

glass deep processing processes and<br />

features an air blower with internal<br />

circulation structures. With its<br />

Solar Glass Washing Machine<br />

industrial aluminum alloy splicing<br />

structure and market-leading position<br />

in China, it stands as a testament to<br />

Handong’s commitment to excellence.<br />

Establishing excellence<br />

With over two decades of experience,<br />

Shenzhen Handong Glass Equipment<br />

Manufacturing Company Limited has<br />

expanded its operations to include<br />

sheet metal, welding, machining,<br />

painting, electrical installation,<br />

and other complete processes in<br />

the production department. This<br />

robust infrastructure ensures strong<br />

production capacity, guaranteeing the<br />

timely delivery of products.<br />

Handong has forged deep and<br />

meaningful collaborations with<br />

industry giants such as Lens<br />

Technology, Huaxing Optoelectronics,<br />

BOE, Foxconn, Berne Optics, CSG<br />

Group, Flat Group, China National<br />

Building Materials Group, Kibing<br />

Group, PSG Group, Fuyao Group,<br />

Saint-Gobain Group, Taiwan Glass<br />

Group, NSG Pilkington, and more<br />

than 1,000 other glass processing<br />

enterprises.<br />

Handong’s machines are exported<br />

to dozens of countries and regions<br />

across five continents and four<br />

oceans, establishing the company as<br />

a global leader in the glass processing<br />

industry.<br />

In 2022, Handong marked a new<br />

chapter with the establishment of<br />

a 50,000 square meters production<br />

base in Changzhou. Looking ahead,<br />

Handong is set to own two production<br />

bases in Shenzhen and Changzhou,<br />

solidifying its position as a leading<br />

innovator.<br />

Future endeavors will focus on<br />

deep processing of architectural<br />

glass, thin sheet glass processing for<br />

electronic products, solar photovoltaic<br />

glass processing, and new energy<br />

vehicle glass processing.<br />

In essence, Handong, with its<br />

commitment to precision, innovation,<br />

and customer satisfaction, stands<br />

as a stalwart in the glass industry,<br />

shaping the future with cutting-edge<br />

technology and a vision for excellence.<br />

May Xian<br />

Email: sale@szhdglass.com<br />

Thomas Tong<br />

Email: thomas_tong@szhdglass.com<br />

Website: www.szhdglass.com<br />

Glass Bulletin | <strong>January</strong> - <strong>March</strong>, <strong>2024</strong> 85

Company Report<br />

Empowering excellence: Safety and<br />

Quality Forum by Institution of Engineers<br />

Championing Safety and Quality for 20 Years: A Pinnacle in Professional<br />

Practices and Industry Advancement<br />

Mr. Dinesh Kumar,<br />

Chairman, SQF-IEI<br />

Safety and Quality Forum (SQF), a<br />

pivotal division of the Institution<br />

of Engineers (India) (IEI), has<br />

been at the forefront for two decades,<br />

promoting knowledge and awareness in<br />

safety and quality across the country.<br />

Established in 1920 and awarded<br />

the Royal Charter in 1935, IEI, with<br />

over 9 lakh members, stands as the<br />

largest multi-disciplinary professional<br />

body of engineers in India.<br />

Situated at IEI, Delhi Centre,<br />

SQF, since its inception in 2003, has<br />

aimed to instil a culture of safety<br />

and quality through ethical and<br />

professional practices. The mission is<br />

to create a productive and sustainable<br />

working environment while optimizing<br />

Mr. Praveen Kumar Singh,<br />

Director, SQF-IEI<br />

Mr. R.N. Rajpoot,<br />

Past Chairman, SQF-IEI<br />

resource usage. SQF collaborates with<br />

government bodies, local authorities,<br />

and educational institutions to enforce<br />

rules, conduct audits, and develop<br />

courses in safety, reliability, and quality<br />

management.<br />

With a pool of senior professionals,<br />

SQF engages in consultancy and<br />

auditing, focusing on safety audits,<br />

electrical safety, fire safety, HAZOP<br />

studies, environmental assessment,<br />

and emergency preparedness. Actively<br />

conducting training programs since<br />

2003, SQF enhances awareness<br />

and knowledge in safety and quality,<br />

networking with national and<br />

international organizations.<br />

Entering an MoU with nonprofit<br />

bodies, SQF is dedicated to<br />

propagating the culture of safety<br />

and quality among the masses.<br />

The annual Safety and Quality<br />

Conventions, featuring Safety and<br />

Quality Innovation Awards, recognise<br />

organizations for their innovative<br />

procedures and outstanding<br />

contributions.<br />

The 21st Safety Innovation<br />

Convention <strong>2024</strong> is set for September<br />

in Delhi, while the 3rd Quality<br />

Innovation Convention <strong>2024</strong> will be<br />

hosted at the International Automobile<br />

Centre of Excellence (IACE), Gandhi<br />

Nagar, Gujarat, on 11-12 <strong>March</strong><br />

<strong>2024</strong>. SQF continues to be a beacon<br />

of excellence, driving engineering<br />

practices towards a safer and more<br />

quality-centric future.<br />

Speaking about the event, Glass<br />

Bulletin Editor & Publisher Mr Lakhan<br />

Singh said, “There is a lot of scope for<br />

coordination and involvement of the<br />

glass and hardware industries with<br />

SQF, as they are custodians and known<br />

for the quality and safety of their<br />

products.”<br />

Email: sqfdelhi1@gmail.com,<br />

praveen8771@gmail.com<br />

Website: www.sqfiei.in<br />

Dr G Ranganathan, President IEI, giving award with Er. J C Singhal, Council Member, Er. G Kumawat, SQF, and Chairman<br />

Jharkhand Centre, to Safety Quiz winner at 38th Indian Engineering Congress on 28th December 2023, at Jabalpur, MP.<br />

Networking opportunities - Er. Shashi Kant, former Dy<br />

Adviser, Planning Commission, and Dr R K Bhandari,<br />

former Director CBRI, discussing during SQF Convention.<br />

86 Glass Bulletin | <strong>January</strong> - <strong>March</strong>, <strong>2024</strong>

Company News<br />

Sisecam will reduce carbon emissions<br />

with AI technology<br />

To Reduce Both Production Waste Rate And Carbon Emissions By<br />

Eliminating Colour Issues<br />

Always placing sustainability at the centre of its business operations, Sisecam is now<br />

working on an artificial intelligence project supported by TÜBİTAK.<br />

Sisecam – committed to<br />

developing solutions for a<br />

sustainable world and more<br />

efficient production processes – is<br />

currently implementing the Glass<br />

Color Optimization Project (CROP)<br />

with artificial intelligence and<br />

machine learning methods.<br />

This initiative aims to eliminate<br />

colour issues during the manufacture<br />

of glass. The project will reduce<br />

the production waste rate and the<br />

resulting carbon emissions.<br />

The forward-looking project is<br />

being carried out by a consortium<br />

that includes Sisecam, Koç University,<br />

TÜBİTAK Artificial Intelligence<br />

Institute, and Analythinx. CROP<br />

aims to develop an infrastructure to<br />

minimize colour differences and to<br />

identify and quickly resolve the root<br />

cause of colour-related problems<br />

in glass production with artificial<br />

intelligence models. Designed to<br />

improve colour quality in the glass<br />

industry, the project will integrate<br />

advanced technology and artificial<br />

intelligence know-how into production<br />

operations while expanding the<br />

country’s industrial knowledge base.<br />

CROP will start at the Sisecam<br />

Eskişehir Glassware plant and last<br />

for two years. This initiative once<br />

again demonstrates the value Sisecam<br />

attaches to innovation and continuous<br />

development. The project is expected<br />

to have a major impact through<br />

information transfer to other Sisecam<br />

plants.<br />

CROP is one of 17 projects<br />

supported as a result of TÜBİTAK’s<br />

1711 Artificial Intelligence Ecosystem<br />

Call in 2023. The project includes<br />

modelling that will help manage<br />

the change created by artificial<br />

intelligence, achieve results to<br />

benefit humanity, produce value from<br />

artificial intelligence, and achieve full<br />

independence in critical technologies.<br />

About Sisecam<br />

Sisecam was founded in 1935 to<br />

establish Turkey’s glass industry in<br />

line with the vision of Mustafa Kemal<br />

Atatürk. Today, Sisecam is a major<br />