Model Transflow - Hubbell Electric Heater Co.

Model Transflow - Hubbell Electric Heater Co.

Model Transflow - Hubbell Electric Heater Co.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

30 - 120 GALLON CAPACITIES<br />

FEATURES<br />

■ Heavy Duty <strong>Co</strong>nstruction<br />

— Hydrastone cement lining<br />

provides long tank life<br />

— <strong>Co</strong>pper-silicon tappings cannot<br />

rust or corrode<br />

— High impact composite jacket<br />

cannot rust or corrode and<br />

eliminates damage during transit<br />

and installation<br />

■ High Efficiency<br />

— 2" thick polyurethane foam<br />

insulation reduces heat loss<br />

— Built-in heat trap lowers operating<br />

costs<br />

■ Advanced Heating <strong>Co</strong>il<br />

— Heating coil can be easily<br />

removed for simple maintenance<br />

— Heavy gauge copper fin tube coil<br />

provides maximum heat transfer<br />

APPLICATIONS<br />

■ Residential<br />

■ Industrial Facilities<br />

■ Office Buildings<br />

■ Schools<br />

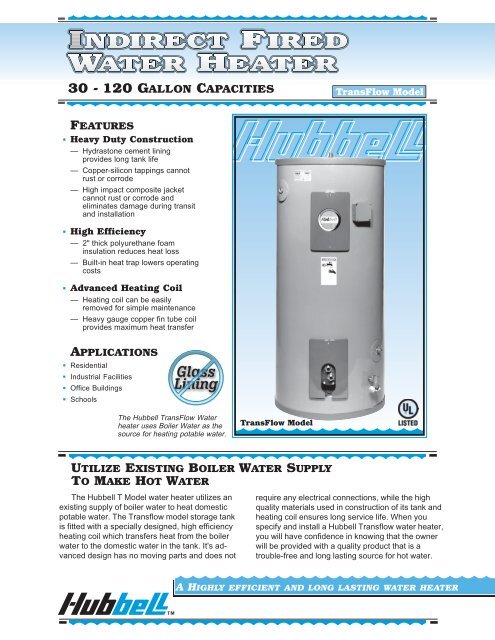

The <strong>Hubbell</strong> TransFlow Water<br />

heater uses Boiler Water as the<br />

source for heating potable water.<br />

TransFlow <strong>Model</strong><br />

UTILIZE EXISTING BOILER WATER SUPPLY<br />

TO MAKE HOT WATER<br />

The <strong>Hubbell</strong> T <strong>Model</strong> water heater utilizes an<br />

existing supply of boiler water to heat domestic<br />

potable water. The <strong>Transflow</strong> model storage tank<br />

is fitted with a specially designed, high efficiency<br />

heating coil which transfers heat from the boiler<br />

water to the domestic water in the tank. It's advanced<br />

design has no moving parts and does not<br />

TransFlow <strong>Model</strong><br />

require any electrical connections, while the high<br />

quality materials used in construction of its tank and<br />

heating coil ensures long service life. When you<br />

specify and install a <strong>Hubbell</strong> <strong>Transflow</strong> water heater,<br />

you will have confidence in knowing that the owner<br />

will be provided with a quality product that is a<br />

trouble-free and long lasting source for hot water.<br />

A HIGHLY EFFICIENT AND LONG LASTING WATER HEATER

2<br />

OUTLINE DIMENSIONS<br />

Hot Water Outlet<br />

Protective Jacket<br />

Tank Cross<br />

Section<br />

1/2"<br />

Steel<br />

Pressure<br />

Vessel<br />

<strong>Co</strong>mbination <strong>Co</strong>ld<br />

Water Inlet & Drain<br />

18"<br />

Withdrawal<br />

Space<br />

Side View<br />

45 o<br />

T&P Relief Valve<br />

2" Foam Insulation<br />

Immersion Thermostat<br />

<strong>Co</strong>ntroller<br />

Boiler Water Inlet<br />

Heating <strong>Co</strong>il<br />

Boiler Water Outlet<br />

45 o<br />

10 o<br />

Top View<br />

Front View<br />

A<br />

T&P Relief Valve<br />

Hot Water Outlet<br />

<strong>Co</strong>mbination <strong>Co</strong>ld<br />

Water Inlet & Drain<br />

Thermostat<br />

Heating Dimensions (Inches) Inlet /<br />

Base Storage <strong>Co</strong>il First Hour Outlet Shipping<br />

<strong>Model</strong> Capacity Size Rating * Overall Overall Inlet <strong>Co</strong>il Thermostat T&P Valve Size Weight<br />

(Gallons) (Sq Ft) (Gallons) Diameter Height “A” “B” “C” “D” (Inches) (lbs.)<br />

T30-15 30 15 128 20 40.5 7 10 13 34 3/4 180<br />

T40-15 40 15 139 20 58.75 7 10 13 51 3 /4 230<br />

T65-20 65 20 165 26 48 8 10 14 40 3 /4 310<br />

T80-20 80 20 182 26 58 8 10 14 51 3 /4 340<br />

T120-20 120 20 188 28 69.25 8 11 17 62 3/4 420<br />

T120-40 120 (2) 20 306 28 69.25 8 11 17 62 1 1 /2 435<br />

TU40-20 40 20 152 26 33 7 8 14 24 3 /4 235<br />

* First hour ratings based on a 80 o F rise (40-120 o F) when supplied with 6 GPM of 200 o F boiler water.<br />

STANDARD EQUIPMENT<br />

■ 1/2" thick Hydrastone cement lined steel tank<br />

■ All copper-silicon non-ferrous tank openings<br />

■ Built-in copper heat trap to improve operating<br />

efficiency and prevent heat migration<br />

■ Removable design heating coil<br />

■ High efficiency copper fin tube heating coil<br />

■ Immersion adjustable thermostat to regulate the<br />

flow of boiler water through the heating coil<br />

■ ASME rated temperature and pressure relief valve<br />

set at 150psi, 210 o F, 200,000 BTU max<br />

■ 2" thick polyurethane foam insulation<br />

■ High impact colorized composite protective jacket<br />

OPTIONAL EQUIPMENT<br />

1. 1 1/2" male NPT inlet / outlet water connections<br />

2. Double wall copper heating coil with a leak<br />

detection port. (Available in 20 Sq. / Ft. coils only)<br />

3. Integrally welded seismic attachment points<br />

4. <strong>Electric</strong> back-up heating element in various<br />

wattages and voltages (consult factory)<br />

1"<br />

B<br />

C<br />

D

TRANSFLOW MODEL<br />

TYPICAL INSTALLATION<br />

Hot Water<br />

Outlet<br />

T&P Relief<br />

Valve<br />

Immersion<br />

Thermostat<br />

Removable<br />

Heating <strong>Co</strong>il<br />

<strong>Co</strong>ld Water<br />

Inlet And<br />

Drain<br />

Tank: Hydrastone cement Lined<br />

Steel<br />

Capacities: 30 thru 120 Gallons<br />

Orientation: Vertical<br />

Inlet Size:<br />

3/4" Female NPT<br />

Outlet Size: 3/4" Male NPT<br />

Drain Size:<br />

3/4" Hose <strong>Co</strong>nnection<br />

Relief Valve Size: 3/4" Female NPT<br />

Tank Rating: 150 psi WP, 300 psi TP<br />

<strong>Co</strong>il Type: Removable<br />

<strong>Co</strong>il Material: <strong>Co</strong>pper Fin Tube<br />

<strong>Co</strong>il Rating: 150 psi WP, 300 psi TP<br />

Boiler Water<br />

To <strong>Co</strong>il<br />

Boiler Water<br />

Out Of <strong>Co</strong>il<br />

MODEL NUMBER DESIGNATION<br />

■ Step 1<br />

Base<br />

Base<br />

<strong>Model</strong>:<br />

<strong>Model</strong>:<br />

T or TU<br />

TU<br />

Boiler Water<br />

Supply<br />

TRANSFLOW MODEL<br />

WATER HEATER SPECIFICATIONS<br />

Boiler<br />

Shut-off Valve<br />

Check Valve<br />

Union<br />

Boiler <strong>Co</strong>ntrols<br />

Circulator<br />

Drain<br />

Pipes<br />

Boiler Water<br />

Return<br />

<strong>Co</strong>il Surface Area: 15, 20 Square Feet<br />

<strong>Co</strong>il Tube Size: 5/8" ID, 7/8" OD<br />

<strong>Co</strong>il <strong>Co</strong>nnections 3/4" Male NPT<br />

Max. Input: 199,900 BTU/Hour<br />

Thermostat:<br />

Warranty<br />

120 Volt S.P.S.T.<br />

Tank: Full Seven (7) Years<br />

<strong>Co</strong>il: Full Seven (7) Years<br />

Jacket: High Impact <strong>Co</strong>lorized<br />

<strong>Co</strong>mposite<br />

<strong>Co</strong>lor: Brown and Tan<br />

■ Step 2<br />

Storage<br />

Storage<br />

Capacity:<br />

Capacity:<br />

30-120 Gallons<br />

—<br />

■ Step 3<br />

<strong>Co</strong>il <strong>Co</strong>il Size: Size:<br />

Size:<br />

15, 20, 40<br />

■ Step 4<br />

Style:<br />

Style:<br />

S = Single Wall<br />

D = Double Wall<br />

3

4<br />

JOB NAME<br />

REPRESENTATIVE<br />

MASTER SPECIFICATIONS: TRANSFLOW MODEL<br />

ENGINEER<br />

CONTRACTOR<br />

GENERAL<br />

Provide a quantity of <strong>Transflow</strong> water heater(s) <strong>Model</strong> No.<br />

as manufactured by HUBBELL <strong>Electric</strong> <strong>Heater</strong> <strong>Co</strong>., Stratford, CT. The entire unit is to be complete with all<br />

operating controls and requires only plumbing and electrical service connections. The tank shall be all<br />

welded steel commercial construction designed for 150psi working pressure and contain gallons<br />

of storage. The tank shall be lined with seamless Hydrastone cement to a minimum thickness of 1 /2" on<br />

100% of all interior tank surfaces and does not require any type of anodic protection. The tank shall be<br />

designed and fabricated with non-ferrous copper-silicon threaded tappings and non-ferrous inlet and<br />

outlet piping for maximum corrosion resistance. Steel tank tappings will not be acceptable. The entire tank<br />

is to be insulated with a minimum of 2" thick polyurethane foam insulation and exceed the latest ASHRAE<br />

standard for stand-by heat loss. The complete heater shall be supplied with a high impact colorized<br />

composite protective jacket which cannot rust or corrode and does not require painting. The unit shall<br />

bear the UL listing mark certifying the entire water heater.<br />

The cold water inlet shall be 3 /4" Female NPT ( Optional Specification: 1 1 /2" Male NPT ) and include a<br />

non-corrosive strata-flow diffuser which prevents incoming cold water from mixing too rapidly with hot<br />

water in the tank. A 3 /4" hose connection drain is supplied. The hot water outlet shall be 3 /4" Male NPT<br />

( Optional Specification: 1 1 /2" Male NPT ) and shall include a factory installed built-in heat trap to<br />

prevent hot water from radiating through the piping during stand-by periods. A separate 3 /4" Female NPT<br />

tapping is to be provided for relief valve installation. An ASME rated automatic reseating combination<br />

temperature and pressure safety relief valve set at 150psi and 210 o F shall be factory supplied.<br />

HEATING COIL<br />

The tank shall be fitted with a heating coil which transfers heat from the boiler water to the domestic<br />

water. Boiler water shall be in the tubes, and domestic water in the tank. The heating coil shall be of<br />

single wall ( Optional Specification: double wall ) copper construction for maximum heat transfer<br />

efficiency and coil longevity. The coil shall have (Specify 15, 20, 40) square feet of heating<br />

surface and shall be fully removable from the tank to allow for periodic inspection and maintenance<br />

without the need to move or lift the storage tank from its installed position. The heating coil shall have<br />

3 /4" Male NPT threaded connections.<br />

THERMOSTAT<br />

The tank shall be fitted with an immersion 110-170 o F adjustable temperature controller to control the flow<br />

of boiler water through the heating coil. The S.P.S.T. 120 volt, 1 phase thermostat opens or closes the<br />

control circuit to the circulation pump or zone valve (by others) in order to regulate the flow of boiler water<br />

through the coil and thereby maintain the desired water temperature in the tank.<br />

WARRANTY<br />

The water heater manufacturer shall warranty all components against defects in workmanship and<br />

material for a period of one (1) year from date of start-up, and the pressure vessel including the heating<br />

coil for a full seven (7) years Non Pro-Rated from date of start-up, provided that the unit is started within<br />

three (3) months of date of shipment and installed and operated within the scope of the tank design and<br />

operating capability. Each water heater shall be shipped with a complete set of installation and operating<br />

instructions including spare parts list and approved drawings.<br />

The <strong>Electric</strong> <strong>Heater</strong> <strong>Co</strong>mpany ■ P.O. Box 288 ■ Stratford, CT 06615-0288 ■ Phone: (203) 378-2659 ■ FAX: (203) 378-3593<br />

E-mail: info@hubbellheaters.com ■ Internet: http://www.hubbellheaters.com