Fluitek Orsenigo Srl presentation - Global Supply Line

Fluitek Orsenigo Srl presentation - Global Supply Line

Fluitek Orsenigo Srl presentation - Global Supply Line

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

To: Whom it may to be concerned<br />

Subject: <strong>Fluitek</strong> <strong>Orsenigo</strong> <strong>Srl</strong> <strong>presentation</strong><br />

Dear Sirs,<br />

FLUITEK ORSENIGO <strong>Srl</strong> has been manufacturing ball valves in Italy for 20 years.<br />

With an annual turnover of 23 M per annum, the company has extensive experience<br />

in specailised engineered ball valves supplying the domestic market (ENI Group of<br />

Company in Italia, Ansaldo, General Electric), as well as with major organizations in the<br />

international arena (eg. ARAMCO, BP, PTT, PTT EP, KOC, SHELL, PDO,<br />

OXYDENTAL, EXXON MOBIL, MAERSK OIL, KCC, QGPC and many others).<br />

Hundreds of EPC’s & End Users can testify to the high level of quality product and<br />

service provided by <strong>Fluitek</strong> <strong>Orsenigo</strong> <strong>Srl</strong> whilst delivering in short delivery on time at a<br />

very competitive price.<br />

FLUITEL ORSENIGO’s production range has gradually increased over the last 20 years<br />

and now includes high technology special design applications for critical and exotic<br />

service applications such as:-<br />

- API 6A split body bolted bonnet & Top entry ball valves (entire API 6A range)<br />

- Full cryogenic application (-196ºC) split body bolted body & top entry balls<br />

- Metal to metal seated ball valves for very high temp and abrasive service<br />

- Double block & bleed modular ball valves<br />

We can supply very high pressure and large diameter ball valves. (Recently our factory<br />

produced 56 inch 300 class valves for KOC Kuwait).<br />

FLUITEK ORSENIGO <strong>Srl</strong>, on the basis of the extensive history and experience of the<br />

company have now embarked on an expansion program which will cement the company<br />

as a world leader in the supply of ball valves.<br />

Capitale Soc. 3.470.000,00 i.v.<br />

N. Reg. Imprese Bergamo 03389780168<br />

R.E.A. Bergamo n. 374323<br />

Cod. Fisc. – Partita IVA 03389780168

Consequently, over the next three years we plan to increase our annual output to 50M<br />

and with this aim have just strongly reinforced his Management staff as follows:<br />

Eng Rino Gammino, President, Managing Director & Owner<br />

11 years with Ansaldo Energia, as Business Unit Deputy Manager, 6 years Managing<br />

Director of a Mechanical Industrial Group, last 5 years as Managing Director and<br />

shareholder of <strong>Orsenigo</strong> Spa.<br />

Mr Giuseppe Belotti, Chief Of The Operation<br />

26 years with OMB Valves, in several roles. His experience includes 5 years as QA/QC<br />

Manager, 5 years as Engineering Manager and 8 years as Director of Production. Also<br />

1 year at OMB UK as Director of Production and Managing Director as well as 4 years at<br />

FBV as Director of Production.<br />

Eng Francesco Cavallaro, Engineering Manager<br />

10 years at Ansaldo as Technical coordinator for Nuclear Power Plant design, 9 years at<br />

Ringo Valves as Engineering Manager< 4 years at PCC Ball Valves as Project Manager.<br />

Eng Andrea Marchi, Technical Commercial Manager<br />

9 years at PBVS as Application Engineer, 7 years at PCC Ball Valves as Technical<br />

Commercial Manager.<br />

Mr Giulio Barletta, Export Director<br />

12 years at Petrol Valves as Area Sales Manager, 7 years at PCC Ball Valves as<br />

Lead Export Manager & Seales Administration Director.<br />

All the staff in Management have many years experience in the valve industry and have<br />

significant experience and the ability to put in place long terms relationships with key<br />

Italian sub suppliers for raw material (both forging & casting), as well as with key<br />

machining ship & specialized labs for specific production processes for valve<br />

applications (special cladding application, hard facing, special sealing technologies,<br />

exotic painting, etc… ).<br />

Due to the nature of our product (eg. High engineered valves for special application/<br />

heavy duty and high pressure) we do use mostly Italian sources and are looking to<br />

develop global international supply chains to increase our competitiveness on<br />

commodity valves.<br />

di 2<br />

Pag 2

The vision of the NEW Fuitek <strong>Orsenigo</strong> <strong>Srl</strong> is to become a new center of excellence in<br />

the valve industry, putting the customer first and guaranteeing a cost and time<br />

effectiveness solution based on enhanced efficient R & D design and utilizing a reliable<br />

strong network of first class working partners (raw material sub suppliers & satellite<br />

workshops).<br />

We are looking for long term relationships with clients who can allow both companies to<br />

grow in an efficient and effective manner whilst ensuring good communications.<br />

FLUITEK ORSENIGO <strong>Srl</strong> are a strong tight knit group of personnel who are proud and<br />

enthusiastic. You are invited to witness our professional approach personally by visiting<br />

our premises in Italy.<br />

<strong>Fluitek</strong> <strong>Orsenigo</strong> <strong>Srl</strong> are honored to invite your company for a Plant audit we can<br />

introduce all of our Management Staff, and present our premises and introduce you to<br />

the NEW FLUITEK ORSENIGO Sr.<br />

Remaining at your total disposal in case of any further clarification/assistance you may<br />

require in commencing registration with FLUITEK ORSENIGO.<br />

Regards,<br />

Ing. Andrea Marchi Mr Giulio Barletta<br />

<strong>Fluitek</strong> <strong>Orsenigo</strong> S.r.l. <strong>Fluitek</strong> <strong>Orsenigo</strong> S.r.l.<br />

Technical Sales Manager Export Director<br />

CC: Ing Rino Gammino, President & Managing Director<br />

Mr Giuseppe Belotti, Chief of the Operation<br />

Ing Francesco Cavallaro, Engineering Manager<br />

di 3<br />

Pag 3

New Manufacturing Plant:<br />

4200 sqm covered &<br />

5500 sqm uncovered area

High Engineering Ball Valves<br />

by design - application - exotic production process<br />

Full Cryogenic ball valves (-196°C)<br />

8"/2500# Split body bolted bonnet metal seated,<br />

Class E to TOTAL PVV-142<br />

400 micron Tungsten Carbide<br />

30"/600# Top Entry ball valve<br />

High Sour Service Alloy 625 fully cladded<br />

all wetted parts

Largest Valve<br />

produced by FLUITEK ORSENIGO <strong>Srl</strong>:<br />

Split bolted body 56"/300# (weight : 38.4 Tons)<br />

Supplied ON TIME last September 2007 with Contractor & K.O.C. full satisfaction.<br />

PROJECT : NEW 56SPUR LINE FOR MAA<br />

EPC : SPECIAL OILFIELD SERVICE<br />

End User : Kuwait Oil Company (K.O.C.)<br />

Commodities : MOV's 56"/300# 1 off, 48"/300# 11 off<br />

& 36"/600# 3 off<br />

Amount : 3 Millions Euro

Quality:<br />

• Certified ISO 9001 (since 1993)<br />

• API 6D Monogram - Nº 6D/0272<br />

• API 6A Monogram - Nº 6A/0450<br />

• TUV certificate no 047026304<br />

• CE mark certified since 2003<br />

• PED certified production - cert. No PED-H-64(DNV)<br />

• Fire Safe tested and certified main production according to API6FA, API RP6F,<br />

BS 6755 p.2<br />

• SIL 3 (Safety Integrity Level)<br />

• Company facilities allow to perform inside:<br />

• PMI, LP, MT, UT (by 2º level qualified personnel)<br />

• High Pressure gas tests<br />

• Fugitive Emission Tests<br />

• Cryogenic Tests<br />

6D-0272 6A-0450<br />

0496<br />

PED.12.0083.<br />

05/2162.1<br />

ISO 9001<br />

07389-2000-AQ-<br />

MIL-SINCERT

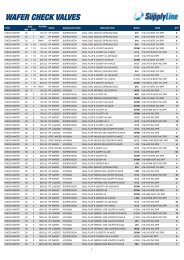

Product Range<br />

Side Entry Ball Valve<br />

Top p Entry y Ball Valve<br />

Floating or Trunnion Mounted Ball<br />

Soft or Metal to Metal Seated<br />

Double Block & Bleed modular valve<br />

Manual or Actuated (MOV, ESDV, BDV, XV)<br />

Production Range<br />

API API-6D 6D ANSI ffrom Cl Class 150# tto 4500#<br />

API-6A API 2000 to 15000 psi<br />

NPS: from ½” ½ to 60 60”<br />

All material selection from CS to Ni Alloys & Ti<br />

Full range of Thermoplastic and Elastomeric Seals

Available Features<br />

Fire Safe Tested & Certified (API-6FA, 607, BS6755)<br />

Antistatic Device<br />

Single Piston Self-Relieving Type (Std.)<br />

Double Piston Effect Seat (upon ( p request) q )<br />

Combined seats, SR/DPE seats (preferred direction)<br />

Emergency Seat & Stem Sealant Injection<br />

Flanged Vent & Drain Connection<br />

Stem Extension for Pit or Buried Installation<br />

Rised <strong>Line</strong>s for Underground Installation<br />

Vertical <strong>Line</strong> - Horizontal Stem Installation

Special Service Application<br />

Low Temperature<br />

Blow Down Service (Operable or Not)<br />

Full Cryogenic Valves (LNG –160°C)<br />

High g Temperature p<br />

Extreme Sour Service (up to 20% H2S)<br />

Abrasive and Erosive (dirty service)<br />

Off-Shore Riser Isolation & ESDV<br />

Pig Trap isolation<br />

Hot Tapping<br />

Subsea SSIV, ROV & Diver Operated<br />

HIPPS S application li i<br />

Multiways valves for switching and isolation purpose,<br />

Transflow and Not Not-Transflow Transflow design

MAIN APPROVALS <br />

<br />

• ADNOC Group of Company (ADCO, ADGAS, TAKREER, ADMA, ZADCO, etc) <br />

• AGIP <br />

• AMEC (UK) <br />

• Ansaldo <br />

• ARAMCO <br />

• BP AZERBAJAN <br />

• BP INDONESIE <br />

• BP UK <br />

• CHIYODA Corporation <br />

• Daewoo Shipbuilding and Marine Engineering <br />

• ENEL (Italian National Electrical Agency) <br />

• FPCC/FCC (Pormosa Petrochemical and Formosa Chemical Co.) <br />

• GASCO (Registered) <br />

• JGC Corporation <br />

• Mc Dermott <br />

• NORSKE SHELL <br />

• Nuovo Pignone (General Electric) <br />

• PDO OMAN (May 2006) <br />

• PETROFAC U..E. <br />

• PFD (Parsons Fluor Daniel) <br />

• PTT <br />

• PTT EP <br />

• SAIPEM <br />

• SHELL <strong>Global</strong> Solution (Under process – March 2006) <br />

• STATOIL <br />

• Talisman (Canada/UK) <br />

• TECHNIP <br />

<br />

APPROVALS UNDER PROCESS (NOV. 2007) <br />

<br />

• ADNOC Group of Company (ADCO, <br />

• BAELIM <br />

• GASCO QATAR PETROLEUM <br />

• GS Engineering & Construction <br />

• Hyundai Heavy Industries (HHI) <br />

• Petrobas <br />

• Samsung Engineering <br />

• Samsung Heavy Industries Co. Ltd <br />

• Single Buoy Moorings (SBM) <br />

• SK Engineering <br />

• Sonatrac <br />

• Total <br />

<br />

APPROVALS TARGET IN THE NEXT YEAR <br />

<br />

• PETRONAS <br />

• SHELL <br />

• TOTAL‐FINA <br />

<br />

Reference List – Approvals

www.globalsupplyline.com.au<br />

GLOBAL SUPPLY LINE PTY LTD<br />

Major Stockists <strong>Supply</strong>ing Worldwide