SHS Jointing, Flowdrill & Hollo-Bolt - Tata Steel

SHS Jointing, Flowdrill & Hollo-Bolt - Tata Steel

SHS Jointing, Flowdrill & Hollo-Bolt - Tata Steel

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

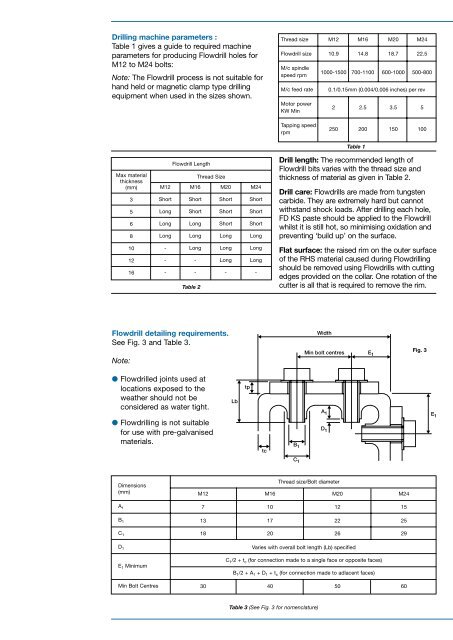

Drilling machine parameters :<br />

Table 1 gives a guide to required machine<br />

parameters for producing <strong>Flowdrill</strong> holes for<br />

M12 to M24 bolts:<br />

Note: The <strong>Flowdrill</strong> process is not suitable for<br />

hand held or magnetic clamp type drilling<br />

equipment when used in the sizes shown.<br />

Max material<br />

thickness<br />

(mm)<br />

<strong>Flowdrill</strong> detailing requirements.<br />

See Fig. 3 and Table 3.<br />

Note:<br />

3<br />

5<br />

6<br />

8<br />

10<br />

12<br />

16<br />

Table 2<br />

● <strong>Flowdrill</strong>ed joints used at<br />

locations exposed to the<br />

weather should not be<br />

considered as water tight.<br />

● <strong>Flowdrill</strong>ing is not suitable<br />

for use with pre-galvanised<br />

materials.<br />

Dimensions<br />

(mm)<br />

A 1<br />

B 1<br />

C 1<br />

D 1<br />

E 1 Minimum<br />

Min <strong>Bolt</strong> Centres<br />

M12<br />

Short<br />

Long<br />

Long<br />

Long<br />

-<br />

-<br />

-<br />

<strong>Flowdrill</strong> Length<br />

M16<br />

Short<br />

Short<br />

Long<br />

Long<br />

Long<br />

-<br />

-<br />

Thread Size<br />

M12<br />

7<br />

13<br />

18<br />

30<br />

M20<br />

Short<br />

Short<br />

Short<br />

Long<br />

Long<br />

Long<br />

-<br />

Lb<br />

tp<br />

M24<br />

Short<br />

Short<br />

Short<br />

Long<br />

Long<br />

Long<br />

-<br />

tc<br />

M16<br />

10<br />

17<br />

20<br />

40<br />

Thread size<br />

<strong>Flowdrill</strong> size<br />

M/c spindle<br />

speed rpm<br />

M/c feed rate<br />

Motor power<br />

KW Min<br />

Tapping speed<br />

rpm<br />

Table 3 (See Fig. 3 for nomenclature)<br />

M12<br />

10.9<br />

1000-1500<br />

2<br />

250<br />

M16<br />

14.8<br />

700-1100<br />

Table 1<br />

Drill length: The recommended length of<br />

<strong>Flowdrill</strong> bits varies with the thread size and<br />

thickness of material as given in Table 2.<br />

Drill care: <strong>Flowdrill</strong>s are made from tungsten<br />

carbide. They are extremely hard but cannot<br />

withstand shock loads. After drilling each hole,<br />

FD KS paste should be applied to the <strong>Flowdrill</strong><br />

whilst it is still hot, so minimising oxidation and<br />

preventing ‘build up’ on the surface.<br />

Flat surface: the raised rim on the outer surface<br />

of the RHS material caused during <strong>Flowdrill</strong>ing<br />

should be removed using <strong>Flowdrill</strong>s with cutting<br />

edges provided on the collar. One rotation of the<br />

cutter is all that is required to remove the rim.<br />

B 1<br />

C 1<br />

Width<br />

Min bolt centres<br />

Thread size/<strong>Bolt</strong> diameter<br />

2.5<br />

200<br />

M20<br />

18.7<br />

600-1000<br />

3.5<br />

150<br />

M24<br />

22.5<br />

500-800<br />

0.1/0.15mm (0.004/0.006 inches) per rev<br />

M20<br />

12<br />

22<br />

26<br />

Varies with overall bolt length (Lb) specified<br />

C 1/2 + t c (for connection made to a single face or opposite faces)<br />

B 1/2 + A 1 + D 1 + t c (for connection made to adlacent faces)<br />

A 1<br />

D 1<br />

50<br />

E 1<br />

M24<br />

15<br />

25<br />

29<br />

60<br />

5<br />

100<br />

Fig. 3<br />

E 1