Adhesives for Wax Artifacts - Institut canadien de conservation

Adhesives for Wax Artifacts - Institut canadien de conservation

Adhesives for Wax Artifacts - Institut canadien de conservation

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

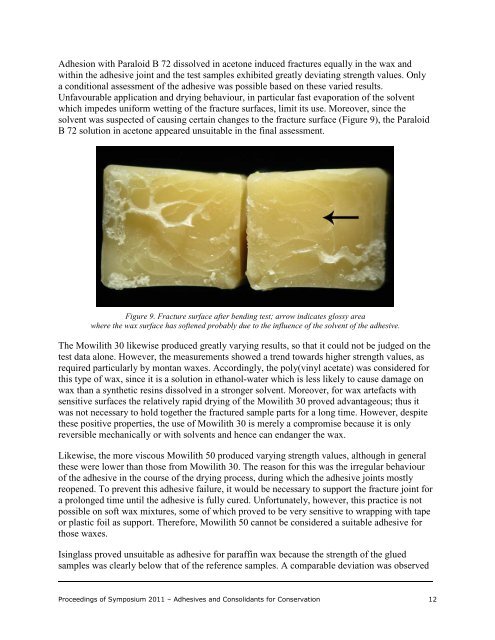

Adhesion with Paraloid B 72 dissolved in acetone induced fractures equally in the wax and<br />

within the adhesive joint and the test samples exhibited greatly <strong>de</strong>viating strength values. Only<br />

a conditional assessment of the adhesive was possible based on these varied results.<br />

Unfavourable application and drying behaviour, in particular fast evaporation of the solvent<br />

which impe<strong>de</strong>s uni<strong>for</strong>m wetting of the fracture surfaces, limit its use. Moreover, since the<br />

solvent was suspected of causing certain changes to the fracture surface (Figure 9), the Paraloid<br />

B 72 solution in acetone appeared unsuitable in the final assessment.<br />

Figure 9. Fracture surface after bending test; arrow indicates glossy area<br />

where the wax surface has softened probably due to the influence of the solvent of the adhesive.<br />

The Mowilith 30 likewise produced greatly varying results, so that it could not be judged on the<br />

test data alone. However, the measurements showed a trend towards higher strength values, as<br />

required particularly by montan waxes. Accordingly, the poly(vinyl acetate) was consi<strong>de</strong>red <strong>for</strong><br />

this type of wax, since it is a solution in ethanol-water which is less likely to cause damage on<br />

wax than a synthetic resins dissolved in a stronger solvent. Moreover, <strong>for</strong> wax artefacts with<br />

sensitive surfaces the relatively rapid drying of the Mowilith 30 proved advantageous; thus it<br />

was not necessary to hold together the fractured sample parts <strong>for</strong> a long time. However, <strong>de</strong>spite<br />

these positive properties, the use of Mowilith 30 is merely a compromise because it is only<br />

reversible mechanically or with solvents and hence can endanger the wax.<br />

Likewise, the more viscous Mowilith 50 produced varying strength values, although in general<br />

these were lower than those from Mowilith 30. The reason <strong>for</strong> this was the irregular behaviour<br />

of the adhesive in the course of the drying process, during which the adhesive joints mostly<br />

reopened. To prevent this adhesive failure, it would be necessary to support the fracture joint <strong>for</strong><br />

a prolonged time until the adhesive is fully cured. Un<strong>for</strong>tunately, however, this practice is not<br />

possible on soft wax mixtures, some of which proved to be very sensitive to wrapping with tape<br />

or plastic foil as support. There<strong>for</strong>e, Mowilith 50 cannot be consi<strong>de</strong>red a suitable adhesive <strong>for</strong><br />

those waxes.<br />

Isinglass proved unsuitable as adhesive <strong>for</strong> paraffin wax because the strength of the glued<br />

samples was clearly below that of the reference samples. A comparable <strong>de</strong>viation was observed<br />

Proceedings of Symposium 2011 – <strong>Adhesives</strong> and Consolidants <strong>for</strong> Conservation 12