RR_v65-3.indd - PPG Industries

RR_v65-3.indd - PPG Industries

RR_v65-3.indd - PPG Industries

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

�������<br />

������<br />

���������������<br />

����������������������<br />

������������<br />

������������������

<strong>PPG</strong><br />

Repaint Reporter<br />

Volume 65, Number 3<br />

Executive Editor<br />

Tara Strunk<br />

Creative Director<br />

T. Jon Worden<br />

Design Director<br />

Dave Buffington<br />

Design Staff<br />

John Janiec<br />

Kevin Nowak<br />

Mark Francisco<br />

Bob Santoro<br />

Contributing Editors<br />

Ann Donati<br />

Meredith Simpson<br />

Writers<br />

T.G. Morrisey<br />

Gail Driver<br />

Brian Meitz<br />

John Stanley<br />

John Outcalt<br />

Production Manager<br />

Shellie Hill<br />

Contributing Photographers<br />

Jackson Hill<br />

Todd Anderson<br />

Larry Evans<br />

Robin Nelson<br />

William Thomas Cain<br />

<strong>PPG</strong> Repaint Reporter is published<br />

by the Advertising Department of<br />

<strong>PPG</strong> Automotive Refinish. Send<br />

comments and questions regarding<br />

this publication to:<br />

<strong>PPG</strong> <strong>Industries</strong><br />

Repaint Reporter Editor<br />

19699 Progress Drive<br />

Strongsville, Ohio 44149<br />

Or, fax to: (440) 572-6880<br />

C o n t e n t s<br />

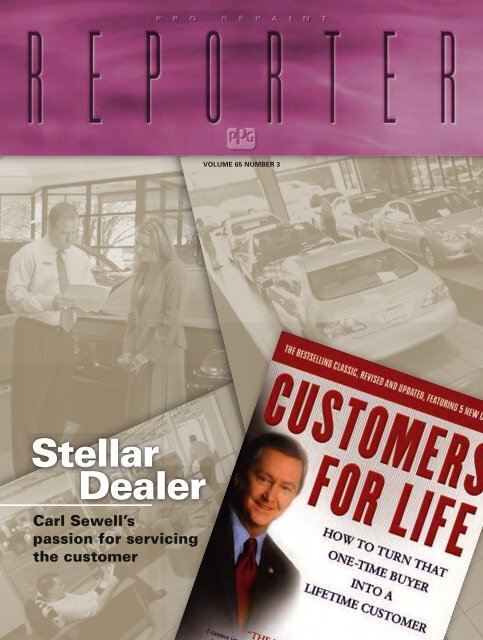

6 CUSTOMERS<br />

FOR LIFE<br />

Car dealer Carl Sewell<br />

wrote the book on<br />

turning one-time buyers<br />

into lifetime customers.<br />

10<br />

FAMILY MATTER<br />

<strong>PPG</strong>’s 2005 Platinum<br />

Distributor of the Year<br />

is a family-owned and<br />

family-run business.<br />

16<br />

CROWNING GLORY<br />

<strong>PPG</strong> helps Crown<br />

Collision Center improve<br />

an already thriving business.<br />

24<br />

COMMERCIAL<br />

ESTIMATING<br />

COMES OF AGE<br />

Penske Truck Leasing<br />

puts <strong>PPG</strong>’s AdjustRite TM<br />

heavy duty truck estimating<br />

system to the test.<br />

D e p a r t m e n t s<br />

4 Inside Line<br />

Our new GM, John Outcalt, offers his perspective on <strong>PPG</strong><br />

performance-based programs.<br />

4 Team <strong>PPG</strong><br />

The latest news and information from <strong>PPG</strong> across the nation<br />

and around the world.<br />

8 “What Have You Done for Me Lately?”<br />

Scotch ®<br />

Performance Masking Tape 233 from 3M can<br />

improve masking productivity by eliminating extra steps.<br />

9 The Power of Precision<br />

The 3M TM<br />

Trizact TM<br />

Hookit TM<br />

II Blending Disc makes deep scratch<br />

and adhesion concerns a thing of the past.<br />

12 Taking Care of Business<br />

The <strong>PPG</strong> Online Precision Marketing Program for CertifiedFirst ®<br />

Network participants offers valuable customer information<br />

tailored to a shop’s specific location.<br />

14 Tech Talk<br />

The Mottle Effect: What is it, why does it happen and<br />

how can it be prevented?<br />

19 Off and Running<br />

The Sewer Equipment Company manufactures equipment<br />

that holds up to extreme conditions.<br />

20 Training Update<br />

<strong>PPG</strong> and Harley-Davidson team up to benefit SkillsUSA.<br />

22 (Up-In-The-) Air Guitar<br />

Kojis Signs builds the world’s largest guitar for the Hard<br />

Rock Casino in Biloxi, Mississippi.<br />

27 Gallery<br />

A street rod Vette and a do-it-yourself showstopper.

Inside Line<br />

B y J o h n O u t c a l t<br />

G e n e r a l M a n a g e r , P P G Au t o m o t i v e R e f i n i s h<br />

Having spent a year away from<br />

the automotive refinish team as<br />

the General Manager, Insurance<br />

and Services business unit, I rejoin<br />

our refinish team with a fresh<br />

perspective of the<br />

collision repair industry<br />

and the evolving<br />

dynamics that impact<br />

our collision shop<br />

customers. I am now<br />

more convinced than ever<br />

that <strong>PPG</strong> leads the way in developing<br />

key alliances that will help assure<br />

the success of our distributors and<br />

collision shop customers in the<br />

coming years, as well as offer<br />

insurers and their policyholders<br />

high levels of customer satisfaction<br />

and effective business solutions.<br />

At the forefront of these strategic<br />

alliances are our LYNXSelect ®<br />

and<br />

CertifiedFirst ®<br />

Network programs.<br />

They are proving to offer industryleading<br />

opportunities for <strong>PPG</strong><br />

collision shops to build their<br />

businesses and enhance<br />

relationships with insurance<br />

companies, agents and consumers<br />

in their local market.<br />

For example, as a 24/7 national<br />

provider of automotive physical<br />

damage (APD) repair management<br />

services, LYNXSelect is now<br />

efficiently processing claims for<br />

10 different national insurance<br />

companies and handling well in<br />

excess of 20,000 claims a year—<br />

a number that will continue to grow<br />

rapidly. Benefiting from these<br />

claims are some 3,000 collision<br />

repair shops that comprise the<br />

4<br />

LYNXSelect nationwide network.<br />

For those insurance companies<br />

that prefer to handle claims<br />

themselves, the CertifiedFirst<br />

Network is proving to be a viable<br />

asset. Aside from benefiting from<br />

local marketing efforts such as the<br />

Continuing Education for Insurers<br />

Program and exposure through<br />

www.certifiedfirst.com, a site<br />

that has received over 20 million<br />

hits since its launch and over<br />

300,000 searches for bodyshops,<br />

CertifiedFirst Network shops have<br />

enjoyed the benefits of over<br />

$30,000,000 in claims assignments<br />

year-to-date, provided through our<br />

alliances with national insurance<br />

and fleet management providers.<br />

The network of participating<br />

shops is expected to reach 2,000<br />

by year-end.<br />

Self-insured fleets is another<br />

area where <strong>PPG</strong> is developing<br />

meaningful alliances, such as CEI.<br />

CEI works with the largest fleet<br />

programs in the United States and<br />

is providing tens of thousands of<br />

claims each year to our network<br />

of participating collision shops.<br />

The growing success of <strong>PPG</strong>’s<br />

alliance programs is good evidence<br />

that these programs are delivering<br />

value to all parties involved: the<br />

insurer, the policyholder, the agent<br />

and the collision shop. If your shop<br />

is not currently participating in<br />

<strong>PPG</strong>’s performance-based programs,<br />

I strongly urge you to reconsider<br />

and take advantage of them. They<br />

represent the future of where the<br />

collision repair industry is heading.<br />

T E A M P P G<br />

Sam Eisenberg, 4, of Dallas, a leukemia survivor, and twin brother Ethan,<br />

his bone marrow donor; both honored patients of The Leukemia & Lymphoma<br />

Society, were at Texas Motor Speedway in April to help kick off the Charity<br />

Chopper tour.<br />

Year-Long Charity Chopper<br />

Effort Raises $134,000<br />

For The Leukemia &<br />

Lymphoma Society<br />

The Charity Chopper, a<br />

custom built, one-of-a-kind<br />

V-twin motorcycle has been<br />

the centerpiece of a year-long<br />

fundraising effort in 2005 sponsored<br />

by <strong>PPG</strong> Automotive Refinish, Ray<br />

Evernham of Evernham Motorsports<br />

and Dave Perewitz of Perewitz Cycle<br />

Fab. This unique chopper, designed<br />

and built by Dave Perewitz, and<br />

featuring a spectacular Liquid<br />

Crystal paint finish from the <strong>PPG</strong><br />

Vibrance Collection TM<br />

, made dozens<br />

of appearances this year across the<br />

U.S. at custom car and bike shows,<br />

special events and select NASCAR<br />

races to raise funds for The<br />

Leukemia & Lymphoma Society.<br />

Funds were raised at raffles and<br />

auctions, through merchandising,<br />

and during monthly auctions held on<br />

eBay, where NASCAR collectibles<br />

and memorabilia were auctioned to<br />

benefit the Society. Including the sale<br />

of the Charity Chopper in October,<br />

the effort has raised $134,000 for<br />

The Leukemia & Lymphoma Society.<br />

Mike Murphy, the lucky new<br />

owner of the Charity Chopper, was<br />

presented with the bike during a<br />

special media event on NASCAR<br />

race day, November 6th, at Texas<br />

Motor Speedway in Fort Worth.<br />

Garry A. Goudy, vice president,<br />

Automotive Aftermarket for <strong>PPG</strong><br />

<strong>Industries</strong>, along with Ray Evernham<br />

and Dave Perewitz presented a<br />

check for $134,000 to Society<br />

officials. For more information on<br />

The Leukemia & Lymphoma Society,<br />

go to www.LLS.org. ■<br />

<strong>PPG</strong> Honors Nine<br />

Companies as<br />

Excellent Suppliers<br />

<strong>PPG</strong> <strong>Industries</strong> has presented<br />

nine Excellent Supplier<br />

Awards for superior<br />

performance in 2004. Award criteria<br />

included product quality, delivery,<br />

documentation, innovation,<br />

responsiveness, continuous<br />

improvement and participation in<br />

<strong>PPG</strong>’s Supplier Added Value Effort<br />

($AVE) program.<br />

Kathleen McGuire, <strong>PPG</strong> vice<br />

president, corporate purchasing and<br />

distribution, praised the performance<br />

of the award-winning suppliers.<br />

“Their products, services, reliability,<br />

innovation and overall value in 2004<br />

were outstanding,” she said. “We<br />

consider them invaluable business<br />

partners who provide us a significant<br />

competitive advantage.”<br />

On an annual basis, <strong>PPG</strong> purchases<br />

more than $5 billion in materials and<br />

services from thousands of suppliers.<br />

The companies earning the 2004<br />

Excellent Supplier Award, and the<br />

products and services they provide, are:<br />

• Applied Industrial Technologies,<br />

based in Cleveland, supplies<br />

bearings and engineered products<br />

as well as power-transmission<br />

and fluid-power components to<br />

<strong>PPG</strong>’s automotive coatings, glass,<br />

flat glass, fiber glass and chloralkali<br />

and derivatives businesses<br />

in the United States.<br />

• Brock Service Painting Company Inc.,<br />

of Beaumont, Texas, provides<br />

painting and related services to the<br />

Lake Charles, La., chemicals facility.<br />

• BYK Chemie GmbH, Wesel,<br />

Germany, provides chemical<br />

additives for the automotive<br />

original-equipment coatings and<br />

refinish as well as industrial and<br />

packaging coatings businesses in<br />

Europe, South America, Australia<br />

and the United States.<br />

• Eckart Aluminum GmbH,<br />

headquartered in Fürth, Germany,<br />

supplies aluminum pigments to<br />

automotive original-equipment<br />

coatings and refinish as well as<br />

industrial and packaging coatings<br />

businesses in Europe, South America,<br />

Australia and the United States.<br />

• EPSCO International, with<br />

facilities in Texas and Louisiana,<br />

provides non-metallic pipe, valves<br />

and fittings to U.S. chlor-alkali<br />

and derivatives, fine chemicals<br />

and silicas businesses.<br />

• Hartman & Hartman, Inc., of<br />

Washington, Pa., provides general<br />

construction services for U.S.<br />

automotive glass, flat glass,<br />

automotive refinish and chloralkali<br />

and derivatives businesses.<br />

• Kerr-McGee Chemical LLC,<br />

Oklahoma City, supplies titanium<br />

dioxide to <strong>PPG</strong>’s worldwide<br />

architectural finishes, originalequipment<br />

automotive coatings<br />

and industrial coatings businesses.<br />

• Kyowa Hakko, headquartered in<br />

Tokyo, supplies amino acids to the<br />

U.S. fine chemicals business.<br />

• Oxiteno S/A Industria e Comércio,<br />

with facilities in Brazil and Mexico,<br />

provides butoxy ethanol to originalequipment<br />

automotive coatings,<br />

industrial coatings, automotive<br />

refinish and packaging coatings<br />

businesses in South America. ■<br />

Expanded Color Library<br />

Phone Support<br />

We are pleased to<br />

announce that<br />

beginning November<br />

15, 2005, <strong>PPG</strong> will introduce a<br />

new and improved Color Library<br />

phone service. Part of this upgrade<br />

includes an expanded color team<br />

to assist with color “look-up”<br />

calls and provide faster response<br />

to the large number of calls the<br />

department receives.<br />

<strong>PPG</strong> will also offer expanded hours<br />

of service, from 8 a.m. to 7 p.m.,<br />

SunClean ®<br />

Self-Cleaning Glass<br />

Since 1883, <strong>PPG</strong> has<br />

learned to love<br />

everything about<br />

windows… except cleaning them!<br />

SunClean self-cleaning glass is a<br />

coated glass product with<br />

photocatalytic and hydrophilic<br />

properties that combine to result in<br />

windows that are easier to clean.<br />

The durable, transparent coating on<br />

SunClean self-cleaning glass is<br />

applied to hot glass during the<br />

formation process, making it an<br />

integral part of the outer glass<br />

surface. The photocatalytic<br />

properties of the glass’ coating are<br />

energized by UV rays to help slowly<br />

break down and loosen organic dirt.<br />

Eastern Standard Time. With the<br />

extended hours and additional<br />

personnel to answer customer<br />

calls, we expect to offer greater<br />

efficiency and faster response<br />

time. Customers should continue<br />

to use the Color Library contact<br />

number at 1-800-647-6050 for all<br />

color inquires.<br />

The upgraded Color Library phone<br />

service is part of <strong>PPG</strong>’s continuing<br />

effort to offer our customers the<br />

best possible service. ■<br />

The hydrophilic properties cause<br />

water to sheet evenly over the glass<br />

surface, instead of beading. This<br />

sheeting action helps to flush the<br />

surface clean and to accelerate<br />

drying, leaving the glass with<br />

minimal spotting and streaking.<br />

SunClean self-cleaning glass can<br />

be used in standard and energysaving<br />

low-E windows. SunClean<br />

glass is available to makers of<br />

wood, vinyl and aluminum windows<br />

serving the new construction and<br />

remodeling markets, allowing<br />

SunClean glass to be one of the<br />

exciting new options available to<br />

consumers. So put away the bucket<br />

and throw away the squeegee! ■<br />

5

A L I F E T I M E of<br />

R E P E A T B U S I N E S S<br />

Dallas car dealer<br />

Carl Sewell wrote the book on<br />

keeping Customers for Life<br />

Like most car dealers, Carl Sewell appears to be his<br />

customers’ best friend—cheerful, at ease, sincerely<br />

listening to what they have to say and just generally<br />

making them feel like a million bucks.<br />

The difference is that, unlike many<br />

car dealers, Carl Sewell probably is<br />

his customers’ best friend. If they<br />

have a flat tire on the way to work,<br />

he’ll send out a service tech to change<br />

it—for free. When they’re having<br />

work done at his dealership, he<br />

doesn’t rent them something to<br />

drive in the meantime—he loans<br />

them a current year’s vehicle. When<br />

he calls them, it’s not to badger<br />

them about coming in to trade up—<br />

it’s to invite them to dinner, on him.<br />

From the outside, it looks like<br />

he’s giving money away. But that’s<br />

not how Carl Sewell sees it.<br />

“It’s all a matter of perspective,”<br />

Sewell says. “And perspective starts<br />

with how you see the customer.<br />

If you see the person who walks in<br />

your door as an opportunity to sell<br />

one vehicle, or do one repair, then<br />

you might see a much larger margin<br />

from that transaction, but you probably<br />

won’t see that customer again.<br />

“If, on the other hand, you see<br />

that person as a potential lifetime of<br />

repeat business, then you’re going to<br />

treat him or her differently,” Sewell<br />

continues. “Just think of it—how nice<br />

would you be to someone if a halfmillion-dollar<br />

business deal was<br />

hanging in the balance? I think you’d<br />

be pretty nice. And in car and truck<br />

sales, every customer is easily worth<br />

a half million dollars of business over<br />

the course of a lifetime. So that’s how<br />

we treat every customer who walks<br />

through our door—as if half a million<br />

dollars were hanging on how well<br />

we accommodated their needs.”<br />

Sewell’s approach is a different way<br />

of running a business—so different that,<br />

with business writer Paul B. Brown,<br />

he wrote a book about it in 1990.<br />

Customers for Life: How to Turn that<br />

One-Time Buyer into a Lifetime<br />

Customer has been published in<br />

17 languages, and has sold more<br />

than 1,000,000 copies.<br />

And Carl Sewell’s way of doing<br />

business was so refreshingly different<br />

that it convinced Steve Pearce,<br />

who had retired comfortably at age<br />

41 after two decades of owning and<br />

operating collision shops, to come<br />

out of retirement and go to work as<br />

manager of the 80,000-square-foot<br />

Sewell Collision Center and the<br />

65,000-square-foot Sewell Lexus<br />

Body Shop. Both shops lie within<br />

three blocks of one another in Dallas,<br />

and both do volumes that would set<br />

most managers’ heads spinning.<br />

“It’s kind of like a cult,” says Pearce.<br />

“And I mean that in a good way. We<br />

have a rule here at Sewell called the<br />

‘Ten Foot Rule.’ If a customer comes<br />

within ten feet of you, you smile,<br />

acknowledge them and ask if you can<br />

help them, if that’s appropriate. And<br />

we have a policy of looking at every<br />

car that comes in, not as the customer’s<br />

car, but as your mother’s car, or your<br />

spouse’s car. You never just do the<br />

requested repair; you always look at<br />

the job and ask, ‘What can I do that<br />

will make this person happy with<br />

their decision to have us do the work?’<br />

And after you’ve done it this way for<br />

a while, doing business any other<br />

way just seems rude. It doesn’t take<br />

long to think of this as the only way<br />

to run a shop.”<br />

Because so much of service depends<br />

on the technician’s attitude, Sewell’s<br />

management team interviews<br />

extensively for every opening, tests<br />

each promising applicant for aptitude<br />

and takes each finalist to breakfast or<br />

lunch to see how they are in a social<br />

continued on page 26<br />

“We have a policy of<br />

looking at every car that<br />

comes in, not as the<br />

customer’s car, but as<br />

your mother’s car, or<br />

your spouse’s car,”says<br />

manager Steve Pearce.<br />

“You never just do the<br />

requested repair; you<br />

always look at the job<br />

and ask, “What can I do<br />

that will make this person<br />

happy with their decision<br />

to have us do the work?”<br />

continues Pearce.<br />

6 7

8<br />

S H O P C O S T S R I S I N G :<br />

Time to Ask Your Tape,<br />

“What Have You Done for Me Lately?”<br />

In almost every industry, people continually look<br />

for ways to increase performance levels while<br />

lowering costs. In the paint and body shop business,<br />

the solution may be as easy as upgrading a tool you use<br />

everyday to something that lasts longer and/or gets<br />

better results more consistently. Take, for instance,<br />

masking tape.<br />

In today’s changing market,<br />

new paint chemistries and higher<br />

temperature bake cycles place great<br />

physical demands on masking tapes.<br />

In the automotive refinish industry,<br />

applying masking tape accounts for<br />

six percent of labor revenue generated<br />

on repair orders, or $56 on a<br />

typical repair order of $2,000. Since<br />

productivity equals profitability,<br />

consider how much time is spent<br />

performing compensating behaviors<br />

caused by the performance limitations<br />

of low priced masking tapes.<br />

Megan Scherb, masking solutions<br />

business manager for 3M Automotive<br />

Aftermarket Division, explains that<br />

most painters, without realizing it,<br />

have changed their behavior<br />

to compensate for the<br />

limitations of lower priced<br />

tape. She notes, for<br />

example, that before<br />

spraying, painters<br />

typically inspect the<br />

vehicle to ensure the<br />

masking tape has<br />

not lifted since<br />

application. If it<br />

has, they must<br />

spend time pressing<br />

the tape down in<br />

order to prevent paint<br />

blow-by. Compensating behaviors<br />

such as these require extra time that<br />

could be used more productively<br />

on revenue generating activity.<br />

It seems that to save money in one<br />

area (labor) you must spend more<br />

money in another (supplies), but<br />

sometimes the costs for better materials<br />

are minimal compared to productivity<br />

gained, so it’s important to do your<br />

research and compare costs. To illustrate<br />

the productivity advantage that<br />

Scotch ®<br />

Performance Masking Tape<br />

233+ brings to a paint job, 3M has<br />

designed an interactive value analysis<br />

tool. The tool helps the shop owner or<br />

manager understand the value of the<br />

time gained by utilizing the shop’s<br />

specific operating costs. “Masking<br />

tape can have a big impact on labor<br />

revenue while contributing a relatively<br />

small amount to material costs.<br />

Because of its excellent performance,<br />

using Scotch ®<br />

Performance Masking<br />

Tape 233+ may improve masking<br />

productivity up to 10 percent per<br />

repair order by eliminating extra<br />

steps,” says Scherb.<br />

Scotch ®<br />

Performance Masking Tape<br />

233+ is ideal for all body shop paint<br />

masking applications. According to<br />

Scherb, its balanced construction<br />

provides excellent adhesion with clean<br />

removal—even from difficult surfaces<br />

like EPDM rubber moldings,<br />

after contact with moisture<br />

and chemicals or prolonged<br />

outdoor exposure—all<br />

qualities that can contribute<br />

to increased productivity.<br />

For more information<br />

about Scotch ®<br />

Performance<br />

Masking Tape 233+, visit<br />

3M’s Web site at www.3M.<br />

com/automotive or call 1-<br />

877-MMM-CARS (1-877-<br />

666-2277). ■<br />

3M and Scotch are trademarks of 3M Company.<br />

P o w e r P r e c i s i o n<br />

The of<br />

No matter what method is used<br />

for preparing panels for clearcoat and<br />

color blends—traditional DA sanding<br />

discs, wet sanding sheets or scuff<br />

pads—all present obstacles to achieving<br />

a premium finish that results in an<br />

undetectable blend. For example,<br />

scuff pads conform very well to the<br />

panel surface but do not remove all<br />

gloss which can result in clearcoat<br />

adhesion failures. Scuff pads also have<br />

a tendency to leave deep scratches<br />

which may show through on metallic<br />

and pearl colors. Abrasives such as<br />

DA Discs and wet sanding sheets sand<br />

aggressively and remove more gloss,<br />

but do not offer the conformability of<br />

a scuff pad. This lack of conformability<br />

often leaves shiny spots that remain<br />

in the lower areas of the texture or<br />

“orange peel”. To remove this<br />

remaining gloss, the technician will<br />

not only spend additional sanding time<br />

but also increase the risk of sanding<br />

or “burning” through on an edge,<br />

contour or body line. The result is<br />

additional time spent reworking this<br />

previously undamaged area.<br />

3M, the industry leader in abrasive<br />

technology has recently introduced the<br />

company’s most advanced product for<br />

clearcoat and color blending. The<br />

3M TM<br />

Trizact TM<br />

Hookit TM<br />

II Blending<br />

Disc is a foam-backed abrasive disc<br />

designed to conform to the sanding<br />

surface with minimal risk of burn<br />

through on edges, contours or body<br />

lines. The foam backing allows the<br />

disc to conform and sand deep into<br />

orange peel with minimal texture<br />

removal while producing a consistent<br />

matte finish with no “shiny spots,”<br />

something that is difficult to achieve<br />

with traditional DA discs or wet<br />

sanding abrasives. The finish left by<br />

the Trizact TM<br />

Hookit TM<br />

II Blending Disc<br />

makes deep scratch and adhesion<br />

concerns a thing of the past.<br />

The key to Trizact’s excellent<br />

performance is the combination of<br />

its foam backing and unique mineral<br />

construction, which is made up of<br />

micro-replicated, pyramid-shaped<br />

structures. This construction ensures<br />

that fresh mineral is exposed at a<br />

uniform rate, extending the life of<br />

the product while maintaining a<br />

consistent level of cut. Most<br />

importantly, the uniform scratch<br />

pattern left by the Trizact TM<br />

Hookit TM<br />

II Blending Disc allows metallic and<br />

pearl colors to lay down uniformly<br />

resulting in blends that are virtually<br />

transparent which will certainly appeal<br />

to your customer and increase your<br />

shop’s CSI.<br />

For more information about<br />

Trizact TM<br />

Hookit TM<br />

II Blending<br />

Discs from 3M, visit 3M’s Web<br />

site at www.3M.com/automotive<br />

or call 1-800-3M-HELPS (1-800-<br />

364-3577). ■<br />

3M, Trizact, and Hookit are trademarks of<br />

3M Company.<br />

The Process of Precision<br />

STEP 1<br />

STEP 2<br />

STEP 3<br />

SANDING LARGE AREAS<br />

1a. CLEAN the repair area with soap and water,<br />

followed by 3M TM<br />

General Purpose Adhesive Cleaner.<br />

1b. Using a spray bottle, apply enough water to<br />

dampen the 3M TM<br />

Trizact TM<br />

Hookit TM<br />

II Blending<br />

Disc before sanding the panel. DAMP SAND the<br />

entire blend area, including bodylines and edges,<br />

with a DA sander. When necessary, re-dampen<br />

disc with water from spray bottle while sanding.<br />

SANDING HARD-TO-REACH AREAS<br />

Remove Blending Disc from backup pad to sand<br />

hard-to-reach areas and edges.<br />

CLEANING<br />

Wipe off blend area immediately.<br />

9

Family Matter<br />

Bill Flannery Automotive<br />

presently serves more<br />

than 100 major accounts<br />

and employs 27 people,<br />

including technician<br />

Wayne Knight, shown<br />

here mixing paint.<br />

Meet the Flannerys—Billy, Gen, Bill and Tracy—<br />

Winners of the <strong>PPG</strong> 2005<br />

Platinum Distributor of the Year Award<br />

No doubt<br />

that is what<br />

was on Bill<br />

Flannery’s<br />

mind as he<br />

stepped onto<br />

the stage at<br />

the <strong>PPG</strong><br />

Platinum<br />

Awards<br />

Banquet in Orlando earlier<br />

this year. Bill, owner of Bill Flannery<br />

Automotive in Bensalem, PA, was<br />

coming up to receive the final,<br />

and highest, accolade—the glass<br />

trophy recognizing him as Platinum<br />

Distributor of the Year. It was the<br />

culmination of a relationship with<br />

<strong>PPG</strong> that stretches back nearly four<br />

It’s a pretty big deal to be recognized by<br />

your peers, particularly when your peers<br />

are the best in the business.<br />

decades. And it says a lot about Bill’s<br />

business philosophy that, when he<br />

received that trophy, the first thing he<br />

did was turn to his wife, his daughter,<br />

and his son, and mouth the words,<br />

“This belongs to you.”<br />

Running his business as a family<br />

affair is almost second-nature to Bill.<br />

He worked in an automotive partsand-finish<br />

store as a teenager. He liked<br />

the finish business well enough that<br />

he opened a parts and paint store with<br />

two partners. Later, in 1975, he went<br />

to work on his own, working out of<br />

a truck and a trailer. As his business<br />

grew, <strong>PPG</strong> suggested that he open his<br />

own store.<br />

It was just the push he needed. In<br />

1984, he opened a small store in a strip<br />

mall, and by 1987 he had outgrown<br />

that and moved to a 3,000-squarefoot<br />

facility. By 2001, even that was<br />

too small, so Bill Flannery Automotive<br />

built the 11,000-square-foot location<br />

in which it is currently headquartered,<br />

a facility that sells shop supplies and<br />

tools, as well as paint. That was joined<br />

in 2003 by a 1,000-square-foot satellite<br />

location in nearby Telford, PA, opened<br />

for strategic expansion. Bill Flannery<br />

Automotive presently serves more<br />

than 100 major accounts and employs<br />

THE <strong>PPG</strong> PLATINUM<br />

DISTRIBUTOR PROGRAM<br />

AT A GLANCE<br />

• Launched in 1994<br />

• A partnership between the best<br />

entrepreneurs in the business and <strong>PPG</strong><br />

• Combines the talents of more than 650<br />

single-line <strong>PPG</strong> distributors<br />

• The size and scope of a 32,000-person,<br />

Fortune 500 company<br />

27 people, three of which are his wife<br />

Gen (who handles payroll, accounts<br />

payable and human resources), son<br />

Billy (operations director) and daughter<br />

Tracy (who handles “purchasing, sales<br />

and anything else that is needed”).<br />

Tracy became an employee of Bill<br />

Flannery Automotive nearly 20 years<br />

ago, when she was in her teens, but<br />

worked at the shop unofficially long<br />

before that. She remembers coming<br />

in during Christmas vacation at age<br />

nine to help take year-end inventory—<br />

a memory that’s a mixture of joy and<br />

family pride.<br />

“My mom, my brother and I are<br />

here because we want to be here,”<br />

Tracy says. “We have three brothers<br />

who have lives outside the paint<br />

business. But Billy and I love this,<br />

because our father showed us that,<br />

at its heart, this is a people business,<br />

and your customers can be like family.<br />

Dad’s a great businessman—he was a<br />

member of the original <strong>PPG</strong> jobber<br />

council, the fifth Platinum contract<br />

to be signed with <strong>PPG</strong>, and he’s been<br />

Platinum Plus every year since 1999.<br />

But his real talent is that he is a peopleperson;<br />

he’s always interested in<br />

helping someone else be the best<br />

that they can be.”<br />

That interest in elevating others<br />

led Bill to work with a local highschool<br />

teacher and Skills USA mentor<br />

to help students learn the ins and<br />

outs of the collision-repair business,<br />

sponsoring a scholarship every year.<br />

Two of those former students are<br />

now employees, and several are<br />

now valued customers of Bill<br />

Flannery Automotive.<br />

To be ready with answers when<br />

customers ask questions, Bill and<br />

his staff take full advantage of <strong>PPG</strong><br />

training classes, have been to the<br />

Jobber Management Program, and<br />

participate enthusiastically in the<br />

East Two Forum (“An absolute<br />

wealth of knowledge and a truly<br />

invaluable resource,” says Bill).<br />

They also offer their customers<br />

the full range of <strong>PPG</strong> training.<br />

When asked for the secret<br />

of his success, Bill is quick to<br />

direct the spotlight elsewhere.<br />

Gesturing at his modern showroom,<br />

he says, “None of this would be<br />

possible without the talented<br />

people who make this place run,<br />

and the loyal people who have traded<br />

with us now for a quarter of a<br />

century. They’re the ones who make<br />

this happen.”<br />

But daughter Tracy is quick to<br />

amend that, “Whenever we’ve had<br />

to make a tough decision, Dad has<br />

always—always—stressed that if at the<br />

end of the day you have your integrityyou<br />

have it all. Our customers, our<br />

employees, and even our competitors<br />

know that, above all else, we are going<br />

to be honest and fair.”<br />

After all, when you think of your<br />

customers and your business as family—<br />

how else would you treat them? ■<br />

<strong>PPG</strong> PLATINUM<br />

DISTRIBUTOR<br />

OF THE YEAR<br />

Awarded annually to the <strong>PPG</strong><br />

Platinum Distributor who best…<br />

• Demonstrates a consistent<br />

increase in annual sales<br />

• Has received exemplary<br />

customer-satisfaction scores<br />

• Has met a variety of other<br />

criteria of excellence over<br />

the last year<br />

Employees Jason Shuck<br />

and Bob Sherlock<br />

stocking shelves at Bill<br />

Flannery Automotive.<br />

10 11

zer<br />

T A K I N G C A R E O F B U S I N E S S<br />

CertifiedFirst ®<br />

Network’s Online Precision Marketing—<br />

moving your customer profiles from ‘guesses’ to ‘knowledge’<br />

CertifiedFirst Network participants<br />

can log on to www.certifiedfirst.com/<br />

participants and gain access to a<br />

Precision Marketing Report tailored<br />

to their specific location. The Report<br />

offers a wealth of information, including<br />

a Collision Repair Potential (CRPI)<br />

map (above) that shows the likelihood<br />

of consumers in the area to use a<br />

body shop.<br />

You probably already know that, in today’s<br />

competitive collision repair market, with its high<br />

capacities and educated consumers, attracting and<br />

keeping customers is practically a full-time job.<br />

You probably also know that you<br />

don’t have to go it alone. With the<br />

CertifiedFirst Network, you get the<br />

quality reputation and high-end<br />

resources of a national network…<br />

working just for you and your<br />

business’ success.<br />

But did you know that, as a<br />

participant of the CertifiedFirst<br />

Network, you have access to the <strong>PPG</strong><br />

Online Precision Marketing Program,<br />

a sophisticated e-tool (valued at<br />

more than $1,200) that lets you zero<br />

in on valuable customer information<br />

in the areas where you are currently<br />

doing business or where you plan to<br />

do business?<br />

The Online Precision Marketing<br />

Report is based on the adage that<br />

“birds of a feather flock together.”<br />

In other words, people often choose<br />

to live near others who have similar<br />

lifestyles, beliefs and customs. These<br />

groups of individuals are called<br />

“clusters.” By combining data about<br />

these clusters with specific information<br />

about the collision repair industry,<br />

this report brings you insight into<br />

each group’s collision repair buying<br />

habits. It also lets you see which<br />

clusters are high-use when it comes<br />

to collision repair services, perhaps<br />

because they typically have more<br />

drivers in the family, own newer<br />

model vehicles, or because they<br />

simply tend to drive more miles on<br />

average - resulting in more collisions.<br />

“There are other services—some<br />

of them quite costly—that can give<br />

you basic census and demographic<br />

information about population<br />

movement and household income,”<br />

says Georgina Sweeney, Director–<br />

Refinish Alliance Programs. “But<br />

only the Online Precision Marketing<br />

Report can combine that information<br />

with <strong>PPG</strong>’s own Collision Repair<br />

Potential Index (CRPI), for powerful<br />

marketplace intelligence that points<br />

to your best business prospects.”<br />

And you don’t have to be a<br />

marketing guru—or a computer<br />

guru—to use this powerful tool. As a<br />

CertifiedFirst Network participant, all<br />

you need to do is go online to www.<br />

certifiedfirst.com/participants and<br />

enter the site with your shop’s unique<br />

user name and password. Click the<br />

in<br />

“Precision Marketing” tab on the<br />

web page that opens, and then click<br />

the line that says “Click Here For<br />

Your Precision Marketing Report.”<br />

That opens on a page with two<br />

options. The first, “Determine<br />

Market Size and Growth,” allows<br />

you to look at an area (centered on<br />

an address, an intersection, or even a<br />

latitude-and-longitude readout from<br />

a GPS unit), and generate a report<br />

that includes:<br />

• a Collision Repair Potential<br />

(CRPI) map<br />

• an estimated sales map<br />

• top customers location by ZIP<br />

code spreadsheet<br />

• a 5-year market growth report, and<br />

• an executive summary that<br />

explains it all<br />

Want to zero in even further?<br />

Click the second option on the page,<br />

“Retrieve Advanced Cluster<br />

Information,” enter a ZIP code,<br />

and you can generate reports that tell<br />

you the top five cluster “types”<br />

living in that area, and an executive<br />

summary providing demographic<br />

information and trends.<br />

Reports are generated as Adobe<br />

Acrobat documents that you can<br />

print out for use in meetings, save for<br />

future reference, or view onscreen<br />

with widely and freely available<br />

software. Click on a cluster name<br />

while you’re online, and that opens<br />

to a page telling you what that<br />

particular<br />

customer group is<br />

like—from income,<br />

age range, education,<br />

employment and<br />

median income, to<br />

lifestyle and leisure preferences.<br />

“If you’re planning your advertising<br />

schedules, the Advanced Cluster<br />

Information will tell you not only<br />

what sort of radio stations your target<br />

customers listen to, but what times<br />

they are most apt to be listening,<br />

and what parts of the newspaper<br />

they are apt to spend the most time<br />

in,” says Sweeney.<br />

The Precision Marketing Report<br />

is designed to work with what you<br />

already know about the area where<br />

you do business. It can reassure you<br />

that you are correctly gauging the<br />

business potential of an area, help<br />

you zero in on particular parts of<br />

that area that are most apt to use<br />

your services, or provide valuable<br />

intelligence—including growth<br />

trends—when you’re considering<br />

relocation or expansion to an additional<br />

location. And the professional<br />

reports provide valuable<br />

substantiation for presentations to<br />

financial partners, zoning or<br />

planning commissions, or other<br />

stakeholder organizations.<br />

“The Online Precision Marketing<br />

Program helps you base your business<br />

decisions, not on hunches, or even<br />

educated guesses, but on measured<br />

and professionally accumulated facts,”<br />

says Sweeney. “The best collision<br />

repair professionals don’t guess on<br />

their estimates or their paint formulas.<br />

They calculate, using professional<br />

Marketing Reports, you can apply a<br />

similar technology when it comes to<br />

market analysis and customer types.”<br />

For more information on Online<br />

Precision Marketing, please call 1-<br />

800-647-6050, option 4 (8 a.m.–5<br />

p.m. EST). ■<br />

The Online Precision<br />

Marketing Report<br />

provides you with<br />

information on the<br />

collision repair buying<br />

habits of potential<br />

customers in your<br />

target market area.<br />

12 13

14<br />

T E C H T A L K<br />

Avoiding the<br />

A ‘mottle,’ ‘blotchy’ or ‘patchy’ type appearance can<br />

sometimes result after spraying a metallic finish,<br />

particularly in lighter colors. So, what is it, why does<br />

it happen and how can it be prevented?<br />

At one time or another virtually every refinish<br />

painter will have come across the ‘mottle’ effect.<br />

It describes the appearance of light and dark areas<br />

within a metallic finish and is also referred to as<br />

‘patchiness.’ These light and dark patches appear due to<br />

the incorrect orientation of the aluminum particles<br />

within the paint film.<br />

It’s a problem that’s almost<br />

impossible to detect at the basecoat<br />

stage since most basecoats dry to a<br />

silky matte finish. That means the<br />

effect doesn’t become evident until<br />

after the clearcoat is applied. Naturally,<br />

at that point it’s way too late to<br />

rectify the problem, and the only<br />

course of action is a re-do which can<br />

lead to serious film build problems.<br />

Cause and cure<br />

There are two main contributing<br />

factors—incorrect thinning of the<br />

paint and the application technique.<br />

The first scenario results from an<br />

insufficient thinning ratio or using<br />

a thinner that’s too fast for the<br />

prevailing conditions—for instance,<br />

when trying to push a job through<br />

quickly. After application the solvents<br />

in the thinner evaporate too rapidly<br />

and the paint film sets so quickly<br />

that it doesn’t let the metallic particles<br />

lay down smoothly, resulting in a<br />

mottle effect.<br />

Using compatible thinners is also<br />

vital. <strong>PPG</strong> thinners are specifically<br />

designed for use with <strong>PPG</strong> products<br />

in the correct thinning ratio and<br />

according to the ambient air<br />

temperature. Following these<br />

guidelines can assist in dramatically<br />

reducing the mottle effect.<br />

While working with individual<br />

bodyshops to help them with mottle<br />

control, <strong>PPG</strong> technical staff came<br />

across the following examples. One<br />

shop was thinning all colors to 1:1.<br />

This was working fine with dark<br />

colors, but with light colors there<br />

was mottle. It was discovered that the<br />

air pressure was around 45–55 psi<br />

which is too high for basecoat and is<br />

a major mottle contributor because it<br />

doesn’t allow the metallic basecoat to<br />

be applied in a wet, even film. After<br />

reducing the air pressure to 25–35<br />

psi, mottle was dramatically reduced.<br />

Application technique is another<br />

important factor in reducing mottle<br />

and it’s here that modern metallic<br />

paint finishes (such as in <strong>PPG</strong>’s<br />

Deltron ®<br />

and GRS paint systems)<br />

require a modern technique.<br />

Previously, the final technique or<br />

pattern coat may have been applied<br />

over a dry film. However, this can<br />

cause mottle due to the paint film<br />

setting too quickly which prevents<br />

the metallic particles from laying<br />

down smoothly. In addition, because<br />

this final coat tends to be dry and<br />

dusty it can result in clearcoat<br />

adhesion problems and reduced gloss<br />

levels. Applied correctly, the basecoat<br />

will appear very smooth and, when<br />

tack ragged, there will be no or<br />

minimal color on the tack rag.<br />

To minimize the chance of<br />

mottle, the basecoat should be<br />

applied to give an even, uniformly<br />

dull appearance and left for the<br />

recommended flash times between<br />

coats. Proper application technique<br />

is critical when spraying light high<br />

metallic colors. Make sure to<br />

maintain a good 50% overlap and<br />

allow each coat to flash for the<br />

recommended time. Also, make sure<br />

to pick the appropriate reducer for<br />

the size and temperature of the job.<br />

Another method is the<br />

crosscoating technique—this is<br />

where the second coat is applied at<br />

right angles to the first and<br />

immediately following the first coat.<br />

The first coat cannot be allowed to<br />

flash or the cross coat will not be<br />

able to re-flow and orientate the<br />

first coat metallics.<br />

It’s a fact of life that most light<br />

colors will have a degree of mottle<br />

and that repairing light colors will<br />

always be more difficult than dark<br />

colors. However, using the above tips<br />

and the following guidelines should<br />

help to avoid mottling:<br />

• Reduce the paint to the<br />

recommended thinning ratio and,<br />

depending on your equipment,<br />

more thinner may be required.<br />

• Use the specified thinner for the<br />

spraying temperature.<br />

• Avoid using high air pressure—<br />

25–35 psi maximum.<br />

• Allow the paint to flash off<br />

properly between coats. Multiple<br />

coats without a f lash off will<br />

make the paint film very ‘wet’<br />

and cause mottle.<br />

• Don’t spray in very cold conditions.<br />

This will slow down the flash off<br />

time of the paint and increase the<br />

chances of mottle.<br />

• Don’t apply the clearcoat too soon.<br />

If the basecoat hasn’t set up fully,<br />

the clearcoat may cause the basecoat<br />

to dissolve and disturb the aluminum<br />

flakes, giving a mottled appearance.<br />

• Ensure that your spray gun has a<br />

good spray pattern and, when<br />

spraying, overlap the strokes of<br />

the gun the correct amount to<br />

ensure an even appearance. Keeping<br />

the gun back from the job will<br />

make the effective fan width<br />

larger and overlapping the gun<br />

strokes will be easier.<br />

• Develop a technique that works<br />

for you.<br />

• Remember, if you do reduce the<br />

pressure, to make the same<br />

allowance on your spray out card. ■<br />

15

16<br />

CROWNING<br />

GLORY Crown Collision Center, in<br />

St. Petersburg, Florida, does<br />

the sort of business that most<br />

collision shop managers only<br />

At this<br />

dream of. Working out of a 45,000-square-foot main facility<br />

Gulf Coast megashop, with 23 technicians and eight painters, Crown processes over<br />

seven-figure months will 300 vehicles a month, at an average repair value of $2000.<br />

soon be a reality<br />

Monthly parts and labor sales exceed $600,000. And that’s<br />

running just a single shift per day.<br />

So—is Crown’s manager satisfied<br />

with her current production standards?<br />

“Not in the slightest,” says Jackie<br />

Zajac, who has managed Crown<br />

Collision Center since June of 2003.<br />

“By this time next year, I am<br />

certain—absolutely certain—that<br />

this center will be producing over a<br />

million dollars a month in total<br />

sales. And long term, beyond that?<br />

Who knows? We intend to beat all<br />

the facility utilization benchmarks.<br />

I’ll tell you the truth—I really don’t<br />

see a ceiling at this point.”<br />

So what’s the reason for Jackie<br />

Zajac’s enthusiasm?<br />

“<strong>PPG</strong>,” she says. “For this center,<br />

the sky’s the limit with <strong>PPG</strong>.”<br />

What makes this story truly<br />

amazing is that Jackie Zajac had<br />

never worked as a collision<br />

center manager prior to joining<br />

the Crown Group.<br />

For years, Jackie had worked<br />

with Crown from the<br />

opposite side of the desk,<br />

managing the DRP program<br />

for Progressive Insurance.<br />

But when she was offered the<br />

position, she readily took it.<br />

Jackie says she made the switch<br />

because, “I consider managing the<br />

Crown Collision Center the<br />

opportunity of a lifetime. This is<br />

one fantastic collision shop, and<br />

one great opportunity.”<br />

17

Crown Collision Center<br />

processes over 300 vehicles<br />

a month, at an average repair<br />

value of $2,000, working<br />

out of a 45,000 square-foot<br />

facility with 23 technicians<br />

and eight painters.<br />

18<br />

That’s something of an<br />

understatement. Crown Collision<br />

is part of the Crown Dealerships Group,<br />

a family of 11 dealerships selling and<br />

servicing 20 car and truck lines,<br />

with most of the dealerships located<br />

on either side of US 19, adjacent to<br />

or near the collision center in St.<br />

Petersburg. Plus, as a DRP manager,<br />

Jackie knew how attractive such a<br />

high-volume facility, accustomed<br />

to working to auto manufacturer<br />

warranty standards, could be. And<br />

with that much of a dealership<br />

presence, insurance carriers could<br />

be highly confident that Crown<br />

would be there for the long run,<br />

ready to back their guarantees.<br />

Another reason for Jackie’s<br />

confidence is <strong>PPG</strong> Distributor Tim<br />

Morrell, who runs Auto Body Express<br />

in Tampa. Crown was under contract<br />

with another finish supplier when<br />

Tim first called on Jackie, but that<br />

didn’t stop him from pitching in<br />

and helping out.<br />

“Tim and <strong>PPG</strong> were here, in this<br />

shop, consulting with me and acting<br />

as business partners for two years<br />

before I purchased a single drop of<br />

paint from them,” Jackie says. “I don’t<br />

want to give you the impression<br />

that the product was unimportant<br />

here, because that’s not the case at<br />

all. My painters consistently told me<br />

that, for color match, and for cycle<br />

time, <strong>PPG</strong> was absolutely the way<br />

to go. And because <strong>PPG</strong> is a global<br />

company, they met the requirements<br />

of all our OEM warranty work.<br />

So certainly they were attractive,<br />

product-wise. But what truly made<br />

the difference for me was the attitude;<br />

<strong>PPG</strong> came in here with a partnership<br />

solution. And it was not a cookiecutter<br />

solution. This is a big business,<br />

with unique challenges, so <strong>PPG</strong><br />

brought in a variety of people,<br />

including Dave Mitchum, <strong>PPG</strong><br />

Business Development Manager,<br />

to look at and analyze the various<br />

aspects of our business. They came<br />

up with not only a plan to help us<br />

attain our specific goals, but the<br />

systems to help us best implement<br />

the plan, such as Throughput<br />

Management and innovative<br />

production models.”<br />

One of <strong>PPG</strong>’s first suggestions<br />

was that Crown adopt Summit<br />

management software, to streamline<br />

the operation, adopt door-to-door<br />

throughput management techniques,<br />

and identify potential issues before<br />

they can turn into real problems.<br />

Summit’s owner, Frank Terlep, flew<br />

in and provided a customized IT<br />

solution that was specific to the<br />

shop’s needs.<br />

“It’s a night-and-day difference,”<br />

Jackie says. “As a shop manager, I need<br />

to know when a car is tracking behind<br />

the scheduled delivery date. When<br />

a car is late for delivery, you’re past<br />

‘problem’ and well into ‘crisis’—<br />

the customer is unhappy because you<br />

didn’t keep your word, the insurer is<br />

unhappy because there’s an additional<br />

rental expense… as a manager, I want<br />

to know when the car is going to be<br />

late going into paint.”<br />

Having such a system in place<br />

has changed Jackie’s outlook as a<br />

shop manager.<br />

“Some managers don’t really<br />

manage,” she says. “They put out<br />

fires. They spend their time looking<br />

at issues and trying to figure out why<br />

they arose. But with systems in place<br />

to avoid the issues in the first place,<br />

I have the opportunity to network<br />

with insurers and really leverage our<br />

CertifiedFirst ®<br />

Network membership. I<br />

have the opportunity to meet with<br />

and understand the needs of our<br />

customers and how we can serve<br />

them better. And I can turn what<br />

I learn into initiatives that make us<br />

more productive and more attractive<br />

to all our stakeholders.”<br />

One such initiative is Crown<br />

Express, a 12,000-square-foot facility<br />

just a short walk from Crown<br />

Collision, where repairs can be<br />

done while the customer waits.<br />

“On simple repairs, a logical<br />

customer question is, ‘Why do I have<br />

to leave the car?’” Jackie says. “And<br />

we thought about that, and decided,<br />

‘You don’t.’ By implementing timesaving<br />

steps, like pre-painting parts,<br />

we can really expedite things. We have<br />

a comfortable lounge, food and<br />

beverages, and a business center where<br />

a customer can check e-mail while<br />

they wait. Insurers absolutely love<br />

this service because they don’t have<br />

to rent a car. And our dealerships<br />

love it because, often, while a repair<br />

is being done, the customer walks<br />

over to one of our showrooms and<br />

shops for a new car or truck.”<br />

Crown has been working with<br />

<strong>PPG</strong> to take even further advantage<br />

of certification and training programs<br />

for collision shop personnel at all levels<br />

of the business, and to incorporate<br />

plans that will help make this already<br />

successful business a phenomenal<br />

success. And Jackie Zajac is confident<br />

of that success.<br />

“As far as I’m concerned,” she says<br />

with a nod. “The sky really is the<br />

limit with <strong>PPG</strong>.”

Off and<br />

Running<br />

Sewer Equipment Company of America<br />

builds gear to keep things that way<br />

When you’re a world leader in your<br />

industry, you know you’ve done<br />

something right. When you’ve been a leader for<br />

more than six decades, you’ve had time to think about<br />

how to keep things right.<br />

And for more than six decades,<br />

Sewer Equipment Company of<br />

America has supplied municipalities<br />

and contractors around the world with<br />

the tools they need to service and<br />

clean sewer and storm-drain systems.<br />

In a 60,000-square-foot<br />

manufacturing facility in rural<br />

Chadwick, Illinois, Sewer Equipment<br />

Company produces specially designed<br />

power equipment ranging from a<br />

$2000 cable auger, used for<br />

cleaning sewer lines, to a $200,000<br />

hydroexcavator that uses pressurized<br />

hot water to excavate lines for repair.<br />

The company is the world’s leading<br />

supplier of trailer jets—which use<br />

high-pressure water to clean lines—<br />

and one of the global leaders in the<br />

production of truck jets, upfitted to<br />

commercial truck chassis.<br />

“With a product line this extensive,<br />

most of our production is done to<br />

order,” says John Wichmann,<br />

production manager for Sewer<br />

Equipment Company. “That<br />

means we might be building rodding<br />

machines one day and a catch-basin<br />

cleaner or a vacuum unit the next.<br />

And what we are painting can vary<br />

dramatically from day to day, as well.”<br />

Yet, regardless of the size and scope<br />

of that day’s production, the Chadwick<br />

plant applies the same brand of<br />

paint—<strong>PPG</strong> Delfleet ®<br />

Evolution.<br />

“Our equipment faces a wide<br />

extreme of road and climate<br />

conditions, from Midwestern<br />

winters and salt-covered roads,<br />

to Middle Eastern summers with<br />

blowing sand,” Wichmann says.<br />

“Plus they face the additional<br />

challenges of graywater, blackwater<br />

and sludge, and road-repair and<br />

construction-type environments.<br />

We need a quality finish that can stand<br />

up to those conditions, yet still be<br />

cost-effective enough to help us<br />

stay competitive.”<br />

Months of testing at Chadwick<br />

showed that Delfleet not only<br />

delivered the quality Sewer<br />

Equipment Company expected—<br />

it provided coverage superior to<br />

competitive products.<br />

“That was one pleasant surprise,”<br />

says John Wichmann. “And the other<br />

pleasant surprises were the up-front<br />

analysis <strong>PPG</strong> and our distributor—<br />

A & B Autobody Supply, of Peru,<br />

Illinois—did for us, and the training<br />

that <strong>PPG</strong> offers. We’ve already<br />

<strong>PPG</strong>-certified one painter and one<br />

supervisor, and they came back with<br />

so many great ideas—new ways to<br />

prep welded surfaces, and alternative<br />

drying techniques—that we’re in<br />

the process of certifying two more<br />

of our people. <strong>PPG</strong> is helping Sewer<br />

Equipment Company to do what our<br />

customers expect: provide durable<br />

equipment that looks great and does<br />

the job, no matter where in the<br />

world we ship it.” ■<br />

According to Production<br />

Manager John Wichmann<br />

(shown above) “…what<br />

we are painting can vary<br />

dramatically from day<br />

to day.” Regardless of<br />

the size or scope of the<br />

day’s production, they<br />

apply the same brand of<br />

paint for every job—<strong>PPG</strong><br />

Delfleet ®<br />

Evolution.<br />

19

T R A I N I N G U P D A T E<br />

Cheri Judkins (left),<br />

operations manager<br />

for Harley-Davidson<br />

University, poses<br />

with Don Dunbar, a<br />

SkillsUSA computer<br />

science instructor at<br />

Idaho State University,<br />

who sits astride the<br />

2005 Harley-Davidson<br />

Dyna Super Glide<br />

Custom motorcycle<br />

he won in a raffle to<br />

raise funds for the<br />

SkillsUSA Conference.<br />

20<br />

<strong>PPG</strong> and Harley-Davidson get all fired up<br />

to raise money for SkillsUSA<br />

Most collision-shop owners and techs are familiar<br />

with SkillsUSA—the nation’s premier<br />

organization for the promotion of excellence in<br />

technical education. In fact, if you’re working in<br />

the collision industry today, there’s a pretty good<br />

chance you’re a SkillsUSA alumnus.<br />

And if you<br />

know about<br />

SkillsUSA, then<br />

you know that<br />

the Super Bowl<br />

of vocational<br />

education is<br />

the SkillsUSA<br />

Championships,<br />

where students<br />

with talent<br />

ranging from<br />

baking and<br />

carpentry to computer science and<br />

collision repair gather to compete<br />

for national honors.<br />

This June, during the SkillsUSA<br />

National Leadership and Skills<br />

Conference, <strong>PPG</strong> and Harley-<br />

Davidson got together in a very<br />

special fundraiser.<br />

It all started during one of the<br />

planning meetings for the event,<br />

when Cheri Judkins, operations<br />

manager for Harley-Davidson<br />

HOGWild<br />

I N K A N S A S C I T Y<br />

University, offered on behalf of her<br />

company to donate a 2005 Harley-<br />

Davidson Dyna Super Glide<br />

Custom motorcycle, to be raffled<br />

off as a fundraiser. When Cheri<br />

made her offer, Steve Lehner,<br />

of <strong>PPG</strong>, who was also on<br />

the same committee, said,<br />

“That’s a great idea. I’ll tell you<br />

what—if you’ll donate the bike,<br />

we’ll paint it.”<br />

The result—a genuine<br />

American legend, done up in a<br />

super-trick, color-changing,<br />

faux three-D flame paint<br />

scheme—was enough to quicken the<br />

pulse of any motorcyclist.<br />

It certainly did that for Don<br />

Dunbar, a SkillsUSA computer<br />

science instructor at Idaho State<br />

University. Don, who had toured<br />

the Kansas City Harley plant<br />

earlier in the week, and has<br />

ridden motorcycles for years,<br />

had always dreamed of owning a<br />

Harley-Davidson.<br />

Don had also never won anything<br />

in his life. Still, he bought one ticket<br />

for the raffle (out of the 30,000 sold),<br />

because he wanted to show his<br />

support. And as he videotaped<br />

the motorcycle being<br />

ridden into<br />

Kemper Arena for the prize<br />

announcement at the end of the<br />

awards ceremony, the thing going<br />

through his mind was not, “I hope I<br />

win,” but, “Wow, what a beautiful<br />

bike; I hope whoever wins it will<br />

appreciate it.”<br />

When his name was called as the<br />

winner, Don recalls that he “got so<br />

excited I almost threw the video<br />

camera away.”<br />

As Cheri Judkins said, “It’s always<br />

great when the winner of something<br />

like this is a rider who can really<br />

connect with the Harley mystique.”<br />

And it pleased everyone at <strong>PPG</strong> to<br />

learn that, for the first week after Don<br />

picked the motorcycle up at High<br />

Desert Harley-Davidson in Emmett,<br />

Idaho, the motorcycle was on display<br />

at Idaho State University’s auto body<br />

shop, where students perfecting their<br />

paint and refinish techniques could<br />

take a good, close look at what a master<br />

custom painter can do with products<br />

from <strong>PPG</strong>’s Vibrance Collection TM<br />

. ■<br />

AllFired<br />

Up<br />

C R E AT I N G A P A I N T J O B W O R T H Y O F A L E G E N D<br />

The custom paint on the tank and fenders of Don<br />

Dunbar’s SkillsUSA Harley-Davidson Dyna Super Glide<br />

Custom is the creation of Paul Stoll, instructor at <strong>PPG</strong><br />

Refinish’s Seattle Training Center.<br />

Paul, a custom painter for more than 35 years, first<br />

started painting in a vocational/technical training<br />

environment, much like that fostered by SkillsUSA.<br />

He says that he was “fortunate enough to find custom<br />

painters willing to share their secrets in an era when<br />

most custom painters were not,” and that inspired him to<br />

not only learn to paint, but to share his knowledge. With<br />

techniques that betray his Southern California custom<br />

roots, Paul teaches Vibrance custom painting classes<br />

around the country for <strong>PPG</strong>.<br />

Here are the steps he went through to create the colorchanging<br />

True Fire paint scheme (all products available<br />

through your <strong>PPG</strong> jobber or distributor):<br />

• Obtain OEM body parts in e-coat<br />

(electrodeposition primer).<br />

• Seal e-coat with DAS 3025 Sealer.<br />

• Apply three coats DBC Black Basecoat DMD 1683.<br />

• Apply two coats Vibrance Liquid Crystal Glacier VM4104<br />

(this finish will change color, from emerald to blue,<br />

depending on the angle at which the light strikes it).<br />

• Apply one coat DBC 500 Base Clear to protect work.<br />

• Apply flame motif using airbrush in the True Fire<br />

method created by custom painter Mike Lavallee:<br />

a base of DMD 618 Moly Orange, DMD 639 Chrome<br />

Yellow and DMD 1684 White, with candy topcoats in<br />

Vibrance Radiance ®<br />

II DMX 213 Red, DMX 211 Orange<br />

and DMX 210 Yellow.<br />

• Hand-cut mask of Harley-Davidson logo to create faux<br />

metal appearance with Vibrance VM4201 Liquid Metal.<br />

• Apply DC 4000 Clear atop all work.<br />

• Sand with 600 grit paper and a dual-action (DA) sander<br />

to level topcoat.<br />

• Apply two coats of DC 4000 for final gloss.<br />

Total hours for job = approx. 100<br />

Retail value of similar paintwork = $6500.00<br />

If you are a <strong>PPG</strong> certified painter who’d like to become<br />

hands-on familiar with the technique used to create this<br />

effect, as well as the products, you can learn from Paul<br />

or one of his peers in the <strong>PPG</strong> Vibrance Collection Real<br />

Fire class. For details on how to enroll, contact your <strong>PPG</strong><br />

distributor, look online at www.ppgrefinish.com, or call<br />

the <strong>PPG</strong> Faxback service toll-free at: 1-800-450-2654.<br />

21

Air Guitar<br />

(Up-In-The-)<br />

Doing the impossible puts<br />

one small Louisiana signmaker on the map<br />

It sounds like a tall tale. And it<br />

is. But it’s true.<br />

To break into the big time, all one<br />

Bunkie, Louisiana signmaker had to<br />

do is do what their competitors had<br />

said was impossible. They did…<br />

and now they have a world record<br />

to prove it.<br />

“We’re a small, south-central<br />

Louisiana sign company,” says Todd<br />

Ducote, shop foreman and designer<br />

for Kojis Signs. “We have about 70<br />

people working for us; we were the<br />

sort of company that got most of its<br />

business putting up signs for fastfood<br />

restaurants, that sort of thing.”<br />

That’s fairly steady work. But it’s<br />

not all that Kojis wanted.<br />

“We have always had our eye on<br />

the casino business in this part of the<br />

country,” Ducote says. “But we had,<br />

historically, found it impossible to<br />

break in. There were a select few<br />

big sign companies of national<br />

prominence that the casino<br />

organizations did business with,<br />

and while we would bid on every<br />

job we learned about, it seemed<br />

as if we never heard back.”<br />

Then, last year, they did hear back.<br />

Hard Rock Café International, Inc.,<br />

the global phenomenon with Hard<br />

Rock Cafés, Hotels and Casinos in<br />

more than 40 countries worldwide,<br />

was building a new hotel casino in<br />

Biloxi, and wanted a sign worthy of<br />

its reputation: a neon-lit, aluminum<br />

guitar, realistic down to the smallest<br />

detail. And they wanted it in headlinemaking<br />

proportions, 112 feet tall<br />

and almost three times as large in<br />

surface area as the then-record holder<br />

for the largest guitar in the world<br />

(also on a Hard Rock property).<br />

Just as the folks at Kojis feared,<br />

first consideration went to a major<br />

signmaker, very well-known and<br />

justly well-respected throughout<br />

the industry. But then the call came.<br />

“Hard Rock told us that the<br />

signmaker they were considering<br />

was saying that the radiused curves<br />

necessary to do a faithful rendition<br />

of a guitar would require special dies<br />

that would cost upward of half a<br />

million dollars—just for the dies,”<br />

Ducote recalls. “And they also said<br />

that Hard Rock’s deadline for delivery<br />

of the sign—July 5, 2005—would<br />

be absolutely impossible to meet.”<br />

The door had opened, just a crack.<br />

“We did some experimenting in<br />

our shop, invented a tool that would<br />

create the types of bends needed,<br />

and showed the results to the people<br />

at Hard Rock,” he says. “They<br />

said, ‘Okay, can you meet a July 5<br />

deadline?’ We said we would, and<br />

we got the job.”<br />

Before construction could begin<br />

on the sign, Kojis had to construct<br />

an addition to their shop—an 180foot-long,<br />

27-foot-tall addition, just<br />

to have the space to move and work<br />

on the various pieces of the giant<br />

sign. That began in December of<br />

2004, concurrent with computeraided<br />

design of the sign itself. On<br />

January 27, 2005, work on the<br />

actual sign began.<br />

“To give you an idea of the scope<br />

of this project, we had four of our<br />

painters—Calvin Johnson, Sherman<br />

Black, David Holsomback and Chris<br />

Marcot—working for six months,<br />

straight, just to do the paint and<br />

body work. We had to design the<br />

sign to withstand a light Category<br />

Five hurricane, and because of the<br />

soil composition in that part of the<br />

country, we designed twelve 90-foot<br />

concrete piles for the guitar to stand<br />

on. There were suppliers involved<br />

from four countries—the United<br />

States, Canada, Mexico, and the<br />

hand-drawn neon guitar strings<br />

were brought in from Italy. And<br />

we finished the guitar with $42,000<br />

worth of <strong>PPG</strong> DBU Basecoat/<br />

Clearcoat paint.”<br />

Why <strong>PPG</strong>?<br />

“It’s almost all we shoot,” says<br />

Ducote. “We have never, ever, had<br />

a problem with <strong>PPG</strong> finishes; <strong>PPG</strong><br />

makes just an awesome product.”<br />

In early May, two months away<br />

from deadline, Kojis Signs’ internal<br />

projections were showing that their<br />

competitor may have been right on<br />

at least one of their two objections—<br />

at the rate they were going, the<br />

guitar was going to be late for its<br />

delivery date. Kojis management<br />

called a company-wide meeting,<br />

explained the situation and the<br />

importance of keeping their<br />

promise, and employees agreed to<br />

work seven days a week, 10-13<br />

hours a day, Father’s Day and the<br />

Fourth of July included, to pull the<br />

job back on schedule.<br />

That worked. On July 5, 2005,<br />

the guitar arrived for installation at<br />

the Biloxi construction site. And<br />

The Guinness Book of World Records<br />

is expected to certify Kojis Signs’<br />