The Role of Wafer Bonding in 3D Integration and ... - SUSS MicroTec

The Role of Wafer Bonding in 3D Integration and ... - SUSS MicroTec

The Role of Wafer Bonding in 3D Integration and ... - SUSS MicroTec

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

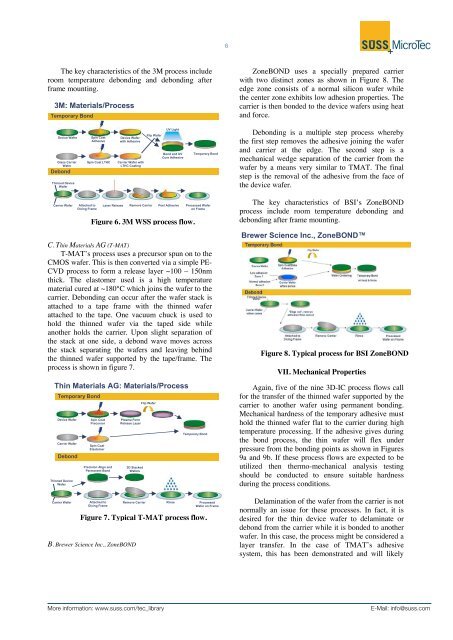

<strong>The</strong> key characteristics <strong>of</strong> the 3M process <strong>in</strong>clude<br />

room temperature debond<strong>in</strong>g <strong>and</strong> debond<strong>in</strong>g after<br />

frame mount<strong>in</strong>g.<br />

3M: Materials/Process<br />

Temporary Bond<br />

Device <strong>Wafer</strong><br />

Glass Carrier<br />

<strong>Wafer</strong><br />

Debond<br />

Th<strong>in</strong>ned Device<br />

<strong>Wafer</strong><br />

Carrier <strong>Wafer</strong><br />

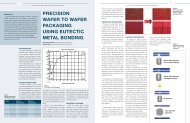

C. Th<strong>in</strong> Materials AG (T-MAT)<br />

T-MATʼs process uses a precursor spun on to the<br />

CMOS wafer. This is then converted via a simple PE-<br />

CVD process to form a release layer ~100 – 150nm<br />

thick. <strong>The</strong> elastomer used is a high temperature<br />

material cured at ~180°C which jo<strong>in</strong>s the wafer to the<br />

carrier. Debond<strong>in</strong>g can occur after the wafer stack is<br />

attached to a tape frame with the th<strong>in</strong>ned wafer<br />

attached to the tape. One vacuum chuck is used to<br />

hold the th<strong>in</strong>ned wafer via the taped side while<br />

another holds the carrier. Upon slight separation <strong>of</strong><br />

the stack at one side, a debond wave moves across<br />

the stack separat<strong>in</strong>g the wafers <strong>and</strong> leav<strong>in</strong>g beh<strong>in</strong>d<br />

the th<strong>in</strong>ned wafer supported by the tape/frame. <strong>The</strong><br />

process is shown <strong>in</strong> figure 7.<br />

Th<strong>in</strong> Materials AG: Materials/Process<br />

Temporary Bond<br />

Device <strong>Wafer</strong><br />

Carrier <strong>Wafer</strong><br />

Debond<br />

Th<strong>in</strong>ned Device<br />

<strong>Wafer</strong><br />

Attached to<br />

Dic<strong>in</strong>g Frame<br />

Sp<strong>in</strong> Coat<br />

Adhesive<br />

Sp<strong>in</strong> Coat LTHC<br />

Sp<strong>in</strong> Coat<br />

Precursor<br />

Sp<strong>in</strong> Coat<br />

Elastomer<br />

Precision Align <strong>and</strong><br />

Permanent Bond<br />

Carrier <strong>Wafer</strong> Attached to<br />

Dic<strong>in</strong>g Frame<br />

Device <strong>Wafer</strong><br />

with Adhesive<br />

Carrier <strong>Wafer</strong> with<br />

LTHC Coat<strong>in</strong>g<br />

Plasma Form<br />

Release Layer<br />

<strong>3D</strong> Stacked<br />

<strong>Wafer</strong>s<br />

Remove Carrier<br />

B. Brewer Science Inc., ZoneBOND<br />

Flip <strong>Wafer</strong><br />

Flip <strong>Wafer</strong><br />

UV Light<br />

Bond <strong>and</strong> UV<br />

Cure Adhesive<br />

Laser Release Remove Carrier Peel Adhesive<br />

Figure 6. 3M WSS process flow.<br />

R<strong>in</strong>se<br />

Temporary Bond<br />

Processed <strong>Wafer</strong><br />

on Frame<br />

Temporary Bond<br />

Figure 7. Typical T-MAT process flow.<br />

Processed<br />

<strong>Wafer</strong> on Frame<br />

6<br />

ZoneBOND uses a specially prepared carrier<br />

with two dist<strong>in</strong>ct zones as shown <strong>in</strong> Figure 8. <strong>The</strong><br />

edge zone consists <strong>of</strong> a normal silicon wafer while<br />

the center zone exhibits low adhesion properties. <strong>The</strong><br />

carrier is then bonded to the device wafers us<strong>in</strong>g heat<br />

<strong>and</strong> force.<br />

Debond<strong>in</strong>g is a multiple step process whereby<br />

the first step removes the adhesive jo<strong>in</strong><strong>in</strong>g the wafer<br />

<strong>and</strong> carrier at the edge. <strong>The</strong> second step is a<br />

mechanical wedge separation <strong>of</strong> the carrier from the<br />

wafer by a means very similar to TMAT. <strong>The</strong> f<strong>in</strong>al<br />

step is the removal <strong>of</strong> the adhesive from the face <strong>of</strong><br />

the device wafer.<br />

<strong>The</strong> key characteristics <strong>of</strong> BSIʼs ZoneBOND<br />

process <strong>in</strong>clude room temperature debond<strong>in</strong>g <strong>and</strong><br />

debond<strong>in</strong>g after frame mount<strong>in</strong>g.<br />

Brewer Science Inc., ZoneBOND<br />

Figure 8. Typical process for BSI ZoneBOND<br />

VII. Mechanical Properties<br />

Aga<strong>in</strong>, five <strong>of</strong> the n<strong>in</strong>e <strong>3D</strong>-IC process flows call<br />

for the transfer <strong>of</strong> the th<strong>in</strong>ned wafer supported by the<br />

carrier to another wafer us<strong>in</strong>g permanent bond<strong>in</strong>g.<br />

Mechanical hardness <strong>of</strong> the temporary adhesive must<br />

hold the th<strong>in</strong>ned wafer flat to the carrier dur<strong>in</strong>g high<br />

temperature process<strong>in</strong>g. If the adhesive gives dur<strong>in</strong>g<br />

the bond process, the th<strong>in</strong> wafer will flex under<br />

pressure from the bond<strong>in</strong>g po<strong>in</strong>ts as shown <strong>in</strong> Figures<br />

9a <strong>and</strong> 9b. If these process flows are expected to be<br />

utilized then thermo-mechanical analysis test<strong>in</strong>g<br />

should be conducted to ensure suitable hardness<br />

dur<strong>in</strong>g the process conditions.<br />

Delam<strong>in</strong>ation <strong>of</strong> the wafer from the carrier is not<br />

normally an issue for these processes. In fact, it is<br />

desired for the th<strong>in</strong> device wafer to delam<strong>in</strong>ate or<br />

debond from the carrier while it is bonded to another<br />

wafer. In this case, the process might be considered a<br />

layer transfer. In the case <strong>of</strong> TMATʼs adhesive<br />

system, this has been demonstrated <strong>and</strong> will likely<br />

More <strong>in</strong>formation: www.suss.com/tec_library E-Mail: <strong>in</strong>fo@suss.com