pgm ore processing at impalals ug-2 concentrator in ... - SGS

pgm ore processing at impalals ug-2 concentrator in ... - SGS

pgm ore processing at impalals ug-2 concentrator in ... - SGS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>SGS</strong> MINERALS SERVICES TECHNICAL BULLETIN 2004-02<br />

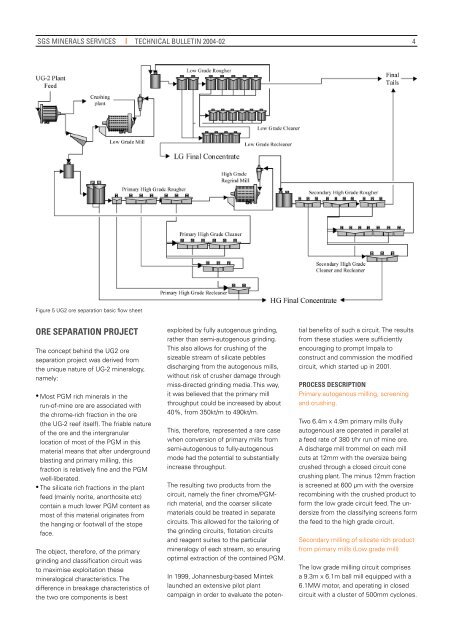

Figure 5 UG2 <strong>ore</strong> separ<strong>at</strong>ion basic flow sheet<br />

Ore sePar<strong>at</strong>iOn PrOJect<br />

The concept beh<strong>in</strong>d the UG2 <strong>ore</strong><br />

separ<strong>at</strong>ion project was derived from<br />

the unique n<strong>at</strong>ure of UG-2 m<strong>in</strong>eralogy,<br />

namely:<br />

• Most PGM rich m<strong>in</strong>erals <strong>in</strong> the<br />

run-of-m<strong>in</strong>e <strong>ore</strong> are associ<strong>at</strong>ed with<br />

the chrome-rich fraction <strong>in</strong> the <strong>ore</strong><br />

(the UG-2 reef itself). The friable n<strong>at</strong>ure<br />

of the <strong>ore</strong> and the <strong>in</strong>tergranular<br />

loc<strong>at</strong>ion of most of the PGM <strong>in</strong> this<br />

m<strong>at</strong>erial means th<strong>at</strong> after underground<br />

blast<strong>in</strong>g and primary mill<strong>in</strong>g, this<br />

fraction is rel<strong>at</strong>ively f<strong>in</strong>e and the PGM<br />

well-liber<strong>at</strong>ed.<br />

• The silic<strong>at</strong>e rich fractions <strong>in</strong> the plant<br />

feed (ma<strong>in</strong>ly norite, anorthosite etc)<br />

conta<strong>in</strong> a much lower PGM content as<br />

most of this m<strong>at</strong>erial orig<strong>in</strong><strong>at</strong>es from<br />

the hang<strong>in</strong>g or footwall of the stope<br />

face.<br />

The object, theref<strong>ore</strong>, of the primary<br />

gr<strong>in</strong>d<strong>in</strong>g and classific<strong>at</strong>ion circuit was<br />

to maximise exploit<strong>at</strong>ion these<br />

m<strong>in</strong>eralogical characteristics. The<br />

difference <strong>in</strong> breakage characteristics of<br />

the two <strong>ore</strong> components is best<br />

exploited by fully autogenous gr<strong>in</strong>d<strong>in</strong>g,<br />

r<strong>at</strong>her than semi-autogenous gr<strong>in</strong>d<strong>in</strong>g.<br />

This also allows for crush<strong>in</strong>g of the<br />

sizeable stream of silic<strong>at</strong>e pebbles<br />

discharg<strong>in</strong>g from the autogenous mills,<br />

without risk of crusher damage thro<strong>ug</strong>h<br />

miss-directed gr<strong>in</strong>d<strong>in</strong>g media. This way,<br />

it was believed th<strong>at</strong> the primary mill<br />

thro<strong>ug</strong>hput could be <strong>in</strong>creased by about<br />

40%, from 350kt/m to 490kt/m.<br />

This, theref<strong>ore</strong>, represented a rare case<br />

when conversion of primary mills from<br />

semi-autogenous to fully-autogenous<br />

mode had the potential to substantially<br />

<strong>in</strong>crease thro<strong>ug</strong>hput.<br />

The result<strong>in</strong>g two products from the<br />

circuit, namely the f<strong>in</strong>er chrome/PGMrich<br />

m<strong>at</strong>erial, and the coarser silic<strong>at</strong>e<br />

m<strong>at</strong>erials could be tre<strong>at</strong>ed <strong>in</strong> separ<strong>at</strong>e<br />

circuits. This allowed for the tailor<strong>in</strong>g of<br />

the gr<strong>in</strong>d<strong>in</strong>g circuits, flot<strong>at</strong>ion circuits<br />

and reagent suites to the particular<br />

m<strong>in</strong>eralogy of each stream, so ensur<strong>in</strong>g<br />

optimal extraction of the conta<strong>in</strong>ed PGM.<br />

In 1999, Johannesburg-based M<strong>in</strong>tek<br />

launched an extensive pilot plant<br />

campaign <strong>in</strong> order to evalu<strong>at</strong>e the poten-<br />

tial benefits of such a circuit. The results<br />

from these studies were sufficiently<br />

encourag<strong>in</strong>g to prompt Impala to<br />

construct and commission the modified<br />

circuit, which started up <strong>in</strong> 2001.<br />

PrOcess descriPtiOn<br />

Primary autogenous mill<strong>in</strong>g, screen<strong>in</strong>g<br />

and crush<strong>in</strong>g.<br />

Two 6.4m x 4.9m primary mills (fully<br />

autogenous) are oper<strong>at</strong>ed <strong>in</strong> parallel <strong>at</strong><br />

a feed r<strong>at</strong>e of 380 t/hr run of m<strong>in</strong>e <strong>ore</strong>.<br />

A discharge mill trommel on each mill<br />

cuts <strong>at</strong> 12mm with the oversize be<strong>in</strong>g<br />

crushed thro<strong>ug</strong>h a closed circuit cone<br />

crush<strong>in</strong>g plant. The m<strong>in</strong>us 12mm fraction<br />

is screened <strong>at</strong> 600 µm with the oversize<br />

recomb<strong>in</strong><strong>in</strong>g with the crushed product to<br />

form the low grade circuit feed. The undersize<br />

from the classify<strong>in</strong>g screens form<br />

the feed to the high grade circuit.<br />

Secondary mill<strong>in</strong>g of silic<strong>at</strong>e rich product<br />

from primary mills (Low grade mill)<br />

4<br />

The low grade mill<strong>in</strong>g circuit comprises<br />

a 9.3m x 6.1m ball mill equipped with a<br />

6.1MW motor, and oper<strong>at</strong><strong>in</strong>g <strong>in</strong> closed<br />

circuit with a cluster of 500mm cyclones.