Programmable Universal Lathes - Romi

Programmable Universal Lathes - Romi

Programmable Universal Lathes - Romi

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

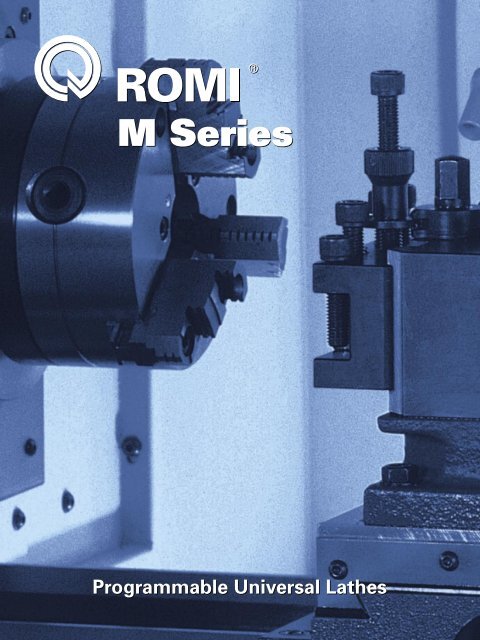

M Series<br />

<strong>Programmable</strong> <strong>Universal</strong> <strong>Lathes</strong>

2<br />

M Series<br />

<strong>Programmable</strong> <strong>Universal</strong> <strong>Lathes</strong><br />

M 17 M 20<br />

M 23<br />

M 27<br />

M 33<br />

Center height in 8.46 10.04 11.42 13.78 16.73 21.65<br />

Distance between centers in 40 40 / 60 / 80 40 / 80 / 120 40 / 80 / 120 80 / 140 / 200 80 / 140 / 200<br />

Swing over bed in 16.93 20.47 22.83 26.97 33.46 43.31<br />

Swing over cross slide in 8.03 10.24 12.05 16.93 21.65 27.56<br />

Swing over carriage wings in 15.75 17.72 17.32 21.26 32.68 40.94<br />

X axis travel in 8.66 11.02 14.17 14.17 18.70 22.64<br />

Z axis travel<br />

Bed<br />

in 40 40 / 60 / 80 40 / 80 / 120 40 / 80 / 120 80 / 140 / 200 80 / 140 / 200<br />

Width in 12.01 13.39 14.96 14.96 23.62 23.62<br />

Length<br />

Headstock (standard)<br />

in 13.77 13.22 15.74 15.74 18.11 18.11<br />

Spindle nose ASA A2-5” A2-6” A2-8” A2-8” A2-11” A2-15”<br />

Spindle hole diameter in 2.09 2.56 3.15 4.09 5.39 6.89<br />

Speed range rpm 4 to 4,000 3 to 3,000 2 to 2,500 2 to 1,800 7 to 1,200 6 to 1,000<br />

Range I rpm - - 2 to 629 2 to 441 7 to 260 6 to 210<br />

Range II<br />

Headstock (Optional)<br />

rpm - - 2 to 2,500 2 to 1,800 7 to 1,200 6 to 1,000<br />

Spindle nose ASA A2-6” A2-8” - A2-11” A2-15” A2-20”<br />

Spindle hole diameter in 2.56 3.15 - 6.77 9.92 14.76<br />

Speed range rpm 3 to 3,000 2 to 2,200 - 2 to 1,000 5 to 750 3 to 500<br />

Range rpm - - - 2 to 245 5 to 170 3 to 100<br />

Range<br />

Headstock (Optional)<br />

rpm - - - 2 to 1,000 5 to 750 3 to 500<br />

Spindle nose ASA D1-6” D1-8” D1-8” D1-11” - -<br />

Spindle hole diameter in 2.09 3.15 3.15 4.1 - -<br />

Speed range rpm 3 to 3,000 2 to 2,200 2 to 2,500 2 to 1,000 - -<br />

Range rpm - - 2 to 629 2 to 245 - -<br />

Range<br />

Feed<br />

rpm - - 2 to 2,500 2 to 1,000 - -<br />

Rapid traverse (z axis) ipm 394 394 295 295 315 315<br />

Rapid traverse (x axis) ipm 295 295 295 295 315 / 197 (*) 315 / 197 (*)<br />

Quick Change Tool Holder (optional)<br />

Stations 2 or 3 2 or 3 2 or 3 2 or 3 - -<br />

Tool size:<br />

square<br />

bar (diameter)<br />

in<br />

in<br />

1 x 1<br />

1<br />

1 x 1<br />

1<br />

1 x 1<br />

1<br />

1 x 1<br />

1<br />

-<br />

-<br />

-<br />

-<br />

Gang Tool Holder (optional)<br />

Tool size:<br />

square<br />

bar (diameter)<br />

in<br />

in<br />

1 x 1<br />

1<br />

1 x 1<br />

1<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

Rear Tool Holder (optional)<br />

Tool size:<br />

square<br />

bar (diameter)<br />

in<br />

in<br />

1 x 1<br />

1<br />

1 x 1<br />

1<br />

1 x 1 1 x 1 1 x 1 1 x 1<br />

1 /4 1 1 /2 1 1 /2 3 1 /8 3 1 Technical Specifications<br />

Capacity<br />

M 17 M 20 M 23 M 27 M 33 M 43<br />

/8<br />

Four-Way Toll Post (optional)<br />

Tool Size: square in - - - - 2 x 2 2 x 2<br />

8-Station Disk Type Automatic Turret (optionaI)<br />

Number of stations / tools 8 / 8 8 / 8 8 / 8 8 / 8 8 / 8 8 / 8<br />

Next tool index time s 0.6 0.6 0.8 0.8 1.2 1.2<br />

180° index time s 1.5 1.5 1.9 1.9 3.0 3.0<br />

Tool size: square in 1 x 1 1 x 1 1 x 1 1 x 1 1 1 /4 x 1 1 /4 1 1 /4 x 1 1 /4<br />

bar (diameter) in 1 1 /4 1 1 /2 1 1 /2 1 1 /2 1 1 /2 1 1 /2<br />

4-Station Square Automatic Turret (optionaI)<br />

Number of stations / tools - - 4 / 4 4 / 4 4 / 4 4 / 4<br />

Next tool index time s - - 0.7 0.7 2.1 2.1<br />

180° index time s - - 1.6 1.6 4.2 4.2<br />

Tool size: square in - - 1 x 1 1 x 1 1 1 /4 x 1 1 /4 1 1 /4 x 1 1 bar (diameter) in - - 1<br />

/4<br />

1 /2 1 1 /2 3 1 /8 3 1 Manual Tailstock<br />

/8<br />

Body positioning manual manual manual manual<br />

manual /<br />

move with sadle<br />

manual /<br />

move with sadle<br />

Quill travel in 4.72 5.12 7.09 7.09 9.84 9.84<br />

M 43

Technical Specifications<br />

Manual Tailstock<br />

M 17 M 20 M 23 M 27 M 33 M 43<br />

Quill diameter in 2.36 3.15 3.94 3.94 5.91 5.91<br />

Quill taper MT 4 4 5 5 6 6<br />

Quill activation manual manual manual manual manual manual<br />

Automatic Tailstock (optional)<br />

Body positioning manual manual manual manual<br />

manual /<br />

move with sadle<br />

manual /<br />

move with sadle<br />

Quill travel in 4.72 5.12 7.09 7.09 9.84 9.84<br />

Quill diameter in 2.36 3.15 3.94 3.94 7.87 7.87<br />

Quill taper MT 4 4 5 5 6 6<br />

Quill activation<br />

Electrical Specifications<br />

pneumatic pneumatic hydraulic hydraulic hydraulic hydraulic<br />

AC spindle motor kW / hp 7.5 / 10 11 / 15 15 / 20 22 / 30 37 / 50 44.5 / 60<br />

Power consumption kVA 15 20 25 40 57 68<br />

Dimensions and Weights (approximate)<br />

Floor space required (**)<br />

version: 40” in 107.09 x 50.00 124.01 x 64.96 136.22 x 79.92 136.22 x 79.92 - -<br />

version: 60” in - 143.70 x 64.96 - - - -<br />

version: 80” in - 163.38 x 64.96 175.59 x 79.92 175.59 x 79.92 239.76 x 96.45 239.76 x 112.20<br />

version: 120” in - - 214.96 x 79.92 214.96 x 79.92 - -<br />

version: 140” in - - - - 299.60 x 96.45 299.60 x 112.20<br />

version: 200” in - - - - 359.84 x 96.45 359.84 x 112.20<br />

Net weight (approximate)<br />

version: 40” lbs 6,284 6,615 11,025 12,745 - -<br />

version: 60” lbs - 7,717 - - - -<br />

version: 80” lbs - 8,269 12,172 13,892 33,075 39,690<br />

version: 120” lbs - - 13,560 15,435 - -<br />

version: 140” lbs - - - - 38,588 46,305<br />

version: 200” lbs - - - - 44,100 52,920<br />

(*) For machine with 200" between centers (**) Without chip conveyor<br />

Standard Equipment<br />

• Apron with 2 electronic handwheels and spindle motor switch<br />

for manual operation<br />

• Automatic lubrication system with line filter (M 17, M 20, M 23<br />

and M 27)<br />

• Automatic lubrication system with line filter and monitoring<br />

sensors (M 33, M 43 and M 51)<br />

• Chip conveyor interface<br />

Optional Equipment<br />

M 17 / M 20<br />

• 8 - station disk type automatic turret, electrically driven<br />

(tool holders and reduction sleeves not included)<br />

• A2-6” spindle cartridge, with Ø 2.56” (Ø 65 mm) through hole<br />

spindle (3,000 rpm max.)<br />

• A2-8” spindle cartridge, with Ø 3.15” (Ø 80 mm) through hole<br />

spindle (2,200 rpm max.)<br />

• Air operated tailstock quill (pneumatics and foot switch included)<br />

• Auto-transformer 8 taps: 200 a 250 Vca, 50/60 Hz, 15 Kva (M 17)<br />

or 25 Kva (M 20); 360 a 480 Vca, 50/60 Hz, 15 Kva (M 17) or<br />

25 Kva (M 20); 460 a 480 Vca, 50/60 Hz, 25 Kva (M 20)<br />

• Chip conveyor (hinged belt - TCE), with 26.4 gallons (100 liters)<br />

of coolant reservoir capacity, transverse (M 17)<br />

• Chip conveyor (hinged belt - TCE) for 40” (1,000 mm) version<br />

with 26.4 gallons (100 liters) of coolant reservoir capacity,<br />

transverse; for 60” (1,500 mm) version with 26.4 gallons<br />

(100 liters) of coolant reservoir capacity, transverse; for 80”<br />

(2,000 mm) version with 29 gallons (110 liters) of coolant<br />

reservoir capacity, longitudinal (M 20)<br />

• D1-6” spindle cartridge, with Ø 2.09” (Ø 53 mm) through hole<br />

spindle (3,000 rpm max.)<br />

• D1-8” spindle cartridge, with Ø 3.15” (Ø 80 mm) through hole<br />

spindle (2,200 rpm max.)<br />

• Fixed cover over tailstock and mechanical interlock between<br />

safety doors<br />

• Follow rest with rollers: Ø 1/2” to Ø 2” (Ø 12 to Ø 50 mm) capacity<br />

(M 17) and Ø 5/8” to Ø 3 1/8” (Ø 15 to Ø 80 mm) capacity (M 20)<br />

• Gang-tooling plate, with 2 boring bar holder, 2 facing tool<br />

holder, 1 turning tool holder and 3 reduction sleeves Ø 1/2”<br />

or Ø 12 mm, Ø 5/8” or Ø 16 mm, Ø 3/4” or Ø 20 mm and MT-1<br />

• Individual adapter plate Parat RD 2 (M 17) or Parat RD 3 (M 20)<br />

• Ø 6.3” (Ø 160 mm) universal chuck with set of three hard jaws<br />

for A2-5” / A2-6” / D1-6” spindle nose (M 17)<br />

• Ø 7.9” (Ø 200 mm) universal chuck with set of three hard jaws<br />

for A2-5” / A2-6” / D1-6” spindle nose (M 17)<br />

• Ø 7.9” (Ø 200 mm) universal chuck with set of three hard jaws<br />

for A2-6” / A2-8” / D1-8” spindle nose (M 20)<br />

• Coolant system - 10 l/min - 1.2 bar - 0.16 hp (M 17, M 20,<br />

M 23, M 27) and 10 l/min - 2 bar - 0.24 hp / (M 33 , M 43)<br />

• Electrical installation for 230 V, 50/60 Hz<br />

• Fully enclosed splash guard, with additional safety door,<br />

interlocked with safety switch (open access to tailstock)<br />

• GE-Fanuc control Series 21i-T with Manual Guide software system<br />

• Removable chip box<br />

• Sealed Worklight<br />

• Ø 10” (Ø 254 mm) universal chuck with set of three hard jaws<br />

for A2-6” / A2-8” / D1-8” spindle nose (M 20)<br />

• Ø 6.5” (Ø 165 mm) pneumatic operated chuck (rear closed center<br />

air cylinder), with Ø 1.69” (Ø 43 mm) bar capacity, 21.5” (540 mm)<br />

maximum bar length inside the draw tube and one set of soft<br />

jaws (“K” type nuts and jaws, with millimeters serration), for<br />

A2-5” spindle nose, pneumatics and foot switch included (M 17)<br />

• Ø 8” (Ø210 mm) pneumatic operated chuck (rear closed center<br />

air cylinder), with Ø 1.5” (Ø 39 mm) bar capacity, 21.5” (540 mm)<br />

maximum bar length inside the draw tube and one set of soft<br />

jaws (“K” type nuts and jaws, with millimeters serration), for<br />

A2-5” spindle nose (3.000 rpm max.), pneumatics and foot<br />

switch included (M 17)<br />

• Ø 8” (Ø 210 mm) pneumatic operated chuck (rear closed center<br />

air cylinder), with Ø 2” (Ø 50.8 mm) bar capacity, 21.5” (540 mm)<br />

maximum bar length inside the draw tube and one set of soft<br />

jaws, for A2-6” spindle nose ( 3,000 rpm max.), pneumatics<br />

and foot switch included (M 17 / M 20)<br />

• Ø 10” (Ø 254 mm) pneumatic operated chuck (rear closed center<br />

air cylinder) (2,000 rpm max.), with Ø 2” (Ø 50,8 mm) bar<br />

capacity (A2-6” spindle nose) or Ø 2,5” (Ø 63,5 mm) bar<br />

capacity (A2-8” spindle nose), 25.6” (650 mm) of maximum bar<br />

length inside draw tube, and one set of soft jaws; pneumatics<br />

and foot switch included (M 20)<br />

• Oil Skimmer<br />

• Quick change tool holder base, with one boring bar holder Ø 1”<br />

or Ø 25 mm and one turning tool holder 3/4” x 3/4” or 20 x 20 mm<br />

(M 17) and 1” x 1” or 25 x 25 mm (M 20)<br />

• Rear tool holder, with a T-slot base, one boring bar holder Ø 1”<br />

or Ø 25 mm (M 17) and Ø 1 1/4” or Ø 32 mm (M 20); and one<br />

turning / facing tool holder 3/4” x 3/4” or 20 x 20 mm (M 17)<br />

and 1” x 1” or 25 x 25 mm (M 20)<br />

• Steady rest (closed or open) with bronze tips, Ø 5/16” to<br />

Ø 3 1/8” (Ø 8 to Ø 80 mm) capacity (M 17)<br />

• Steady rest (U type) with rollers, Ø 4” to Ø 8” (Ø 101.6 to<br />

Ø 203.2 mm) capacity (M 17) and Ø 5” to Ø 10” (Ø 127 to<br />

Ø 254 mm) capacity (M 20)<br />

• Set of levelling screws and nuts<br />

• Set of operating, maintenance, programming, installation and<br />

parts manuals<br />

• Set of wrenches for machine operation<br />

• Standard colors: 10B - 3/4 Munsell blue textured enamel epoxy<br />

and textured gray RAL 7035 powder epoxy paint<br />

• Tailstock with manually operated quill (M 17, M 20, M 23 and<br />

M 27)<br />

• Tailstock drag device<br />

• T-slotted faceplates:<br />

■ A2-5” x Ø 16” (Ø 400 mm) (375 rpm max.); or A2-6” x Ø 16”<br />

(Ø 400 mm) (375 rpm max.); or D1-6” x Ø 16” (Ø 400 mm)<br />

(375 rpm max.) (M 17)<br />

■ A2-6” x Ø 16” (Ø 400 mm) (375 rpm max.); or A2-8” x Ø 16”<br />

(Ø 400 mm) (375 rpm max.); or D1-8” x Ø 16” (Ø 400 mm)<br />

(375 rpm max.) (M 20)<br />

• VDI 20 Axial Disk (M 17) or VDI 30 Axial Disk (M 20) in place of<br />

standard disk (VDI tool holder not included)<br />

• 8 - station turret accessories: tool holders and reduction<br />

sleeves in mm and inches<br />

• Gang-tooling accessories: T-slot base, tool holders and<br />

reduction sleeves in mm and inches<br />

• Quick change tool accessories: Boring bar holder Ø 1” or<br />

Ø 25 mm, Turning tool holder 1” x 1” or 25 x 25 mm<br />

• Pneumatic chuck accessories: set of three hard and soft jaws<br />

for Ø 165 mm (Ø 6.5”) chuck (M 17); for Ø 210 mm (Ø 8”) chuck<br />

(M 17 and M 20); for Ø 254 mm (Ø 10”) chuck (M 20)<br />

• Rear tool holder accessories: tool holders in mm and inches<br />

• Steady rest (closed) accessories: additional set of bronze tips<br />

Ø 3 1/8” to Ø 6” (Ø 80 to Ø 152 mm) capacity; Ø 5/16” to<br />

Ø 3 1/8” (Ø 8 to Ø 80 mm) capacity; Ø 3 1/8” to Ø 6”<br />

(Ø 80 to Ø 152 mm) capacity<br />

• Steady rest (U type) accessories: additional set of rollers Ø 2”<br />

to Ø 7” (Ø 50.8 to Ø 177.8 mm) capacity<br />

M 23 / M 27<br />

• 4 - station square automatic turret electrically driven<br />

(tool holders and reduction sleeves not included)<br />

• 8 - station disk type automatic turret, electrically driven<br />

(tool holders and reduction sleeves not included)<br />

• Auto-transformer for 200 / 210 - 220 / 230 - 240 / 250 V; or 200 /<br />

210 / 220 / 230 / 240 / 250 / 380 / 420 / 440 / 460 / 480 V,<br />

50/60 Hz, 25 KVA (M 23)<br />

• Autotransformer 3 taps 200 to 220 Vca, or 50 / 60 Hz, 40 Kva (M 27)<br />

• Autotransformer 8 taps 230 to 360 Vca, or 380 to 480 Vca,<br />

50 / 60 Hz, 40 Kva (M 27)<br />

3

• A2-11” spindle nose, with Ø 6.7” (Ø 172 mm) through hole<br />

spindle (1,000 rpm max.) (M 27)<br />

• Chip conveyor (hinged belt), for 40” (1,000 mm) version with<br />

31.6 gallons (120 liters) of coolant reservoir capacity; for 80”<br />

(2,000 mm) version with 48.9 gallons (185 liters) of coolant<br />

reservoir capacity; for 120” (3,000 mm) version with 64.5 gallons<br />

(244 liters) of coolant reservoir capacity, longitudinal (TCE)<br />

• D1-8” spindle nose, with Ø 3.15” (Ø 80 mm) through hole<br />

spindle (M 23)<br />

• D1-11” spindle nose, with Ø 4.1” (Ø 104 mm) through hole<br />

spindle (M 27)<br />

• Fixed cover over the tailstock and mechanical interlock between<br />

safety doors<br />

• Hydraulically operated tailstock quill (hydraulic power unit and<br />

foot switch included)<br />

• Individual adapter plate Parat RD 3<br />

• Main spindle indexing with 72 position (5°) for ASA A2-8” or<br />

ASA A2-11” spindle<br />

• Ø 10” (Ø 254 mm) universal chuck with set of three hard jaws<br />

for A2-8” / D1-8” spindle nose (M 23)<br />

• Ø 12.4” (Ø 315 mm) universal chuck with set of three hard jaws<br />

for A2-8” / D1-8” spindle nose (M 23)<br />

• Ø 10” (Ø 254 mm) universal chuck with set of three hard jaws<br />

A2-8” / A2-11” / D1-11” spindle nose (M 27)<br />

• Ø 12.4” (Ø 315 mm) universal chuck with set of three hard jaws<br />

A2-8” / A2-11” / D1-11” spindle nose (M 27)<br />

• Ø 15.7” (Ø 400 mm) universal chuck with set of three hard jaws<br />

A2-8” / A2-11” / D1-11” spindle nose (M 27)<br />

• Ø 15.7” (Ø 400 mm) four jaws independent chuck for A2-8” /<br />

A2-11” spindle nose (M 27)<br />

• Ø 10” (Ø 254 mm) hydraulic operated chuck, with Ø 2,5”<br />

(Ø 63,5 mm) bar capacity and one set of soft jaws, for A2-8” spindle<br />

nose only hydraulic power unit and foot switch included (M 27)<br />

• Ø 12.4” (Ø 315 mm) hydraulic operated chuck for A2-8” spindle<br />

nose, with Ø 2.5” (Ø 63.5 mm) bar capacity (M 23) or with<br />

Ø 3.5” (Ø 90 mm) bar capacity (M 27), and one set of soft jaws;<br />

hydraulic power unit and foot switch included<br />

• Oil Skimmer<br />

• Quick change tool holder base, with one boring bar holder<br />

(Ø 32 mm) and one turning tool holder (32 x 32 mm)<br />

• Rear boring bar holder, with a T-slot base Ø 1 1/2” or Ø 40 mm<br />

• Rear centralizing ring with Ø 6,7” (Ø 172 mm) hole or Ø 4,1”<br />

(Ø 104 mm) hole (M 23)<br />

CNC Features - GE-Fanuc 21i-T<br />

Versatile and highly<br />

reliable control<br />

The M Series offers the user the flexibility of<br />

selecting different operating modes:<br />

• Manual Mode<br />

• Basic Mode<br />

• Fixed Cycles Mode<br />

• G Code Programming Mode<br />

Manual Mode<br />

For additional and updated information visit our site: www.romi.com.br<br />

Indústrias <strong>Romi</strong> SA<br />

Av Pérola Byington 56<br />

Santa Bárbara d’Oeste SP<br />

13453 900 Brazil<br />

Phone +55 (19) 3455 9199<br />

Fax +55 (19) 3455 1030<br />

export-mf@romi.com.br<br />

www.romi.com.br<br />

• Rear tool holder, for turning or facing, with a T-slot base<br />

1” x 1” or 25 x 25 mm<br />

• Steady rest (closed) with bronze tips Ø 1/2” to Ø 6” (Ø 12 to<br />

Ø 152 mm) capacity (M 23) or Ø 1/2” to Ø 6” (Ø 12 to Ø 152 mm)<br />

capacity (M 27)<br />

• Steady rest (U type) with rollers Ø 6” to Ø 12” (Ø 152,4 to<br />

Ø 304,8 mm) capacity (M 23) or Ø 12” to Ø 16” (Ø 305 to<br />

Ø 406 mm) capacity (M 27)<br />

• Tailstock quill with built in live center<br />

• T-slotted faceplate, A2-8” x 16” (Ø 400 mm) diameter<br />

(375 rpm max.) (M 23)<br />

• VDI 40 axial disk, in place of std. disk (VDI tool holder not included)<br />

• 4 - station square turret accessories: tool holders and reduction<br />

sleeves in mm and inches<br />

• 8 - station turret accessories: tool holders and reduction<br />

sleeves in mm and inches<br />

• Quick change tool accessories: Boring bar holder Ø 1 1/4” or<br />

Ø 32 mm; Turning tool holder 1 1/4” x 1 1/4” or 32 x 32 mm<br />

• Hydraulic chuck accessories: set of three soft and hard jaws<br />

• Steady rest (closed) accessories: additional set of rollers Ø 1/2”<br />

to Ø 6” (Ø 12 to Ø 152 mm) capacity<br />

• Steady rest (U type) accessories: additional set of rollers Ø 2”<br />

to Ø 7” (Ø 50.8 to Ø 177.8 mm) capacity<br />

M 33 / M 43<br />

• 4 - station square automatic turret, electrically driven<br />

(tool holders and reduction sleeves not included)<br />

• 8 - station disk type automatic turret VDI 50, electrically driven<br />

(tool holder and reduction sleeves not included)<br />

• Auto-transformer for 200 - 250V Hz or 360 - 390V, or 410 - 480V,<br />

50/60 Hz, 60 KVA (M 33) - 70 KVA (M 43)<br />

• Chip conveyor set (hinged belt - TCE) including 2 transverse and 1<br />

longitudinal for 80” (2,000 mm) version; or including 3 transverse<br />

and 1 longitudinal for 140” (3,500 mm) version, or including 4<br />

transverse and 1 longitudinal for 200” (5,000 mm) version<br />

• Deep hole boring support, with transverse 3rd guide, Ø6,3”<br />

(Ø 160 mm) and Ø 31,5” (Ø 800 mm) max length<br />

• Four-way toll post<br />

• Individual adapter plate Parat, Multifix<br />

• Main spindle indexing with 72 positions (5°) - ASA A2-11” or<br />

ASA A2-15”<br />

• Ø 15.7” (Ø 400 mm) universal chuck with set of three hard jaws<br />

for A2-11” spindle nose (M 33)<br />

Using the electronic handwheels, a workpiece<br />

can be manually machined as in an engine lathe.<br />

Basic Mode<br />

The first workpiece can be machined step-bystep<br />

through the electronic handwheels and<br />

simultaneously each step of the operation can<br />

be recorded. In this mode, the control provides<br />

canned cycles to aid manual cutting, for<br />

example; taper and circular machining.<br />

<strong>Romi</strong> Machine Tools, Ltd<br />

1845 Airport Exchange Blvd<br />

Erlanger KY<br />

41018 USA<br />

Phone +1 (859) 647 7566<br />

Fax +1 (859) 647 9122<br />

sales@romiusa.com<br />

www.romiusa.com<br />

Specific data for the operation to be performed<br />

must be introduced in the respective command<br />

screens using only one electronic handwheel<br />

the X and Z axes are moved simultaneously.<br />

Movements and other commands can be<br />

recorded as a program to reproduce parts<br />

geometrically the same as the first one.<br />

Fixed Cycles Mode<br />

The CNC possesses fixed cycles for:<br />

• Roughing and finishing<br />

• Grooving<br />

• Thread cutting<br />

• Drilling<br />

• Rigid tap<br />

It enables the operator to generate a program<br />

based on information he has entered in the<br />

profile generating graphic screens.<br />

The operator enters the machining information<br />

(feed, speed, and depth of cut) as guided by the<br />

software.<br />

<strong>Romi</strong> Europa GmbH<br />

Wasserweg 19<br />

D 64521 Gross Gerau<br />

Germany<br />

Phone +49 (6152) 8055 0<br />

Fax +49 (6152) 8055 50<br />

sales@romi-europa.de<br />

• Ø 19.7” (Ø 500 mm) universal chuck with set of three hard jaws<br />

for A2-11” / A2-15” spindle nose (M 33)<br />

• Ø 25” (Ø 630 mm) universal chuck with set of three hard jaws<br />

for A2-15” spindle nose (M 33)<br />

• Ø 19.7” (Ø 500 mm) universal chuck with set of three hard jaws<br />

for A2-15” spindle nose (M 43)<br />

• Ø 25” (Ø 630 mm) universal chuck with set of three hard jaws<br />

for A2-15” / A2-20” spindle nose (M43)<br />

• Ø 31.5” (Ø 800 mm) universal chuck with set of three hard jaws<br />

for A2-20” spindle nose (M 43)<br />

• Ø 19.7” (Ø 500 mm) four jaws independent chuck for A2-11” /<br />

A2-15” spindle nose (M 33)<br />

• Ø 25” (Ø 630 mm) four jaws independent chuck for A2-15”<br />

spindle nose (M 33)<br />

• Ø 25” (Ø 630 mm) four jaws independent chuck for A2-15” /<br />

A2-20” spindle nose (M 43)<br />

• Ø 31.5” (Ø 800 mm) four jaw independent chuck for A2-15” /<br />

A2-20” spindle nose (M 43)<br />

• Ø 40.10” (Ø 1,020 mm) four jaw independent chuck for A2-15” /<br />

A2-20” spindle nose (M 43)<br />

• Oil Skimmer<br />

• Rear centralizing ring for ASA A2-15” spindle, with Ø 9.92”<br />

(Ø 252 mm) hole (M 33); or Ø 6.9” (Ø 175 mm) hole (M 43)<br />

• Rear centralizing ring for ASA A2-20” spindle, with Ø 14.7”<br />

(Ø 375 mm ) hole (M 43)<br />

• Steady rest (U type ), Ø 4” to Ø 12” (Ø 100 to Ø 305 mm) /<br />

Ø 115” to Ø 173” (Ø 292 to Ø 440 mm) capacity: Steady rest<br />

body (rollers not included), Set of rollers for Ø 4” to Ø 12”<br />

(Ø 100 to Ø 305 mm) capacity or Set of rollers for Ø 115” to<br />

Ø 173” (Ø 292 to Ø 440 mm) capacity (M 33)<br />

• Steady rest (U type ), 9” to Ø 15.75” (230 to 400 mm) / Ø 15.75”<br />

to Ø 21.65” (Ø 400 to Ø 550 mm) capacity: Steady rest body<br />

(rollers not included); Set of rollers for Ø 9” to Ø 15.75” (Ø 230 to<br />

Ø 400 mm) capacity or Set of rollers for Ø 15.75” to Ø 21.65”<br />

(Ø 400 to Ø 550 mm) capacity (M 43)<br />

• Table rest with rollers Ø 12 1/2” to Ø 20” (Ø 317. 5 to Ø 508 mm)<br />

capacity (M 33) or Ø 17 5/16” to Ø 25” (Ø 440 to Ø 635 mm)<br />

capacity (M 43)<br />

• Tailstock with manually operated quill with gears reduction system<br />

• Tailstock with hydraulic driven quill - 80” (2,000 mm) version; or<br />

140” (3,500 mm) version; or 200” (5,000 mm) version<br />

• 4 - station square electric turret accessories: tool holders and<br />

reduction sleeves in mm and inches<br />

• 8 - station turret accessories for VDI 50 disk, as per DIN 69880<br />

The part geometry is inserted through a series<br />

of lines and/or arcs.<br />

As the part geometry is created, the profile<br />

drawing is shown on the graph.<br />

Once the part and program information is<br />

entered, the machining simulation can be seen<br />

on the screen.<br />

The program is developed in stages properly<br />

sequenced to generate the machining operation.<br />

Commands for tool changes, spindle speed and<br />

miscellaneous functions (M) such as spindle<br />

direction and coolant control are automatically<br />

recorded and introduced through a soft key at<br />

the proper stages in the program.<br />

G Code Programming Mode<br />

The program can be developed directly in G code<br />

language, operating as a typical CNC lathe.<br />

Folheto - M Series - USA / IN / AA - Specifications are subject to change without prior notice - Printed in Brazil - Please recycle