pgm ore processing at impalals ug-2 concentrator in ... - SGS

pgm ore processing at impalals ug-2 concentrator in ... - SGS

pgm ore processing at impalals ug-2 concentrator in ... - SGS

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>SGS</strong> MINERALS SERVICES TECHNICAL BULLETIN 2004-02<br />

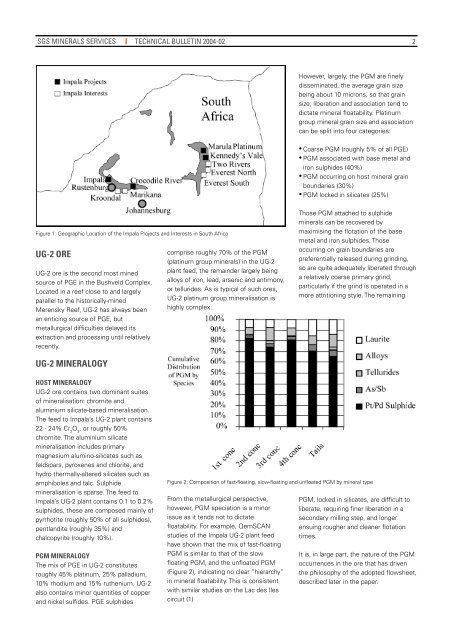

Figure 1: Geographic Loc<strong>at</strong>ion of the Impala Projects and Interests <strong>in</strong> South Africa<br />

UG-2 Ore<br />

UG-2 <strong>ore</strong> is the second most m<strong>in</strong>ed<br />

source of PGE <strong>in</strong> the Bushveld Complex.<br />

Loc<strong>at</strong>ed <strong>in</strong> a reef close to and largely<br />

parallel to the historically-m<strong>in</strong>ed<br />

Merensky Reef, UG-2 has always been<br />

an entic<strong>in</strong>g source of PGE, but<br />

metallurgical difficulties delayed its<br />

extraction and <strong>process<strong>in</strong>g</strong> until rel<strong>at</strong>ively<br />

recently.<br />

UG-2 M<strong>in</strong>eralOGY<br />

hOst M<strong>in</strong>eralOGY<br />

UG-2 <strong>ore</strong> conta<strong>in</strong>s two dom<strong>in</strong>ant suites<br />

of m<strong>in</strong>eralis<strong>at</strong>ion: chromite and<br />

alum<strong>in</strong>ium silic<strong>at</strong>e-based m<strong>in</strong>eralis<strong>at</strong>ion.<br />

The feed to Impala’s UG-2 plant conta<strong>in</strong>s<br />

22 - 24% Cr 2 O 3 , or ro<strong>ug</strong>hly 50%<br />

chromite. The alum<strong>in</strong>ium silic<strong>at</strong>e<br />

m<strong>in</strong>eralis<strong>at</strong>ion <strong>in</strong>cludes primary<br />

magnesium alum<strong>in</strong>o-silic<strong>at</strong>es such as<br />

feldspars, pyroxenes and chlorite, and<br />

hydro thermally-altered silic<strong>at</strong>es such as<br />

amphiboles and talc. Sulphide<br />

m<strong>in</strong>eralis<strong>at</strong>ion is sparse. The feed to<br />

Impala’s UG-2 plant conta<strong>in</strong>s 0.1 to 0.2%<br />

sulphides, these are composed ma<strong>in</strong>ly of<br />

pyrrhotite (ro<strong>ug</strong>hly 50% of all sulphides),<br />

pentlandite (ro<strong>ug</strong>hly 35%) and<br />

chalcopyrite (ro<strong>ug</strong>hly 10%).<br />

PGM M<strong>in</strong>eralOGY<br />

The mix of PGE <strong>in</strong> UG-2 constitutes<br />

ro<strong>ug</strong>hly 45% pl<strong>at</strong><strong>in</strong>um, 25% palladium,<br />

10% rhodium and 15% ruthenium. UG-2<br />

also conta<strong>in</strong>s m<strong>in</strong>or quantities of copper<br />

and nickel sulfides. PGE sulphides<br />

comprise ro<strong>ug</strong>hly 70% of the PGM<br />

(pl<strong>at</strong><strong>in</strong>um group m<strong>in</strong>erals) <strong>in</strong> the UG-2<br />

plant feed, the rema<strong>in</strong>der largely be<strong>in</strong>g<br />

alloys of iron, lead, arsenic and antimony,<br />

or tellurides. As is typical of such <strong>ore</strong>s,<br />

UG-2 pl<strong>at</strong><strong>in</strong>um group m<strong>in</strong>eralis<strong>at</strong>ion is<br />

highly complex.<br />

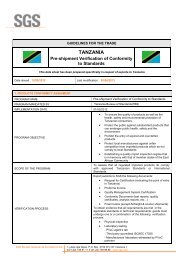

Figure 2: Composition of fast-flo<strong>at</strong><strong>in</strong>g, slow-flo<strong>at</strong><strong>in</strong>g and unflo<strong>at</strong>ed PGM by m<strong>in</strong>eral type<br />

From the metallurgical perspective,<br />

however, PGM speci<strong>at</strong>ion is a m<strong>in</strong>or<br />

issue as it tends not to dict<strong>at</strong>e<br />

flo<strong>at</strong>ability. For example, QemSCAN<br />

studies of the Impala UG-2 plant feed<br />

have shown th<strong>at</strong> the mix of fast-flo<strong>at</strong><strong>in</strong>g<br />

PGM is similar to th<strong>at</strong> of the slow<br />

flo<strong>at</strong><strong>in</strong>g PGM, and the unflo<strong>at</strong>ed PGM<br />

(Figure 2), <strong>in</strong>dic<strong>at</strong><strong>in</strong>g no clear “hierarchy”<br />

<strong>in</strong> m<strong>in</strong>eral flo<strong>at</strong>ability. This is consistent<br />

with similar studies on the Lac des Iles<br />

circuit (1)<br />

However, largely, the PGM are f<strong>in</strong>ely<br />

dissem<strong>in</strong><strong>at</strong>ed, the average gra<strong>in</strong> size<br />

be<strong>in</strong>g about 10 microns, so th<strong>at</strong> gra<strong>in</strong><br />

size, liber<strong>at</strong>ion and associ<strong>at</strong>ion tend to<br />

dict<strong>at</strong>e m<strong>in</strong>eral flo<strong>at</strong>ability. Pl<strong>at</strong><strong>in</strong>um<br />

group m<strong>in</strong>eral gra<strong>in</strong> size and associ<strong>at</strong>ion<br />

can be split <strong>in</strong>to four c<strong>at</strong>egories:<br />

• Coarse PGM (ro<strong>ug</strong>hly 5% of all PGE)<br />

• PGM associ<strong>at</strong>ed with base metal and<br />

iron sulphides (40%)<br />

• PGM occurr<strong>in</strong>g on host m<strong>in</strong>eral gra<strong>in</strong><br />

boundaries (30%)<br />

• PGM locked <strong>in</strong> silic<strong>at</strong>es (25%)<br />

Those PGM <strong>at</strong>tached to sulphide<br />

m<strong>in</strong>erals can be recovered by<br />

maximis<strong>in</strong>g the flot<strong>at</strong>ion of the base<br />

metal and iron sulphides. Those<br />

occurr<strong>in</strong>g on gra<strong>in</strong> boundaries are<br />

preferentially released dur<strong>in</strong>g gr<strong>in</strong>d<strong>in</strong>g,<br />

so are quite adequ<strong>at</strong>ely liber<strong>at</strong>ed thro<strong>ug</strong>h<br />

a rel<strong>at</strong>ively coarse primary gr<strong>in</strong>d,<br />

particularly if the gr<strong>in</strong>d is oper<strong>at</strong>ed <strong>in</strong> a<br />

m<strong>ore</strong> <strong>at</strong>trition<strong>in</strong>g style. The rema<strong>in</strong><strong>in</strong>g<br />

PGM, locked <strong>in</strong> silic<strong>at</strong>es, are difficult to<br />

liber<strong>at</strong>e, requir<strong>in</strong>g f<strong>in</strong>er liber<strong>at</strong>ion <strong>in</strong> a<br />

secondary mill<strong>in</strong>g step, and longer<br />

ensu<strong>in</strong>g ro<strong>ug</strong>her and cleaner flot<strong>at</strong>ion<br />

times.<br />

2<br />

It is, <strong>in</strong> large part, the n<strong>at</strong>ure of the PGM<br />

occurrences <strong>in</strong> the <strong>ore</strong> th<strong>at</strong> has driven<br />

the philosophy of the adopted flowsheet,<br />

described l<strong>at</strong>er <strong>in</strong> the paper.