ENTAM TEST REPORT No. Typology: Harvester Model: MHT 18002 ...

ENTAM TEST REPORT No. Typology: Harvester Model: MHT 18002 ...

ENTAM TEST REPORT No. Typology: Harvester Model: MHT 18002 ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

AGRICULTURAL MACHINES FUNCTIONAL AND SAFETY <strong>TEST</strong>ING<br />

SERVICE<br />

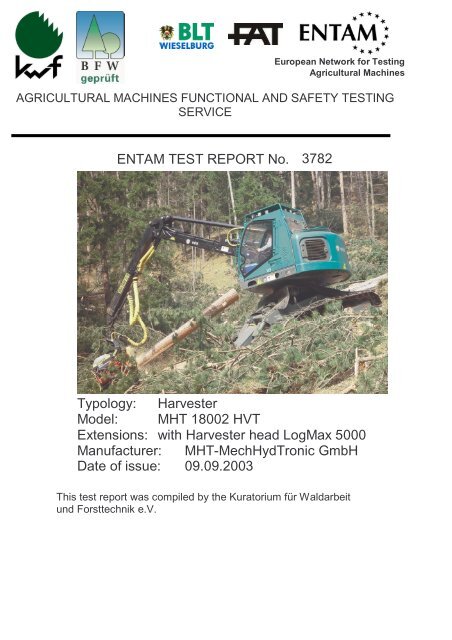

<strong>ENTAM</strong> <strong>TEST</strong> <strong>REPORT</strong> <strong>No</strong>.<br />

European Network for Testing<br />

Agricultural Machines<br />

3782<br />

<strong>Typology</strong>: <strong>Harvester</strong><br />

<strong>Model</strong>: <strong>MHT</strong> <strong>18002</strong> HVT<br />

Extensions: with <strong>Harvester</strong> head LogMax 5000<br />

Manufacturer: <strong>MHT</strong>-MechHydTronic GmbH<br />

Date of issue: 09.09.2003<br />

This test report was compiled by the Kuratorium für Waldarbeit<br />

und Forsttechnik e.V.

1 SUMMARY<br />

1.1 Evaluation - review<br />

<strong>Harvester</strong> <strong>MHT</strong> <strong>18002</strong> HVT; aggregate LogMax 5000<br />

<strong>MHT</strong>-MechHydTronic GmbH, A-4060 Linz, Österreich<br />

Test item Test results Evaluation<br />

<strong>Harvester</strong> class 2 Engine power > 70 to 140 kW<br />

Chief application fiield Soft wood thinning , DBH of stems 20-35 cm; maximum<br />

felling diameter 50 cm<br />

Driving behaviour satisfactory<br />

Driving speed Off-road max. 3.03* km/h<br />

Transport Total height on bunk < 4 m o<br />

Felling/Processing satisfactory<br />

Crane control hydraulic pilot control Kawasaki Negative Control<br />

operator setting cannot be stored<br />

- -<br />

Crane construction Total lifting moment : full reach 5.1 kN, 4 m reach 46 kN<br />

Maximum reach 10.6 m, tilts with upper carriage<br />

+<br />

Stability Lateral stability is provided at maximum reach (loaded<br />

stabilizing moment near 0)<br />

o<br />

Delimbing Feed speed 3.2 m/s, feed force 20.5 kN. +<br />

Mearuring and control<br />

system<br />

Motomit IT o<br />

Ergonomics good<br />

<strong>No</strong>ise Leq = 76 dB(A) o<br />

Vibration K = 7.6 +<br />

Cab Good layout of display and control elements; difficult<br />

o<br />

emergency exit, very simple<br />

Visibility High convex screen, swivelling upper carriage + +<br />

Work space illumination Good, dazzle-free illumination +<br />

Work safety DPLF work safety certificate , Eurotest Certificate (SMP) for<br />

LogMax 5000 aggregate<br />

Ecology satisfactory<br />

Ground impact <strong>No</strong>t evaluated<br />

Hydraulic fluids/ Hazardous<br />

substances<br />

Mineral oil-based hydraulic fluid -<br />

Fuel consumption 13 - 15 l/operating hour (specific consumption 215 g/kWh) o<br />

Leakage prevention<br />

measures<br />

Vacuum pump, electric filler pump + +<br />

Exhaust emissions<br />

Economy<br />

Comply with Euro-Ri 97/68EC Level 2, optionally RME<br />

capability according to DIN 51606<br />

o<br />

Cost (without operator pay) According to calculation scheme 106 EUR/operating hour<br />

(based on 1500 operating hours/year)<br />

Maintenance (incl. refuelling) Approx. ½ hour daily, approx. 2 hours weekly<br />

Power<br />

Additional features<br />

Sufficiently powered for this harvester class<br />

+ + = very good; + = good; o = satisfactory; - adequate; - - = inadequate<br />

(* manufacturer’s declaration)<br />

Kuratorium für Waldarbeit und Forsttechnik, 64823 Groß-Umstadt<br />

Test report, FPA-index no. 1.04.3782

1.2 Short description<br />

• Rigid box frame with two track drive units (H-Form) and decentralized mounted swivelling and<br />

tilting (forward 26 °, lateral 17 °) upper carriage with engine, cab and work elements; dozer blade<br />

on undercarriage<br />

• 2 track drive units with 8 rigid rollers, two supporting rollers; drive and deflection rollers function as<br />

roller; jamming prevention over whole track length; 2 chains with closed, bevelled single piece<br />

pads with cleaning opening.<br />

• Hydrostatic drive unit with double variable displacement motor, under load gear shifting<br />

• Kawasaki hydraulic pilot control for crane, drive and machine functions. Electronic pilot control for<br />

the harvester head<br />

• Crane (Loglift L220 V 100 A) with maximum reach of 10.6 m<br />

• <strong>Harvester</strong> head: LogMax 5000 HD; max. felling diameter 500 mm<br />

• Total weight: 19100 kg<br />

• Engine power: 127 kW<br />

• Length (without crane): 4550 mm<br />

• Transport height on bunk*): 3430 mm<br />

on the road: 3540 mm<br />

• Width (maximum): 2550 (2915) mm<br />

*)lighting roof removed<br />

FPA-approval: Test-no. 3782 from May 31, 2004<br />

Duration of approval: 5 years (31.05.09)

The present test report is valid until the reference regulations for the<br />

harvester <strong>MHT</strong> <strong>18002</strong> HVT with LogMax 5000<br />

and its relative extensions change.<br />

The present test report is officially recognised by the following <strong>ENTAM</strong> Members<br />

with their relative identification numbers:<br />

Logo<br />

Member<br />

FAT<br />

BLT<br />

no member<br />

Country<br />

CH<br />

A<br />

A<br />

Identification<br />

number<br />

D-22.04<br />

048/04<br />

is the Europan Network for Testing Agricultural Machines,<br />

founded to promote cooperation among testing stations in<br />

order to optimise activities and provide better service to<br />

farmers, dealers and manufacturers.<br />

For more information about members and activities<br />

please visit: www.entam.com or send an email to: info@entam.com<br />

Acronym: KWF<br />

Kuratorium für Waldarbeit und Forsttechnik e.V.<br />

German Center for Forest Work and Technology<br />

Street: Spremberger Straße 1<br />

Postal Code/City: 64820 Groß-Umstadt<br />

Country: Germany<br />

Tel.: +49 (0)6078/785-10<br />

Fax: +49 (0)6078/785-39<br />

Email: pruefung@kwf-online.de<br />

www: http://www.kwf-online.de