Medium and Light - Sullivan Tire Company

Medium and Light - Sullivan Tire Company

Medium and Light - Sullivan Tire Company

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Technical Bulletins Load/Inflation General Technical <strong>Light</strong> Truck <strong>Medium</strong> Truck<br />

General Technical Information 2010 Firestone <strong>Medium</strong> <strong>and</strong> <strong>Light</strong> Truck <strong>Tire</strong> Data Book<br />

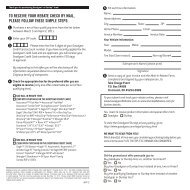

Mounting Radial Truck <strong>Tire</strong>s to<br />

Help Reduce Vibration <strong>and</strong><br />

Irregular Wear<br />

Consistent, correct truck tire mounting is important for<br />

proper bead-to-wheel fit, <strong>and</strong> can help reduce vehicle<br />

vibration <strong>and</strong> irregular wear for better ride <strong>and</strong> longer<br />

original tread life.<br />

46<br />

1. Remove dirt, rust or<br />

corrosion that can interfere<br />

with proper seal or damage<br />

bead.<br />

2. Protect bare metal with<br />

primer or anti-rust paint to<br />

prevent further corrosion.<br />

Allow to dry.<br />

3. Lubricate the wheel bead seat<br />

using vegetable oil-based<br />

lubricant approved for both<br />

tire <strong>and</strong> wheel.<br />

4. Lubricate tire bead. Do not<br />

use petroleum or solventbased<br />

products. They cause<br />

rubber to deteriorate.<br />

All tires should be stored in accordance with the<br />

following recommendations:<br />

1. Avoid storing tires in direct sunlight.<br />

2. Avoid storing tires near a heat source or in the<br />

path of a direct flow of forced air.<br />

3. Keep tires away from electric motors <strong>and</strong><br />

���������� ����� ������� ������<br />

4. Do not store near petroleum products or<br />

chemicals (such as oil, grease, gasoline,<br />

solvent, etc.).<br />

�� ����� ���������� �������� �� � ������� ��<br />

5 feet in height.<br />

P. Storage<br />

Important steps:<br />

1. Clean <strong>and</strong> paint used wheels.<br />

2. Lubricate both tire beads <strong>and</strong> both wheel seats.<br />

3. Check the assembly for even centering.<br />

Always follow all OSHA, RMA <strong>and</strong> manufacturer’s<br />

tire mounting safety precautions! (See Section on<br />

Mounting/Demounting Procedures in this data book.)<br />

B<br />

D<br />

A<br />

C<br />

5. Inflate assembly to set bead<br />

<strong>and</strong> check for leaks around<br />

the wheel.<br />

6. Measure distance from<br />

molded ring on tire to flange<br />

locations, 90 degrees apart.<br />

7. Distances A, B, C, <strong>and</strong> D<br />

������ �� ������ ������ ��<br />

they are not, break down,<br />

re-lubricate <strong>and</strong> mount again.<br />

6. Store un-mounted tires indoors in a dry location.<br />

Steel radial tires may be severely damaged due<br />

to the presence of moisture inside the tire at<br />

��������� ���� ��������������� ���� �������� ���<br />

permeate the casing of the tire <strong>and</strong> cause severe<br />

deterioration of the steel cords.<br />

7. Prior to mounting, inspect the inside<br />

surfaces of the tire <strong>and</strong> remove all foreign<br />

material <strong>and</strong> moisture.<br />

8. Keep compressed air sources for tire inflation<br />

free of moisture.<br />

Failure to follow the above recommendations could<br />

result in sudden tire failure, property damage <strong>and</strong><br />

personal injury.