Thermal Spray Tips - Swinburne University of Technology

Thermal Spray Tips - Swinburne University of Technology

Thermal Spray Tips - Swinburne University of Technology

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Compiled by Jo Ann Gan, Edited and advised by Christopher C. Berndt<br />

<strong>Swinburne</strong> <strong>University</strong> <strong>of</strong> <strong>Technology</strong> <strong>Thermal</strong> <strong>Spray</strong> Group (SwinTS)<br />

Please contact Pr<strong>of</strong>. Christopher Berndt at cberndt @swin.edu.au for further enquiries<br />

2. <strong>Thermal</strong> <strong>Spray</strong> Processes<br />

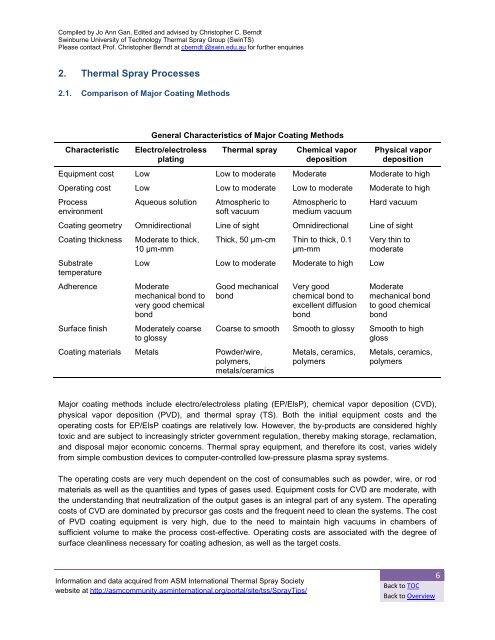

2.1. Comparison <strong>of</strong> Major Coating Methods<br />

Characteristic Electro/electroless<br />

plating<br />

General Characteristics <strong>of</strong> Major Coating Methods<br />

<strong>Thermal</strong> spray Chemical vapor<br />

deposition<br />

Information and data acquired from ASM International <strong>Thermal</strong> <strong>Spray</strong> Society<br />

website at http://asmcommunity.asminternational.org/portal/site/tss/<strong>Spray</strong><strong>Tips</strong>/<br />

Physical vapor<br />

deposition<br />

Equipment cost Low Low to moderate Moderate Moderate to high<br />

Operating cost Low Low to moderate Low to moderate Moderate to high<br />

Process<br />

environment<br />

Aqueous solution Atmospheric to<br />

s<strong>of</strong>t vacuum<br />

Atmospheric to<br />

medium vacuum<br />

Hard vacuum<br />

Coating geometry Omnidirectional Line <strong>of</strong> sight Omnidirectional Line <strong>of</strong> sight<br />

Coating thickness Moderate to thick,<br />

10 μm-mm<br />

Substrate<br />

temperature<br />

Adherence Moderate<br />

mechanical bond to<br />

very good chemical<br />

bond<br />

Surface finish Moderately coarse<br />

to glossy<br />

Thick, 50 μm-cm Thin to thick, 0.1<br />

μm-mm<br />

Low Low to moderate Moderate to high Low<br />

Good mechanical<br />

bond<br />

Coating materials Metals Powder/wire,<br />

polymers,<br />

metals/ceramics<br />

Very good<br />

chemical bond to<br />

excellent diffusion<br />

bond<br />

Very thin to<br />

moderate<br />

Moderate<br />

mechanical bond<br />

to good chemical<br />

bond<br />

Coarse to smooth Smooth to glossy Smooth to high<br />

gloss<br />

Metals, ceramics,<br />

polymers<br />

Metals, ceramics,<br />

polymers<br />

Major coating methods include electro/electroless plating (EP/ElsP), chemical vapor deposition (CVD),<br />

physical vapor deposition (PVD), and thermal spray (TS). Both the initial equipment costs and the<br />

operating costs for EP/ElsP coatings are relatively low. However, the by-products are considered highly<br />

toxic and are subject to increasingly stricter government regulation, thereby making storage, reclamation,<br />

and disposal major economic concerns. <strong>Thermal</strong> spray equipment, and therefore its cost, varies widely<br />

from simple combustion devices to computer-controlled low-pressure plasma spray systems.<br />

The operating costs are very much dependent on the cost <strong>of</strong> consumables such as powder, wire, or rod<br />

materials as well as the quantities and types <strong>of</strong> gases used. Equipment costs for CVD are moderate, with<br />

the understanding that neutralization <strong>of</strong> the output gases is an integral part <strong>of</strong> any system. The operating<br />

costs <strong>of</strong> CVD are dominated by precursor gas costs and the frequent need to clean the systems. The cost<br />

<strong>of</strong> PVD coating equipment is very high, due to the need to maintain high vacuums in chambers <strong>of</strong><br />

sufficient volume to make the process cost-effective. Operating costs are associated with the degree <strong>of</strong><br />

surface cleanliness necessary for coating adhesion, as well as the target costs.<br />

Back to TOC<br />

Back to Overview<br />

6