Pumps and Products for Industrial Assembly - Aquapump

Pumps and Products for Industrial Assembly - Aquapump

Pumps and Products for Industrial Assembly - Aquapump

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

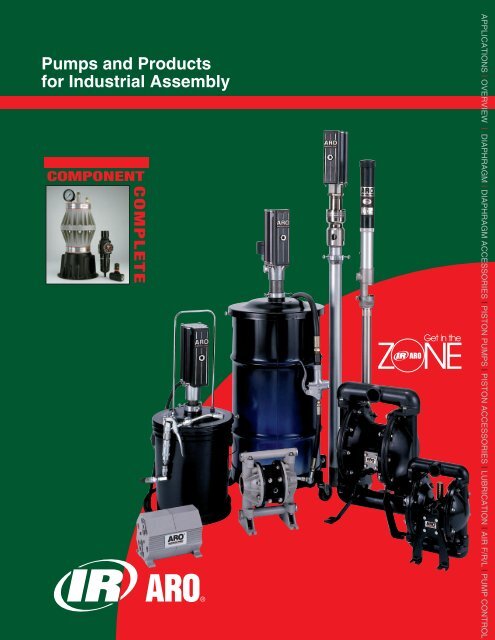

<strong>Pumps</strong> <strong>and</strong> <strong>Products</strong><br />

<strong>for</strong> <strong>Industrial</strong> <strong>Assembly</strong><br />

COMPONENT<br />

COMPLETE<br />

Get in the<br />

APPLICATIONS | OVERVIEW | DIAPHRAGM | DIAPHRAGM ACCESSORIES | PISTON PUMPS | PISTON ACCESSORIES | LUBRICATION | AIR F/R/L | PUMP CONTROL

Welcome<br />

to the ARO ®<br />

Zone.<br />

Get in the<br />

Where Process<br />

<strong>and</strong> Product<br />

Converge<br />

to Achieve<br />

Optimum<br />

Results.<br />

1 1 ⁄2” pumps (with ANSI flanges) at work in a<br />

waste treatment application<br />

This 666053-322 (1/2” Polypropylene<br />

Pump) is used on a parts wash rack<br />

The place where your production<br />

processes <strong>and</strong> our engineered products “converge<br />

to achieve optimum results”. But beyond process <strong>and</strong><br />

product there is a third essential element that makes the<br />

“zone” a very real place: the ARO <strong>Industrial</strong> <strong>Assembly</strong><br />

Distributor. To make the leap from acceptable to optimum<br />

results it takes in-depth, working knowledge of both process<br />

<strong>and</strong> product. Your ARO <strong>Industrial</strong> <strong>Assembly</strong> Distributor knows<br />

both, <strong>and</strong> its knowledge <strong>and</strong> expertise, not hype, that will usher you<br />

<strong>and</strong> your operation into this new dimension of productivity. The<br />

ARO-Zone. . . get into it!<br />

Module/Air 2000 Regulator <strong>and</strong> Stacking<br />

ALPHA Valves control Provenair Cylinders<br />

in a metal fab shop<br />

Provenair <strong>and</strong> Microair Cylinders used to<br />

join plastic components.<br />

Provenair Cylinders advance routers on<br />

this automated machine

A 666101-244 (1” Stainless Steel Pump) is<br />

used to supply water treatment chemicals<br />

An LM2305A-41 (Thunder) pump in a<br />

bulk oil supply application.<br />

This 1/2” pump transfers cutting fluid<br />

through a filtering chamber<br />

Model FO2 flow control is adjusted to<br />

control cylinder retract speed<br />

ARO ® <strong>Pumps</strong> | 1<br />

ARO 1/2” pumps being used in a water<br />

pre-treatment operation<br />

A 666053-X (1/2” Pump) services a multistation<br />

machining center<br />

APPLICATIONS

2 | ARO ® <strong>Pumps</strong><br />

Get in the<br />

From<br />

“Unstallable ”<br />

to unstoppable,<br />

with Aro, its<br />

features that<br />

provide the<br />

<strong>for</strong>ce.<br />

Aro, Owner of the<br />

“Unstallable” Air Valve Design<br />

As relevant today as the day it came to market, Aro is still the sole owner<br />

of the technology <strong>and</strong> the title: Unstallable. Aro uses no magnets,<br />

springs, re-set buttons, or other secondary actuators to insure pump<br />

shifting - only air.<br />

Aro’s patented “unbalanced”<br />

major air valve has constant<br />

air pressure applied to its small<br />

end. This assures that the<br />

pump resets. Competitive<br />

designs lose their signal during<br />

every shift, making them<br />

vulnerable to stalling.<br />

To reverse the valve, air<br />

pressure is supplied to the<br />

larger end of the valve,<br />

allowing the valve to shift -<br />

note that constant air pressure<br />

continues to be applied to the<br />

small end.

For Safety, Reliability <strong>and</strong> Ease<br />

of <strong>Assembly</strong>: Bolted Is Better<br />

Lost Air Is No Bargain<br />

If your pneumatic pumps are not ARO Pneumatic <strong>Pumps</strong>, chances are their<br />

air valves are blowing out perfectly good air to atmosphere, at no small<br />

expense. And this is not intermittent. This is whenever <strong>and</strong> wherever these<br />

pumps are operating.<br />

Kilowatts<br />

4<br />

3.5<br />

3<br />

2<br />

1<br />

0<br />

ARO <strong>Pumps</strong> feature bolted construction to<br />

avoid the proven problems created by<br />

clampb<strong>and</strong> type pump fasteners. These<br />

include material spills <strong>and</strong> leaks, bolt<br />

loosening <strong>and</strong> breakage due to poor joint<br />

integrity, <strong>and</strong> difficult reassembly.<br />

An Air Valve that Forgives <strong>and</strong> Forgets<br />

Aro’s major air valve requires no added<br />

lubrication <strong>and</strong> the “wiping” action of the<br />

seals makes it extremely <strong>for</strong>giving of<br />

contaminated compressed air supplies.<br />

Competitive Pump Design Kilowatts Wasted<br />

2.9<br />

1.6<br />

0.7<br />

120 100 70 40<br />

Air Inlet Pressure<br />

The close fitting air valve designs used on competitive<br />

pumps allow air to by-pass continually - wasting air - even<br />

when not pumping!<br />

ARO ® <strong>Pumps</strong> | 3<br />

REGISTERED<br />

F I R M<br />

Aro’s Bryan, Ohio facility, where our<br />

pumps are manufactured, is<br />

registered by Underwriters<br />

Laboratories Inc. to ISO 9001 Quality<br />

St<strong>and</strong>ards.<br />

5<br />

YEAR<br />

WARRANTY<br />

ARO <strong>Pumps</strong> are backed by a<br />

generous 5-year warranty on<br />

materials <strong>and</strong> workmanship <strong>for</strong> your<br />

purchasing peace of mind.<br />

Aro’s Pump design <strong>and</strong><br />

manufacturing operations have<br />

demonstrated compliance with the<br />

quality process, health <strong>and</strong> safety,<br />

technical file <strong>and</strong> multi-lingual<br />

st<strong>and</strong>ards set <strong>for</strong>th by the FEM<br />

(Federation Europeene de la<br />

Manutention) <strong>for</strong> the European Union<br />

(Communitie Economique).<br />

Get in the<br />

OVERVIEW

4 | ARO ® Diaphragm <strong>Pumps</strong><br />

Design Features<br />

5<br />

YEAR<br />

WARRANTY<br />

Get in the

ARO ® Diaphragm <strong>Pumps</strong> | 5<br />

Ideal For Abrasion And Solids H<strong>and</strong>ling<br />

Because it does not use rotating, sliding seals, like rotary/centrifugal pumps, more process engineers look to Aro diaphragm<br />

pumps <strong>for</strong> h<strong>and</strong>ling tough abrasion applications.<br />

Bolted Construction For Safe Reliability <strong>and</strong> Ease of <strong>Assembly</strong>:<br />

All Aro diaphragm pumps use bolted construction that process professionals dem<strong>and</strong>. And, Aro Non Metallic Diaphragm<br />

<strong>Pumps</strong> utilize fasteners that are constructed of 300 series stainless steel <strong>for</strong> maximum chemical resistance.<br />

Bolted is Safer - bolted construction reduces the risk of spills, environmental contamination <strong>and</strong> the attendant,<br />

m<strong>and</strong>atory reports to regulatory agencies that spills can create.<br />

Bolted is Reliable - Bolted construction withst<strong>and</strong>s the heavy loading that diaphragm pumps are subjected to, without<br />

concerns of breakage or loosening.<br />

Bolted is Easier to Assemble - Aro’s bolted design allows <strong>for</strong> easy positioning <strong>and</strong> alignment of parts during<br />

reassembly. This is a significant advantage over b<strong>and</strong>-clamp style pump fasteners, which are difficult to align <strong>and</strong><br />

hold together during reassembly.<br />

Bolted is Less Expensive - Aro’s design uses st<strong>and</strong>ard bolts which cost significantly less to replace. Non st<strong>and</strong>ard<br />

fastening devices (such as b<strong>and</strong> clamps) are considered “wear parts” <strong>and</strong> are more expensive to replace.<br />

Aro’s Patented “Unbalanced” Air Valve<br />

Aro’s “Unbalanced” air valve design makes this, <strong>and</strong> all of Aro’s Diaphragm <strong>Pumps</strong> “Unstallable”. Because the unbalanced<br />

valve cannot settle in a neutral position when the pump is shut down, it can’t become stuck, requiring the operator to hammer<br />

on the pump in order to start pumping again.<br />

• Eliminates Shifting/Freezing Problems • Uses Significantly Less Power Than Competition<br />

• Does Not Require Lubrication • Forgiving In Dirty Air<br />

Broad Material Selection<br />

Aro offers a wide selection of materials, allowing your choice of the best possible wetted <strong>and</strong> non-wetted materials suited to<br />

your application.<br />

Positive Priming Provides Instant Start-Ups<br />

Check valves are located close to the diaphragm chambers, ensuring a positive prime first time every time.<br />

Get in the<br />

OVERVIEW

6 | ARO ® Diaphragm <strong>Pumps</strong><br />

Model Overview<br />

1/4” Ports<br />

Non-Metallic<br />

1/2” Ports<br />

Non-Metallic<br />

1/2” Metallic Ports 1” Ports<br />

Non-Metallic<br />

MODEL 1/4” (Non-Met.) 1/2” (Non-Met.) 1/2” (Met.) 1” (Non-Met.)<br />

Maximum Flow 4.6 13 13 47<br />

GPM (LPM) (17.4) (49) (49) (178)<br />

Maximum<br />

Discharge 100 100 100 120<br />

Pressure (6.8) (6.8) (6.8) (8.3<br />

PSI (BAR))<br />

Fluid Ports 3/8” (F) - In 1/2” (F) - In/Out 1/2” (F) - In/Out 1” Ansi<br />

Inlet/Outlet 1/4” (F) - Out Flange<br />

(BSP Available) (No BSP) (No BSP) (No BSP)<br />

Materials Polypropylene Polypropylene Stainless Steel Polypropylene<br />

of Groundable Groundable Aluminum<br />

Construction Acetal Acetal<br />

Pump 4.1 (1.85) Poly 8.8 (4.0) Acetal<br />

Weight 4.6 (2.10) Acetal 7.2 (3.3) Poly 14.6 (6.6) SST *20.3 (9.2) Poly<br />

Lbs. (Kg.) 8.4 (3.8) Alum<br />

Maximum<br />

Solids Clean 3/32 3/32 1/8<br />

Inches (mm) Fluids (2.4) (2.4) (3.2)<br />

Best PD02P-APS-PTA 66605J-388 PD05P-ASS-SAA 6661A3-3EB-C<br />

Selling PD02P-APS-PTT 66605J-3EB PD05P-ASS-STT 6661A3-344-C<br />

Models PD02P-ADS-DTT 66605J-344 PD05P-AAS-PAA 6661B3-344-C<br />

(BSP Available) 66605H-644 PD05P-AAS-STT<br />

Recommended<br />

Filter/ P29122-600 P29221-610 P29221-610 P29221-610<br />

Regulator (Filter/Regulator) (Filter/Regulator) (Filter/Regulator) (Filter/Regulator)<br />

Air Line Kit 66073-1 66073-1 66073-1 66073-2<br />

See Page 15 17 16 19<br />

* Weights listed are <strong>for</strong> aluminum air motor models<br />

“Teflon ® is a registered trademark of Dupont Company, Santoprene ® is a registered<br />

trademark of Monsanto Company, licensed to Advanced Elastomer Systems, L.P.”

1” Ports<br />

Metallic<br />

1-1/2” Ports<br />

Non-Metallic<br />

1-1/2” Ports<br />

Metallic<br />

ARO ® Diaphragm <strong>Pumps</strong> | 7<br />

MODEL 1” (Met.) 1-1/2” (Non-Met.) 1-1/2” (Met.) 2” Ball (Met.)<br />

Max. Flow 35 100 100 170<br />

GPM (Liters) (133) (379) (379) (644)<br />

Maximum<br />

Operating 120 120 120 120<br />

Pressure (8.3) (8.3) (8.3) (8.3)<br />

PSI (BAR)<br />

Fluid Ports 1” (F) - In/Out 1-1/2” Flange 1-1/2” (F) 2” (F)<br />

BSP ANSI<br />

Available<br />

Materials Aluminum Polypropylene Aluminum Aluminum<br />

of Stainless Steel Stainless Steel<br />

Construction<br />

Pump *19 (8.6) Alum *62 (28) Poly *51 (23.1) Alum *64 (29) Alum<br />

Weight* *36 (16.3) S. S. 84(38.1) S. S.<br />

Lbs. (Kg.)<br />

Maximum<br />

Solids 1/8 1/4 1/4 1/4<br />

Inches (mm) (3.2) (6.4) (6.4) (6.4)<br />

Best 666100-322-C 6661T3-3EB-C 666150-322-C<br />

Selling 666100-344-C 6661T3-344-C 666150-344-C<br />

Models 666101-344-C 6661U3-344-C 666151-344-C<br />

666101-3EB-C 666151-3EB-C<br />

666111-244-C 666161-244-C<br />

Model Overview<br />

Recommended<br />

Filter/ P29221-610 P29241-610 P29241-610 P29241-610<br />

Regulator (Filter/Regulator) (Filter/Regulator) (Filter/Regulator) (Filter/Regulator)<br />

Air Line Kit 66073-2 66084-1 66084-1 66312<br />

See Page 20 21 22 23<br />

2” Ports<br />

Ball Valve<br />

* weights listed are <strong>for</strong> aluminum air motor models<br />

OVERVIEW

8 | ARO ® N-Series <strong>and</strong> Thunder <strong>Pumps</strong><br />

Design Features<br />

A Pump with Striking Design <strong>and</strong> Powerful<br />

Per<strong>for</strong>mance. This is what the plant professional<br />

wants, <strong>and</strong> with Aro’s N-Series <strong>and</strong> Thunder<br />

Pump, this is what the plant professional gets. From<br />

the pump maker that knows fluid h<strong>and</strong>ling better than<br />

anyone: ARO.<br />

TM<br />

5<br />

YEAR<br />

WARRANTY<br />

5-Year Warranty<br />

on materials <strong>and</strong> workmanship.<br />

Heavy Material Transfer/Supply?<br />

ARO Extrusion <strong>Pumps</strong> are<br />

available in 2-ball (<strong>for</strong> low-tomedium<br />

viscosity materials) <strong>and</strong><br />

chop-check (<strong>for</strong> mid-to-highviscosity<br />

materials) styles. Choose<br />

from basic pumps to complete<br />

pump packages. For more<br />

in<strong>for</strong>mation refer to ARO Catalog<br />

9909-P or www.arozone.com<br />

The Secret to Trouble Free<br />

Fluid H<strong>and</strong>ling?<br />

Simplicity Itself.<br />

Just one look at the air valve design of Aro’s 3-inch<br />

pump tells the whole story: Simple is Better. Aro’s<br />

design uses fewer parts in its air motor than the<br />

comparable competitive industrial pump. With fewer<br />

parts come fewer problems, it’s really just that<br />

simple.<br />

• RELIABLE - A stall-free, ice-free patented air motor<br />

design contained in a rugged housing that will withst<strong>and</strong><br />

most working environments.<br />

• FEWER UNIQUE PARTS - <strong>Pumps</strong> are constructed with<br />

fewer unique parts than the majority of comparable<br />

pumps. Install it <strong>and</strong> see <strong>for</strong> yourself how common parts<br />

translate into fewer headaches when it comes to service<br />

or routine maintenance.<br />

• NO MECHANICAL ASSIST - The patented valving design<br />

uses no trip rods or push pins to break.<br />

• MINIMUM NUMBER OF TOOLS, NO SPECIAL TOOLS -<br />

If you can find a st<strong>and</strong>ard wrench you can service it.<br />

• EASE OF INSTALLATION - Air inlet <strong>and</strong> fluid outlet can<br />

be oriented in 90° increments.<br />

• LUBE-FREE AIR MOTOR<br />

• THE RIGHT LOWER PUMP PACKINGS - Choose from a<br />

wide variety of packing materials, including the ultra-tough<br />

UHMW-PE/Teflon ® combo, <strong>for</strong> the ultimate in pump-toprocess<br />

compatibility.<br />

• CHOOSE YOUR METAL: CARBON STEEL OR<br />

STAINLESS STEEL - Pump lowers are available in two<br />

distinct alloys <strong>for</strong> today’s tough fluid material dem<strong>and</strong>s.<br />

• PUMP PACKAGES PROVIDE “ONE-STOP-SHOPPING -<br />

Portable or stationary airless spray or heavy material<br />

extrusion packages are factory specified <strong>and</strong> assembled

1:1 Ratio Piston<br />

2:1 Ratio Piston 4:1 Ratio<br />

MODEL 1:1 Ratio 2:1 Ratio 4:1 Ratio 1:1 Ratio<br />

Piston Piston Piston Diaphragm<br />

Maximum Flow 18 4 GPM 4.1 GPM 11 GPM<br />

GPM (68.1) (15.1) (15.8) (41.6 LPM)<br />

(LPM)<br />

Maximum<br />

Operating 150 150 150 100<br />

Pressure (10.2) (10.2) (10.2) (6.8)<br />

PSI (BAR)<br />

Materials Carbon Carbon Steel Carbon Steel Polypropylene<br />

of Steel Stainless Steel Stainless Steel Stainless Steel<br />

Construction<br />

Pump 12 12 (5.4) Carbon 32 (14.5) Stub<br />

Weight (5.4) Steel Models 46 (20.9) Drum<br />

Lbs. (Kg.) 16 (7.2) S.S. Stub<br />

19 (8.6) S.S. Drum<br />

ARO ® Piston/Diaphragm <strong>Pumps</strong> | 9<br />

1:1 Ratio<br />

Maximum Clean Clean Clean 3/32<br />

Solids Fluids Fluids Fluids (2.4)<br />

Inches (mm)<br />

Best 612041-1 650110-1C NM2304A-11-311 DA005-PPAA-2-A<br />

Selling 612041-3 650115-1C NM2304A-41-311 DA005-PPTT-2-A<br />

Models 650132-C NM2304B-11-311 DA005-SSTT-2-A<br />

650133 NM2304B-41-311 DA005-APNN-2-A<br />

Recommended C28123-600 C28123-600 C28123-600 P29122-600<br />

Filter/<br />

Regulator<br />

Air Line Kit 66073-1 66073-1 66073-1<br />

See Page 40 41-42 43-44 28-29<br />

“Teflon ® is a registered trademark of Dupont Company, Santoprene ® is a registered<br />

trademark of Monsanto Company, licensed to Advanced Elastomer Systems, L.P.”<br />

OVERVIEW

10 | ARO ® Lubrication <strong>Pumps</strong><br />

Model Overview<br />

5<br />

YEAR<br />

WARRANTY<br />

3:1 Oil<br />

LM2203A-11-B<br />

5:1 Oil<br />

LM2305A-11-B<br />

50:1 Grease<br />

LM2250E-21-B<br />

MODEL 2” 3:1 Oil 3” 5:1 Oil 2” 50:1 Grease 3” 50:1 Grease<br />

Working Flow<br />

GPM (LPM) 6 (23) 6 (23) 4 lbs. (1.8 Kg.) 4 lbs. (1.8 Kg.)<br />

lbs. (Kg.)<br />

Free Flow<br />

GPM 9 (34) 9 (34) 7.5 lbs. (3.3 Kg.) 7.5 lbs. (3.3 Kg.)<br />

Lbs.(Kg.)<br />

Air Inlet 1/4” 1/4” 1/4” 1/4”<br />

NPT (F)<br />

Fluid<br />

Inlet/Outlet 3/4”-1-1/2” 1/2”-1-1/2” 3/8” 3/8”<br />

NPT(F)<br />

Materials<br />

of Carbon Steel Carbon Steel Carbon Steel Carbon Steel<br />

Construction<br />

Recommended<br />

Filter/ P29122-600 P29122-600 P29122-600 P29122-600<br />

Regulator<br />

Air Line Kit 66073-1 66073-1 66073-1 66073-1<br />

See Page 46 46 47 47<br />

50:1 Grease<br />

LM2350E-41-B

Model Overview<br />

1” Ports<br />

Stainless<br />

(3:1 Ratio)<br />

MODEL 1”, 3:1 (Met.) 1”, 1-1/2”, 2” AMU2 Series AMU4 Series 3” Ports Series 35<br />

Max. Flow 24 1” : 29 (110) 11.8 31.7 275 120<br />

GPM (Liters) (90.7) 1-1/2” : 75 (284) (45) (120) (1,041) (480)<br />

2” : 105 (397)<br />

Maximum<br />

Operating 300 1” : 120 (8.3) 120<br />

Pressure (20.7) 1-1/2” : 120 (8.3) (8.3)<br />

PSI (BAR) 2” : 120 (8.3)<br />

Fluid Ports 1” (F) - In/Out 1” (F) - In 3/4” 1” 1-1/2” (F) - 2” (F) - 3” (F) In/Out 2”<br />

BSP 1-1/2” (F) - In<br />

Available 2” (F) - In.<br />

Materials Stainless Aluminum Carbon<br />

of Steel Aluminum Polypropylene Carbon Steel<br />

Construction Steel<br />

Pump 1” : 19 (8.6) 6.6 17.6 113 79<br />

Weight* *90 (40.7) S.S. 1-1/2” : 51 (23.1) (3) (8) (51.3) (36)<br />

Lbs. (Kg.) 2” : 64 (29)<br />

Maximum<br />

Solids 1/8 – – – 3/8 1”<br />

Inches (mm) (3.2) (9.5) (25)<br />

Best PH10A-ASS-SST 1” : 650717-C See See See<br />

Selling PH10A-ASS-HHT 1-1/2” : 650718-C Page Page Page<br />

Models 2” : 650719-C 25 27 26<br />

Recommended 1” : P29221-610 1” : P29221-610<br />

Filter/ P29231-610 1-1/2” : P29241-610 2” : P29241-610 –<br />

Regulator (Filter/Regulator) 2” : P29241-610 3” : F25457-110 (Filter)<br />

27354-600 (Regulator)<br />

Air Line Kit N/A 1” : 66073-2<br />

1-1/2” : 66084-1<br />

2” : 66312<br />

Fuel <strong>Pumps</strong> ARO Mag-Drive<br />

<strong>Pumps</strong><br />

ARO ® Speciality <strong>Pumps</strong> | 11<br />

Screened Inlet<br />

Diaphragm<br />

<strong>Pumps</strong><br />

Centrifugal<br />

<strong>Pumps</strong><br />

See Page 24 30 25 27 26<br />

* weights listed are <strong>for</strong> aluminum air motor models<br />

OVERVIEW

12 | ARO ® Pneumatic Valves (For complete in<strong>for</strong>mation see our Pneumatic Valves <strong>and</strong> Cylinders catalog <strong>for</strong>m# 0020-M)<br />

Component Overview<br />

Sierra Series<br />

Compact 2-position, 4-way valves that are lightweight, yet<br />

durable.<br />

15mm or 18mm wide. Body ported or sub-base mounted. Single<br />

<strong>and</strong> double solenoids available. M5 (10-32) <strong>and</strong> 1/8" ports.<br />

MaxAir Series<br />

4-way air solenoid, pilot <strong>and</strong> h<strong>and</strong> lever<br />

valves feature excellent flow in a compact,<br />

lightweight package.<br />

Alpha Series<br />

High flow, 2-<strong>and</strong>-3-position, 4-way valves that are compact in size<br />

with many features. The family includes: Body Threaded,<br />

Stacking, Bar Manifold <strong>and</strong> Assembled Manifold. Single <strong>and</strong><br />

double solenoids, or pilot actuators are available. 1/8", 1/4" <strong>and</strong><br />

3/8" ports.<br />

Genesis Series<br />

Manifold mounted, 4-way valves that meet ISO 5599-1 & -2, Size<br />

1 specifications <strong>for</strong> both domestic <strong>and</strong> international applications.<br />

Available in 2-<strong>and</strong>-3-position, solenoid <strong>and</strong> pilot actuators. Plug-<br />

In design means easy, uncluttered, unexposed wiring. 1/4" <strong>and</strong><br />

3/8" ports.<br />

Cat Series<br />

Small, 3-way solenoid valves. Perfect <strong>for</strong> small bore, single<br />

acting cylinders <strong>and</strong> electric to air interfacing applications. Body<br />

ported <strong>for</strong> st<strong>and</strong> alone applications, stacking or base manifold.<br />

Available as normally open or normally closed. 1/8" <strong>and</strong> 1/4"<br />

ports.<br />

50 Series<br />

3-way <strong>and</strong> 4-way body ported valves. Six manual, mechanical<br />

<strong>and</strong> pilot actuator styles available. 1/8" ports.<br />

E-Series<br />

3-way <strong>and</strong> 4-way body ported valves. Nine manual, mechanical,<br />

pilot <strong>and</strong> solenoid actuator styles available. 1/4" ports.<br />

K-Series<br />

Manual, Pilot <strong>and</strong> Solenoid, heavy duty 4-way valves. Available<br />

as body threaded or bottom ported <strong>for</strong> st<strong>and</strong> alone sub-base.<br />

Seven actuator styles available. Manual: 3/8" <strong>and</strong> 1/2" ports.<br />

Solenoid <strong>and</strong> Pilots: 3/8", 1/2", 3/4" <strong>and</strong> 1" ports.<br />

H-Series<br />

(For complete in<strong>for</strong>mation see our<br />

Pneumatic Valves <strong>and</strong> Cylinders<br />

catalog <strong>for</strong>m# 0020-M), or check<br />

out www.arozone.com

ARO ® Pneumatic Cylinders (For complete in<strong>for</strong>mation see our Pneumatic Valves <strong>and</strong> Cylinders catalog <strong>for</strong>m# 0020-M) | 13<br />

Component Overview<br />

Series 01 Micro-Air Cylinders<br />

(1/2” thru 1-1/8” bore)<br />

Micro-Air Cylinders, small bore, repairable, double-acting<br />

cylinders, are designed <strong>for</strong> light duty applications. Available in<br />

1/2, 3/4, <strong>and</strong> 1-1/8 inch bore sizes. Operate on air pressure to<br />

200 PSI, generating thrusts from 4.9 to 199 pounds. They are<br />

available in stroke lengths up to 6 inches <strong>and</strong> in several mounting<br />

styles.<br />

Series S Silverair Cylinders<br />

(1/2” thru 2-1/2” bore)<br />

Silverair Cylinders, small <strong>and</strong> medium bore, disposable, single<strong>and</strong><br />

double-acting cylinders are designed <strong>for</strong> light duty<br />

applications. Available in bore sizes from 1/2 inch to 2-1/2<br />

inches. Operate on air pressures to 200 PSI, generating thrusts<br />

up to 982 pounds.<br />

Series 23, 24 & 28 Economair ® Cylinders<br />

(1-1/8” thru 4” bore)<br />

Economair Cylinders, round line repairable cylinders, are<br />

designed <strong>for</strong> medium to heavy-duty use in a wide range of<br />

applications. Available in 1-1/8 to 4-inch bore sizes. Operate on<br />

air pressure to 200 PSI, generating thrusts from 25 to 2,513<br />

pounds. Available as double-acting, with optional cushions,<br />

magnetic pistons or double rod ends. O-ring seals are st<strong>and</strong>ard.<br />

U-cup or low friction seals are optional. A variety of mounts are<br />

available to meet a wide range of application requirements.<br />

Series AN & SN Provenair ® Cylinders<br />

(1-1/2” thru 10” bore)<br />

Provenair Cylinders are NFPA interchangeable square head<br />

cylinders designed <strong>for</strong> rugged use. Available in 1-1/2 to 10-inch<br />

bore sizes. They operate on air pressure up to 250 PSI,<br />

generating thrusts up to 3,141 pounds. They are available as<br />

double-acting, with optional cushions, magnetic pistons <strong>and</strong>/or<br />

with double rod ends. A broad selection of NFPA st<strong>and</strong>ard<br />

mounts makes them dimensionally interchangeable with other<br />

NFPA cylinders.<br />

OVERVIEW

14 | ARO ® Pneumatic Valves (For complete in<strong>for</strong>mation see our Pneumatic Valves <strong>and</strong> Cylinders catalog <strong>for</strong>m# 0020-M)<br />

Component Overview<br />

Accessory Valves<br />

• 100 Series - 3-way N.C., miniature limit valves.<br />

• 200 Series - 3-way limit valve-ideal <strong>for</strong> sensing devices such as cylinders,<br />

slides <strong>and</strong> gates.<br />

• 400 Series - Heavy duty 3-way limit valves, 4 actuator arms available.<br />

• 460 Series - 3-way palm button valves.<br />

• The 200, 400 <strong>and</strong> 460 are multipurpose valves, plumb N.O., N.C., diverter,<br />

<strong>and</strong> selector.<br />

• In line <strong>and</strong> right angle flow controls, in line needle <strong>and</strong> check valves.<br />

Valve Accessories <strong>and</strong> Special Valves<br />

• Bleed valves: manual button <strong>and</strong> pilot operated.<br />

• Quick exhaust valves <strong>for</strong> enhancing cylinder speed.<br />

• One shot pulse valve to convert continuous air supply to a momentary output.<br />

• Shuttle valves operate as a check when two inlets are required.<br />

• Micro switch converts pneumatic signal into an electric signal.<br />

• Exhaust mufflers, exhaust speed controls, breather vents.<br />

Pneumatic Logic Controls<br />

• Two-h<strong>and</strong> anti-tie-down unit <strong>for</strong> monitoring operators h<strong>and</strong>s during work cycle.<br />

• Pneumatic pulse <strong>and</strong> delay timers <strong>for</strong> use in simple valve circuitry.<br />

• Pneumatic counters.<br />

Mounts<br />

Micro-Air<br />

Silverair<br />

Economair ®<br />

Provenair ® (1-1/2 thru 10-inch bore)<br />

Provenair ® Stainless Steel (1-1/2 thru 8-inch bore)<br />

Rod End Accessories<br />

Micro-Air<br />

Silverair<br />

Economair ®<br />

Provenair ® (1-1/2 thru 10-inch bore)<br />

Alignment Couplers<br />

Switches, Cylinder Mounted<br />

Flow Control Valves<br />

Volume Chambers<br />

Repair Kits<br />

460 Series<br />

Valve<br />

Exhaust<br />

Muffler<br />

Mounts<br />

Alignment<br />

Couplers<br />

200 Series Valve<br />

Quick<br />

Exhaust<br />

Valve<br />

2-H<strong>and</strong> Anti-<br />

Tie Down<br />

Rod End<br />

Accessories<br />

Electrical Switches<br />

Right Angle<br />

Flow Controls

4.6 GPM (17.4 LPM) / 1/4- Inch Ports • Non-Metallic Diaphragm <strong>Pumps</strong> | 15<br />

Per<strong>for</strong>mance Specifications<br />

RATIO: 1:1<br />

MAXIMUM G.P.M. (Liters): 4.6 (17.4)<br />

DISPLACEMENT GALLONS<br />

(Liters) PER CYCLE: .014 (.053)<br />

AIR INLET: 1/4" (F)<br />

FLUID INLET: 3/8" (F)<br />

FLUID OUTLET: 1/4" (F)<br />

MAX. OPERATING PRESSURE PSI (bar): 100 (6.8)<br />

SUSPENDED SOLIDS MAX. DIA. IN. (mm): Clean Fluids Only<br />

WEIGHT - LBS. (KGS): 4.1 (1.85)Poly, 4.6 (2.10) Acetal<br />

MAX. DRY SUCTION LIFT: 20 ft.<br />

Dimensional Data<br />

Ordering<br />

Base Model<br />

Best Selling Models | PD02P-APS-PTA, PD02P-APS-PTT, PD02P-ADS-DTT<br />

Center<br />

Section<br />

Port<br />

Wet<br />

End<br />

Hardware<br />

Seat<br />

Material<br />

Disk Check/<br />

Diaphragm<br />

P D O 2 P A X X X X X<br />

1/4” Pump Polypropylene<br />

A NPT Single Inlet/Single Outlet<br />

D NPT Single Inlet/Dual Outlet<br />

E NPT Dual Inlet/Single Outlet<br />

H NPT Dual Inlet/Dual Outlet<br />

S Stainless Steel<br />

D Acetal<br />

P Polypropylene<br />

TA Teflon/Santoprene<br />

TG Teflon/Nitrile<br />

TT Teflon/Teflon<br />

D Acetal<br />

P Polypropylene<br />

Accessories<br />

Recommended Filter/Regulator<br />

Filter / Regulator: P29122-600<br />

(See Page 49)<br />

For complete airline connection kit,<br />

see page 34.<br />

For Diaphragm Pump<br />

Accessories see pages 33-34.<br />

P29122-600<br />

360°<br />

mounting<br />

versatility!<br />

Get in the<br />

DIAPHRAGM

16 | 13 GPM (49 LPM) / 1/2-Inch Ports • Metallic Diaphragm Pump<br />

Per<strong>for</strong>mance Specifications<br />

RATIO: 1:1<br />

MAXIMUM G.P.M. (Liters): 13 (49)<br />

DISPLACEMENT GALLONS<br />

(Liters) PER CYCLE: .040 (.15)<br />

AIR INLET: 1/4-inch NPT (F)<br />

FLUID INLET: 1/2-inch NPT (F)<br />

FLUID OUTLET: 1/2-inch NPT (F)<br />

MAX. OPERATING PRESSURE PSI (bar): 100 psi (6.9 bar)<br />

SUSPENDED SOLIDS MAX. DIA. IN. (mm): 3/32” (2.4mm)<br />

WEIGHT - LBS. (Kg): 14.6 lbs (6.6 kgs)SST, 8.4 lbs<br />

(3.8 kgs) Alum<br />

MAX DRY SUCTION LIFT: 10 ft. (Teflon fitted)<br />

Dimensional Data<br />

Stainless Steel<br />

Aluminum<br />

11-5/8"<br />

(295mm)<br />

6-7/16"<br />

(164mm)<br />

6"<br />

(152mm)<br />

4-7/8"<br />

(124mm)<br />

5-1/2"<br />

(140mm)<br />

Get in the<br />

11-1/16"<br />

(279mm)<br />

2"<br />

(51mm)<br />

7-11/16"<br />

(195mm)<br />

5/16" Slot<br />

(8mm)<br />

6-1/8"<br />

(156mm)<br />

8-1/4"<br />

(209mm)<br />

Ordering<br />

Base Model<br />

Material Outlet<br />

1/2 - 14 N.P.T.F.-1<br />

Air Inlet<br />

1/4 - 18 P.T.F. SAE Short<br />

Material Inet<br />

1/2 - 14 N.P.T.F.-1<br />

Center<br />

Section<br />

Port<br />

Wet<br />

End<br />

Accessories<br />

Recommended Filter/Regulator<br />

Filter / Regulator: P29122-600<br />

(See Page 49)<br />

For Diaphragm Pump<br />

Accessories see pages 33-34.<br />

Hardware<br />

Seat<br />

Material<br />

Ball Check/<br />

Diaphragm<br />

P29122-600<br />

Best Selling Models | PD05P-ASS-SAA, PD05P-ASS-STT, PD05P-AAS-PAA, PD05P-AAS-STT<br />

P D O 5 P A S S S X X<br />

1/2” Pump Polypropylene<br />

A NPT<br />

S 316 St. Steel<br />

A Aluminum<br />

For Pulsation Dampener,<br />

see page 31.<br />

For complete airline connection kit,<br />

see page 39.<br />

S Stainless Steel<br />

AA Santoprene/Santoprene<br />

GG Nitrile/Nitrile<br />

SA SS/Santoprene<br />

ST SS/Teflon<br />

TT Teflon/Teflon<br />

S 300 Series<br />

P Polypropylene

Per<strong>for</strong>mance Specifications<br />

RATIO: 1:1<br />

MAXIMUM G.P.M. (Liters): 13 (49) Ball 10 (37.9) Duckbill Check<br />

DISPLACEMENT GALLONS<br />

(Liters) PER CYCLE: .04 (.15) Ball .032 (.12) Duckbill Check<br />

AIR INLET: 1/4-inch NPT(F)<br />

FLUID INLET: 1/2-inch NPT(F)<br />

FLUID OUTLET: 1/2-inch NPT(F)<br />

MAX. OPERATING PRESSURE PSI (bar): 100 (6.9)<br />

SUSPENDED SOLIDS MAX. DIA. IN. (mm): 3/32-inch (2.4) Duckbill Check- Fibers<br />

WEIGHT - LBS. (Kg): 7.2 (3.3) Polypropylene<br />

MAX. DRY SUCTION LIFT: 10 ft. (Teflon fitted)<br />

Dimensional Data<br />

Ordering<br />

Base Model<br />

6 6 6 0<br />

13 GPM (49 LPM) / 1/2- Inch Ports • Non-Metallic Diaphragm Pump | 17<br />

Single-Piece Manifold Model<br />

(Order model 66605J)<br />

Best Selling Models | 66605J-388, 66605J-3EB, 66605J-344<br />

Air<br />

Motor<br />

Wetted<br />

Parts<br />

Check<br />

Valve Seats<br />

Ball Check/<br />

Diaphragm<br />

5 X X X X<br />

1/2” Pump<br />

Polypropylene<br />

2 Stainless Steel<br />

All hardware is 300 Series Stainless Steel.<br />

See next page <strong>for</strong> special, groundable models<br />

J* Polypropylene<br />

3 Polypropylene<br />

3<br />

6<br />

0<br />

Polypropylene<br />

Acetal<br />

Duckbill<br />

* Single piece manifold<br />

Accessories<br />

Recommended Filter/Regulator<br />

Filter / Regulator: P29122-600<br />

(See Page 49)<br />

For Pulsation Dampener,<br />

see page 31.<br />

For complete airline connection kit,<br />

see page 34.<br />

For Diaphragm Pump<br />

Accessories see pages 33-34.<br />

22 Nitrile/Nitrile<br />

44 Teflon/Teflon<br />

88 Polyurethane/Polyurethane<br />

A4 Stainless Steel/Teflon<br />

EB Santoprene/Santoprene<br />

D2 Nitrile/Nitrile<br />

P29122-600<br />

World’s<br />

Best<br />

Selling<br />

Model<br />

Get in the<br />

DIAPHRAGM

18 | 13 GPM (49 LPM) / 1/2-Inch Ports • Non-Metallic Groundable Diaphragm <strong>Pumps</strong><br />

VOLTS<br />

Per<strong>for</strong>mance Specifications<br />

RATIO: 1:1<br />

MAXIMUM G.P.M. (Liters): 13 (49)<br />

DISPLACEMENT GALLONS<br />

(Liters) PER CYCLE: .04 (.15)<br />

AIR INLET: 1/4-inch NPT(F)<br />

FLUID INLET: 1/2- inch NPT(F)<br />

FLUID OUTLET: 1/2 inch NPT(F)<br />

MAX. OPERATING PRESSURE PSI (bar): 100 (6.9)<br />

SUSPENDED SOLIDS MAX. DIA. IN. (mm): 3/32-inch (2.3)<br />

WEIGHT - LBS. (Kg): 8.8 (4.0) Acetal<br />

MAX. DRY SUCTION LIFT: 10 ft. (Teflon fitted)<br />

Dimensional Data<br />

See 1/2-inch (ports) non-metallic pump<br />

dimensional <strong>and</strong> flow data on page 17.<br />

Independent Laboratory Test Results<br />

GROUND<br />

11K<br />

9K<br />

7K<br />

5K<br />

3K<br />

1K<br />

20<br />

0<br />

Ungrounded<br />

Polypropylene<br />

27 KV<br />

TIME<br />

18-22 KV<br />

ARO<br />

UNRESTRICTED FLOW TESTS<br />

This test involved readings taken<br />

with a electro-static field strength<br />

meter during free-flow operation of<br />

the three pumps. Readings were<br />

taken at each pump’s metallic<br />

clamps <strong>and</strong> fasteners, traditional<br />

electro-static “hot-spots.”<br />

Model Overview<br />

ARO ® Groundable Diaphragm Pump is<br />

constructed from a patented<br />

material blend that serves<br />

to route electrostatic<br />

buildup to a single bleedoff<br />

point, ensuring safe<br />

operation. This exclusive<br />

body composition also<br />

provides superior<br />

compatibility with<br />

harsh industrial<br />

solvents <strong>and</strong> other<br />

volatile materials.<br />

Accessories<br />

An independent lab test showed that the Aro Groundable pump, pumping materials such as paint thinner, diesel fuel <strong>and</strong> enamel paint under high flow<br />

conditions, accumulated a maximum of .0032 millijoules of energy. The report concluded that energies of this magnitude are not sufficient to ignite flammable<br />

vapors. Reported minimum ignition energies of several flammable fluids are as follows:<br />

Methyl Ethyl Ketone: 0.53 millijoules Acetone: 1.15 millijoules<br />

Isopropyl Alcohol: 0.65 millijoules Hydrogen: 0.02 millijoules<br />

Perfect <strong>for</strong><br />

solvents, or<br />

solvent based<br />

paints,<br />

lacquers <strong>and</strong><br />

coatings.<br />

PAINT THINNER (HIGH CONDUCTANCE)<br />

Get in the<br />

ARO<br />

Ordering<br />

Base Model<br />

VOLTS<br />

6 6 6 0<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

20<br />

0<br />

UnGrounded<br />

Polypropylene<br />

Air<br />

Motor<br />

1/2” Pump Polypropylene<br />

Wetted<br />

Parts<br />

ARO<br />

ENAMEL PAINT (LOW CONDUCTANCE)<br />

Check<br />

Valve Seats<br />

Ball Check/<br />

Diaphragm<br />

5 X X X X<br />

H Single Piece Manifold<br />

6 3 Piece Manifold<br />

VOLTS<br />

11K<br />

9K<br />

7K<br />

5K<br />

3K<br />

1K<br />

20<br />

0<br />

Best Selling Models | 66605H-2A4, 66605H-244, 66605H-644<br />

Recommended Filter/Regulator<br />

Filter / Regulator: P29122-600<br />

(See Page 49)<br />

For complete airline connection kit,<br />

see page 34.<br />

For Diaphragm Pump<br />

Accessories see pages 33-34.<br />

2 Stainless Steel<br />

6 Acetal<br />

UnGrounded Polypropylene<br />

A1 SS/Neoprene<br />

A4 SS/Teflon<br />

44 Teflon/Teflon<br />

P29122-600<br />

ARO<br />

DIESEL FUEL (MODERATE CONDUCTANCE)<br />

* A groundable pump is<br />

defined as one which<br />

is not able to<br />

accumulate a charge<br />

of sufficient energy to<br />

ignite flammable<br />

vapors. Be sure that<br />

every component in<br />

your system is<br />

properly grounded.

47 GPM (178 LPM) / 1-Inch Ports • Non-Metallic Diaphragm Pump | 19<br />

Per<strong>for</strong>mance Specifications<br />

RATIO: 1:1<br />

MAXIMUM G.P.M. (Liters): 47 (178)<br />

DISPLACEMENT GALLONS<br />

(Liters) PER CYCLE: .170 (.64)<br />

AIR INLET: 1/4-inch NPT(F)<br />

FLUID INLET: ANSI Class 150, 1-inch Pipe Flange<br />

FLUID OUTLET: ANSI Class 150, 1-inch Pipe Flange<br />

MAX. OPERATING PRESSURE PSI (bar): 120 (8.3)<br />

SUSPENDED SOLIDS MAX. DIA. IN. (mm): 1/8-inch (3.2)<br />

WEIGHT - LBS. (Kg): 20.2 (9.2) Polypropylene<br />

For Cast Iron center section models,<br />

add 8.5 lbs. (3.81 kg.)<br />

MAX. DRY SUCTION LIFT: 15 ft. (Rubber fitted)<br />

Dimensional Data<br />

Ordering<br />

Base Model<br />

6 6 6 1<br />

Best Selling Models | 6661A3-3EB-C, 6661A3-344-C, 6661B3-344-C<br />

Air<br />

Motor<br />

Wetted<br />

Parts<br />

1” Pump A Aluminum<br />

B Cast Iron<br />

All hardware is 300 Series Stainless Steel. 3 Polypropylene<br />

Check<br />

Valve Seats<br />

Ball Check/<br />

Diaphragm<br />

X X X X X<br />

3 Polypropylene<br />

8 Stainless Steel<br />

(400, hardened)<br />

Accessories<br />

Recommended Filter/Regulator<br />

Filter / Regulator: P29221-610<br />

(See Page 49)<br />

67078 - Polypropylene Flange<br />

Kit 1” NPT (F)<br />

For Pulsation Dampener,<br />

see page 31.<br />

For complete airline connection kit,<br />

see page 34.<br />

For Diaphragm Pump<br />

Accessories see pages 33-34.<br />

22 Nitrile/Nitrile<br />

44 Teflon/Teflon<br />

EB Santoprene/Santoprene<br />

P29221-610<br />

Perfect <strong>for</strong><br />

aggressive<br />

chemicals<br />

Get in the<br />

DIAPHRAGM

20 | 35 GPM (132 LPM) / 1-Inch Ports • Metallic Diaphragm Pump<br />

Per<strong>for</strong>mance Specifications<br />

RATIO: 1:1<br />

MAXIMUM G.P.M. (Liters): 35 (132)<br />

DISPLACEMENT GALLONS<br />

(Liters) PER CYCLE: .16 (.60)<br />

AIR INLET: 1/4-inch NPT(F)<br />

FLUID INLET: 1-inch NPT(F) or BSP(F)<br />

FLUID OUTLET: 1-inch NPT(F) or BSP(F)<br />

MAX. OPERATING PRESSURE PSI (bar): 120 (8.3)<br />

SUSPENDED SOLIDS MAX. DIA. IN. (mm): 1/8-inch (3.2)<br />

WEIGHT - LBS. (Kg): 19 (8.6) Aluminum<br />

36 (16.3) Stainless Steel<br />

For Cast Iron center section models,<br />

add 8.5 lbs. (3.81 kg.)<br />

MAX. DRY SUCTION LIFT: 20 ft. (Rubber fitted)<br />

Dimensional Data<br />

Ordering<br />

Get in the<br />

Air<br />

Motor<br />

Wetted<br />

Parts<br />

Accessories<br />

Best Selling Models | 666100-322-C, 666101-344-C, 666101-3EB-C, 666100-344-C, 666111-244-C<br />

Base Model<br />

Check<br />

Valve Seats<br />

Ball Check/<br />

Diaphragm<br />

P29221-610<br />

6 6 6 1 X X X X X C<br />

1” Pump<br />

0 Aluminum<br />

1 Cast Iron<br />

2 BSP Aluminum<br />

3 BSP Cast Iron<br />

0 Aluminum<br />

1 316 Stainless Steel<br />

A Aluminum w/SS Hardware<br />

B 316 SS w/SS Hardware<br />

Recommended Filter/Regulator<br />

Filter / Regulator: P29122-610<br />

(See Page 49)<br />

For Pulsation Dampener,<br />

see page 31.<br />

For complete airline connection kit,<br />

see page 34.<br />

For Diaphragm Pump<br />

Accessories see pages 33-34.<br />

2 316 Stainless Steel<br />

3 Polypropylene<br />

8 400 SS (400, Hardened)<br />

22 Nitrile/Nitrile<br />

44 Teflon/Teflon<br />

EB Santoprene/Santoprene<br />

A4 SST/Teflon

100 GPM (379 LPM) / 1-1/2 Inch Ports • Non-Metallic Diaphragm Pump | 21<br />

Per<strong>for</strong>mance Specifications<br />

RATIO: 1:1<br />

MAXIMUM G.P.M. (Liters): 100 (379)<br />

DISPLACEMENT GALLONS<br />

(Liters) PER CYCLE: .72 (2.7)<br />

AIR INLET: 1/2-inch NPT (F)<br />

FLUID INLET: ANSI Class 150, 1-1/2-inch Pipe Flange<br />

FLUID OUTLET: ANSI Class 150, 1-1/2-inch Pipe Flange<br />

MAX. OPERATING PRESSURE PSI (bar): 120 (8.3)<br />

SUSPENDED SOLIDS MAX. DIA. IN. (mm): 1/4-inch (6.4)<br />

WEIGHT - LBS. (Kg): 62 (28) Polypropylene<br />

For Cast Iron center section,<br />

add 23 lbs. (10.4 kg)<br />

MAX. DRY SUCTION LIFT: 14 ft. (Rubber fitted)<br />

Dimensional Data<br />

Ordering<br />

Base Model<br />

Best Selling Models | 6661T3-3EB-C, 6661U3-344-C, 6661T3-344-C<br />

Air<br />

Motor<br />

Wetted<br />

Parts<br />

Check<br />

Valve Seats<br />

Ball Check/<br />

Diaphragm<br />

Accessories<br />

Recommended Filter/Regulator<br />

Filter / Regulator: P29241-610<br />

(See Page 49)<br />

For Diaphragm Pump<br />

Accessories see pages 33-34.<br />

6 6 6 1 X X X X X C<br />

1-1/2” Pump<br />

All hardware is 300 Series Stainless Steel.<br />

T Aluminum<br />

U Cast Iron<br />

3 Polypropylene<br />

3 Polypropylene<br />

8 400 SS (400, Hardened)<br />

67079 - Polypropylene Flange Kit<br />

1-1/2” NPT (F)<br />

For complete airline connection kit,<br />

see page 34.<br />

22 Nitrile/Nitrile<br />

44 Teflon/Teflon<br />

EB Santoprene/Santoprene<br />

P29241-610<br />

Perfect <strong>for</strong><br />

aggressive<br />

chemicals<br />

Get in the<br />

DIAPHRAGM

22 | 100 GPM (379 LPM) / 1-1/2 Inch Ports • Metallic Diaphragm Pump<br />

Per<strong>for</strong>mance Specifications<br />

RATIO: 1:1<br />

MAXIMUM G.P.M. (Liters):<br />

DISPLACEMENT GALLONS<br />

100 (379)<br />

(Liters) PER CYCLE: .73 (2.76)<br />

AIR INLET: 1/2-inch NPT(F)<br />

FLUID INLET: 1-1/2-inch NPT(F) or BSP(F)<br />

FLUID OUTLET: 1-1/2-inch NPT(F) or BSP(F)<br />

MAX. OPERATING PRESSURE PSI (bar): 120 (8.3)<br />

SUSPENDED SOLIDS MAX. DIA. IN. (mm): 1/4-inch (6.4)<br />

WEIGHT - LBS. (Kg): 51 (23.1) Aluminum<br />

84 (38.1) Stainless Steel<br />

For Cast Iron center section<br />

models, add 23 lbs. (10.4 kg.)<br />

MAX. DRY SUCTION LIFT: 19 ft. (Rubber fitted)<br />

Dimensional Data<br />

For viscous<br />

materials,<br />

stainless steel<br />

ball & checks<br />

available<br />

Ordering<br />

Get in the<br />

Base Model<br />

Air<br />

Motor<br />

Wetted<br />

Parts<br />

Accessories<br />

Recommended Filter/Regulator<br />

Filter / Regulator: P29241-610<br />

(See Page 49)<br />

For Diaphragm Pump<br />

Accessories see pages 33-34.<br />

Best Selling Models | 666150-322-C, 666150-344-C, 666151-344-C, 666161-244-C<br />

Check<br />

Valve Seats<br />

Ball Check/<br />

Diaphragm<br />

P29241-610<br />

6 6 6 1 X X X X X C<br />

1-1/2” Pump<br />

5 Aluminum<br />

6 Cast Iron<br />

7 BSP Aluminum<br />

8 BSP Cast Iron<br />

2 316 Stainless Steel<br />

3 Polypropylene<br />

8 400 SS (Hardened)<br />

0 Aluminum<br />

1 316 Stainless Steel<br />

A Aluminum w/SS Hardware<br />

B 316 SS w/SS Hardware<br />

For Pulsation Dampener,<br />

see page 32.<br />

For complete airline connection kit,<br />

see page 34.<br />

22 Nitrile/Nitrile<br />

44 Teflon/Teflon<br />

EB Santoprene/Santoprene

Per<strong>for</strong>mance Specifications<br />

RATIO: 1:1<br />

MAX. G.P.M. (LPM): 170 (644)<br />

DISPLACEMENT GALLONS<br />

(Liters) PER CYCLE: 1.4 (5.3)<br />

AIR INLET: 3/4” NPTF (f)<br />

AIR EXHAUST: 1-1/2” X 11 NPTF (f)<br />

FLUID INLET: 2” NPTF (f), BSP (f) or Flange<br />

FLUID OUTLET: 2” NPTF (f), BSP (f) or Flange<br />

MAX. OP. PRESSURE PSI (bar): 120 (8.3)<br />

PASS SOLIDS MAX. DIA. IN. (mm): 1/4 (6.4)<br />

WEIGHT LBS. (Kgs.): 64 (29) Aluminum<br />

MAX. DRY SUCTION LIFT: 19 ft. (Rubber fitted)<br />

Dimensional Data<br />

Air Motor Muffler Now Included! (Muffler Dimensions Not Shown)<br />

2” NPT/ANSI Flange<br />

PD20X-ASX-X<br />

2” BSP/DIN Flange<br />

PD20X-BSX-X<br />

Ordering<br />

Base Model<br />

Center<br />

Section<br />

Port Wetted<br />

End<br />

Hardware<br />

Seat<br />

Material<br />

Accessories<br />

Recommended Filter-Regulator<br />

(See Page 49)<br />

Filter / Regulator: P29241-610<br />

For Diaphragm Pump Accessories see pages 33-34.<br />

Best Selling Models | PD20A-AAP-AAA, PD20A-AAP-GGG, PD20A-AAP-KTT, PD20A-AAP-STT<br />

Ball Check/<br />

Diaphragm<br />

P D 2 0 X X X X X X X<br />

2” Pump A Aluminum<br />

170 GPM (644 LPM) / 2-Inch Ports • Metallic Diaphragm Pump | 23<br />

A NPT<br />

A Aluminum<br />

P Plated Steel<br />

A Santoprene<br />

G Nitrile<br />

K Kynar (PVDF)<br />

S 316 St. Steel<br />

For complete airline connection kit,<br />

see page 32, item “B”.<br />

Pulsation Dampener, see page 34.<br />

AA Santoprene/Santoprene<br />

GG Nitrile/Nitrile<br />

TT Teflon®/Teflon<br />

P29241-610<br />

Screened Inlet Kits Available. See Page 27.<br />

The most<br />

advanced<br />

process pump<br />

on the market.<br />

Get in the<br />

DIAPHRAGM

24 | High Pressure Metallic Diaphragm Pump • Specialty <strong>Pumps</strong><br />

Per<strong>for</strong>mance Specifications<br />

RATIO: 3:1<br />

MAXIMUM G.P.M. (LPM): 24 (90.7) Free Flow<br />

(12 GPM at 125 psi back pressure)<br />

DISPLACEMENT GALLONS<br />

(Liters) PER CYCLE: .09 (.341)<br />

AIR INLET: 3/8”-18 NPTF (f)<br />

FLUID INLET: 1”-11 NPTF (f) or 1”-11 BS Rp (f)<br />

FLUID OUTLET: 1”-11 NPTF (f) or 1”-11 BS Rp (f)<br />

MAX. OPERATING PRESSURE PSI (bar): 300 (20.4)<br />

PASS SOLIDS MAX. DIA. IN. (mm): 1/8-inch (3.2)<br />

WEIGHT - LBS. (Kg): 90 (40.7) Stainless Steel<br />

Dimensional Data<br />

Use the Aro High pressure pump in<br />

these <strong>and</strong> other applications:<br />

All stainless<br />

steel is<br />

electro-polished<br />

passivated.<br />

• Systems with long piping<br />

runs <strong>and</strong> friction losses<br />

• Inks<br />

• Adhesives<br />

Ordering<br />

Get in the<br />

Base Model<br />

P H 1 0<br />

1” Pump<br />

• Filled Materials<br />

• Drilling Grout<br />

• Caulking<br />

• Resins<br />

Per<strong>for</strong>mance Curves<br />

Accessories<br />

Recommended Filter/Regulator<br />

(See Page 49)<br />

Filter / Regulator: P29231-610<br />

67142 - Wall Mount Bracket<br />

For Diaphragm Pump<br />

Accessories see pages 33-34.<br />

P29231-610<br />

For recommended key models, refer to the ARO diaphragm<br />

pump price book (Form 2240-2). If the specific model you<br />

seek is not in the price book, consult the factory <strong>for</strong> further<br />

selection assistance.<br />

Center<br />

Wetted<br />

Section Port End Hardware Seat Ball Diaphragm<br />

A X S S X X T<br />

Aluminum<br />

A NPT<br />

B BSP<br />

Stainless Steel<br />

Stainless Steel<br />

HH 440 SS / 440 SS<br />

SS 316 SS / 316 SS<br />

Teflon

Features<br />

Magnetically - Driven <strong>Pumps</strong><br />

Totally sealless design - superior wear-parts endurance - 10-20,000<br />

hour abrasion parts life expectancy. AROMAG AM series mag-drive<br />

pumps feature polypropylene wetted material construction <strong>for</strong> broad<br />

fluid compatibility. Main bearing support incorporates a special hightemperature<br />

rated design that avoids temperature-induced<br />

misalignment, the single most common failure point in traditional magdrive<br />

pump designs. Their compact design <strong>and</strong> quiet operation make<br />

them ideal in a broad variety of installations including photo processing<br />

equipment, vending <strong>and</strong> medical equipment, as well as PC board mfg.,<br />

D.I. water systems <strong>and</strong> semi-conductor applications.<br />

AROMAG AMU2 Series<br />

• OEM <strong>and</strong> General Applications<br />

• 47” Long Electrical Cord<br />

• Ceramic Bearings <strong>and</strong> Spindles -<br />

20,000 Hour Life Expectancy<br />

• TEFC UL Recognized Motors<br />

• Employs Either Open or Closed Impellers <strong>for</strong> Maximum<br />

Flow/head Range<br />

• Viton O-ring<br />

• Low Flow Applications<br />

AroMag Mag-Drive <strong>Pumps</strong> • Specialty <strong>Pumps</strong> | 25<br />

Connection Voltage Max. Head Max. Flow Weight Liquid<br />

No. Hose NPT 110 Watts Feet Meters GPM Liters lbs. Temp.<br />

AMU22S010-H14PA01 14 mm • 10 10.1 3.1 4.4 17 3.7 32-140°F (0-60°C)<br />

AMU22S010-T07PA01 3/4 • 10 10.1 3.1 4.4. 17 2.7 32-140°F (0-60°C)<br />

AMU25S020-H18PA01 14 mm • 20 12.1 3.7 7.9 30 4.6 32-140°F (0-60°C)<br />

AMU25S020-T07PA01 3/4 • 20 12.4 3.8 7.9 30 4.6 32-140°F (0-60°C)<br />

AMU27S045-T07PA01 3/4 • 45 16.9 5.0 9.7 37 5.7 32-140°F (0-60°C)<br />

AMU27S065-T07PA01 3/4 • 65 20.6 6.3 11.8 45 6.6 32-140°F (0-60°C)<br />

AROMAG AMU4 Series<br />

• Open Impeller Mouth Design <strong>for</strong> Low NPSH<br />

• TEFC Motors<br />

• 47” Long Electrical Cable<br />

• Viton O-ring<br />

• H<strong>and</strong>les Fluids up to 138° F (70°C)<br />

• Low-to-Moderate Flow Applications<br />

AMU22S010 AMU25S020<br />

AMU43S090 AM6435250<br />

Connection Voltage Max. Head Max. Flow Weight<br />

No. NPT 110 Watts Feet Meters GPM Liters lbs.<br />

AMU43S090-T10PR01 1” • 90 26.9 8.2 19.6 72 11.9<br />

AM643S150-T10PR01 1” • 150 39.8 12.0 29.0 110 15.4<br />

AM643S250-T10PR01 1” • 250 95.9 14.0 31.7 120 17.6<br />

For a broader selection refer to catalog 0004-P.<br />

For in<strong>for</strong>mation about repair kits, please contact the factory<br />

NEW<br />

FROM OM THE<br />

AMU27S045<br />

REPLACES:<br />

• Iwaki ®<br />

• Little Giant ®<br />

• March ®<br />

• Low-Glow Mag Drives<br />

Get in the<br />

SPECIALTY

26 | Centrifugal Sump Pump • Specialty <strong>Pumps</strong><br />

Model Overview<br />

Its a messy job , but some pump’s gotta’ do it. Mud, leaves,<br />

twigs, bilge gunk, sewage, ...when trash like this collects <strong>and</strong><br />

clogs up the work site, you need a pump that can be easily<br />

submerged into the mess, <strong>and</strong> won’t quit until the site is dry.<br />

The I-R/ARO Super Sumps are the perfect pumps <strong>for</strong> this<br />

kind of job. They run on compressed air, so there are no fuel<br />

tanks, electrical connections or burnt-out motors to worry<br />

about. They can discharge over 200 GPM (750 l/m) <strong>and</strong> their<br />

ultra-rugged construction is accustomed to abuse. But best<br />

of all, their compact size <strong>and</strong> light-weight make them the “go<br />

anywhere, pump anything” fluid h<strong>and</strong>ler of choice to the<br />

Series 35<br />

Series 237<br />

host of professionals whose daily dem<strong>and</strong>s simply don’t allow time <strong>for</strong> pump problems. Try an<br />

I-R/ARO Super Sump on your toughest job, <strong>and</strong> see <strong>for</strong> yourself what a true trash pump can do.<br />

Pump Features<br />

• Simple Design, Few Moving Parts<br />

• H<strong>and</strong>les a Wide Variety of Debris - Laden Applications<br />

• Can Also Be Used <strong>for</strong> Simple Transfer Requiring High Flows (200<br />

+ GPM/ 750 LPM Avg.)with High Discharge Head (65 Feet/20<br />

Meters Avg.)<br />

• Self - Priming<br />

• Adjustable Impeller <strong>and</strong> Impeller Cover Helps Maintain Peak<br />

Per<strong>for</strong>mance<br />

• Closed-Type Impeller Promotes Greater Efficiency when Pumping<br />

Against High Heads<br />

• Ultra-Rugged Body Construction Insures Durability<br />

• Lightweight <strong>and</strong> Extremely Portable<br />

• Pressurized Lubrication of the Impeller Shaft Seals prolongs<br />

Operational Life <strong>and</strong> Resists Leakage<br />

• Patented Speed Controller is Guaranteed <strong>for</strong> the Life of the Pump<br />

• Totally Submersible<br />

Typical Applications:<br />

CONSTRUCTION<br />

• Pumping out excavations,<br />

flooded work sites, tunnels<br />

MINING<br />

• Pumping out shafts, tunnels &<br />

quarry pits<br />

CHEMICAL PROCESS<br />

• Pumping fluids with acids,<br />

pumping slurries<br />

Ordering<br />

INDUSTRIAL MAINTENANCE<br />

• Cleaning tanks, pumping out<br />

detailed tank cars, machine<br />

coolant supply, pumping out<br />

fuel tanks<br />

MARINE<br />

• Pumping out dry dock,<br />

cleaning ship holds <strong>and</strong> tanks,<br />

emergency bilge pumping<br />

Size of Opening<br />

Discharge<br />

Pipe Tap<br />

Air Inlet<br />

Pipe Tap Size<br />

Exhaust<br />

Pipe Tap Size Pump<br />

Pump Will Size Size Hose Size Hose Housing Max.<br />

Height Weight Pass Through NPT BSP NPT Recomm. NPT Recomm. Material CFM Flow<br />

Model in. mm lb. kg. in. x in. mm x mm in. in. in. in. mm in. in. mm Gal. Lit.<br />

P237A1-EU 17 5 ⁄8 448 48 21.8 8 3 ⁄4 x 8 3 ⁄4 222 x 222 2 1 ⁄2 - 3<br />

⁄4<br />

3<br />

⁄4 19 1 1 ⁄4<br />

1 1 ⁄4 32 Iron 100 See Flow Curve<br />

P237A3-EU 17 5 ⁄8 448 48 21.8 8 3 ⁄4 x 8 3 ⁄4 222 x 222 - 2 1 ⁄2<br />

3 ⁄4<br />

Internal Oiler<br />

End Plates<br />

Fluid Discharge<br />

Basket Style Inlet<br />

Strainer Cover<br />

Air Inlet<br />

Air Inlet<br />

Patented Speed<br />

Controller<br />

(Available on the 237<br />

Model Only)<br />

Air Exhaust<br />

Direct-Drive,<br />

Multi-Vane<br />

Air Motor<br />

3 ⁄4 19 1 1 ⁄4 1 1 ⁄4 32 Iron 100 See Flow Curve<br />

P35A1-EU 22 1 ⁄2 570 79 36 8 7 ⁄16 x 14 1 ⁄16 214 x 357 2 - 1 1 25 1 1 ⁄4 1 1 ⁄4 32 Iron 160 See Flow Curve<br />

P35A3-EU 22 1 ⁄2 570 79 36 8 7 ⁄16 x 14 1 ⁄16 214 x 357 - 2 1 1 25 1 1 ⁄4 1 1 ⁄4 32 Iron 160 See Flow Curve<br />

Impeller<br />

Shaft

Model Overview<br />

Screened Inlet Diaphragm <strong>Pumps</strong><br />

Special Strainer on Fluid Inlet Prevents Unwanted Solids Intake<br />

Pump Features<br />

Typical Applications:<br />

• CONSTRUCTION • MINING • PLANT MACHINE SUMPS<br />

Ordering<br />

Max. Max. Max. Pass<br />

Gallons Gallons Air Operating Solids<br />

GPM Per Cycle Inlet/ Pressure Max. Solids<br />

Model (Liters) (Liters) Exhaust PSI (Bar) Diameter<br />

1-1/2” Ports, Aluminum Construction<br />

PS15A-AAS-PAA 100 (379) .73 (2.7) 1/2” 120 (8.3) 1/4”<br />

2” Ports, Aluminum Construction<br />

PS20A-AAS-AAA 170 (644) 1.4 (5.3) 3/4” 120 (8.3) 1/4”<br />

3” Ports, Aluminum Construction<br />

PS30A-AAS-AAA 275 (1,041) 2.8 (10.6) 3/4” 120 (8.3) 3/8”<br />

Screened Inlet Diaphragm <strong>Pumps</strong> • Specialty <strong>Pumps</strong> | 27<br />

Known throughout industry as the “Unstallables”, the ARO Diaphragm Pump line has long been a<br />

favorite <strong>for</strong> fluid h<strong>and</strong>ling professionals <strong>for</strong> their patented no-stall <strong>and</strong> ice-free operation, along with a<br />

host of other distinct design attributes. To further exp<strong>and</strong> your ARO Pump’s application latitude, a<br />

selection of preassembled screened inlet pumps as well as retrofittable inlet kits are built, tested <strong>and</strong><br />

ready to tackle the unavoidable, unwanted debris problems that are clogging up your transfer operation.<br />

• Get the Kit or the Entire Pump<br />

Available in 1-1/2”, 2”, <strong>and</strong> 3” port models or as a retrofit kit, you can now experience the<br />

kind of stall-free, ice-free, debris-free fluid h<strong>and</strong>ling that only Aro can deliver.<br />

• Easy, Fast Field Conversion<br />

Only four bolts required to attach or detach the Screened Inlet assembly<br />

• Tough, Metallic Construction<br />

All pumps are constructed of aluminum <strong>and</strong> are fitted with stainless steel fasteners. The<br />

screen itself is constructed of carbon steel with an e-coat finish.<br />

• No Special Manifold Required<br />

Unlike competitive offerings, the Aro screened inlet unit works by merely adding the<br />

screen to a st<strong>and</strong>ard product. The screen comes installed on the pump, making it ready<br />

<strong>for</strong> immediate service.<br />

• All the Perks, None of the Problems<br />

With the Aro Screened Inlet Pump, you can at last experience stall-free, ice-free <strong>and</strong><br />

debris-free fluid h<strong>and</strong>ling, along with the added security of Aro’s 5-Year Pump Warranty.<br />

Pre-Assembled Screened-Inlet Pump Models<br />

Screened Inlet Kits<br />

Kit<br />

Model<br />

Fits<br />

Pump Description<br />

67174-15 1-1/2” Ports Kit includes screen/manifold assembly <strong>and</strong> installation hardware.<br />

67174-20 2” Ports Kit includes screen/manifold assembly <strong>and</strong> installation hardware.<br />

*Will not fit on 2” stainless pumps.<br />

NOTE: Will not fit on 666200 design<br />

67174-30 3” Ports Kits includes screen/manifold assembly with installation hardware.<br />

NOTE: Will fit A model or B model, Aluminum models only.<br />

1-1/2” Ports<br />

PS15A-AAS-PAA<br />

2” Ports<br />

PS20A-AAS-AAA<br />

3” Ports<br />

PS30A-AAS-AAA<br />

Screened-Inlet Kits<br />

SPECIALTY

28 | Drum Pump<br />

Pump Features<br />

• Choose from Aluminum, Stainless Steel or Polypropylene Body Construction -<br />

ARO Drum <strong>Pumps</strong> are available in three body materials <strong>for</strong> optimum fluid compatibility.<br />

• 11 GPM Flow Capability - Drum <strong>Pumps</strong> offer plenty of capacity to satisfy a broad<br />

range of transfer application volume dem<strong>and</strong>s.<br />

• Stall-Free Operation - ARO Diaphragm Drum <strong>Pumps</strong> feature a patented "unbalanced"<br />

air valve design that avoids stall-out, even under low air-inlet pressures<br />

• Bolted Construction - Unlike traditional b<strong>and</strong>-clamp style pumps, ARO Diaphragm<br />

Drum <strong>Pumps</strong> utilize bolted fasteners <strong>for</strong> leak-tight integrity.<br />

• 5-Year Warranty<br />

Pump Packages<br />

• Package Components Factory-Matched - ARO Drum Pump package<br />

components (adapters, siphon tubes, etc.) contain pre-specified, matching<br />

materials of construction <strong>for</strong> complete fluid compatibility.<br />

• Choose from Basic to Complete - Drum Pump Packages can be ordered<br />

in 3 styles:<br />

• Basic: Pump, Bung Adapter, Air Safety Shut-Off, Siphon Tube, Weather Seal<br />

<strong>and</strong> base<br />

• Complete/Transfer: Basic Pump plus Fluid Hose or Fluid Hose with<br />

Non-Drip Nozzle<br />

• Complete/ Dispensing: Basic Pump plus Foot Valve, Hose <strong>and</strong><br />

Dispensing Nozzle<br />

Accessories<br />

Tailor your own Drum Pump package with any of these accessories:<br />

• Hoses - 1/2” ID hose comes with factory installed cam coupler on one end to<br />

attach to pump. Other end comes either bare or with a preassembled fitting <strong>for</strong><br />

dispense nozzle. Hose materials available are: Nitrile, EPDM, Vinyl or Nylon.<br />

• Tank Adapters - For bulk tank applications, tank adapter kit comes complete with<br />

all necessary hardware <strong>and</strong> works like a bulk head fitting.<br />

• Foot Valves - For quick priming. Foot valves are available in either stainless steel<br />

or polypropylene.<br />

• Drum Adapter Kits - 55-gallon bung adapter kits come complete with base,<br />

weather seal, threaded adapter, siphon tube <strong>and</strong> stainless fasteners. Choose<br />

from polypropylene, stainless steel or aluminum construction.<br />

Ordering In<strong>for</strong>mation<br />

Body Seat Ball/Diaph. Fluid<br />

Model Material Material Material Service<br />

DA005-PPUU-2-A Polypropylene Polypropylene Polyurethane Water/Oil<br />

DA005-PPNN-2-A<br />

DA005-PPTT-2-A<br />

Polypropylene<br />

Polypropylene<br />

Polypropylene<br />

Polypropylene<br />

Nitrile<br />

Teflon<br />

Water/Oil<br />

® DA005-SSTT-2-A Stainless Steel Stainless Steel Teflon<br />

Mild Acid<br />

® DA005-ASTT-2-A Aluminum Stainless Steel Teflon<br />

Solvent<br />

® Basic Packages (Each package includes Pump, Bung Adapter, Air Shut-off, Siphon Tube, Weather Seal <strong>and</strong> Base)<br />

Solvent<br />

DA005-APNN-2-A Aluminum Polypropylene Nitrile Oil<br />

Complete/Transfer Packages (Each package contains Basic Package plus Cam Coupler, 10-Feet of Fluid Hose or<br />

10-Feet of Fluid Hose with Non-Drip Nozzle.)<br />

Ball/ Non-<br />

Body Seat Diaph. Hose Drip Fluid<br />

Model Material Material Material Material Nozzle Service<br />

DA005-PPUU-2-C Polypropylene Polypropylene Polyurethane Vinyl No Water/Oil<br />

DA005-PPNN-2-N Polypropylene Polypropylene Nitrile Nitrile No Water/Oil<br />

DA005-PPNN-B-M Polypropylene Polypropylene Nitrile Nitrile Yes Oil<br />

DA005-APNN-2-0 Aluminum Polypropylene Nitrile Nitrile No Oil<br />

DA005-APNN-B-P Aluminum Polypropylene Nitrile Nitrile Yes Oil<br />

ARO ® TM<br />

Drum <strong>Pumps</strong><br />

PUMP<br />

NEW<br />

NEW<br />

FR FROM FR FROM OM THE<br />

•Quick,<br />

Convenient<br />

Drum<br />

Changeout<br />

•Choose from<br />

Basic to<br />

Complete<br />

Pump<br />

Packages<br />

•5-Year<br />

Warranty<br />

•Broad<br />

Assortment<br />

of<br />

Accessories<br />

•Package<br />

Components<br />

Factory-<br />

Matched <strong>for</strong><br />

Optimum<br />

Compatibility

Ordering In<strong>for</strong>mation<br />

Complete/Dispensing Packages (Each package contains Basic Package Plus Foot Valve <strong>Assembly</strong>,<br />

10’ Hose, Cam Coupler <strong>and</strong> Dispensing Nozzle.)<br />

Ball/<br />

Body Seat Diaph. Hose Dispense Fluid<br />

Model Material Material Material Material Fixture Services<br />

DA005-PPNN-B-J Polypropylene Polypropylene Nitrile Nitrile Bibb w/ Water/<br />

Trigger Oil<br />

DA005-APNN-B-D Aluminum Polypropylene Nitrile N/A Oil<br />

Tapper<br />

Oil<br />

DA005-APNN-B-L Aluminum Polypropylene Nitrile Nitrile Bibb w/ Water/<br />

Trigger Oil<br />

Note: Foot valve check material matches diaphragm<br />

55-Gallon Drum Bung Adapter Kits<br />

(Kit contains Base, Bung Adapter, Bung Seal, Siphon Tube, Weather Seal <strong>and</strong> Hardware)<br />

Model Base Material Tube Material Weather Seal Base Seal<br />

67231 Polypropylene Polypropylene UHMW PE Viton<br />

67231-6 Aluminum Stainless Steel Viton Viton<br />

67231-7 Stainless Steel Stainless Steel Viton Viton<br />

Note: Fasteners are 300 Series Stainless Steel<br />

Bulk Tank Adapter Kit (Kit contains Base, Threaded Adapter, <strong>and</strong> Hardware)<br />

67234 Polypropylene / Viton O-Ring Seal<br />

67234-7 Stainless Steel (300 Series) / Viton O-Ring Seal<br />

Note: Fasteners are 300 Series Stainless Steel<br />

Foot Valves (Recommended <strong>for</strong> use with dispensing nozzle. <strong>Assembly</strong> includes Housing, Ball Check & O-Ring)<br />

637336 Polypropylene w/Viton O-Ring & Ball use with 67231<br />

637337 Stainless Steel w/Viton O-Ring & Ball use with 67231-6, or 67231-7<br />

Fluid Hose (1/2” ID Hose comes in 10-feet lengths <strong>and</strong> with Cam Coupler)<br />

Pump Fittings<br />

Dispensing<br />

Nozzle Used w/<br />

Model Material Used With End/End (Order Separately)<br />

621517-10 Nitrile Polypropylene Cam/Bare N/A<br />

621516-10 Nitrile Polypropylene Cam/Brass<br />

1/4-18 NPT Male<br />

635129<br />

621523-10 Nitrile Polypropylene Cam/Non-Drip<br />

Nozzle<br />

Included<br />

621515-10 EPDM Polypropylene Cam/Bare N/A<br />

621519-10 Vinyl Polypropylene Cam/Bare N/A<br />

621514-10 EPDM Polypropylene Cam / 1” NPT 95199<br />

622514-10 Nylon Polypropylene 1/2” NPT / 1/2” NPT<br />

316 Stainless Steel<br />

621518-10 Nitrile Aluminum Cam/Bare N/A<br />

621520-10 Nitrile Aluminum Cam/Brass<br />

1/4-18 NPTF<br />

635129<br />

621524-10 Nitrile Aluminum Cam/Non-Drip Nozzle Included<br />

Note: Hose requires 95189 to adapt to 1/2” port<br />

Fluid Dispensing Nozzles<br />

Model Description<br />

95199 Composite Nozzle - High flow nozzle works like gasoline nozzle. Features tough<br />

composite (polypropylene) construction <strong>for</strong> caustic service.<br />

95200 Swivel - 1” M X 1” FNPT Polypropylene hose swivel attaches between hose <strong>and</strong> dispensing<br />

nozzle <strong>and</strong> allows operator to rotate freely. Use with 95199.<br />

95183 Oil Tapper - Easy-pull tapper attaches directly to pump outlet port <strong>and</strong> provides even flow<br />

dispensing. Aluminum construction <strong>for</strong> oil service.<br />

77617-Z Oil Tapper Fitting - Plated carbon steel 1/2-14 NPTF X 3/8-18 NPTF -1. Used to attach<br />

95183 Oil Tapper to 1/2” Aluminum pump<br />

635129 Bibb with Trigger - 1/4” NPTF inlet, zinc die casting with brass <strong>and</strong> nitrile seals <strong>for</strong><br />

water or oil service. Radiator type bibb has 1/4” fluid inlet <strong>and</strong> nondrip<br />

tip.<br />

Pump Outlet Adapter<br />

95189 Composite Fitting - 1/2” Male NPT x MaleCam adapter (Polypropylene)<br />

95190 Aluminum Fitting - 1/2” Male NPT x MaleCam adapter (Aluminum)<br />

Drum<br />

Adapter Kit<br />

Tank Adapter<br />

Drum Pump | 29<br />

Foot Valve<br />

67231<br />

67234<br />

637336<br />

Hose, Swivel & Dispensing Nozzle<br />

621514-10, 95200, 95199<br />

Hose & Dispensing Bibb<br />

621516-10<br />

Hose & NonDrip Nozzle<br />

635129<br />

621523-10<br />

SPECIALTY

30 | Specialty <strong>Pumps</strong> • Fuel <strong>Pumps</strong><br />

Per<strong>for</strong>mance Specifications<br />

1 Inch 1-1/2 Inch 2 Inch<br />

RATIO: 1:1 1:1 1:1<br />

MAX. G.P.M. (Liters): 29 (110) 75 (284) 105 (284)<br />

AIR INLET: 1/4” NPT(F) 1/2” NPT(F) 1/2” NPT(F)<br />

PORT SIZE: 1” NPT(F) 1-1/2” NPT(F) 2” NPT(F)<br />

MAX. OP. PRESSURE PSI (bar): 50 (3.40) 50 (3.4) 50 (3.4)<br />

PASS SOLIDS MAX.DIA. IN. (mm): 1/8” (3.2) 1/4” (6.4) 1/4” (6.4)<br />

WEIGHT LBS. (Kgs.): 19 (8.6) 51 (23.1) 54 (24.5)<br />

Dimensional Data<br />

See pg. 20 <strong>for</strong> 1” Metallic Pump dimensional data. See pg. 22 <strong>for</strong> 1-1/2”<br />

Metallic Pump dimensional data. The dimensions <strong>for</strong> the 1-1/2” Metallic<br />

Pump are the same <strong>for</strong> the 2” U.L. Fuel Pump.<br />

U.L. Listed Fuel<br />

Transfer <strong>Pumps</strong><br />

These Aro Diaphragm <strong>Pumps</strong> have been designed<br />

specifically <strong>for</strong> dispensing petroleum-based fuel. These<br />

pumps meet UL-79 specification, code <strong>and</strong> are<br />

compatible with:<br />

• GASOLINE • AVIATION FUEL<br />

• DIESEL FUEL • FUEL OIL<br />

• KEROSENE • UNLEADED FUEL<br />

Used <strong>for</strong> high-volume transfer, bulk-unloading or fueling<br />

applications. To meet UL-79 specification, a 50 PSI<br />

pressure relief valve opens <strong>and</strong> bleeds off excess<br />

pressure. The relief valve can be plumbed to return the<br />

bleed-off fuel to the storage container.<br />

Ordering<br />

Get in the<br />

2-inch<br />

1-inch<br />

FLUID<br />

INLET/OUTLET<br />

MODEL PORT SIZE SEAT BALL<br />

DIAPHRAGM<br />

Air Connectors shown<br />

are not included.<br />

Recommended Filter/Regulator<br />

(See Page 49)<br />

1” Diaphragm Pump<br />

Filter / Regulator: P29221-610<br />

1-1/2” Diaphragm Pump<br />

Filter / Regulator: P29241-610<br />

2” Diaphragm Pump<br />

Filter: F25451-110<br />

Regulator: 27354-600<br />

ALUMINUM CONSTRUCTION<br />

650709-C 1-inch NPT Kynar ® PVDF Acetal Nitrile<br />

Unleaded 650717-C 1-inch NPT Kynar PVDF Acetal Viton ®<br />

650710-C 1-1/2-inch NPT Kynar PVDF Acetal Nitrile<br />

Unleaded 650718-C 1-1/2-inch NPT Kynar PVDF Acetal Viton<br />

650711-C 2-inch NPT Kynar PVDF Acetal Nitrile<br />

Unleaded 650719-C 2-inch NPT Kynar PVDF Acetal Viton<br />

1-1/2 -inch<br />

Accessories<br />

P29221-610<br />

F25451-110<br />

27354-600<br />

Viton Diaphragms<br />

are recommended<br />

<strong>for</strong> use with<br />

unleaded fuels.

Automatic Shock Blocker Pulsation Dampeners <strong>for</strong> 1/2” & 1” Port Diaphragm <strong>Pumps</strong> | 31<br />

Dimensional Data<br />

3" (76mm)<br />

45°<br />

3-3/8"<br />

(86mm)<br />

5-13/16"<br />

(148mm)<br />

2-1/2"<br />

(64mm)<br />

11/32" (8mm)<br />

4-1/2"<br />

(114mm)<br />

1-1/4"<br />

(32mm)<br />

7/16"<br />

(11mm)<br />

8-1/8"<br />

(206mm)<br />

3-3/4"<br />

(95mm)<br />

1-11/16" (43mm)<br />

Ordering<br />

3-3/4"<br />

(95mm)<br />

18-5/16"<br />

(465mm)<br />

9"<br />

(229mm)<br />

15-3/4"<br />

(400mm)<br />

5-1/4"<br />

(133mm)<br />

3/8" NPT<br />

Specifications<br />

23-9/16"<br />

(598mm)<br />

21"<br />

(533mm)<br />

10-1/2"<br />

(267mm)<br />

INCLUDES 66911-1<br />

AIR TAMER<br />

66108<br />

(1) Comes<br />

St<strong>and</strong>ard<br />

With Unit<br />

Additional<br />

Base <strong>for</strong><br />

1" Piping<br />

- -<br />

Per<strong>for</strong>mance<br />

Notice: All possible options are shown in the chart below, however, certain combinations may not be<br />

recommended. Consult a representative or the factory if you have questions concerning availability.<br />

S B X X X X X X X<br />

10 - 1”<br />

P - Polypropylene (Glass Filled)<br />

D - Conductive Acetal<br />

PULSATION DAMPENER TYPE: Non-Metallic / Automatic<br />

MATERIAL / WEIGHT-LBS (kgs): Polypropylene 8.2 (3.7)<br />

Conductive Acetal 9.5 (4.3)<br />

Pure Kynar (PVDF) 8.2 (3.7)<br />

MATERIAL INLET/OUTLETS: SB10X-AXX 1” - NPTF (Female), St<strong>and</strong>ard<br />

SB10X-BXX - 1” BSP (Female)<br />

AIR INLET: Air Chuck Style Valve, St<strong>and</strong>ard<br />

Air Tamer is 3/8” NPTF (Male) (Optional)<br />

MAXIMUM AIR INLET PRESSURE: 100 PSIG (6.9 bar)<br />

MAXIMUM MATERIAL INLET PRESSURE: 100 PSIG (6.9 bar)<br />

MAXIMUM TEMPERATURE LIMITS: Polypropylene 35° F - 150° F (+1.6° C - 65.5° C)<br />

Conductive Acetal 10° F - 180° F (-12° C - 82° C)<br />

Kynar 10° F - 200° F (-12° C - 93° C)<br />

MAXIMUM FLUID VOLUME: 85 in 3<br />

Blocker Size Air Body<br />

Thread<br />

Fluid<br />

Construction Hardware Diaphragm<br />

A - NPT<br />

B - BSP<br />

S - Stainless (304)<br />

P - Polypropylene (Glass Filled)<br />

D - Conductive Acetal<br />

1/2” Pump: 85% pulsation reduction @ 60PSI<br />

back pressure / 5 GPM<br />

1” Pump: 80% pulsation reduction @ 60PSI<br />

back pressure / 10 GPM<br />

A- Santoprene ®<br />

G- Nitrile<br />

T- Teflon ®<br />