The SL3 dedicated Clamp-on Transit Time Ultrasonic Flow Meter ...

The SL3 dedicated Clamp-on Transit Time Ultrasonic Flow Meter ...

The SL3 dedicated Clamp-on Transit Time Ultrasonic Flow Meter ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<str<strong>on</strong>g>The</str<strong>on</strong>g> <str<strong>on</strong>g>SL3</str<strong>on</strong>g> <str<strong>on</strong>g>dedicated</str<strong>on</strong>g> <str<strong>on</strong>g>Clamp</str<strong>on</strong>g>-<strong>on</strong> <strong>Transit</strong><br />

<strong>Time</strong> Ultras<strong>on</strong>ic <strong>Flow</strong> <strong>Meter</strong> provides<br />

for accurate liquid flow measurement<br />

from outside the pipe.<br />

Employing state-of-the-art technology in ultras<strong>on</strong>ic flow measurement<br />

and digital processing, the self-adapting proprietary signal quality tracking<br />

allows the system to optimally adapt to the pipe material and flow profile<br />

automatically. <str<strong>on</strong>g>The</str<strong>on</strong>g> unique clamp-<strong>on</strong> fixture design makes the<br />

Installati<strong>on</strong> very straightforward and requires no special tools or skills.<br />

Due to the n<strong>on</strong>-invasive nature of clamp-<strong>on</strong> transducers, there is no<br />

pressure drop, no moving parts, no leaks, and no risk of c<strong>on</strong>taminati<strong>on</strong> or<br />

corrosi<strong>on</strong>.<br />

Ideal for new build and retrofit applicati<strong>on</strong>s, the <str<strong>on</strong>g>SL3</str<strong>on</strong>g> is perfectly suited to<br />

HVAC applicati<strong>on</strong>s where its affordability ensures a rapid return <strong>on</strong><br />

investment. Well managed systems are measured systems and this easy to implement flow data provider allows for<br />

access and c<strong>on</strong>trol over your systems with fast results and the potential for immediate energy savings and applicati<strong>on</strong><br />

fine tuning. D<strong>on</strong>’t leave it to your best estimates, get accurate data fast with the <str<strong>on</strong>g>SL3</str<strong>on</strong>g> clamp <strong>on</strong> flow meter.<br />

With maximum l<strong>on</strong>g term reliability built in, the <str<strong>on</strong>g>SL3</str<strong>on</strong>g> provides sustained operati<strong>on</strong> in a wide range of industrial<br />

applicati<strong>on</strong>s and envir<strong>on</strong>ments and due to the n<strong>on</strong>-intrusive nature of the clamp-<strong>on</strong> technique, no mechanical parts<br />

need to be inserted through the pipe wall or to protrude into the flow system so there is no pressure drop (save energy),<br />

no moving parts (low maintenance), no leaks and no c<strong>on</strong>taminati<strong>on</strong>.<br />

Perfectly suited to the measurement of flows in clean, n<strong>on</strong>-aerated fluids such as water, water/glycol and oils in full pipes<br />

from 1/2” to 180” (12 to 4570 mm) diameter can be measured and the ultras<strong>on</strong>ic signal penetrates all comm<strong>on</strong> metal and<br />

plastic pipe materials.<br />

User friendly and no cumbersome hardware, begin reading flow and gathering useful data as so<strong>on</strong> as the transducers<br />

are mounted. C<strong>on</strong>nect the <str<strong>on</strong>g>SL3</str<strong>on</strong>g> to external displays, recorders, data loggers, c<strong>on</strong>trollers and BMS systems via a wide<br />

range of industry standard outputs such as HART, Modbus and RS485.<br />

Doc <str<strong>on</strong>g>SL3</str<strong>on</strong>g> | 1.0 |2010<br />

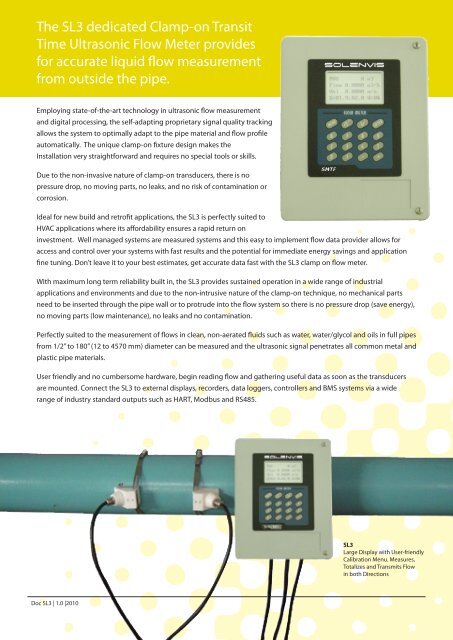

<str<strong>on</strong>g>SL3</str<strong>on</strong>g><br />

Large Display with User-friendly<br />

Calibrati<strong>on</strong> Menu. Measures,<br />

Totalizes and Transmits <strong>Flow</strong><br />

in both Directi<strong>on</strong>s

Accurate <strong>Flow</strong> measurement of Clean Fluids from Outside Plastic or Metal Pipes<br />

How it Works:<br />

<strong>Transit</strong> <strong>Time</strong> flow meters utilize two transducers that functi<strong>on</strong> as both ultras<strong>on</strong>ic<br />

transmitters and receivers. <str<strong>on</strong>g>The</str<strong>on</strong>g> transducers are clamped <strong>on</strong> the outside of a<br />

vertical or horiz<strong>on</strong>tal pipe at a specific distance calculated by the instrument.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> elapsed time between transmitted and received signals varies very slightly<br />

depending <strong>on</strong> whether the signal is traveling upstream or downstream and<br />

by comparing these time differences an accurate calculati<strong>on</strong> of the flow rate is<br />

possible and is displayed in your choice of engineering units. As the ultras<strong>on</strong>ic<br />

beam crosses the pipe, compensati<strong>on</strong> for laminar or turbulent flow is automatic.<br />

Depending <strong>on</strong> the applicati<strong>on</strong> and flow profile, the transducers can be mounted<br />

in V-method in which case the ultra sound transverses the pipe twice, the<br />

W-method in which case the ultra sound transverses the pipe four times or the<br />

Z-method in which case the transducers are mounted <strong>on</strong> opposite sides of the<br />

pipe and the ultra sound transverses the pipe <strong>on</strong>ly <strong>on</strong>ce. <str<strong>on</strong>g>The</str<strong>on</strong>g>se modes are<br />

automatically selected by the instrument and are also user selectable. (X de-<br />

notes the distance between the transducers, this is automatically calculated by<br />

the instrument at setup depending <strong>on</strong> the inputted applicati<strong>on</strong> data)<br />

comms<br />

Doc <str<strong>on</strong>g>SL3</str<strong>on</strong>g> | 1.0 |2010<br />

Hardware & Operati<strong>on</strong><br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> <str<strong>on</strong>g>SL3</str<strong>on</strong>g> electr<strong>on</strong>ics are housed in a rugged cast<br />

aluminum NEMA 4 (IP65) enclosure incorporating the<br />

graphic display, keypad, sensor and output facility<br />

c<strong>on</strong>necti<strong>on</strong>s. Programming the unit is carried out by<br />

selecting the opti<strong>on</strong>s displayed in the main menu and<br />

by following the simple instructi<strong>on</strong>s. Enter the pipe<br />

diameter, wall thickness, pipe material, liquid and<br />

temperature and the optimum mounting method and<br />

separati<strong>on</strong> distance for the transducers is automatically calculated and displayed <strong>on</strong> screen. An acoustic<br />

gel (supplied) is used between the transducers and the outside of the pipe to ensure that sound is<br />

c<strong>on</strong>ducted from the sensors through the pipe wall. Signal strength, time and date, as well as flow<br />

informati<strong>on</strong> are all c<strong>on</strong>tinuously displayed, keeping the user fully aware of the measurement<br />

process.<br />

power supply<br />

<strong>Flow</strong> Transducers<br />

transducers<br />

Only 3 types are needed to cover the pipe ranges 12mm (1/2”) up to 4750mm (190”) so<br />

selecti<strong>on</strong> is straightforward and the flow electr<strong>on</strong>ics is able to work with different<br />

transducer sets depending <strong>on</strong> the unit supplied and the<br />

applicati<strong>on</strong>. Opti<strong>on</strong>al high temperature sensors are also<br />

available for use up to 250C.<br />

< Explosi<strong>on</strong> Proof type<br />

ATEX certified versi<strong>on</strong> (Ex<str<strong>on</strong>g>SL3</str<strong>on</strong>g>) is also available to ExdIIBT6 as an opti<strong>on</strong>, please c<strong>on</strong>tact<br />

Solenvis for supporting documentati<strong>on</strong> and detailed specificati<strong>on</strong>.<br />

X<br />

V mode, number of sound paths: 2<br />

X<br />

W mode, number of sound paths: 4<br />

Z mode, number of sound paths: 1<br />

X<br />

Transducers<br />

Easy to install, IP67 rated and supplied<br />

with cable up to 100m/300ft

Technical data <str<strong>on</strong>g>SL3</str<strong>on</strong>g><br />

Transmitter<br />

Transducer<br />

Accessories<br />

Dimensi<strong>on</strong>s <str<strong>on</strong>g>SL3</str<strong>on</strong>g><br />

193mm<br />

Doc <str<strong>on</strong>g>SL3</str<strong>on</strong>g> | 1.0 |2010<br />

Power Supply<br />

Velocity<br />

Display<br />

Units<br />

Rate<br />

Totalized<br />

Output<br />

Accuracy<br />

Sensitivity<br />

Repeatability<br />

Security<br />

Weight and<br />

Dimensi<strong>on</strong>s<br />

Liquid Types<br />

Liquid<br />

Temperature<br />

Cable Length<br />

Pipe Size<br />

Transducer<br />

Size<br />

Couplant<br />

Data Logger<br />

Transducer<br />

Hardware<br />

241mm<br />

Electr<strong>on</strong>ics enclosure<br />

115/230VAC 50/60Hz ±15%@ 5VA max. 10-28 VDC @ 2.5VA max.<br />

Solar powered opti<strong>on</strong><br />

0 ~ ±40 ft/s (0 ~ ±12m/s), bi-directi<strong>on</strong>al<br />

Backlit LCD 4 line×16 character English menu,<br />

total �ow, �ow rate, velocity and meter running status etc. displayed<br />

User C<strong>on</strong>�gured (Imperial and Metric)<br />

Rate and Velocity Display<br />

(FWD, NET, REV or BATCH) gall<strong>on</strong>s, ft3, barrels, lbs, liters, m3,kg<br />

4~20mA, OCT Pulse, Relay, RS232C or RS485,<br />

Hart +(4~20mA), Modbus<br />

±1.0% of reading at rates >0.5 m/s<br />

±0.003 m/s of reading at rates

N<strong>on</strong>-C<strong>on</strong>tacting - Measures <strong>Flow</strong> from Outside the Pipe<br />

- Simple, User-Friendly Calibrati<strong>on</strong> System<br />

Applicati<strong>on</strong>s Support<br />

Take advantage of our applicati<strong>on</strong>s experience. C<strong>on</strong>tact <strong>on</strong>e of our sales<br />

engineers, describe your requirements and receive our prompt quotati<strong>on</strong>.<br />

Our Guarantee<br />

Warranted against defects in materials and workmanship for a period of <strong>on</strong>e year<br />

from date of purchase. Refer to our limited warranty included with each product.<br />

How to Order<br />

A simple to use order sheet is available with all the available opti<strong>on</strong>s, if you prefer,<br />

call us now and we can go through the opti<strong>on</strong>s with you to ensure that your<br />

requirements are fully met.<br />

No Risk Appraisal<br />

We are committed to providing the highest levels of service, in some cases it<br />

may be necessary to test the applicati<strong>on</strong> in questi<strong>on</strong> to ensure total satisfacti<strong>on</strong>.<br />

Please c<strong>on</strong>tact us to arrange a performance test.<br />

Doc <str<strong>on</strong>g>SL3</str<strong>on</strong>g> | 1.0 |2010<br />

Industries:<br />

Water<br />

Building Services<br />

Energy Management<br />

Power Generati<strong>on</strong><br />

Chemical<br />

Pharmaceutical<br />

Petrochemical<br />

Food<br />

Recommended For:<br />

Potable water<br />

River water<br />

Cooling water<br />

Demineralised water<br />

Water/glycol soluti<strong>on</strong>s<br />

Hydraulic oil<br />

Diesel and fuel oils<br />

Chemicals<br />

Petroleum products<br />

Applicati<strong>on</strong>/use:<br />

HVAC and energy measurement<br />

Check system meters<br />

Pump verificati<strong>on</strong><br />

Boiler testing<br />

Leak detecti<strong>on</strong><br />

Filter sizing<br />

Ultrapure water measurement<br />

Heavy fuel oil metering<br />

C<strong>on</strong>densate measurement<br />

Balancing systems<br />

Clean in place evaluati<strong>on</strong><br />

Fire system testing<br />

Hydraulic system testing<br />

Marine operati<strong>on</strong> and<br />

maintenance