Water & Wastewater Asia March/April 2024

Water & Wastewater Asia is an expert source of industry information, cementing its position as an indispensable tool for trade professionals in the water and wastewater industry. As the most reliable publication in the region, industry experts turn this premium journal for credible journalism and exclusive insight provided by fellow industry professionals. Water & Wastewater Asia incorporates the official newsletter of the Singapore Water Association (SWA).

Water & Wastewater Asia is an expert source of industry information, cementing its position as an indispensable tool for trade professionals in the water and wastewater industry. As the most reliable publication in the region, industry experts turn this premium journal for credible journalism and exclusive insight provided by fellow industry professionals. Water & Wastewater Asia incorporates the official newsletter of the Singapore Water Association (SWA).

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

HOTSEAT<br />

of 95-100°С. It requires bulky<br />

equipment and a large production<br />

floor space. A generalised typical<br />

diagram of an industrial plant for<br />

phenol-containing wastewater<br />

treatment is shown in Fig. 1.<br />

FERROMAGNETIC PARTICLES AVS<br />

IN WASTEWATER TREATMENT<br />

PROCESSES<br />

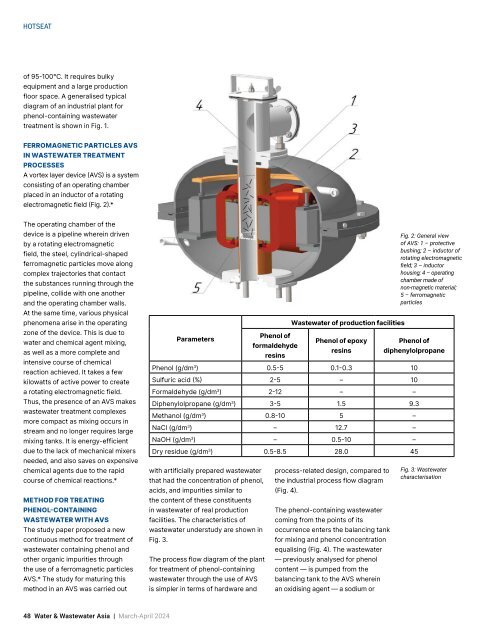

A vortex layer device (AVS) is a system<br />

consisting of an operating chamber<br />

placed in an inductor of a rotating<br />

electromagnetic field (Fig. 2).*<br />

The operating chamber of the<br />

device is a pipeline wherein driven<br />

by a rotating electromagnetic<br />

field, the steel, cylindrical-shaped<br />

ferromagnetic particles move along<br />

complex trajectories that contact<br />

the substances running through the<br />

pipeline, collide with one another<br />

and the operating chamber walls.<br />

At the same time, various physical<br />

phenomena arise in the operating<br />

zone of the device. This is due to<br />

water and chemical agent mixing,<br />

as well as a more complete and<br />

intensive course of chemical<br />

reaction achieved. It takes a few<br />

kilowatts of active power to create<br />

a rotating electromagnetic field.<br />

Thus, the presence of an AVS makes<br />

wastewater treatment complexes<br />

more compact as mixing occurs in<br />

stream and no longer requires large<br />

mixing tanks. It is energy-efficient<br />

due to the lack of mechanical mixers<br />

needed, and also saves on expensive<br />

chemical agents due to the rapid<br />

course of chemical reactions.*<br />

METHOD FOR TREATING<br />

PHENOL-CONTAINING<br />

WASTEWATER WITH AVS<br />

The study paper proposed a new<br />

continuous method for treatment of<br />

wastewater containing phenol and<br />

other organic impurities through<br />

the use of a ferromagnetic particles<br />

AVS.* The study for maturing this<br />

method in an AVS was carried out<br />

Parameters<br />

Phenol of<br />

formaldehyde<br />

resins<br />

<strong>Wastewater</strong> of production facilities<br />

Phenol of epoxy<br />

resins<br />

Fig. 2: General view<br />

of AVS: 1 – protective<br />

bushing; 2 – inductor of<br />

rotating electromagnetic<br />

field; 3 – inductor<br />

housing; 4 – operating<br />

chamber made of<br />

non-magnetic material;<br />

5 – ferromagnetic<br />

particles<br />

Phenol of<br />

diphenylolpropane<br />

Phenol (g/dm 3 ) 0.5-5 0.1-0.3 10<br />

Sulfuric acid (%) 2-5 – 10<br />

Formaldehyde (g/dm 3 ) 2-12 – –<br />

Diphenylolpropane (g/dm 3 ) 3-5 1.5 9.3<br />

Methanol (g/dm 3 ) 0.8-10 5 –<br />

NaCl (g/dm 3 ) – 12.7 –<br />

NaOH (g/dm 3 ) – 0.5-10 –<br />

Dry residue (g/dm 3 ) 0.5-8.5 28.0 45<br />

with artificially prepared wastewater<br />

that had the concentration of phenol,<br />

acids, and impurities similar to<br />

the content of these constituents<br />

in wastewater of real production<br />

facilities. The characteristics of<br />

wastewater understudy are shown in<br />

Fig. 3.<br />

The process flow diagram of the plant<br />

for treatment of phenol-containing<br />

wastewater through the use of AVS<br />

is simpler in terms of hardware and<br />

process-related design, compared to<br />

the industrial process flow diagram<br />

(Fig. 4).<br />

The phenol-containing wastewater<br />

coming from the points of its<br />

occurrence enters the balancing tank<br />

for mixing and phenol concentration<br />

equalising (Fig. 4). The wastewater<br />

— previously analysed for phenol<br />

content — is pumped from the<br />

balancing tank to the AVS wherein<br />

an oxidising agent — a sodium or<br />

Fig. 3: <strong>Wastewater</strong><br />

characterisation<br />

48 <strong>Water</strong> & <strong>Wastewater</strong> <strong>Asia</strong> | <strong>March</strong>-<strong>April</strong> <strong>2024</strong>