TEST REPORT Forwarder Komatsu 860.4

TEST REPORT Forwarder Komatsu 860.4

TEST REPORT Forwarder Komatsu 860.4

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

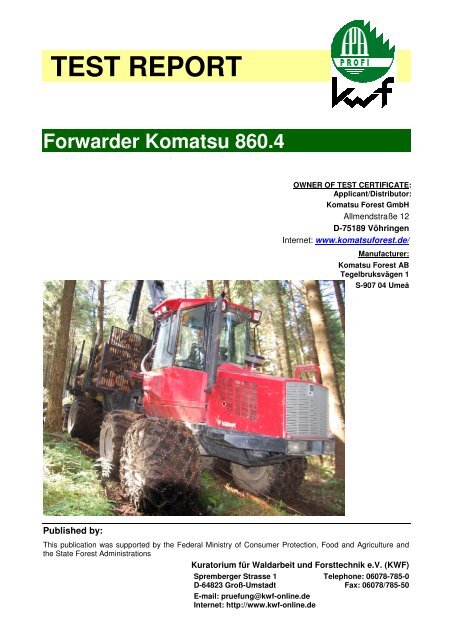

<strong>TEST</strong> <strong>REPORT</strong><br />

<strong>Forwarder</strong> <strong>Komatsu</strong> <strong>860.4</strong><br />

Published by:<br />

OWNER OF <strong>TEST</strong> CERTIFICATE:<br />

Applicant/Distributor:<br />

<strong>Komatsu</strong> Forest GmbH<br />

Allmendstraße 12<br />

D-75189 Vöhringen<br />

Internet: www.komatsuforest.de/<br />

Manufacturer:<br />

<strong>Komatsu</strong> Forest AB<br />

Tegelbruksvägen 1<br />

S-907 04 Umeå<br />

This publication was supported by the Federal Ministry of Consumer Protection, Food and Agriculture and<br />

the State Forest Administrations<br />

Kuratorium für Waldarbeit und Forsttechnik e.V. (KWF)<br />

Spremberger Strasse 1 Telephone: 06078-785-0<br />

D-64823 Groß-Umstadt Fax: 06078/785-50<br />

E-mail: pruefung@kwf-online.de<br />

Internet: http://www.kwf-online.de

<strong>Forwarder</strong> <strong>Komatsu</strong> <strong>860.4</strong><br />

Evaluation – Review<br />

Test item Test results Evaluation<br />

<strong>Forwarder</strong> class 2 Payload 10 – 14 t<br />

chief application field forwarding logs between 2 – 6 m long also in difficult terrain<br />

Loading very good<br />

crane construction<br />

measured lifting power at 4 m reach 17.7 kN, maximum reach 9.5 m;<br />

timber can be loaded from the front of the machine<br />

crane control 10 operator settings can be stored, 1 factory setting + +<br />

stability<br />

lateral stability is provided with empty bunk and fully loaded crane at<br />

maximum reach (Factor >2),<br />

transportation total height per axle 3.91m +<br />

Transport good<br />

calculated load rating 14000 kg (= 79.0 % of net weight) o<br />

weight load utilization<br />

driving speed<br />

very good relationship between bunk, pay load and weight distribution<br />

(103 evaluation points)<br />

off-road 8 km/h<br />

road 20 km/h<br />

off-road capabilities off-road capability coefficient 0.30 -<br />

Ergonomie very good<br />

noise<br />

vibration<br />

cab design<br />

attenuating forces<br />

visibility<br />

Leq = 68 dB(A) + +<br />

A (8) = 0.32 m/s² +<br />

spacious, very comfortable cab with good air conditioning + +<br />

very low + +<br />

good view of wood bunk and around the machine +<br />

workspace illumination provides good and glare-free illumination for most of the workspace +<br />

work safety EuroTest Certificate SMP, Sweden<br />

Ecology good<br />

fuel consumption<br />

average 9 l/ machine operating hour (specific consumption 218<br />

g/kWh)<br />

ground impact maximum ground pressure: 5.2 bar (o); wheel load: 50.7 kN (- -) -<br />

operational fluids<br />

ready-filled with bio-degradable hydraulic fluid WGK 1 (water hazard<br />

class), several hazardous substances with a WGK > 1<br />

emissions complies with Euro-Guideline 97/68 EC level III A +<br />

Economy<br />

maintenance (incl.<br />

refuelling)<br />

approx. ¼ hour daily, approx. ½ hour weekly<br />

power within limits for this forwarder class<br />

cost (without wages)<br />

Special features<br />

according to calculation scheme 44 EUR/ operating hour<br />

(based on 2000 operating hours/year)<br />

hydraulic adjustment of headboard – horizontally and vertically,<br />

Crane tip with protected hose guides, 2 rear view cameras<br />

+ + = very good; + = good; o = satisfactory; - adequate; - - = inadequate<br />

2/9<br />

+<br />

+ +<br />

+ +<br />

++<br />

o<br />

o

Short description<br />

Figure 1: Machine sketch and crane work area diagram<br />

• frame constructed front and rear bogie, decentralized articulated joint, interleaving joint with 2 doubleaction<br />

hydraulic cylinders; front and rear bogie axles, 8 equal sized wheels<br />

• hydrostatic transmission, two step range gear (can be changed while stopped) and power divider, each<br />

axle with permanent transmission; rear drive release<br />

• decentralized articulated joint, interleaving joint with hydraulic interleaving joint brake (tooth rack brake)<br />

• test tyres: Nokian TRS-LS2 710/45-26.5 16 PR<br />

• digital integrated control system Maxi <strong>Forwarder</strong>, 10 programmable settings<br />

• length (without crane) 9920 mm<br />

• transport height (flat bed trailer): 3906 mm<br />

for road driving: 3906 mm<br />

• width (maximum) 2960 mm<br />

Zuladung [kg]<br />

16000<br />

14000<br />

12000<br />

10000<br />

8000<br />

6000<br />

4000<br />

2000<br />

Valmet <strong>860.4</strong><br />

0<br />

0 1000 2000 3000 4000 5000 6000 7000 8000 9000<br />

Sortimentslänge [mm]<br />

3/9<br />

Maximale Zuladung<br />

Maximale Vorderachslast<br />

Maximale Hinterachslast<br />

Minimale Vorderachslast<br />

Laubholz weit<br />

Nadelholz weit<br />

Nadelholz eng<br />

Laubholz eng<br />

Ende Rungenkorb<br />

Figure 2: Weight distribution diagram Figure 3: Wood bunk<br />

Min.<br />

Akt.<br />

Max.<br />

Gross lifting moment (kNm)<br />

66,0<br />

126,0<br />

151,0<br />

0 20 40 60 80 100 120 140 160<br />

Figure 4: Comparison between the current test machine and the minimum<br />

and maximum values from the 12 machines tested to date in the same<br />

engine power class.

Axle loads and payload<br />

unloaded *<br />

Softwood<br />

loaded **<br />

Hardwood<br />

4/9<br />

permitted according to<br />

German traffic<br />

legislation<br />

permitted according to<br />

manufacturer’s declaration<br />

gross weight (kg) 17720 31720 31720 18000 35500<br />

payload (kg) 14000 14000 14000<br />

front axle load (kg)<br />

(%)<br />

rear axle load (kg)<br />

(%)<br />

10140<br />

57<br />

7580<br />

43<br />

11042<br />

35<br />

20678<br />

65<br />

12990<br />

41<br />

18730<br />

59<br />

* measured weight of the fully refuelled machine without operator<br />

** calculated values according to loading scheme for maximum utilization (see chapter 3.2)<br />

Softwood, fresh, sort length 5.7 m, load volume ca. 17 cubic meters<br />

Hardwood, , fresh, sort length 4.0 m, load volume ca. 12 cubic meters<br />

Engine<br />

10500 14500<br />

7700 21000<br />

Sisu Diesel 660 U 12544, water cooled 6-cylinder Common-Rail diesel engine with turbo charger and charge cooling.<br />

Approved for RME/FAME according to DIN EN 14214 and ASTM D6751 (max. 20 %). Engine complies with emmision<br />

guideline 97/68 EG Level III A<br />

capacity 6600 cm³<br />

power nominal engine<br />

speed<br />

2200 1/min 145 kW<br />

max. torque engine speed 1500 1/min 800 Nm<br />

torque increase 28,0 %<br />

specific fuel<br />

consumption<br />

nominal engine<br />

speed<br />

2200 1/min 239 g/kWh<br />

engine speed 1500 1/min 218 g/kWh<br />

average fuel consumption under working conditions 8 - 10 l/ machine<br />

operating<br />

hour<br />

fuel tank volume 160 l<br />

Min.<br />

Akt.<br />

Max.<br />

Engine power (kW)<br />

90,0<br />

145,0<br />

172,0<br />

0 50 100 150 200<br />

Figure 5: Comparison between the current test machine and the minimum and<br />

maximum values from the 12 machines tested to date in the same engine power class.<br />

Min.<br />

Akt.<br />

Max.<br />

Fuel consumption (l/operating hr)<br />

6,6<br />

8,0<br />

10,0<br />

0 2 4 6 8 10 12<br />

Figure 6: Comparison between the current test machine and the minimum and<br />

maximum values from the 12 machines tested to date in the same engine power class<br />

(see also chapter 7.4).

Hydraulics work circuit<br />

open load sensing single circuit hydraulic system with adjustable reciprocating pump<br />

hydraulic pump Parker P 2145 (145)<br />

capacity at 2000 rev/min<br />

(max. 2200 1/min)<br />

input power at 2000 rev/min<br />

at 1500 rev/min<br />

Hydraulic<br />

pressure<br />

5/9<br />

0 – 290<br />

0 – 145<br />

126<br />

94<br />

l/min<br />

cm³/rev<br />

maximum 26 MPa<br />

released 3 MPa<br />

Fuel tank capacity joint tank with transmission circuit 100 l<br />

Hydraulics transmission circuit<br />

electronically controlled hydrostatic transmission<br />

hydraulic pump Sauer Danfoss H 1 P 147<br />

capacity at nominal engine speed<br />

(2000 1/min)<br />

input power (installed<br />

power)<br />

at 2000 Rev/min<br />

at 1500 Rev/min<br />

0 – 294<br />

0 – 147<br />

hydraulic pressure maximum 43 MPa<br />

hydraulics engine: Sauer Danfoss BR 51<br />

211<br />

158<br />

kW<br />

kW<br />

l/min<br />

cm³/rev<br />

released 3 MPa<br />

absorption volume 32,2 – 160,9 cm³/rev<br />

tank capacity: joint tank with work circuit 100 l<br />

The machine is approved for operation with specific bio-degradable hydraulic fluids<br />

Crane<br />

pedestal mounted on the rear bogie longitudinal frame stays just in front of the articulated joint between the headboard<br />

and cab, comprises a colomn and slewing mechanism as well as a boom and jib with a two step telescoping mechanism;<br />

Protec crane tip with protected hose guide ("Protec"-System)<br />

type CRF 11 C<br />

maximum reach (incl.2-step telescope) 9.5 m<br />

gross lifting torque * 126 kNm<br />

lifting torque at 4 m reach 17.7 kN<br />

slewing torque 23.2 kNm<br />

turning area (left/right) 360<br />

°<br />

maximum working pressure 26.0 MPa<br />

required amount of hydraulic fluid * n.s. l/min<br />

boom weight (with rotator and grapple) *<br />

* manufacturer’s declaration<br />

2268 kg<br />

Min.<br />

Akt.<br />

Max.<br />

Maximum reach (m)<br />

7,2<br />

9,5<br />

10,1<br />

0 2 4 6 8 10 12<br />

Figure 7: Comparison between the current test machine and the minimum and<br />

maximum values from the 12 machines tested to date in the same engine power<br />

class.<br />

kW<br />

kW

Grapple and rotator<br />

Manufacturer Valmet<br />

attached to jib with rotator and 1 swing brake and slewing axle<br />

endless rotator Valmet/Indexator G 121 V 19<br />

weight (with/without rotator) * 326/270 kg<br />

enclosure area n.s. m 2<br />

maximum grapple opening 1820 mm<br />

length of tongs 520 mm<br />

* manufacturer’s declaration<br />

Wood bunk<br />

4 formed bunks (welded box profile) with 8 steel tube stakes with inserted, bolted (removable) extensions; last 3 bunks are<br />

bolted to rear bogie frame; hydraulically operated front bunk attached to headboard<br />

load area length 4805 mm<br />

load area cross section 5.8 m²<br />

longitudinal movement gate and 1st stake pair 623 mm<br />

maximum payload *<br />

* manufacturer’s declaration<br />

14000 kg<br />

Min.<br />

Akt.<br />

Max.<br />

Maximum bunk area length (m)<br />

4,0<br />

4,8<br />

5,0<br />

0 1 2 3 4 5 6<br />

Figure 8: Comparison between the current test machine and the minimum and maximum<br />

values from the 12 machines tested to date in the same engine power class (see also<br />

chapter 7.4).<br />

Min.<br />

Akt.<br />

Max.<br />

Bunk area cross-section (m²)<br />

3,1<br />

5,0 5,8<br />

0 1 2 3 4 5 6 7<br />

Figure 9: Comparison between the current test machine and the minimum and<br />

maximum values from the 12 machines tested to date in the same engine power<br />

class.<br />

6/9

Spare parts supply, handbooks and service<br />

good,<br />

time required for daily<br />

maintenance<br />

time required for<br />

weekly maintenance<br />

Cab<br />

proprietary safety cab tested according to ISO 8082 (ROPS), ISO 8083 (FOPS) und ISO 8084 (OPS)<br />

operator seat 180 ° swivelling operator seat KAB 500 Air, highly adjustable, load-sensitive automatic<br />

pneumatic suspension, with dampening; swivel unit with electro-magnetic brakes; with<br />

lumbar support<br />

Comments / Evaluation Complies with<br />

standards<br />

cab size and design generous and spacious cab; fully lined, comfortable with good visibility,<br />

provides just satisfactory storage spaces; a cool box would be a<br />

welcome feature<br />

cab climate useful heating with continuously adjustable ventilator (audible at higher speeds), air<br />

conditioner<br />

control elements all important control elements and the control system display (only in<br />

work position) are easy to reach and within the field of vision; sensible<br />

control elements, well marked apart from crane controls<br />

levelling none<br />

work field illumination the lateral and near-crane workfield illumination is very good; illumination of front and rear<br />

workfield is incomplete and therefore only satisfactory; crane lights provide good illumination<br />

of grapple; Xenon lights would improve illumination; some unavoidable shading in the wood<br />

bunk area<br />

visibility large window area provides good visibility of workfield from cab. The view of the wood bunk<br />

is only satisfactory since it is somewhat restricted by the upper edge of the headboard (even<br />

when lowered) and covering of the crane column (2 hose packets); unavoidable restriction of<br />

visibility when wood bunk is fully loaded. Good all-round visibility, satisfactory visibility of the<br />

load area; load dependant visibility restrictions must be taken into account; machine is<br />

equipped with two cameras to improve visibility.<br />

noise low noise level 68 dB(A) yes<br />

vibration A (8) = 0.32 m/s² yes<br />

storage space on the<br />

machine<br />

approx. ½ hour<br />

approx. 1 hour.<br />

maintainability access to maintenance points: good; access to crane: satisfactory<br />

maintenance scope according to schedule and necessity<br />

operator’s manual succinct, clear and well structured, not quite up-to-date<br />

spare parts list well illustrated and structured; all spare parts are easy to find<br />

training customer receives briefing on delivery, 1-day additional training available on request, further<br />

training available on request<br />

2 relatively small storage spaces available left and right at the front of the machine<br />

storage space in the cab sufficient for manuals and first-aid kit; limited space provided for personal belongings; oilaccident<br />

set attached inside cab<br />

7/9<br />

yes<br />

yes

Machine cost and calculation basis<br />

Price for tested version 265000 €<br />

workload operating hours/year 1500 2000 2500 total service life [operating hours] 21000<br />

recovery period (years) 14 10.5 8.4 repair cost factor 0.7<br />

€/MAS €/MAS €/MAS<br />

recovery 12.60 12.60 12.60 interest rate [%] 8.0<br />

repair and maintenance 8.80 8.80 8.80 Transport costs [€]/ operating hour 2.00<br />

fuel and lubricants 9.20 9.20 9.20 Additional costs [€] 12985<br />

interest rate 7.10 5.30 4.20<br />

transport, driving 2.00 2.00 2.00 technical work productivity<br />

others 8.70 6.50 5.20 13 cubic meters/operating<br />

hour<br />

machine costs 48.40 44.40 42.00 within the forwarder class 2<br />

8/9

Additional equipment (not tested)<br />

Hydraulic oil fill pump, fuel fill pump, vacuum pump, clam bunk equipment, alternative tyres (600/55-26.5)<br />

alternative profiles (FK) alternative tyre manufacturer (Trelleborg), bogie lift (ready prepared for mounting),<br />

crane tilting mechanism, swivelling last bunk, frame extension (hydraulically operated, 450 mm extension),<br />

alternative crane lengths, hydraulically operated front blade (fixed push blade), branch deflector to protect<br />

engine, Xenon work-field illumination, cab glass in different hues and tints, windscreen wipers for lateral<br />

windows, central lubrication. Automatic fire extinguishing system<br />

Test<br />

Remaining requirements: none<br />

Recommendations: The available exterior storage space should be increased, plastic components<br />

should be marked for recycling, customer should be informed about the use of<br />

bypass filters<br />

Test Institute<br />

Kuratorium für Waldarbeit und Forsttechnik e. V., Groß-Umstadt<br />

Author<br />

Günther Weise and Lars Nick, KWF-Central, Groß-Umstadt<br />

KWF-utility test<br />

Test-No. 4993, valid until 30.06.2016<br />

According to the test regulations, the applicant is entitled to display the test mark on machines of this<br />

type and to use the certification for advertising purposes.<br />

9/9