Finite Element Modeling and Mesh Quality Checks Lecture - 2 ...

Finite Element Modeling and Mesh Quality Checks Lecture - 2 ...

Finite Element Modeling and Mesh Quality Checks Lecture - 2 ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

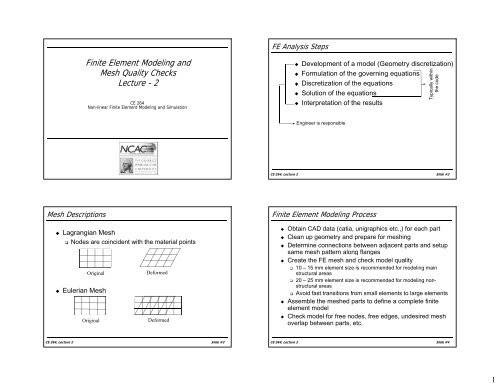

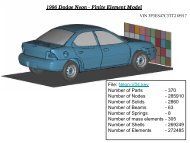

<strong>Mesh</strong> Descriptions<br />

<strong>Finite</strong> <strong>Element</strong> <strong>Modeling</strong> <strong>and</strong><br />

<strong>Mesh</strong> <strong>Quality</strong> <strong>Checks</strong><br />

<strong>Lecture</strong> <strong>Lecture</strong> - 22<br />

� Lagrangian <strong>Mesh</strong><br />

CE 264<br />

Non-linear <strong>Finite</strong> <strong>Element</strong> <strong>Modeling</strong> <strong>and</strong> Simulation<br />

� Nodes are coincident with the material points<br />

Original<br />

� Eulerian <strong>Mesh</strong><br />

Deformed<br />

Original Deformed<br />

CE 264, <strong>Lecture</strong> 2 Slide #3<br />

FE Analysis Steps<br />

� Development of a model (Geometry discretization)<br />

� Formulation of the governing equations<br />

within<br />

�� Discretization sc et at o oof tthe e equat equations o s<br />

lly<br />

� Solution of the equations<br />

� Interpretation of the results<br />

Engineer is responsible<br />

Typical<br />

the code<br />

CE 264, <strong>Lecture</strong> 2 Slide #2<br />

<strong>Finite</strong> <strong>Element</strong> <strong>Modeling</strong> Process<br />

� Obtain CAD data (catia, unigraphics etc.,) for each part<br />

� Clean up geometry <strong>and</strong> prepare for meshing<br />

� Determine connections between adjacent parts <strong>and</strong> setup<br />

same mesh pattern along flanges<br />

� Create the FE mesh <strong>and</strong> check model quality<br />

� 10 – 15 mm element size is recommended for modeling main<br />

structural areas<br />

� 20 – 25 mm element size is recommended for modeling nonstructural<br />

areas<br />

� Avoid fast transitions from small elements to large elements<br />

�� Assemble the meshed parts to define a complete finite<br />

element model<br />

� Check model for free nodes, free edges, undesired mesh<br />

overlap between parts, etc.<br />

CE 264, <strong>Lecture</strong> 2 Slide #4<br />

1

<strong>Modeling</strong> Guidelines – General<br />

� The element mesh should be orthogonal to the centerline<br />

of the part<br />

� The element mesh should be on the mid-plane of the<br />

cross section of the component thickness<br />

� The mid-plane is established by offsetting the geometry by<br />

1/2 of the gage thickness in the direction that the material is<br />

shown in the cross section of the drawing<br />

� No component thickness penetration or part intersection<br />

is allowed<br />

� <strong>Element</strong> size should be uniform whenever possible<br />

� Maintain a smooth transition from Coarse to Fine <strong>Mesh</strong><br />

CE 264, <strong>Lecture</strong> 2 Slide #5<br />

<strong>Modeling</strong> Guidelines – Flanges<br />

� Flanges of Crash models are to be modeled with<br />

three (3) elements across the flange<br />

� Two (2) elements can be used if the flange width is<br />

lless th than 15 mm<br />

CE 264, <strong>Lecture</strong> 2 Slide #7<br />

<strong>Modeling</strong> Guidelines – General<br />

� <strong>Element</strong> mesh is to be orthogonal to the centerline of the part<br />

� Transition <strong>Mesh</strong><br />

CE 264, <strong>Lecture</strong> 2 Slide #6<br />

<strong>Modeling</strong> Guidelines – Flanges<br />

� Bend radii less than 8mm are to be modeled as a<br />

sharp corner angle<br />

� Bend Radii greater than 8mm are to have a minimum<br />

of 2 elements elements, 1 node, node following the geometry<br />

CE 264, <strong>Lecture</strong> 2 Slide #8<br />

2

<strong>Modeling</strong> Guidelines – Beads <strong>and</strong> Ribs<br />

� Heights less than 3mm<br />

� ignore <strong>and</strong> mesh as flat<br />

� Heights between 3-5mm<br />

� increase the height to 5mm<br />

� Heights greater than 5mm<br />

� mesh as 3 equal length sides on the geometry<br />

CE 264, <strong>Lecture</strong> 2 Slide #9<br />

<strong>Modeling</strong> Guidelines – Notches<br />

� Notches greater than 20 mm l < 20 mm<br />

� Keep notch <strong>and</strong> split<br />

element to a minimum of 2<br />

across the width<br />

� Notches less than 20 mm<br />

� eliminate <strong>and</strong> replace with 2<br />

triangular elements<br />

� Notches less than 6 mm l < 6 mm<br />

� eliminate <strong>and</strong> replace with 2<br />

triangular g elements ( (larger g<br />

than 6 mm) →<br />

→<br />

CE 264, <strong>Lecture</strong> 2 Slide #11<br />

<strong>Modeling</strong> Guidelines – Holes<br />

� Holes<br />

� Holes with a diameter less<br />

than 10 mm are ignored<br />

� Holes with a diameter<br />

greater than h 10 mm are to<br />

be included<br />

� When meshing around<br />

holes, a minimum of 6<br />

elements is required<br />

d < 10 mm<br />

d > 10 mm<br />

CE 264, <strong>Lecture</strong> 2 Slide #10<br />

<strong>Modeling</strong> Guidelines – Transitions<br />

� <strong>Mesh</strong> Transition<br />

� Use triangular elements to<br />

transition<br />

�� Check aspect ratio of<br />

triangular elements<br />

� Triangular elements are<br />

stiffer than quad elements,<br />

particularly for coarse mesh<br />

� Use Co option in LS-DYNA<br />

(*CONTROL_SHELL, full<br />

sorting) ti )<br />

� Triangular elements.<br />

should be less than 10% of<br />

total elements<br />

→<br />

→<br />

<strong>Mesh</strong> Transition<br />

CE 264, <strong>Lecture</strong> 2 Slide #12<br />

3

<strong>Modeling</strong> Guidelines – Transitions<br />

2-D <strong>and</strong> 3-D <strong>Element</strong>s<br />

1-2 Transition 1-3 Transition<br />

CE 264, <strong>Lecture</strong> 2 Slide #13<br />

<strong>Modeling</strong> Guidelines – Special Shapes<br />

NOT DESIRABLE<br />

2-D <strong>and</strong> 3-D <strong>Element</strong>s<br />

DESIRABLE<br />

CE 264, <strong>Lecture</strong> 2 Slide #15<br />

<strong>Modeling</strong> Guidelines – Special Shapes<br />

� Special <strong>Mesh</strong> Shape<br />

� It is possible to use quad<br />

elements for triangular<br />

meshes<br />

Trapezoidal <strong>Mesh</strong><br />

2-D <strong>and</strong> 3-D <strong>Element</strong>s<br />

Triangular <strong>Mesh</strong><br />

CE 264, <strong>Lecture</strong> 2 Slide #14<br />

<strong>Modeling</strong> Guidelines – General<br />

2D <strong>and</strong> 3-D <strong>Element</strong>s<br />

� When modeling a sectional structure component<br />

� Use a minimum of 3 rows of elements to get a good in-plane<br />

bbending di<br />

� Use a minimum of 5 elements for a buckle<br />

CE 264, <strong>Lecture</strong> 2 Slide #16<br />

4

<strong>Modeling</strong> Guidelines – Solids<br />

� Solid <strong>Element</strong> Selection<br />

3-D <strong>Element</strong>s<br />

� Regular shaped 8-node brick is recommended (hexa)<br />

� Avoid 4, 5 <strong>and</strong> 7 node solid elements<br />

CE 264, <strong>Lecture</strong> 2 Slide #17<br />

<strong>Element</strong> <strong>Quality</strong> Check - Warpage<br />

CE 264, <strong>Lecture</strong> 2 Slide #19<br />

<strong>Element</strong> <strong>Quality</strong> Check<br />

� Warpage<br />

� Amount by which an element or element face (solid elements)<br />

deviates from being planar<br />

� Should be less than 15 0<br />

� Aspect Ratio<br />

� Ratio of the longest edge of an element to its shortest edge<br />

� Should be less than 5:1<br />

� Skew<br />

� Should be less than 60 0<br />

� Jacobian<br />

� Measure of the deviation of an element from an ideally shaped<br />

element<br />

� Ranges from 0 to 1.0, where 1.0 represents a perfectly shaped<br />

element<br />

� Should be greater than 0.6<br />

CE 264, <strong>Lecture</strong> 2 Slide #18<br />

<strong>Element</strong> <strong>Quality</strong> Check - Skew<br />

CE 264, <strong>Lecture</strong> 2 Slide #20<br />

5

Final <strong>Quality</strong> <strong>Checks</strong> – Shells<br />

CE 264, <strong>Lecture</strong> 2 Slide #21<br />

Final <strong>Quality</strong> <strong>Checks</strong><br />

� Align element NORMALS for each component in 1<br />

direction<br />

� BOUNDARY CHECK<br />

� SHELL ELEMENTS: No SPLITS or CRACKS allowed<br />

in the mesh<br />

� SOLID ELEMENTS: No interior SPLITS or CRACKS<br />

allowed in the mesh<br />

� Check for <strong>and</strong> eliminate DUPLICATE ELEMENTS<br />

� Check for <strong>and</strong> eliminate FREE 1-D ELEMENTS<br />

� Check for <strong>and</strong> eliminate RIGID DEPENDENCIES<br />

<strong>and</strong> RIGID LOOPS or CIRCULAR DEPENDENCIES<br />

CE 264, <strong>Lecture</strong> 2 Slide #23<br />

Final <strong>Quality</strong> <strong>Checks</strong> – Solids<br />

CE 264, <strong>Lecture</strong> 2 Slide #22<br />

Homework<br />

� http://crash.ncac.gwu.edu/pradeep/<br />

� Select CE-264<br />

�� Download Homework No No. 1 (HM file)<br />

� <strong>Mesh</strong> file using Hypermesh<br />

� Use element size of 10 mm<br />

� Check <strong>Mesh</strong> <strong>Quality</strong><br />

� Homework due Feb 24, 2009<br />

�� EE-mail mail Hypermesh ( (.hm) hm) file <strong>and</strong> <strong>Mesh</strong> <strong>Quality</strong> Form<br />

to pradeep@ncac.gwu.edu.<br />

CE 264, <strong>Lecture</strong> 2 Slide #24<br />

6