Loup Generator — Spring 2024

In this issue: Rebuilding the Genoa Headworks following the March 2019 storm that breached the canal in six spots, the District's new outage mapping system, and chainsaw safety.

In this issue: Rebuilding the Genoa Headworks following the March 2019 storm that breached the canal in six spots, the District's new outage mapping system, and chainsaw safety.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

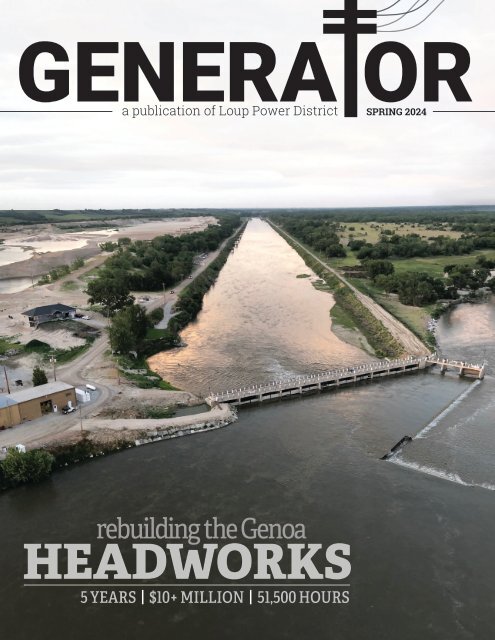

GENERA OR<br />

a publication of <strong>Loup</strong> Power District SPRING <strong>2024</strong><br />

Behind the Scenes:<br />

Power Restoration<br />

<strong>2024</strong> Retail Rates<br />

EnergyWise Incentives<br />

rebuilding the Genoa<br />

HEADWORKS<br />

5 YEARS | $10+ MILLION | 51,500 HOURS

BOARD OF DIRECTORS<br />

Bob Cerv<br />

Chairman<br />

Jim Donoghue<br />

First Vice Chairman<br />

Mike Fleming<br />

Second Vice Chairman<br />

Rich Aerni<br />

Secretary<br />

Dick Tooley<br />

Treasurer<br />

Alan Drozd<br />

Steve Heesacker<br />

Larry Zach<br />

EXECUTIVE STAFF<br />

Neal Suess<br />

President/CEO<br />

Walt Williams<br />

Vice President,<br />

Accounting & Finance/CFO<br />

Todd Duren<br />

Vice President,<br />

Corporate Services<br />

Korey Hobza<br />

Vice President, Engineering<br />

Dan Hellbusch<br />

Vice President, Operations<br />

The <strong>Loup</strong> <strong>Generator</strong> is<br />

published quarterly<br />

as a service for <strong>Loup</strong><br />

employees, families,<br />

friends, and associates.<br />

For feedback, story ideas,<br />

and submissions, contact:<br />

Stacy Wemhoff<br />

Communications Coordinator<br />

402-562-5711<br />

swemhoff@loup.com<br />

Counties receive $2.2 million<br />

<strong>Loup</strong> Power District recently delivered<br />

inside revenue payments and the second<br />

half of the in-lieu-of-tax payments to the<br />

counties it serves. This is a benefit of being<br />

served by a locally controlled, not-forprofit<br />

utility.<br />

Like other businesses, <strong>Loup</strong> Power District<br />

pays sales tax, gasoline taxes, motor<br />

vehicle license fees, and permit fees.<br />

The in-lieu-of-tax payments are made to<br />

service area counties in lieu of occupation,<br />

personal property, and real estate taxes.<br />

County treasurers distribute the funds to<br />

the various taxing bodies in each county.<br />

Total in-lieu-of-tax payments for 2023:<br />

Platte <strong>—</strong> $ 9,713.77<br />

<strong>Loup</strong> pays communities $1.3 million<br />

<strong>Loup</strong> Power District recently delivered lease payment checks totaling more than $1.3<br />

million to area communities. Each of these communities owns their electric distribution<br />

systems. These payments compensate them for the use of those systems for the fourth<br />

quarter of 2023. Communities use the funds for a variety of public projects.<br />

The payments were:<br />

Columbus <strong>—</strong> $982,982.15<br />

Platte Center <strong>—</strong> $8,782.13<br />

Monroe <strong>—</strong> $12,154.80<br />

Tarnov <strong>—</strong> $1,325.09<br />

Creston <strong>—</strong> $5,596.81<br />

Humphrey <strong>—</strong> $24,595.31<br />

Lindsay <strong>—</strong> $55,944.93<br />

<strong>Loup</strong> Power District renewed its membership<br />

in Community Clubs and Chambers of<br />

Commerce in towns throughout its service<br />

area.<br />

Checks totaling $32,330 were presented<br />

to communities in Boone, Colfax, Nance,<br />

Platte, and Madison counties. Payment<br />

amounts are based on the 2023 gross revenues<br />

in each community.<br />

“Membership renewal demonstrates <strong>Loup</strong><br />

Power District’s commitment to community<br />

involvement in all of our area towns,”<br />

said Todd Duren, Vice President of Corporate<br />

Services.<br />

Boone <strong>—</strong> $5,078.34<br />

Nance <strong>—</strong> $ 6,445.84<br />

Colfax <strong>—</strong> $240.48<br />

Madison <strong>—</strong> $359.27<br />

Total <strong>—</strong> $ 21,837.70<br />

Cornlea <strong>—</strong> $1,765.33<br />

Newman Grove <strong>—</strong> $17,819.12<br />

Duncan <strong>—</strong> $15,041.53<br />

Fullerton <strong>—</strong> $28,815.39<br />

Genoa <strong>—</strong> $21,247.02<br />

Belgrade <strong>—</strong> $2,965.83<br />

Richland <strong>—</strong> $2,986.81<br />

Howells <strong>—</strong> $17,451.91<br />

The District also makes additional<br />

payments to the counties to guarantee<br />

they receive 5 percent of the inside<br />

revenues from the towns in their areas<br />

subject to the in-lieu-of-tax payments.<br />

Additional payments for 2023:<br />

Madison <strong>—</strong> $35,869.84<br />

Platte <strong>—</strong> $1,768,090.36<br />

Nance <strong>—</strong> $125,372.12<br />

Colfax <strong>—</strong> $114,618.87<br />

Boone <strong>—</strong> $196,221.84<br />

Total <strong>—</strong> $2,240,173.03<br />

Leigh <strong>—</strong> $15,474.99<br />

Clarkson <strong>—</strong> $17,669.39<br />

Albion <strong>—</strong> $47,082.59<br />

Cedar Rapids <strong>—</strong> $19,551.01<br />

Primrose <strong>—</strong> $1,254.35<br />

Petersburg <strong>—</strong> $9,840.82<br />

St. Edward <strong>—</strong> $17,708.58<br />

Total <strong>—</strong> $1,328,055.89<br />

<strong>Loup</strong> renews community memberships<br />

Towns and their payments include:<br />

Columbus Area Chamber<strong>—</strong>$22,848<br />

Albion Chamber of Commerce<strong>—</strong>$1,645<br />

Lindsay Community Club<strong>—</strong>$1,552<br />

Fullerton Chamber of Commerce<strong>—</strong>$1,104<br />

Genoa Chamber of Commerce<strong>—</strong>$753<br />

Humphrey Community Club<strong>—</strong>$817<br />

Howells Community Club<strong>—</strong>$601<br />

Clarkson Community Club<strong>—</strong>$601<br />

Newman Grove Community Club<strong>—</strong>$551<br />

St. Edward Community Club<strong>—</strong>$555<br />

Cedar Rapids Community Club<strong>—</strong>$475<br />

Petersburg Community Club<strong>—</strong>$291<br />

Leigh Community Club<strong>—</strong>$437<br />

Primrose Community Club<strong>—</strong>$100<br />

Front page: Sgt. Joe Yates with the Nebraska National Guard took this photo of the Genoa Headworks<br />

during a flyover in a UH-60 Blackhawk in July 2020.<br />

2 | GENERATOR

president’s message<br />

<strong>Loup</strong> still waiting on payment<br />

for March 2019 storm repair<br />

I was reflecting the other day about a<br />

number of things that are ongoing here at<br />

<strong>Loup</strong> Power District, and it occurred to me that<br />

we are approaching the 5-year anniversary of<br />

the mid-March 2019 storm event.<br />

I know that many people ask me why I call it<br />

a storm event, and I am quick to point out that<br />

from an insurance perspective it was a storm<br />

and not a flood, even though most people call<br />

it a flood.<br />

It is amazing the amount of coordination<br />

and work that went on in the days of the storm<br />

and the weeks and months that followed.<br />

February and early March that year were very<br />

cold and significant ice built up on all the<br />

rivers and streams in our area. Combine that<br />

with a rapid warm up and significant rain fall<br />

and you get the aftermath that occurred in<br />

mid-March 2019.<br />

On the Wednesday night when the damage<br />

began to occur to the District’s hydroelectric<br />

system and water breached the <strong>Loup</strong> Power<br />

Canal, I was awakened by a phone call from<br />

our hydro operators indicating water was<br />

pouring into the canal. We gathered all of<br />

our operations people as soon as possible and<br />

began to assess the damage and how to begin<br />

to make repairs.<br />

I was summoned by the Mayor of Columbus<br />

and Platte County Emergency Management to<br />

assist them in dealing with the storm, and we<br />

all gathered in the emergency operation center<br />

to analyze the situation and develop a plan to<br />

move forward.<br />

I was proud of the teamwork between<br />

all the parties that day and our continued<br />

communication to develop a plan of attack.<br />

Obviously, District crews did a magnificent<br />

job in repairing the damage and getting<br />

everything back up and running.<br />

On the electrical side, damage in St. Edward<br />

and Columbus was repaired, and everyone was<br />

back up relatively quickly. It did take longer to<br />

repair the damage to the hydroelectric system<br />

(specifically, the canal) as that damage was<br />

excessive. However, all District employees<br />

worked tirelessly to get the system back up and<br />

operational as quickly as possible.<br />

The thing that has taken the longest is<br />

getting payment from the federal government<br />

for the repairs that were made and the<br />

promises of payment made by these entities.<br />

As I am sure you have heard on<br />

many occasions, the District has spent<br />

approximately $10 million on repairs from<br />

the mid-March 2019 storm, but has received<br />

only half of the money to which we are entitled<br />

from this disaster.<br />

The mid-March 2019 storm event is,<br />

hopefully, a once in a lifetime event. District<br />

Board of Directors and management have<br />

worked hard to keep up with the repairs and to<br />

make sure that the repairs will be beneficial in<br />

the long run. By staying vigilant, we will make<br />

sure the hydroelectric system is a long-term<br />

valuable asset for the District.<br />

NEAL SUESS<br />

President/CEO<br />

SPRING <strong>2024</strong> | 3

Outage mapping system impro<br />

Years ago, <strong>Loup</strong> Power District’s line technicians carried large books of distribution line<br />

maps in their trucks.<br />

They noted upgrades, repairs, and changes on those maps as they went about their work and<br />

then transferred those notes to large wall maps in each division’s home office. Those wall maps<br />

were periodically removed, updated by computer drafters, and rehung.<br />

The system was tedious and somewhat inefficient, but that’s how it was done before the<br />

technological advances that brought about online infrastructure maps, smart meters, and realtime<br />

notes.<br />

Today, <strong>Loup</strong>’s employees are able to view online maps with a plethora of information about<br />

infrastructure and assets. They can view notes made by coworkers and see which customers are<br />

out of power at any given time.<br />

“This has changed the way we operate,” said Meter Maintenance Superintendent Tim<br />

Ramaekers.<br />

FIRST STEP: AMI GRIDSTREAM METERS<br />

Back in 2018, <strong>Loup</strong> installed 227 Gridstream energy meters in Columbus as part of a pilot<br />

project. The meters relayed outage notifications within seconds. They also successfully noted<br />

when power was restored.<br />

With that success, <strong>Loup</strong> began a five-year plan to install 21,000 meters throughout its<br />

service territory.<br />

“Before this technology, we had to rely on customers to call us and tell us when<br />

their power was out,” Ramaekers said.<br />

That meant that big outages sometimes resulted in confusion.<br />

Line techs were dispatched to different locations to try and<br />

diagnose problems. Some customers didn’t report outages<br />

right away and were overlooked.<br />

“Our response times are so much faster now because we<br />

can go directly to the problem,” Ramaekers said.<br />

NEXT: A FULL-SERVICE SYSTEM<br />

The system worked as it should following the<br />

successful installation of all the smart meters. They<br />

correctly noted outage locations and customer<br />

information. Still, the system had limitations.<br />

So employees in the Meter Maintenance<br />

and Engineering Departments<br />

joined forces with RVW, a local<br />

engineering firm located in<br />

Columbus.<br />

Together, they developed a fullfeatured<br />

outage map that relays<br />

outage information in addition to<br />

<strong>Loup</strong> assets, equipment, maps, and<br />

notes.<br />

“This is an amazing asset to our<br />

employees,” said Korey Hobza, Vice President of<br />

Engineering. “It will put all of our information at their<br />

fingertips when they need it.”<br />

The interactive one-line diagram maps of <strong>Loup</strong>’s<br />

distribution system offer a broad look at real-time<br />

energy operations as well as detailed notes and<br />

4 | GENERATOR<br />

Journey Line Technician Tommy Wemhoff and Line<br />

Technician Beau Schommer reference the Outage Mapping<br />

System while discussing a project.

ves efficiency, response time<br />

equipment descriptions.<br />

Operations personnel can log in to the system from<br />

tablets equipped with cell service. This means they can get<br />

all the information they might need about a project at any<br />

given time.<br />

They can zoom in on a meter to learn the transformer and<br />

meter number, service address, and meter type and voltage.<br />

They can overlay a Google map, click an outage icon, and<br />

simply click “Navigate” to get directions.<br />

Overlaying a topology map will inform them about terrain<br />

so they have proper equipment and a radar map overlay lets<br />

employees know that severe weather and lightning are on<br />

the way.<br />

CUSTOMER BENEFITS<br />

<strong>Loup</strong> customers have access to a pared-down version of<br />

the map, accessible at loup.com.<br />

Customers can still call their local office to report an<br />

outage. But they also have the additional option of checking<br />

in on outages online.<br />

The map lets customers know that <strong>Loup</strong> is aware of<br />

outages by displaying the general location and number of<br />

outages. This expanded radius means customers won’t have<br />

to worry about the public knowing exactly who is out of<br />

power.<br />

Customers can report their specific outage via a link on<br />

the map if desired.<br />

Engineering Tech Aric Alt and Drafting Technician Clint<br />

Albracht helped create the map information by noting GPS<br />

locations and technical information. With that done, it’s just<br />

a matter of maintaining that information.<br />

This used to be done by referring to red marks on a<br />

wall map. Today, the line techs send details over to the<br />

Engineering Department so those changes can be made<br />

electronically and updated by the next day.<br />

Alt said this means faster response times for customers in<br />

the event of an unplanned outage.<br />

Before, he said, employees might have to go to an outage<br />

location to learn about breakers, switches, transformers, or<br />

fuses. Then, they’d have to go back to the service center to<br />

gather the proper equipment, and make their way back for<br />

repair.<br />

Now, they can access all that information from the getgo.<br />

An example of a planned outage as it appears to<br />

<strong>Loup</strong> employees using the new Outage Mapping<br />

System.<br />

This customer outage map shows four outages<br />

in the highlighted radius in Columbus.<br />

Meter Maintenance Superintendent Tim<br />

Ramaekers views District electrical maps.<br />

Visit loup.com to check out<br />

the new Outage Map.<br />

OUTAGE<br />

MAP<br />

SPRING <strong>2024</strong> | 5

6 | GENERATOR

Headworks repairs nearing<br />

completion 5 years after storm<br />

“Heartbreaking.”<br />

“Sick to my stomach.”<br />

“Way more than we expected.”<br />

Memories of March 15, 2019,<br />

are painful for many <strong>Loup</strong><br />

Power District employees.<br />

Uncontrolled water into the<br />

canal. Six breaches. Roads<br />

washed away. A home destroyed.<br />

The shop addition<br />

ripped off and the boiler gone.<br />

The dredge full of water.<br />

“How long it was going to<br />

take to fix wasn’t a thought in<br />

my mind,” said Hydro Superintendent<br />

Brad Morton. “It<br />

was ‘how’ and ‘where do we<br />

start?’”<br />

Five years and 51,500 working<br />

hours later, the repair is nearing<br />

completion.<br />

So far, the damages total more<br />

than $10 million. The Federal<br />

Emergency Management Agency has reimbursed<br />

<strong>Loup</strong> about $4.4 million.<br />

Headworks Supervisor Randy Prososki recalls the<br />

long, difficult days right after the storm. And then,<br />

the years of work that followed.<br />

“It’s been a long haul,” he said.<br />

WINTER STORM ULMER<br />

The destruction at the Genoa Headworks was caused<br />

by a series of events that caused flooding throughout<br />

Nebraska.<br />

February was unusually cold and early March followed<br />

suit. River ice became exceptionally thick.<br />

Headworks employees noticed it was nearly two feet<br />

thick in spots. They busted up some of that ice with<br />

dynamite and a crane on Monday, March 11.<br />

It was so cold, that soil frost<br />

levels were deep and much of the<br />

area had several inches of snow<br />

still on the ground.<br />

Then, the bomb cyclone Winter<br />

Storm Ulmer arrived with highs<br />

shooting into the 60s, accelerating<br />

snowmelt and dropping rain<br />

on frozen ground.<br />

The rain and melting snow broke<br />

up river ice, causing water to<br />

surge through rivers and over<br />

land.<br />

Federal authorities estimate<br />

damage from the flood at more<br />

than $3 billion in Nebraska<br />

alone. It's considered one of the<br />

nation’s costliest inland flood<br />

events on record.<br />

BREACHES & DESTRUCTION<br />

The Headworks is the start of<br />

<strong>Loup</strong>’s canal system. Employees<br />

there began noticing rising<br />

water on the evening of March<br />

13. Late that night Headworks<br />

Supervisor Randy Prososki called extra employees in<br />

to sandbag the intake approach.<br />

During the work, they heard a loud pop and ran toward<br />

the shop. Then they saw a light pole fall over as<br />

the whole approach disappeared.<br />

The water began flowing north and they realized<br />

Headworks Park would likely flood. Prososki ordered<br />

them home before they weren’t able to leave at all.<br />

Employees were anxious to survey the damage the<br />

following morning, but they couldn't. Some roads<br />

were covered in water. Others were completely<br />

washed away.<br />

On March 15, drone footage and a helicopter ride<br />

revealed the full damage.<br />

“When we first got in here, my heart just sank,”<br />

Prososki said.<br />

LEFT: The Genoa Headworks before 2019, right after the storm, and today. Above, the Nebraska National Guard<br />

dropped sandbags to help fill an inaccessible breach on the south side of the canal.<br />

SPRING <strong>2024</strong> | 7

MAKING A PLAN<br />

The south side of the canal before,<br />

after the storm, and today.<br />

The area was inaccessible after the storm<br />

because the approach and the weir bridge<br />

(shown below) were both destroyed.<br />

The initial reaction to the damage<br />

was so overwhelming that it<br />

seemed nearly impossible to know<br />

where to start.<br />

“The way we went about doing<br />

the work was to stay in business,”<br />

Morton said.<br />

That meant the first order of<br />

business was stopping the<br />

uncontrolled water coming<br />

into the canal through the two<br />

breaches at the intake.<br />

“We quickly knew that we couldn’t<br />

do it all ourselves,” he said.<br />

<strong>Loup</strong> was fortunate enough to<br />

have help from its neighbor,<br />

Preferred Sands, which helped<br />

create makeshift roads and carry<br />

fill material for the breaches.<br />

The biggest help came from the<br />

Nebraska National Guard, which<br />

dropped 280 massive sandbags<br />

to stop the south breach, which<br />

was inaccessible because the weir<br />

bridge washed away.<br />

Once those big issues were tackled,<br />

it was time to look to long-term<br />

repair.<br />

“Everybody just dug in and started<br />

to work and we came up with a<br />

plan,” said President/CEO Neal<br />

Suess.<br />

<strong>Loup</strong> recruited help from<br />

engineering firms and other<br />

contractors. It also had to ensure<br />

that it followed procedures<br />

mandated by the Federal Energy<br />

Regulatory Commission (FERC).<br />

Suess said <strong>Loup</strong> employees are<br />

used to dealing with emergencies<br />

like icy conditions and summer<br />

storms that may damage<br />

infrastucture. While this situation<br />

was much different, the response<br />

was the same.<br />

"You just get down to work," he<br />

said. "Little by little, things got<br />

done."<br />

And, most importantly, things got<br />

done safely, despite long hours of<br />

hard work in sometimes difficult<br />

conditions.<br />

“The amazing thing was how<br />

people came together at the time,"<br />

Suess said.<br />

Morton said that <strong>Loup</strong> employees'<br />

dedication is always evident, but<br />

maybe never more so than in<br />

March of 2019.<br />

“The great support of our<br />

company helped us endure the<br />

hardship," he said.<br />

The weir bridge washed away but the supports held and were used to rebuild the bridge .<br />

8 | GENERATOR

HEADWORKS REPAIR TIMELINE<br />

2019<br />

• New weir bridge.<br />

• Dredge motor removed and refurbished.<br />

• A containerized boiler was installed in a temporary<br />

location near the shop. Crews at the GHW steam the<br />

intake and sluice gates each winter to prevent ice<br />

buildup and damage. The original boiler room was<br />

washed away.<br />

2020<br />

• New wingwall/approach reinforced with sheet piling.<br />

• Construction begins on new Headworks Operator<br />

home.<br />

2021<br />

• Headworks Park reopens following repair.<br />

2022<br />

• The water eroded the north bank of the settling basin.<br />

Water continued to erode fill along the bank, dumping<br />

it into the settling basin. To fix the problem, a sheet pile<br />

wall was installed. The pilings are 30' long and driven<br />

20' in the ground with tie backs to secure it.<br />

• New volleyball court at Headworks Park.<br />

• New concrete approach on the south side of the intake.<br />

The north breach was closed with temporary fill for more than<br />

a year. Sheet piling was used in construction of a new wingwall<br />

and approach in September of 2020.<br />

2023<br />

• Bank repair from the Headworks to Highway 22.<br />

• Started repairing damages to the Tailrace banks and<br />

jetties.<br />

• Boiler moved to new, permanent spot.<br />

<strong>2024</strong><br />

• Construction begins on new Headworks shop.<br />

Learn more about the storm, the employees,<br />

and the partnerships in an article originally<br />

published in April 2020 at bit.ly/GHW19.<br />

The breach by Highway 22.<br />

More than four feet of water filled the Pawnee II dredge.<br />

The motors had to be removed and refurbished.<br />

SPRING <strong>2024</strong> | 9

Downed trees? Put safety<br />

first when using chainsaws<br />

<strong>Spring</strong> usually means storms. Those storms can knock down<br />

trees that homeowners need to clean up and chainsaws are the<br />

perfect tool for accomplishing this task.<br />

Operating a chainsaw can be hazardous, though. Around 36,000<br />

people are treated in ERs for chainsaw-related injuries every year. That<br />

risk is lessened with proper personal protective equipment and safe<br />

operating procedures.<br />

Here are some tips to keep in mind any time you operate a chainsaw.<br />

BEFORE STARTING A CHAINSAW<br />

• Check controls, chain tension, and all bolts and handles to ensure<br />

that they are functioning properly and that they are adjusted<br />

according to the manufacturer’s instructions.<br />

• Make sure that the chain is always sharp and that the oil tank is full.<br />

• Start the saw on the ground or on another firm support. Do not<br />

drop start the saw.<br />

• Start the saw at least 10 feet from the fueling area, with the chain’s<br />

brake engaged.<br />

FUELING A CHAINSAW<br />

• Use approved containers for transporting fuel to the saw.<br />

• Dispense fuel at least 10 feet away from any sources of ignition<br />

when performing construction activities.<br />

• Use a funnel or a flexible hose when pouring fuel into the saw.<br />

• Never attempt to fuel a running or HOT saw.<br />

CHAINSAW SAFETY<br />

• Clear dirt, debris, small tree limbs and rocks from the saw’s chain<br />

path. Look for nails, spikes or other metal in the tree before cutting.<br />

• Shut off the saw or engage its chain brake when carrying the saw on<br />

rough or uneven terrain.<br />

• Keep your hands on the saw’s handles, and maintain balance.<br />

• Wear proper personal protective equipment when operating<br />

the saw, including hand, foot, leg, eye, face, hearing and head<br />

protection. Do not wear loose-fitting clothing.<br />

• Be careful that the trunk or tree limbs will not bind against the saw.<br />

• Gasoline-powered chainsaws must be equipped with a protective<br />

device that minimizes chainsaw kickback.<br />

• Be cautious of saw kickback. To avoid kickback, do not saw with the<br />

tip. Keep tip guard in place.<br />

WATCH FOR SPRINGING BRANCHES<br />

Take extra care in cutting trees or branches that were bent, twisted,<br />

hung up, or caught under another object during a high wind. If the<br />

branch is suddenly released, it may strike the chainsaw operator or a<br />

bystander with enough force to cause serious injury or death. Even a<br />

seemingly small tree or branch may pose a hazard when it is released<br />

from tension.<br />

To ensure your safety, identify the maximum point of tension on the<br />

spring pole and slowly shave the underside of the tree rather than cut<br />

through to allow the tree or branch to release tension slowly.<br />

36,000<br />

1in5<br />

$<br />

Head Injuries<br />

3,418<br />

Chainsaw Stats<br />

Kickback causes<br />

1 in 5 chainsaw injuries.<br />

Kickback, binding, and pull-in<br />

cause the most injuries<br />

from chainsaws.<br />

Source: Centers for Disease Control and Prevention<br />

Source: U.S. Product Safety Commission<br />

Each year, 36,000 people<br />

are treated in hospital ERs<br />

for chainsaw-related injuries.<br />

36%<br />

- INJURIES -<br />

Upper Body Area<br />

2,141<br />

Arm and Hand Area<br />

17,994<br />

Thirty-six percent<br />

of chainsaw accidents<br />

result in injuries<br />

to the legs and knees.<br />

The average chainsaw injury<br />

requires 110 stitches.<br />

Most common places for injuries:<br />

front left thigh & back of the left hand.<br />

Medical costs for chainsaw<br />

injuries amount to about<br />

$350 million per year.<br />

Foot Area<br />

2,885<br />

Leg Area<br />

16,348<br />

Sources: Occupational Safety and Health Administration and Centers for Disease<br />

Control and Prevention.

employee notes<br />

JON BLASER<br />

Customer Service Supervisor<br />

Jon Blaser joined<br />

<strong>Loup</strong> in 1999 as<br />

Accountant/Collector<br />

at the Columbus<br />

General Office. He<br />

was promoted to<br />

Customer Service<br />

Supervisor in 2016.<br />

Blaser’s responsibilities<br />

include supervision<br />

in the areas of<br />

customer services<br />

and billing.<br />

Blaser is a graduate of Monroe High<br />

School and earned an Associate of<br />

Applied Science Degree in Accounting<br />

from Lincoln School of Commerce. He<br />

and his wife, Gina, have three children<br />

<strong>—</strong> Jessica, Connor, and Colton.<br />

MICHAEL JONES<br />

Computer Support Specialist<br />

Michael Jones<br />

joined <strong>Loup</strong> in 2009<br />

as Computer Support<br />

Specialist at the<br />

Columbus General<br />

Office. His duties<br />

include installing,<br />

maintaining, and<br />

repairing the computers,<br />

software, and<br />

communications<br />

systems throughout<br />

the District.<br />

25 YEARS<br />

15 YEARS<br />

Jones was born in Columbus and grew<br />

up in the Rockford, Illinois, area. He<br />

graduated from Harlem High School<br />

in Loves Park, Illinois, and studied<br />

Information Technology-Electronic at<br />

Central Community College-Columbus.<br />

He and his wife, Beth, have three sons<br />

<strong>—</strong> Benjamin, Steven, and David.<br />

TYLER HINER<br />

Equipment Operator<br />

Tyler Hiner joined<br />

<strong>Loup</strong> Power District<br />

as an Equipment<br />

Operator at the<br />

Columbus Service<br />

Center in 2023.<br />

Hiner operates the<br />

District’s heavy<br />

equipment and is<br />

part of the crew that<br />

performs maintenance<br />

on the canal<br />

1 YEAR<br />

system from Genoa to Columbus. He<br />

also works at the two powerhouses<br />

when needed, helps build substations,<br />

and maintains District parks and lakes.<br />

Hiner is a graduate of Howells High<br />

School and Wayne State College. He<br />

and his wife, Megan, have a daughter,<br />

Addilynn.<br />

NANCY NELSEN<br />

Customer Service Representative<br />

Nancy Nelsen joined<br />

<strong>Loup</strong> Power District<br />

as a part-time<br />

Customer Service<br />

Representative in<br />

the Newman Grove<br />

office in 2019.<br />

Her responsibilities<br />

include greeting<br />

customers; processing<br />

payments; setting<br />

up, transferring,<br />

or closing service;<br />

taking service calls; and preparing<br />

reports.<br />

5 YEARS<br />

Nelsen graduated from Lincoln High<br />

School and earned an Associate of<br />

Applied Science degree from Southeast<br />

Community College.<br />

She and her husband, Chris, have a<br />

daughter, Halie.<br />

TRAVIS SHIVELY<br />

Dredge/Maintenance Canal Technician<br />

Travis Shively joined<br />

<strong>Loup</strong> as Maintenance<br />

Technician at<br />

the Genoa Headworks<br />

in 2023. He<br />

was recently<br />

promoted to<br />

Dredge/Canal Maintenance<br />

Technician.<br />

He is responsible<br />

for maintaining<br />

1 YEAR<br />

District vehicles<br />

and equipment at<br />

the Headworks. He also troubleshoots<br />

the mechanical components of the<br />

District’s dredge, the Pawnee II.<br />

Shively is a graduate of St. Edward High<br />

School and has an Associate of Applied<br />

Science degree in diesel technology<br />

from Northeast Community College.<br />

BRANDON RAMAEKERS<br />

Journey Line Technician<br />

Brandon Ramaekers<br />

joined <strong>Loup</strong> Power<br />

District in 2014 as<br />

a Lineman on the<br />

Columbus Line Crew<br />

at the Columbus<br />

Service Center.<br />

He was promoted<br />

to Journey Line<br />

Technician in 2016.<br />

He is a member of<br />

10 YEARS<br />

the line crew that is<br />

responsible for the<br />

construction, operation, and maintenance<br />

of <strong>Loup</strong>’s electrical transmission<br />

and distribution system in the Columbus<br />

Division.<br />

Ramaekers is a graduate of Norfolk<br />

Catholic High School and earned an<br />

Associate of Applied Science Degree<br />

in Utility Line from Northeast<br />

Community College in Norfolk.<br />

NEBRASKA IS #1 IN POWER GRID RELIABILITY <strong>—</strong> U.S. NEWS & WORLD REPORT STATE RANKINGS<br />

U.S. News & World Report put Nebraska at the top of the list for power grid reliability based on the minutes of<br />

power outages the average customer experiences in a year. Here at <strong>Loup</strong>, our employees maintain thousands<br />

of poles and nearly 900 miles of distribution, transmission, and underground lines covering more than 2,200<br />

miles! And they do so with a reliability rating of more than 99.9 percent.<br />

SPRING <strong>2024</strong> | 11

2404 15th Street | PO Box 988<br />

Columbus, NE 68602-0988<br />

3WAYS TO LIMIT<br />

TREE TRIMMING<br />

Did you know that <strong>Loup</strong> is required to trim trees that grow<br />

too close to overhead power lines? This means balancing<br />

nature with power reliability and safety. Here are some tips<br />

if you’re planning to plant trees this spring.<br />

FT.<br />

FT.<br />

FT.<br />

RIGHT PLACE<br />

Trees that will grow less than 40 feet tall<br />

should be planted at least 25 feet away<br />

from power lines. Trees more than 40<br />

feet tall should be planted at least 50 feet<br />

away.<br />

DONT BLOCK TRANSFORMERS<br />

Plant shrubs at least 10 feet away from<br />

transformer doors and 4 feet from<br />

transformer sides.<br />

REPORT DANGEROUS BRANCHES<br />

Let us know if you spot a tree or branch<br />

that is dangerously close to power lines.