Beat Migration Bloom on Chocolate Products by Optimizing ... - AAK

Beat Migration Bloom on Chocolate Products by Optimizing ... - AAK

Beat Migration Bloom on Chocolate Products by Optimizing ... - AAK

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

a tempering with some amount of Form III/IV<br />

formati<strong>on</strong> and/or too fast a cooling of the choco-<br />

late where some Form III/IV formati<strong>on</strong> happens<br />

afterwards. While alternatively a special “after”<br />

cooling compensates for too high a producti<strong>on</strong><br />

speed and for that reas<strong>on</strong> an insufficient remov-<br />

al of crystallizati<strong>on</strong> heat from the product before<br />

packing and an insufficient structure building<br />

in the filling. Often product is stored in rooms<br />

held at 12°C to 16°C. During this special cool-<br />

ing the TAG compositi<strong>on</strong> in fillings and shells<br />

has found its optimum network structure.<br />

<str<strong>on</strong>g>Migrati<strong>on</strong></str<strong>on</strong>g> speed will be minimized and<br />

therefore the migrati<strong>on</strong>-induced bloom will be<br />

reduced. Again it is a compensati<strong>on</strong> for insuf-<br />

ficient cooling time in the producti<strong>on</strong> line and it<br />

actually takes much l<strong>on</strong>ger to remove all crys-<br />

tallizati<strong>on</strong> heat from a filling if it is in the center<br />

of a pallet and the risk of migrati<strong>on</strong>-induced<br />

bloom is higher than if the product had been<br />

cooled correctly at the start.<br />

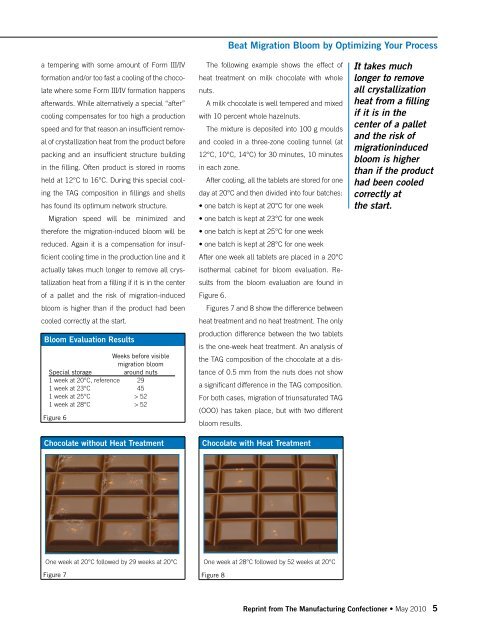

<str<strong>on</strong>g>Bloom</str<strong>on</strong>g> Evaluati<strong>on</strong> Results<br />

Weeks before visible<br />

migrati<strong>on</strong> bloom<br />

Special storage around nuts<br />

1 week at 20°C, reference 29<br />

1 week at 23°C 45<br />

1 week at 25°C > 52<br />

1 week at 28°C > 52<br />

Figure 6<br />

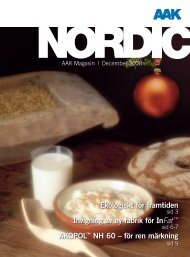

<strong>Chocolate</strong> without Heat Treatment<br />

Figure 7<br />

<str<strong>on</strong>g>Beat</str<strong>on</strong>g> <str<strong>on</strong>g>Migrati<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>Bloom</str<strong>on</strong>g> <strong>by</strong> <strong>Optimizing</strong> Your Process<br />

The following example shows the effect of<br />

heat treatment <strong>on</strong> milk chocolate with whole<br />

nuts.<br />

A milk chocolate is well tempered and mixed<br />

with 10 percent whole hazelnuts.<br />

The mixture is deposited into 100 g moulds<br />

and cooled in a three-z<strong>on</strong>e cooling tunnel (at<br />

12°C, 10°C, 14°C) for 30 minutes, 10 minutes<br />

in each z<strong>on</strong>e.<br />

After cooling, all the tablets are stored for <strong>on</strong>e<br />

day at 20°C and then divided into four batches:<br />

• <strong>on</strong>e batch is kept at 20°C for <strong>on</strong>e week<br />

• <strong>on</strong>e batch is kept at 23°C for <strong>on</strong>e week<br />

• <strong>on</strong>e batch is kept at 25°C for <strong>on</strong>e week<br />

• <strong>on</strong>e batch is kept at 28°C for <strong>on</strong>e week<br />

After <strong>on</strong>e week all tablets are placed in a 20°C<br />

isothermal cabinet for bloom evaluati<strong>on</strong>. Re-<br />

sults from the bloom evaluati<strong>on</strong> are found in<br />

Figure 6.<br />

Figures 7 and 8 show the difference between<br />

heat treatment and no heat treatment. The <strong>on</strong>ly<br />

producti<strong>on</strong> difference between the two tablets<br />

is the <strong>on</strong>e-week heat treatment. An analysis of<br />

the TAG compositi<strong>on</strong> of the chocolate at a dis-<br />

tance of 0.5 mm from the nuts does not show<br />

a significant difference in the TAG compositi<strong>on</strong>.<br />

For both cases, migrati<strong>on</strong> of triunsaturated TAG<br />

(OOO) has taken place, but with two different<br />

bloom results.<br />

<strong>Chocolate</strong> with Heat Treatment<br />

One week at 20°C followed <strong>by</strong> 29 weeks at 20°C One week at 28°C followed <strong>by</strong> 52 weeks at 20°C<br />

Figure 8<br />

It takes much<br />

l<strong>on</strong>ger to remove<br />

all crystallizati<strong>on</strong><br />

heat from a filling<br />

if it is in the<br />

center of a pallet<br />

and the risk of<br />

migrati<strong>on</strong>induced<br />

bloom is higher<br />

than if the product<br />

had been cooled<br />

correctly at<br />

the start.<br />

Reprint from The Manufacturing C<strong>on</strong>fecti<strong>on</strong>er • May 2010 5