Beat Migration Bloom on Chocolate Products by Optimizing ... - AAK

Beat Migration Bloom on Chocolate Products by Optimizing ... - AAK

Beat Migration Bloom on Chocolate Products by Optimizing ... - AAK

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

equipment is unable to make the high inflecti<strong>on</strong><br />

level or there is ignorance about how important<br />

it is or how to change it, then it is much worse<br />

and more difficult to change.<br />

COOLING FOR TEMPER TESTERS<br />

AND SHELL COOLING<br />

Nearly all tempermeters use a cooling tempera-<br />

ture somewhere between +7° and +10°C even<br />

though cocoa butter prefers gentle cooling to<br />

ensure Form V crystallizati<strong>on</strong>. Years ago an ice-<br />

and-water bath was used; this was even further<br />

away from “perfect” chocolate cooling.<br />

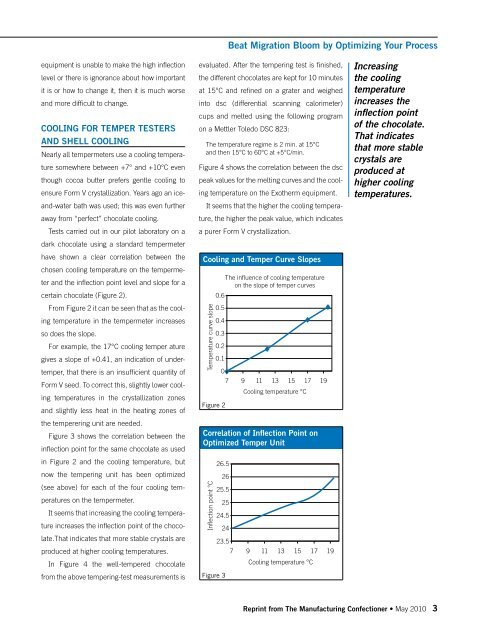

Tests carried out in our pilot laboratory <strong>on</strong> a<br />

dark chocolate using a standard tempermeter<br />

have shown a clear correlati<strong>on</strong> between the<br />

chosen cooling temperature <strong>on</strong> the temperme-<br />

ter and the inflecti<strong>on</strong> point level and slope for a<br />

certain chocolate (Figure 2).<br />

From Figure 2 it can be seen that as the cool-<br />

ing temperature in the tempermeter increases<br />

so does the slope.<br />

For example, the 17°C cooling temper ature<br />

gives a slope of +0.41, an indicati<strong>on</strong> of under-<br />

temper, that there is an insufficient quantity of<br />

Form V seed. To correct this, slightly lower cool-<br />

ing temperatures in the crystallizati<strong>on</strong> z<strong>on</strong>es<br />

and slightly less heat in the heating z<strong>on</strong>es of<br />

the temperering unit are needed.<br />

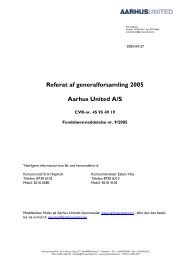

Figure 3 shows the correlati<strong>on</strong> between the<br />

inflecti<strong>on</strong> point for the same chocolate as used<br />

in Figure 2 and the cooling temperature, but<br />

now the tempering unit has been optimized<br />

(see above) for each of the four cooling tem-<br />

peratures <strong>on</strong> the tempermeter.<br />

It seems that increasing the cooling tempera-<br />

ture increases the inflecti<strong>on</strong> point of the choco-<br />

late.That indicates that more stable crystals are<br />

produced at higher cooling temperatures.<br />

In Figure 4 the well-tempered chocolate<br />

from the above tempering-test measurements is<br />

<str<strong>on</strong>g>Beat</str<strong>on</strong>g> <str<strong>on</strong>g>Migrati<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>Bloom</str<strong>on</strong>g> <strong>by</strong> <strong>Optimizing</strong> Your Process<br />

evaluated. After the tempering test is finished,<br />

the different chocolates are kept for 10 minutes<br />

at 15°C and refined <strong>on</strong> a grater and weighed<br />

into dsc (differential scanning calorimeter)<br />

cups and melted using the following program<br />

<strong>on</strong> a Mettler Toledo DSC 823:<br />

The temperature regime is 2 min. at 15°C<br />

and then 15°C to 60°C at +5°C/min.<br />

Figure 4 shows the correlati<strong>on</strong> between the dsc<br />

peak values for the melting curves and the cool-<br />

ing temperature <strong>on</strong> the Exotherm equipment.<br />

It seems that the higher the cooling tempera-<br />

ture, the higher the peak value, which indicates<br />

a purer Form V crystallizati<strong>on</strong>.<br />

Cooling and Temper Curve Slopes<br />

Temperature curve slope<br />

0.6<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

Figure 2<br />

Correlati<strong>on</strong> of Inflecti<strong>on</strong> Point <strong>on</strong><br />

Optimized Temper Unit<br />

Inflecti<strong>on</strong> point °C<br />

Figure 3<br />

0<br />

7 9 11 13 15 17 19<br />

Cooling temperature °C<br />

26.5<br />

The influence of cooling temperature<br />

<strong>on</strong> the slope of temper curves<br />

26<br />

25.5<br />

25<br />

24.5<br />

24<br />

23.5<br />

7 9 11 13 15 17 19<br />

Cooling temperature °C<br />

Increasing<br />

the cooling<br />

temperature<br />

increases the<br />

inflecti<strong>on</strong> point<br />

of the chocolate.<br />

That indicates<br />

that more stable<br />

crystals are<br />

produced at<br />

higher cooling<br />

temperatures.<br />

Reprint from The Manufacturing C<strong>on</strong>fecti<strong>on</strong>er • May 2010 3