Water & Wastewater Asia March/April 2024

Water & Wastewater Asia is an expert source of industry information, cementing its position as an indispensable tool for trade professionals in the water and wastewater industry. As the most reliable publication in the region, industry experts turn this premium journal for credible journalism and exclusive insight provided by fellow industry professionals. Water & Wastewater Asia incorporates the official newsletter of the Singapore Water Association (SWA).

Water & Wastewater Asia is an expert source of industry information, cementing its position as an indispensable tool for trade professionals in the water and wastewater industry. As the most reliable publication in the region, industry experts turn this premium journal for credible journalism and exclusive insight provided by fellow industry professionals. Water & Wastewater Asia incorporates the official newsletter of the Singapore Water Association (SWA).

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

HOTSEAT<br />

Energy-independent<br />

industrial effluent<br />

treatment technologies<br />

By Dr Kiran Kumar Manga, founder and director of HAIDRO<br />

As a Singapore-based company offering<br />

electrochemical treatment technology for<br />

industrial effluent treatment applications,<br />

HAIDRO was founded in 2021. The company<br />

was part of local startup incubator focused on<br />

the water sector — Ripple2wave Incubator’s<br />

2023 cohort. Ripple2wave is supported by<br />

Enterprise Singapore and PUB, Singapore’s<br />

National <strong>Water</strong> Agency.<br />

Globally, 359 billion tonnes of wastewater<br />

are produced per year, of which 48% is<br />

discharged without treatment due to lack of<br />

low cost and sustainable solutions. About 30%<br />

of the total wastewater treatment cost is spent<br />

on energy, as they are traditionally dependent<br />

on grid power. As the demand grows, this<br />

burden will increase exponentially, impacting<br />

the environment. In 2022, the wastewater<br />

treatment industry was responsible for<br />

emitting 3 Gigatonnes (Gt) of carbon due to<br />

the use of energy-intensive technologies.<br />

HAIDRO provides chemical-free, thermal-free,<br />

net energy positive wastewater treatment<br />

solutions which reduces 40% of energy bills<br />

and 90% of waste disposal costs in F&B,<br />

chemical and construction industries.<br />

ECR TECHNOLOGY<br />

Conventional effluent treatment technologies<br />

such as aerobic or anaerobic digestion (AD),<br />

electrocoagulation and electrooxidation,<br />

require external energy to drive the microbial<br />

or electrochemical reactions and treat<br />

high chemical oxygen demand (COD) and<br />

biochemical oxygen demand (BOD) effluents.<br />

Electrochemical techniques, especially,<br />

utilise external electricity to initiate the<br />

anodic or cathodic reactions to generate the<br />

reactive species to coagulate or oxidise the<br />

contaminants. Although these techniques<br />

are effective to mitigate the contaminations,<br />

they are highly energy-intensive and<br />

require continuous external power supply<br />

which makes them unsustainable for future<br />

industrial effluent treatment demands.<br />

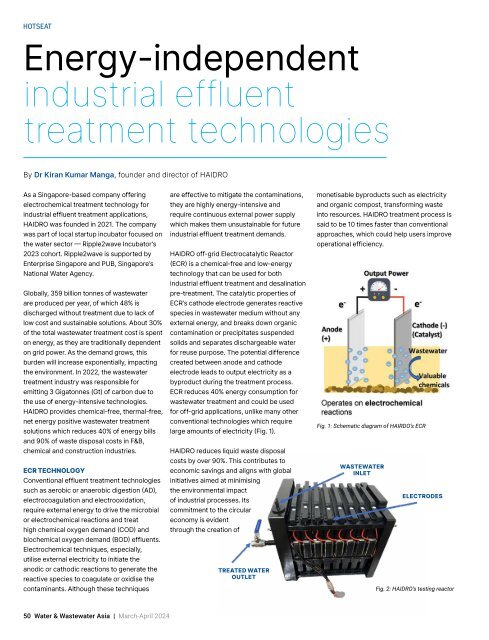

HAIDRO off-grid Electrocatalytic Reactor<br />

(ECR) is a chemical-free and low-energy<br />

technology that can be used for both<br />

industrial effluent treatment and desalination<br />

pre-treatment. The catalytic properties of<br />

ECR’s cathode electrode generates reactive<br />

species in wastewater medium without any<br />

external energy, and breaks down organic<br />

contamination or precipitates suspended<br />

solids and separates dischargeable water<br />

for reuse purpose. The potential difference<br />

created between anode and cathode<br />

electrode leads to output electricity as a<br />

byproduct during the treatment process.<br />

ECR reduces 40% energy consumption for<br />

wastewater treatment and could be used<br />

for off-grid applications, unlike many other<br />

conventional technologies which require<br />

large amounts of electricity (Fig. 1).<br />

HAIDRO reduces liquid waste disposal<br />

costs by over 90%. This contributes to<br />

economic savings and aligns with global<br />

initiatives aimed at minimising<br />

the environmental impact<br />

of industrial processes. Its<br />

commitment to the circular<br />

economy is evident<br />

through the creation of<br />

TREATED WATER<br />

OUTLET<br />

monetisable byproducts such as electricity<br />

and organic compost, transforming waste<br />

into resources. HAIDRO treatment process is<br />

said to be 10 times faster than conventional<br />

approaches, which could help users improve<br />

operational efficiency.<br />

Fig. 1: Schematic diagram of HAIRDO’s ECR<br />

WASTEWATER<br />

INLET<br />

ELECTRODES<br />

Fig. 2: HAIDRO’s testing reactor<br />

50 <strong>Water</strong> & <strong>Wastewater</strong> <strong>Asia</strong> | <strong>March</strong>-<strong>April</strong> <strong>2024</strong>